Documente Academic

Documente Profesional

Documente Cultură

Wali Shah Thesis

Încărcat de

Syed Wali ShahDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Wali Shah Thesis

Încărcat de

Syed Wali ShahDrepturi de autor:

Formate disponibile

1.

An Introduction & History of Clariant Pakistan Limited.

Clariant is a leading global specialty chemicals company with more than 32,000 employees and annual sales of about CHF 10-13824. The young company has grown out of the Sandoz Chemicals division, which was floated on the stock market as a spin-off in the summer of 1995, and the Hoechst specialty chemicals businesses, integrated in the summer of 1997. Clariant operates worldwide with more than 100 group companies in five continents. It is domiciled and headquartered in Muttenz near Basel/Switzerland. 1.2 Corporate Governance

Value-driven and transparent management is the foundation for a successful business. At Clariant, this is reflected in a responsible and efficiently structured organization, in its management, and in control process. 1.2.1 An Introduction & History of Clariant Pakistan Limited. Clariants business policy is aimed at ongoing value enhancement. The focus is on the companys long term success and not on short term opportunities. Priority given to trust based relationship with shareholders, customers and suppliers, to employee satisfaction and to a sound reputation with public and private institutions and among the general public. As proof of its commitment, fairness and responsibility as a business partner, Clariant has established an efficient and transparent division of tasks and responsibilities, effective control instruments and an open information policy. 1.2.2 Constant Improvement Clariant participated in the drafting of the Swiss Code of Best Practice for Corporate Governance, initiated by economiesuisse, in

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

1 Clariant June July 2010

order to benchmark its own organization against tried and proven rules and practices, and to optimize these where possible.

1.2.3 Full Responsibility at Market Level Clariant has created a decentralized and lean management structure in order to streamline operational decisions, bringing them close to the market. The five operating division bear full responsibility as profit centers, within the budget framework set by the Board of Management and in line with the targets of the corporate strategy. Individuals with managerial responsibility are supported by specific guidelines and an array of corporate analysis and control instruments. Decentralized responsibility also plays a role in Clariants successrelated remuneration program. Around 650 managers participate in the process of the value creation and benefit from the companys added value through a share programmed based on the achievement of specific financial targets. 1.2.4 Professional Management and Control All members of the Board of Directors have a proven track record in terms of their professional and strategic competencies. To help hem assess the companys potential realistically, most of them also have many years of executive experience gained with other companies. Through its committees, the Board of Directors analyzes current and future market opportunities and risks in order to define Clariants corporate vision as well as its business, organizational and financial strategies. As the supreme control body, it monitors the Board of Managements implementation of its targets. 1.3 Full Responsibility at Market Level

Clariant: Financial basis secured and strengthened. Clariant is back and 2005

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

2 Clariant June July 2010

competing industry.

with

the

best

in

the 2004 2003

Disposal of business.

Electronic

Materials

New business strategy focused on leading-edge technology and innovations with superior. applications and customer services skills. Comprehensive transformation program started to restore profitability and increase financial strength. Disposal of cellulose Ether business. Acquisition of BTP plc. Merger Clariant Hoechst Specialty Chemicals Foundation of two joint ventures in China and the start of construction work for the plant in Tianjin. 1997 1996

2005

2000

Paper Chemicals integrated into the Division. Printing plats sold to Agfa. Acquisition of the pigments business from Cookson/USA. Foundation of joint ventures in China (Masterbatches: Guanzhou; Pigments: Tianjin)

Demerger of Sandoz Chemicals Division by the Establishment of Clariant Ltd. Muttenz, as an autonomous company listed on the stock exchange.

1995

1994 1996

Further restructuring and reorganization of the Hoechst Specialty Chemicals Division: Textile Dyes transferred into the joint venture DyStar (with Bayer

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

3 Clariant June July 2010

AG. The master batches business sector achieves strategic mass by acquiring spectrum colours (USA). The chemicals division becomes an independent entrepreneurial unit within the Sandoz Group. Takeover of Emacolor (Belgium) secures leading position in master batches for synthetic fibres. 1993

1990

1989

Formation of Business Units.

Strategic

With the acquisition of Reed Plastic Corp., USA, Master batches gains foothold on US market. Further takeovers and plants opened in Spain (S.A. Cardoner), US (Sodeyco, Inc.; Reed Plastics (Corp)., Germany (K.J. Quinn GmbH), Italy (Sarma S.p.A), Brazil (Rioquima,), Mexico (Sulcolor), Belgium (Emacolor) and UK (Mercury Plastics).

1988

1957 Production of pigments and additives in Huningue (France) Sandoz Start of production at Muttenz plant near Basel (Switzerland). 1956

Development and production of reactive dyes.

Hoechst Specialty Chemical 1948

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

4 Clariant June July 2010

1932 Production of leather dyes begins. Business expanded to include textile chemicals. Diversification into dyes and chemicals for paper. 1931 1926 1919 1911 1925

Development ethers.

of

cellulose

1904 Sandoze _____ 1897

Successful R&D in various segments of organic color chemistry, development of high-quality dyestuffs with a better resistance against heat, water and sunlight. Corporation of dyestuff makers Farbwerke Hochst and Casella. Hoechst Specialty Chemicals Introduction of a new economic Indigo production process.

