Documente Academic

Documente Profesional

Documente Cultură

Stainless Steel

Încărcat de

SeindahNyaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stainless Steel

Încărcat de

SeindahNyaDrepturi de autor:

Formate disponibile

Stainless steel - Wikipedia, the free encyclopedia

Page 1 of 1

Stainless steel

From Wikipedia, the free encyclopedia

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5[1] or 11% chromium content by mass.[2] Stainless steel does not stain, corrode, or rust as easily as ordinary steel, but it is not stain-proof.[3] It is also called corrosionresistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required. Stainless steel differs from carbon steel by the amount of chromium present. Unprotected carbon steel rusts readily when exposed to air and moisture. This iron oxide film (the rust) is active and accelerates corrosion by forming more iron oxide. Stainless steels contain sufficient chromium to form a passive film of chromium oxide, which prevents further surface corrosion and blocks corrosion from spreading into the metal's internal structure.[4] Passivation only occurs if the proportion of chromium is high enough.

Iron alloy phases

Ferrite (-iron, -iron) Austenite (-iron) Pearlite (88% ferrite, 12% cementite) Martensite Bainite Ledeburite (austenite-cementite eutectic, 4.3% carbon) Cementite (iron carbide, Fe3C) Beta ferrite (-iron) Hexaferrum (-iron) Steel classes Crucible steel Carbon steel (2.1% carbon; low alloy) Spring steel (low or no alloy) Alloy steel (contains non-carbon elements) Maraging steel (contains nickel) Stainless steel (contains 10.5% chromium) Weathering steel Tool steel (alloy steel for tools) Other iron-based materials Cast iron (>2.1% carbon) Ductile iron Gray iron Malleable iron White iron Wrought iron (contains slag)

History

A few corrosion-resistant iron artifacts survive from antiquity. A famous example is the Iron Pillar of Delhi, erected by order of Kumara Gupta I around AD 400. Unlike stainless steel, however, these artifacts owe their durability not to chromium but to their high phosphorus content, which, together with favorable local weather conditions, promotes the formation of a solid protective passivation layer of iron oxides and phosphates, rather than the non-protective cracked rust layer that develops on most ironwork.

The corrosion resistance of ironchromium alloys was first recognized in 1821 by French metallurgist Pierre Berthier, who noted their resistance against attack by some acids and suggested their use in cutlery. Metallurgists of the An announcement, as it appeared in the 19th century were unable to 1915 New York Times, of the development produce the combination of low of stainless steel.[5] carbon and high chromium found in most modern stainless steels, and the high-chromium alloys they could produce were too brittle to be practical.

http://en.wikipedia.org/wiki/Stainless_steel

12/19/2011

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Expansion Tube-Tubesheet JointDocument9 paginiExpansion Tube-Tubesheet JointvaibhavÎncă nu există evaluări

- 2 Biogas Burner CommissioningDocument1 pagină2 Biogas Burner CommissioningSeindahNyaÎncă nu există evaluări

- How to Use a Psychrometric ChartDocument14 paginiHow to Use a Psychrometric ChartSeindahNyaÎncă nu există evaluări

- Testimonial From UTM Energy Manager PDFDocument1 paginăTestimonial From UTM Energy Manager PDFSeindahNyaÎncă nu există evaluări

- 3 Phase Transformers 1Document17 pagini3 Phase Transformers 1vijaykumar_aluriÎncă nu există evaluări

- Coax Cable Theory and ApplicationDocument8 paginiCoax Cable Theory and ApplicationSeindahNyaÎncă nu există evaluări

- 10 Three Phase SystemDocument33 pagini10 Three Phase SystemtheritzÎncă nu există evaluări

- Biogas Scrubbing, Compression and Storage Perspective and Prospectus in Indian Context PDFDocument9 paginiBiogas Scrubbing, Compression and Storage Perspective and Prospectus in Indian Context PDFSeindahNyaÎncă nu există evaluări

- 33 11 KV Substation Training Report PDFDocument41 pagini33 11 KV Substation Training Report PDFPraveen Kumar Kilaparthi75% (4)