Sandoz begins producing textile dyes in Basel, Switzerland.

1886

1880 1878 1863 1.4 Vision, Mission and Values

Sulfer dyes plant in Frankfurt Hoechst Production of Azo dyes and related intermediates. Hoechst starts production of Fuchsin dye.

Clariant Vision Clariant Mission

We aim to be leading service-driven company and the preferred partner in the specially chemicals industry. Our commitment to service contributes to the success of our customers. We combine leading-edge technology and innovations with superior applications

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

5 Clariant June July 2010

and customer service skills. Clariant Value Customer Focus We concentrate our efforts on the individual requirements of our customers and help them strengthen their competitive position and performance. We achieve results through individual commitment, continual skills development and entrepreneurial behavior. We rely on the strength of teamwork to achieve synergies and realize our full potential. We utilize our extensive know-how and experience throughout the company to continuously bring new services, applications and products to the market. We strive for enduring value creation for the benefit of our shareholders.

Personal Engageme nt Team orientation Innovation

Shareholde r commitme nt Integrity

We are a trust worthy, loyal and respectful partner in all our internal and external relationships.

Sustainabili We contribute towards sustainable ty development by finding the best balance environmental, social and economic needs. 1.5 Clariant at a Glance

Clariant is a global leader in the field of specialty chemicals. Strong business relationships, commitment to outstanding service and wide-ranging application know-how make Clariant a preferred partner for its customers. Clariant, which is represented on five continents with over 100 group companies, employees about 25,000 people. Headquartered

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

6 Clariant June July 2010

in Muttenz near Basel, it generated sales of around CHF 8.5 billion in 2004. Clariants businesses are organized in five divisions: 1. 2. 3. 4. 5. Textiles Leather & Paper Chemicals Pigments & Additives, Functional Chemicals Life Science Chemicals Master Batches

Clariant is committed to sustainable growth spring from its own innovative strength. Clariant innovative products play a key role in its customers, manufacturing and treatment processes or else add value to their end products. The companys success is based on the know-how of its people and their ability to identify new customer needs at an early stage and to work together with customers to develop innovative, efficient solutions. 1.5.1 Textile, Leather & Paper Chemicals Profile: The division is one of the worlds leading suppliers of specialty chemicals and dyes for the textile, leather and paper industries. Textile dyes include dispersion, reactive, acid and sulfur dyes. The textile business encompasses special chemicals for pretreatment, dying, printing and finishing of textiles. Optical brighteners and chemicals for functional treatment are also part of the range. The paper business supplies paper dyes, optical brighteners and process and pulping chemical. The leather business produces chemicals for refining. Its offering includes all chemicals for finishing and dyeing as well as complete range of wet-end chemicals. Textile Paper Leather

Business

Markets:

Clothing, home textiles, technical textiles, garment leather, automotive leather, paper packaging construction.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

7 Clariant June July 2010

Products and Services

UV absorbers, fluorochemicals, paper dyes (Cartasol ), disperse dyes (Foron ), reactive dyes (Drimarene ), Optical brighteners, and water, oil and dirt repellant equipment.

1.5.2 Pigments and Additives Profile The division develops and produces pigments for paints and lacquers, for plastics and for special applications. The product range includes high-performance pigments to meet the exacting demands of the automotive and electronics industries printing, pigments are supplied to the printing ink industry and, increasingly, for non impact printing, ink jet and laser printing. The core business also includes additives to improve heat resistance as well as light and weather resistance of plastic and paints. Halogen free flame retardants are used in protective coatings, resins, thermoplastics and polyester fibers. The divisions portfolio also includes high-quality waxes based on various raw materials. Paints, lacquers, coatings, plastics, automotive industry Hostaperm pigments, PV Fast, Graphtol, Novoperm Pigments, Reflex Blue grades, Exolith, Ceridust, Licocence, DPP pigments, luminum paints.

Markets Products and services

1.5.3 Functional Chemicals Profile The divisions products are based on surfactants and polymers. The Detergents Business, which offers anionic and cationic surfactants, as well as bleach activators, is a partner to the detergent industry. Performance Chemicals supplies such different industries as personal care products, crop protection, paints, lacquers and plastics, The Process Chemicals Business markets products and services for the production and refining of oil and natural gas and for metalworking, mining and the aerospace and automotive industry.

Business

-Detergents

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

8 Clariant June July 2010

es Markets

Products and services

-Performance Chemicals -Process Chemicals Detergents, rinses and cleaners, personal care products, aerospace, automotive and machine tools, crop protection, paints and lacquers, plastics, construction, oil and gas extraction, mining, pharmaceutical industry, chemical industy. Anionic, nonionic and cationic surfactants (Genapol , Hostapur SAS, Emulsogen, Prapagen, Genamin), polymers and preservatives, Safewing, Safeway, Dodiflow, Peractive.

1.5.4 Life Science Chemicals Profile The division has two Businesses: pharmaceutical Fine Chemicals and Specialty Fine Chemicals. The Pharmaceutical Fine Chemicals Business is a service partner for the lunch of new drugs and supplies customer-specific late-stage intermediates with high degree of synthesis, patented active ingredients and around 30 different generic active substances. Specialty fine chemicals covers a wide range of industrial applications with its silane derivatives, glyoxalic acid derivatives and diketenebased chemicals. it also supplies precursors and active ingredients for crop protection agents. -Specialty Fine Chemicals -Pharmaceutical Fine Chemicals Pharmaceutical and agrochemical industry. Industries such as coatings, plastics, fragrances and flavorings Pharmaceutical and agrochemical active ingredients, precursors, building, blocks, Life Science Molecule Synthesis Center

Business Markets Products and services

1.5.5 Master Batches Profile The division supplies color and additive concentrates and special mixtures of these components. The combination of worldwide presence and strong local partnerships makes Clariant a preferrend supplier for plastics processors and the textile industry. At the local level, each of the divisions 54 production plants provides a complete technical service for all products

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

9 Clariant June July 2010

and applications.

Business es

-Europe North -Europe West -Europe South -Special Markets - Asia -North America -Latin America Consumer Goods, Automotive, Packaging, Textiles & Technical Fibers, Electrical & Electronics, Medical Devices Cesa, Hyderocerol, Remafin, Omnicolor, Color Works, Enigma. Renol,

Markets

Products and services

On May 21, 1963 Sandoz Pakistan Limited was corporate as wholly owned subsidiary of Sandoz Limited Switzerland with intention of establishing a pharmaceutical manufacturing of Dyestuff textile chemical and agrochemicals in august 1965 the company ways converted in to a public limited offering 25 % shares to the Pakistani public this making a locals investment of 4,000,000 amongst the shareholders there are many members of medicals profession people connected with the pharmaceutical trade. According to personal & Admin Officer, the company has done considerable research and development work in the chemical modifications Sandoz factory situated at Sandoz 0 Acres of land.

1.6 De-Merging Chemicals.

of

Pharmaceuticals,

Dyes

Stuffs

and

In 1995 the Chairman of Sandoz International, Mark More Demanded to merge the Sandoz in two portions, pharmaceuticals Divisions and dyes stuffs and chemicals division. It was a logical step for the Sandoz dyes stuffs chemical manufacturers.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

10 Clariant June July 2010

To take up this separate division of dyes and chemicals because it is total different from the pharmaceuticals the material are measured in grams while in the dyes and chemical stuff the materials are measured in the tons. The Clariant has been acting as a public limited company since 3 October 1996. The progress was made in this field in the field of pigment Clariant specially prepares pigments. Which give a variety of uses of coloration of plastic mfg. of inks emulations etc. (Zafar Manager Admin) 1.6.1 Clariant Merging with Hoechst: According to Annual Report 2004, the Clariant limited Muttenz Switzerland and Hoechst AG Frankfurt Germany have entered into a general agreements with intention of combing their respective special chemicals business with its own activities and integrate it in exchange Hoechst Limited. Clariant will remain headquarter in Muttenz. 1.6.2 Clariant Pakistans Division

According to Director Production there is two divisions of Clariant, viz Dyestuffs and Chemicals. 1. Dyestuff The original field of activates do Sandoz was the production of dyestuffs for the textile industry. The first of July 1896 saw the common cement operations in the Basle of small factory it is true to day color have never figured so largely in daily life as it does today 50 many materials beside textile are alleys or color. Sandoz limited Basle is spending 634 million Swiss Frans annually for research. 2. Chemicals In textile production chemicals are used to prepare the goods for dying and finishing intensive research over many years has resulted in a range of reduction which beside dying assistants (I young, Senatobia) include production more general employment in the textile leather and paper industries years back the chemical activities performed in separated chemical department.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

11 Clariant June July 2010

1.6.3 Clariant Pakistans Production Plants. According to Production Manager, the Clariant Pakistan Limited has three major manufacturer plants. 1. 2. 3. Karachi Jamshoro Lahore

As the Clariant is, the multinational corporation the consistency is quality is very firmly examined. After merging the Hoechst, now these have become five industrial cities as indicated in the comments reports in 1999. Industrial City Production Karachi Kasur Faisalabad Sialkot Lahore Leather, Textile Master Batch Leather Textile Textile, Dyes, Chemical Leather Leather, master Batch

1.6.4 Branches of Clariant in Pakistan As mentioned by personnel & Admin Officer, the Clariant Pakistan Limited Head Office situated in Karachi with three regional plant at Karachi, Jamshoro, Lahore, after merging with Hoechst these have become five regional plants, plant Karachi, Jamshoro, Lahore and Sheikhupura. The Jamshoro site is the main and mother site, produce dyes and chemicals for textile and leather. The two plants of Karachi produce the master batches plastic pigment The Sheikhupura plants produces the polymers PVA. The leather plants the same production of dyes and chemicals produces as in Jamshoro.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

12 Clariant June July 2010

1.7

Objectives of Organizations

Every organization has some basic objectives. The objective may be earning profit-rendering service to the community, employment of capital employment of labour etc. Clariant limited develops manufacture and market dyes pigments additive master bat chess and specially chemicals for dying and finishing textile paper leather plastic and aluminum as well as for paints and inks. Clariant supreme objective are two grow and create benefit for its shareholders and customers to achieve these goals. To establish technological leadership Customers focus world wide A comprehensive services A growing presence in the emerging Asia-Pacific Market. The innovates focuses on the genuine improvement in significant growth segment containing costs and lifting profit ability are an important focus steady growth in earning in the key of further expansion and hence the creation of new jobs. 1.8 Purpose of study