- Hydraulic Oil DescriptionDocument4 paginiHydraulic Oil DescriptionSeindahNyaÎncă nu există evaluări

- Valve Timing Diagram of Four Cycle Diesel EngineDocument3 paginiValve Timing Diagram of Four Cycle Diesel EngineAmila NawarathnaÎncă nu există evaluări

- This Is Valve Timing DiagramDocument1 paginăThis Is Valve Timing DiagramSeindahNyaÎncă nu există evaluări

- Bulletin2005 03abs02Document1 paginăBulletin2005 03abs02SeindahNyaÎncă nu există evaluări

- Talk On Overview of Ms1462-2012 Cidb Seminar 01-03-16Document64 paginiTalk On Overview of Ms1462-2012 Cidb Seminar 01-03-16SeindahNya100% (1)

- Boiler Handbook GuideDocument287 paginiBoiler Handbook Guidevenus energy94% (18)

- Steam Trap - DrawingDocument17 paginiSteam Trap - DrawingSeindahNya100% (1)

- HRST Boiler Biz Newsletter - Winter 07Document6 paginiHRST Boiler Biz Newsletter - Winter 07SeindahNyaÎncă nu există evaluări

- ICE Akta1Document40 paginiICE Akta1SeindahNyaÎncă nu există evaluări

- Boiler CalculationsDocument16 paginiBoiler CalculationsBilly Moerdani100% (1)

- ABB Power EMS Configuration and FunctionalityDocument35 paginiABB Power EMS Configuration and FunctionalitySeindahNya100% (1)

- Testimonial From UTM Energy ManagerDocument1 paginăTestimonial From UTM Energy ManagerSeindahNyaÎncă nu există evaluări

- EE&C Practices at HomeDocument19 paginiEE&C Practices at HomeSeindahNyaÎncă nu există evaluări

- CV Prof JailaniDocument60 paginiCV Prof JailaniSeindahNyaÎncă nu există evaluări

- Energy Management PresentationDocument18 paginiEnergy Management PresentationSeindahNyaÎncă nu există evaluări

- Senarai Program Ditawarkan Semester II Sesi 2012 2013Document12 paginiSenarai Program Ditawarkan Semester II Sesi 2012 2013SeindahNyaÎncă nu există evaluări

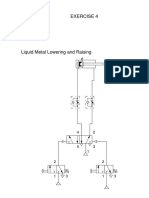

- Liquid Metal Lowering and Raising: Exercise 4Document1 paginăLiquid Metal Lowering and Raising: Exercise 4SeindahNyaÎncă nu există evaluări

- NEED EnergymanagementDocument35 paginiNEED EnergymanagementSeindahNyaÎncă nu există evaluări

- CV DR - OthmanDocument6 paginiCV DR - OthmanSeindahNyaÎncă nu există evaluări

- Gaji ds51Document1 paginăGaji ds51SeindahNyaÎncă nu există evaluări

- Journal Impact FactorDocument2 paginiJournal Impact FactorSeindahNyaÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Bachelor of Urban Planning University of Cincinnati Class of 2012Document16 paginiBachelor of Urban Planning University of Cincinnati Class of 2012Shivendu Shekhar SinghÎncă nu există evaluări

- Ray Bradbury Modern WorldDocument12 paginiRay Bradbury Modern WorldDiana ChernyashchukÎncă nu există evaluări

- King Explicitly Invokes Aristotle's Theoretical Statements On Poetics. To Argue, As Does Chinua AchebeDocument20 paginiKing Explicitly Invokes Aristotle's Theoretical Statements On Poetics. To Argue, As Does Chinua AchebeSuhrab Khan JamaliÎncă nu există evaluări

- Zaha Hadid From WikipediaDocument2 paginiZaha Hadid From WikipediaLilyÎncă nu există evaluări

- Russie T. Edaño 12-STEMDocument7 paginiRussie T. Edaño 12-STEMMer VinÎncă nu există evaluări