The study is part of the educational activity in BBA program and conducted by Prof: Noor M. Jamali Professor of Business Administration and Dean Faculty of Commerce, University of Sindh, Jamshoro. The purpose of the study is to teach the students, how to develop the Internship regarding to any specific topic and what are the principles of developing the paper on such topic. The purposes of Internship at Clariant Pakistan are as under: It is partial requirement of MBA program. To learn and understand practical knowledge

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

13 Clariant June July 2010

To know the problems and activities of the manufacturing of a multinational industry. To understand the business environment as well as tolls to handle the firm business effectively. The internship report focused at study the role, performance and important of the Clariant Pakistan Limited in the development and growth of economy of Pakistan. To learn and method of gathering information needed, to put them in organized manner. To learn and understand practical knowledge. To understand the objective function, and service provided by the organization. 1.9 Method of Study

There are various methods of conducting research studies. According to Zikmund (1996:6) research study in the systematic and objectives process of gathering recording and analyzing data for and in making decision similarly Emory (1994:17) refers research as a systematic investigation intended to add available knowledge in a form that is communicable and verifiable. 1.9.1 Primary Data According to Zikmund (1991:40), Primary Data are gathered and assembled specially for the project at hand. (Periodic Lecture) Through observations Through briefing by various executives of Clariant Pakistan Also observed the working atmosphere of the office

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

14 Clariant June July 2010

1.9.2 Secondary Data: Secondary data or historical data, are previously collected and assembled for some projects other than the one at hand. In the collection of Secondary Data the sources were: Operating Manual of Clariant Pakistan Record maintained by the Office Library books Newspapers, Magazines, and Monthly News Letters of Clariant Pakistan. 1.9.3 The Steps in Research Process Designing and conducting a project can be very complicated because of the number of parties involve. Further more a research project must be well planned to ensure that money is well spent organizing the project decision into a series of steps simplifies the planning process. The steps involved in research are formulate the problem; specify the research design develop the data collection procedure design the sampling procedure. Collect the data process and analyze the data and present result below these steps are discussed in brief. 1.9.4 Formulate the problem A through understanding of the problem is essential when panning a research project otherwise; the data collected may not adequately address the problem unfortunately problem definition can be difficult because not enough is know about the situation. If the problem is not properly defined, the collect may be unless. 1.9.5 Specify the Research Design

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

15 Clariant June July 2010

The second step in the process is to specify the general design of the project. These steps involve two decisions the types of research to be conducted and the source of the data. These research objective determine which of the three general types of research namely exploratory research and descriptive research to be used if the objective of the research is to understand a problem and situation, exploratory research is required if the objective is to identify cause and affect relationship. Experimental research is conducted if the research objectives is to provide detailed data on who, what where how why and how often descriptive research is used. Descriptive research typically takes the form of the survey such survey opinions, polls that have become common place in our society. After establishing the basic type of research to be conducted source or sources of the data to be collected must be determined. Marketing search data can be obtained from secondary syndicated and primary data source. Secondary data are the data have already been gathered for some other purpose but that also provides useful information for the current problem. Syndicated data are the data gathered by syndicated service and provided to all subscribes of these services. The third data source, primary data refers to data that are gathered specifically for the project at hand. 1.9.6 Develop the Data Collection Procedure When collecting primary data whether for an exploratory experimental or descriptive study the procedure to be used to collect the data must be developed. Typical decisions at this involve the selection of the method used the data and design of necessary data and design of necessary data collection instruments. A variety of the methods exit to collect data either people can be questioned or their behavior can be observed questioning can occur in person or by phone to be self-administrated. The appropriate ness of each method varies across studies, and researcher must be determined which method is best for study at hand. The design of data collection instrument can influence the accuracy of information collected in study. Simple change in the wording or in the way the questionnaires looks can drastically. Influence the response received. The research must ensure that questions are properly worded and the instrument is properly designed.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

16 Clariant June July 2010

a)

Design the sampling procedure

For most studies only a sample of all possible people or project will be questioned or examined. Designed the sampling procedure to use critical who include as a potential sample numbers, are selected and the seize of the sample are affected what can inferred for the results. b) Collect the Data

Companies hire field service to collect marketing research. The data collected are only as good as the procedures used to collect them. Therefore the research must be institute procedure must be selecting and supervising field service to ensure the desired data collection procedure is as follows: c) Process and Analyze the Data

After the raw data have been collected they must be prepared for analysis and analyzed. It is important that the research select appropriate data analysis procedure, given the information the study the type of data collected. d) Present the Result

Marketing research findings are little of value their meaning can be clearly communicated establishing formats exits for written and oral research presentations. The researcher must see to it that these format are followed (Crask, Fox and Stout 1995: 15.17). Through observation Through briefing by various executive of Clariant Limited The cooperative between employees was observed. Also observed the working atmosphere of the office By referring the journals magazines, research journals, annual report, booklets, broachers and website. Referring textbooks and teachers. The purposes of Internship at Clariant are as under:

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

17 Clariant June July 2010

It is partial requirement of MBA Program. To learn and understand practical knowledge. To know the problems and activities of the manufacturing of a multinational industry. To understand the business environment as well as tolls to handle the firm business effectively. The internship report focused at study the role, performance and important of the Clariant Pakistan Limited in the development and growth of economy of Pakistan.

1.9.7 Research methodology While conducting the Internship study the Internship methods were followed for the collection of data, which are primary data and secondary data. (source class lectures by Dr. Shah) Primary Data According to Zimund (1991:40) Through observations Through briefing by various executives of Clariant Pakistan Also observed the working atmosphere of the office Secondary Data Secondary data or historical data, data are previously collected and assembled for some projects other than the one at hand. In the collection of secondary data the source were: Operating Manual of Clariant Pakistan. Record maintained by the office. Library books Newspapers, magazines and monthly news letter of Clariant Pakistan

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

18 Clariant June July 2010

1.9.8 Limitations regarding study During the internship, the internee faced the following difficulties, which are listed as under: a) 1. b) 1. Shortage of time Time was too short to seek the complete knowledge regarding function of every department of the institution. Secrecy of Data The internee in the order to compile report needed certain data however, the organizations acuities have denied most of the data because the data were said to be confidential in nature.

Company Information: Chairman: Chief Executive & Managing Director Director: Directors:

Dr U Cuntze

Secretary: Bankers:

Farhat A Mirza P Brandenberg Albert Hug Dr Herbert Wohlmann Dr F Dennefeld First Ali S K Mehdi ABN-Amro Bank Credit Agricole Indosuez- The Global French Bank Citibank N.A. Deutsche Bank Habib Bank Limited National Bank of Pakistan Standard Charted Bank Standard Charted Grindlays Bank Societe Generale- The French and International

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

19 Clariant June July 2010

Bank The Hongkong & Shanghai Banking Corporation Limited Auditors: Registered Office: Share Registrars: Factories:

A.F Freguson Accountants.

&

Co.,

Chartered

1-A/1, Sector 20, Korangi Industrial Area, Korangi, Karachi. Ferguson Associates (Pvt.) Ltd. State Life Building 1-A I.I. Chundriger Road Karachi.

Petaro Road, Jamshoro

Korangi Industrial Area, Karachi Katarband Road, Thokar Niaz Baig, Lahore.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

20 Clariant June July 2010

Personnel Administration Section According to personnel & Administration officer this department is headed by the manager Personal and Administration. Factory manager who is directly responsible to the technical director personnel and administration manager perform an important role in the organization. He exercises authority and leadership workers, to create peaceful atmosphere in the factory by maintaining a harmonious complaints for proper administration, co ordinance of all the activities, which are being performed within the organization. 2.1 Function of Personal Department.

The function of personnel Department is presented below. 1. 2. 3. 4. 5. To advise the board on the definition, development and interpretation of personnel policy in management practice. To formulate objective and plans. to provide the company with facilities i.e. special techniques and service of action and information. To recommended the Management on different issues. To find the defectiveness of all management activity that lie with personnel functions that are to do with the development motivation and treatment of the people in the organization context.

There are different heads in Clariant Jamshoro, who control their respective department separately but the administration department provide facilities to all by controlling the office account security. 2.2 Personnel / Administration.

The head of personnel Department in the Clariant is also the head do administration. He reports both the technical director and managing director. The personnel department provides advice, service and function guidance to the management by which management deals the matter effectively concerning hiring of the people. The personnel department also maintains public relation and keeps in contact with the law and administrations outside the

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

21 Clariant June July 2010

Clariant these contest organizational problems.

provide

the

helps

to

solve

many

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

22 Clariant June July 2010

2.2.1

Service.

The factory provide the following service to the employees, canteen service transportation, medical service provident fund, contribution social security telephone service staff welfare. 2.2.2 Canteen Service.

There are two canteens in a factory, one for the workers and one for the officers the canteen timings are between 6 am to 2:00 pm the canteen rum on contract basis, where the tea is free for every worker and lunch is provided on subsidizes rates. 2.2.3 Transportation.

The factory provide the following service to the employees, canteen service transportation, medical service provident fund, contribution social security telephone service staff welfare. 2.2.4 Medical Service

Clariant also provide the medical service to each worker and his or her families of this purpose there are two male one female doctors in the dispensary, which provide 24 Hrs service. 2.2.5 Provident Fund

Clariant contributes 10% basic salary of each worker to entrance the amount of provident fund of that worker. The company provides the facility of loan to workers from the provident fund. This loan is payable within two years at an interest rates of 4%. 2.2.6 Social Security

Clariant pays salary of worker to social security. It includes medical facilities and legal facilities. The social security is only for those, wages are 3000 less. (Manager Admin).