- Growing Up Asian in AustraliaDocument3 paginiGrowing Up Asian in AustraliaLevi LiuÎncă nu există evaluări

- How To Improve Your Pronunciation at METENDocument48 paginiHow To Improve Your Pronunciation at METENdturnb100% (7)

- Performing Arts in The PhilippinesDocument2 paginiPerforming Arts in The PhilippinesAyu GalvezÎncă nu există evaluări

- İNGİLİZCE 7 (501) - 1.dönem Soru Ve Cevapları - 2021: Yöneticilere Ve Emeği Geçenlere Teşekkür EderizDocument3 paginiİNGİLİZCE 7 (501) - 1.dönem Soru Ve Cevapları - 2021: Yöneticilere Ve Emeği Geçenlere Teşekkür EderizDybbukimÎncă nu există evaluări

- MspowerpointDocument78 paginiMspowerpointAaruni BattaÎncă nu există evaluări

- Friendly Letter ExampleDocument2 paginiFriendly Letter Exampleapi-259627125Încă nu există evaluări

- Modern Day Cave PaintingDocument5 paginiModern Day Cave Paintingapi-299065779Încă nu există evaluări

- DP Video Others 13112 DriversDocument144 paginiDP Video Others 13112 Driverslimitless freefireÎncă nu există evaluări

- koreaBaptistHistory PDFDocument286 paginikoreaBaptistHistory PDFEdvaldo GaiãoÎncă nu există evaluări

- Taking-Flight-From-War-Orphan-T - DesconocidoDocument37 paginiTaking-Flight-From-War-Orphan-T - DesconocidoNutts PerezÎncă nu există evaluări

- All The World AstageDocument12 paginiAll The World AstageMuhammad IrfanÎncă nu există evaluări

- BV Doshi: Pioneering Indian ArchitectDocument9 paginiBV Doshi: Pioneering Indian ArchitectMuskaan ChowdharyÎncă nu există evaluări

- Tibetan Buddhist PaintingDocument298 paginiTibetan Buddhist PaintingBhikkhu KesaraÎncă nu există evaluări

- Understanding SelfDocument40 paginiUnderstanding SelfDaniel Cuñado0% (1)

- I Shall See Him by and by - Frank E. Graeff PDFDocument1 paginăI Shall See Him by and by - Frank E. Graeff PDFEducational PurposesÎncă nu există evaluări

- Body in Movement - WorkshopDocument8 paginiBody in Movement - WorkshopAndrew CareyÎncă nu există evaluări

- Graffiti Illustrator TutorialDocument3 paginiGraffiti Illustrator TutorialDoreenÎncă nu există evaluări

- Age of Sigmar Silver Tower Warscrolls Errata enDocument1 paginăAge of Sigmar Silver Tower Warscrolls Errata enGareth McKnightÎncă nu există evaluări

- Dragon Quest V Marriage Waltz Sheet MusicDocument3 paginiDragon Quest V Marriage Waltz Sheet MusicTetsuo KagehiraÎncă nu există evaluări

- The Music of Paul HindemithDocument18 paginiThe Music of Paul Hindemith31088380% (5)

- DH-IPC-HFW2431T-AS-S2: 4MP Lite IR Fixed-Focal Bullet Network CameraDocument3 paginiDH-IPC-HFW2431T-AS-S2: 4MP Lite IR Fixed-Focal Bullet Network CameraZelaya DudÎncă nu există evaluări

- Stunning Digital Photography-PWYCDocument240 paginiStunning Digital Photography-PWYCbucatarum_1100% (1)

- Animation Composition TipsDocument35 paginiAnimation Composition TipsFrancisco Javier Chávez BarriosÎncă nu există evaluări

- Air Jet Loom Parts and Working PrincipleDocument14 paginiAir Jet Loom Parts and Working PrincipleSuza Ahmed Auporbo67% (3)

- Joni Mitchell's Talk To Me TabDocument4 paginiJoni Mitchell's Talk To Me TabDani Cáceres FernándezÎncă nu există evaluări