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

23 Clariant June July 2010

2.2.7

Time Office

The over time is double for ordinary pay and the time ID entered daily in the attendance register of the workers of the factory remain closed for two days in the week but the works work on Saturday on overtime basis (Manager Admin). 2.2.8 Office Account

The head office of Clariant is in the city of Karachi and the operation system account provides the record of each workers leaves overtime etc. to the accounts department to computer the salary for each workers. The record of loan if any worker has it is also recorded in the accounts department with the following accounts. 2.2.9 Salaries

Account department maintains the salaries of each worker the time office provides the record of each workers leaves, overtime etc, to the account department to compute the salary for each workers. The record of loan if any worker has it is also recorded in the account of workers provident fund. The installments of his loan are dedicated every month. 2.2.10 Purchasing As the major portion of accounts department is in the head office, therefore the major purchasing like raw material are directly purchased by head office and they are sent to the factory at Jamshoro but some minor purchases like furniture electrical from here Hyderabad. 2.2.11 Security The Clariant Pakistan Limited Jamshoro has a very strict security on the contact bases as his law and order situation of the area is not satisfactory. The Clariant employees the contractions, who provides them private security guards but they are not allowed to interface in the factory affairs.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

24 Clariant June July 2010

3.

INTRODUCTION

According to Manager Engineering Section, Manager Engineering heads a section under whose control there are seven engineers, who are responsible for providing the services and maintenance or different sections of Clariant. 3.1 Site Maintenance

The main purpose of the engineering section in the Clariant Pakistan Limited Jamshoro is to keep up the production level. The main duties performed by the SITE maintenance is the securities grading maintenance all the places, streets and open drains in the site of Clariant Jamshoro. (Manager Engineer Section). 3.2 Energy Supply

This is the main service of the engineering department to provide all sections of the Clariant Pakistan Limited in case the national supply of the electricity is being stopped, the generators will start their functions just after 30 seconds. 3.3 Plant Maintenance

This is the main function of the Engineering Section with includes the central workshop this section provides the maintenance in the following sections. i. ii. iii. iv. 3.4 Dyes plant Chemical plant Master Batch Plant Utilities

Waste Management

The engineering section also constructs a wastewater treatment plant. This plant was constructed in the Rs.2 million and covering the area, about 10 Acre. The effluent treatment plant at Jamshoro

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

25 Clariant June July 2010

sites based on the lagoon system containing 10 pounds, which treats the waste with the help of atmosphere.

3.5

Warehouse Maintenance

The warehouse of the maintenance in the warehouse of the engineering section also required maintenance. In the warehouse three types of the commodities are kept. i. ii. iii. Parts, general items Spare parts of machine i.e. dye chemical equipments. Filter plants and pant.

All the consumption and the existence of the stock are determined in the systematic way. All the rakes have issuance cards which shown in the computers, installed in the engineering section. 3.6 Projects

The payment of Security Guards are no accommodation is provided the project engineering department construct building, vase on the contract technical services are those services performed for the minor projects up to Rs.50.000 (Manager Engineering Section).

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

26 Clariant June July 2010

4.

INTRODUCTION

The term production is defined as transformation of inputs into outputs. The main object of each organization is to produce something and the productivity is defined as the ratio of output to input and is probably the best indication of efficiency. The overall productivity and efficiency of the Clariant ultimately depends on how ell management organizes and utilize the capital, investment, technology, materials, labor and other inputs. 4.1 Production Clariant

Clariant Pakistan has two main production divisions, which produce various products. The functions and the process of production of Clariant are dyes division, chemical division (Hussain, Director Production Chemical). 4.2 Dyes Department

Dyes plant started in the early 60th. Capacity of the plant was 200kg until 1982. These dyes are used to clout the yarn and leather. The dyes section consist three floors, in which the process is conducted on the first floor the standard solution is prepared I number of vessels of different capacities. After that, a sample is taken and sent to ach in process laboratory (IPL) where it will be checked. After the approval the solution will go through filtration process in the filter machine filter, press has screens covered with canvass on which the solid particles will settle and the liquid will drain out. (Director Production Chemicals). 4.3 Chemical Department

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

27 Clariant June July 2010

The chemical section is on the main section of Clariant Pakistan Ltd. the production of chemical is based on three floors process one of contain. Five different vessels, a rubber line, baseline vessels and steels vessels. On this floor, die rent types of chemicals are produced after reaction is carried out duration a sample is taken to the IPL for checking approval. The chemicals go directly for packing or for filtration or for spray dyeing process. The chemicals, which are in liquid process in sop the chemicals are sent through the pipe lines to a storage vessel from where in small quantities it is sent to the spray dry feed vessels that send the chemical to the spray dryer. (Director Production Chemical).

4.4

Management Process flows for chemical process

Process so describe diagrammatically as follows: 1. Reaction IPL approval Q.A

Packing Reaction Packing (IPL Approval) Filtration Packing (IPL approval)

(Q.A Finished goods) Spray Dying

IPL Approval Quality Assurance. Finished goods

4.5

Manufacturing process flow for dyes production

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

28 Clariant June July 2010

Disperse Dyes Vita Packing Warehouse

Direct Reactive and Derma Dyes Vita IPL Approval

Filter Action (Cake Formation) Melting Quality Control Section Mixing Packing Warehouse

The dyes after going through the dying process is dry out still like caked and have to under process, so that it is in power from this mixing process are homogenous. The final dye is now sent to the quality assurance lag for approval. After that these are sent to the assurance the disperse dyes are made by carrying out the vat reaction and the following are the types of dyes products. 1. 2. 3. 4. Direct Dyes Reactive Dyes Disperse Dyes Derma Dyes The direct dyes are ordinary dyes and are used for cotton. The reactive dyes react with cloth fiber. The disperse dyes is introduced one year before. It is for polyester fiber. The derma dyes are used for leather products. (Hussain Director Production Chemicals)

4.6

Management of production operation

One of the most important functions of management is the maximum utilization of the available production resources at a minimum cost. The existence of especially the world wars created intense international completion. Input Transformation Process Output

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

29 Clariant June July 2010

Input People Skill and facilities Tools, Machine Knowledge worker computer Transformation 1. 2. 3. 4. Choiring the products To be made service To be provide Production planning and control Inventory control Quality control Material Supplies and part Raw material energy Land Equipment

4.7

Analytical lab of Clariant

According to Incharge of analytical laboratory, the main purpose of lab is to check the production of raw material that weather there is any hazards in the colors. The composition of raw material that weather is also checked here. There are a few companies which pay attention to the environment and installing such type of analytical laboratory in there factories.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

30 Clariant June July 2010

5.1

Introduction

Quality control is concerned with the sampling specification testing organization documentation and release procedures, which insures that the necessary and relevant tests are carried out. The materials are not released for use or products are not for sale until and unless their quality has been judge satisfactory. 5.2 Objectives of Quality Assurance Following are the objectives of quality assurance i. To produce the qualitative and approved products. ii. The produce has been complied with the specification. iii. The finished products have been essentially processed according to the defined procedures. iv. The finished products are enclosed in their proper containers in such a way so that they are correctly labeled. In addition, stored and distrusted so that their quality is maintained through out its expected life. 5.3 Raw material analysis chemicals laboratory

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

31 Clariant June July 2010

This laboratory is also called sampling section. All the raw material for the sampling kept in the categorized and taken from the large container of the raw material:a. b. c. d. e. f. Imported Local Principle (Active Ingredient) The raw material is imported from the Europe, Iran, China, Hong Kong, Japan & Taiwan. The local raw material is salt mater, caustic soda etc. The principle or the active ingredient comes from the headquarter Switzerland.

5.3.1 Laboratory There are laboratories on the Clariant Pakistan Limited i. ii. iii. Raw material analysis chemical lab In process lab Quality control lab

5.4

Independent quality control system of Clariant

5.4.1 In process Laboratory (Chemicals) For producing highly qualitative the raw material is sent to the processing again take for the checking. This lab is authorized to take the sample from any vessel. That sample will be taken from any stage from the start of raw material until finished goods. 5.4.2 Importance of in process quality control In process quality control as essentially a tool, which keeps in, maintain product quality at every stage of manufacturing process. In process, quality control demands a high-level quality protection. The quality must meet the customers needs. 5.4.3 Quality control laboratory (Dyes) All the products especially Dyes products are tested the quality control i.e. as the dyes for the leather must have to be checked and analysis of the processing of the whole or requested raw material.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

32 Clariant June July 2010

5.5

Release Decision The decision is based on the result of the sampling inspection of the products, and possibly supplemented by the result of the in process control. A release decision is also necessary, finished product the decision is based on the result of the examination, of a sample from each package batch or from each delivery during the packaging process, by the personnels of the quality control department. (Siddiqui Incharge Quality Control).

5.6

Analytical Records Department maintains the analytical records concerning the examination of all samples taken. The result of every test performed including observation and calculation complies. a. b. c. The product name Batch number Size of the batch number.

5.7

Distribution Records As adequate records have been maintained of the distribution of finished products batches in order to completer recall of the batch if necessary.

5.8

Complaints, Reports and Adverse Reaction The reports of adverse reaction resulting from the use of chemical are forwarded to appropriate authorities. Complaints regarding the quality of chemical including any change in its physical characteristics are toughly investigated.

5.9

Packing & Labeling Concept The packing and labeling operation controlled to ensure that only Clariant products have met the standards are specification established in the records. The packing material is distributed in a way to relent the mis-up between the products during filling packing and leveling operation. To prevent the packaging and labeling errors a know numbers of labeling and packaging is issued such issuance is made

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

33 Clariant June July 2010

against the written signed indicate the quantity and type required.

ENVIRONMENT, SAFETY, & HEALTH AFFAIRS 6.1 INTRODUCTION:

Before the de-merging of Clariant from Sandoz, the name of this department was SNI. After the de-merging of Clariant in 1995, this department was know as she (Safety, Environment, Health), and now known as ESHA (Environment, Safety, & Health Affairs). 6.1.1 SAFETY: Safety in the Processing Safety in the Storage

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

34 Clariant June July 2010

Safety of the Property Fire prevention, Fire fighting

GUIDELINES: As the Clariant is foreign base industry,, which are very much conscious about the safety. The Guidelines, which are given to the Clariant, are as under. Directive issues from Switzerland Corporate instruction, such instruction bound all the chemical industries . Local Law, some times State also impose the law, which must be obeyed by the industries.

6.1.2 ENVIRONMENT: The Clariant Pakistan takes deep care about environment according to the Clariant Principle. The soil of factory site must be free of pollution. The air of factory surroundings must be free of pollution. The matter of factory undertakes of even waste matter must be free of pollution.

GUIDELINES: The Clariant Pakistan follows guidelines for environments, to remove pollution from waste water and of gas stream before discharge in to environment as under: a) To avoid generating waste b) To reduce if cant completely c) To cycle the waste i.e an envelope use for the five times. 6.1.3 HEALTH: The Clariant Pakistan takes deep care about environment according to the Clariant Principle. The monitoring of the work place. The occupational hygienic. The health hazards chemical experiments. Noise pollution.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

35 Clariant June July 2010

GUIDELINES: The Clariant Pakistan follows guidelines for health purpose as under: d) Corporate principle e) International standards f) Local standards.

6.2 6.3

MAIN OBJECTIVES: The main objectives of ESHA are, The main local safety file Technical plant documentation (SAMACO) Air emission Management Incident reporting Clariant emergency Management. Safety system of work Risk portfolio Try to get high yields and make little waste from production. AUDIT OF ESHA CONCEPT:

The auditor team performs the audit of ESHA. The team comes from the head quarter Switzerland to check that weather all the departments perform their work efficiently or not. The team of the auditors comes after each three years. The auditors check the risk portfolio, which provides an overview of major risk for the management at site and determine that how effectively the risk of accident will be managed. 6.4 A GREAT EFFORT TO ECO FRIEND:

(Waste Water Treatment Plant) Clariant Pakistan fulfilling its commitment to the environment of the surroundings Jamshoro site, initiated a pilot wastewater treatment plant in March-1989. After continuously monitoring the wastewater treatment for two years a full-scale effluent treatment plat costing RS.42 Million was constructed covering an area of 10 acres, which was commissioned in September-1995.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

36 Clariant June July 2010

The effluent treatment plat at Jamshoro site s based on the lagoon system containing 10 ponds, which treats the wastewater with the help of atmospheric air, solar radiation and retention time. NO. important equipment or electromechanical energy is required for the treatment mechanism. Instead, certain types of micro organism and algae play their role in different lagoons to carry out biochemical reaction to breakdown the complex compound in the waste, reduce quality of solid, remove biological oxygen demand and other pollution from the waste. The ponds in the lagoon system are of three types; equalization, facultative and maturation ponds. Total capacity of system bas 57,000 with a provision of 20 days retention; a total of 3.600 cubic meters of wastewater can be treated by this system. The samples of all the influent and affluent water streams are taken weekly, and analyzed in the laboratory located in close proximity to this plant. The outgoing treated water, being highly nutrient rich, helped in the growth of vegetation in the surrounding are, where previously the barren land now become lush green. In reality Clariant scientific lacking has brought a green revolution in the surroundings of Jamshoro. 6.5 OCCURRENCE OF ACCIDENT: According to the principle of the Clariant Pakistan Limited, there are two mean reasons of the accidents; 1. Unsafe Conditions in includes, Narrow Space, within grip of moving machine, flying particle, falling things, Slippy surface, sudden Change in the work place, electric shocks, toxic gases, Heavy items, Combustible Items, Sharp Items, Heating & Cooling Effects. 1. Unsafe Activities: it includes, Operating unfamiliar machines, unsafe Speed of Machines, Wrong improper tool, and distributing other, joking/nowseriousness at work place. Dont be discourage Investigate Cause Take remedial measures fore future presentation Inform others about the cause of accident. Periodically review the status There is the form of Accident Report for the information consisting information, where, when, nature of injury, reason of injury, the time loss. It is important step to measure the workers performance.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

37 Clariant June July 2010

6.6

ESHA DOCUMENTATION: 1) Handling Flammable liquid & gases 2) Statue Electricity 3) Isolation of making safe Products 4) Head & Face Protection 5) Color Coding of Gas Cylinder 6) Regulation for use of Solvent 7) List of Waste Substance, When Where, and how to inform 8) Transportation of goods and waste 9) Services ducts entry permit 10) Pressurized glass apparatus and pipe ware.

The risk are and weak points are also to be look after by the N.O open eyes e.g. AIR

Heat

Fire

Fuel

6.7 CHEMICAL REACTIONS: The fireplace requires a greater presentation from the air, fuel, heat and chemical reaction. There is also indication of causes of accident that must be avoided, Production Site Laboratories House waste collection Infrastructure, ventilation, Electric Supply. There are more than 300 fire extinguishers for fire protection. 6.8 PLANNING FOR MANUFACTURING SAFETY: Before State Work: Keep in mind surrounding danger Expect and repair for unexpected risk Inform others about your presence Never do any thing that is likely to endanger yourself and other Help to keep the site tied. Good housekeeping prevent accidents.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

38 Clariant June July 2010

During Working: Observe Safety Regulations The dangerous parts and tools should be used properly Leave more in safe conditions 6.9 PLANNING FOR WAREHOUSE SAFETY: There is the categorization of warehousing. Each category has its own safety measures. Each section Send its own Safety requires guidelines, which must be followed by ESHA. 6.10 PLANNING FOR WASTE SOLID MATERIAL SAFETY: Each drum is not dispose off. All of the drums, after the use washed and reused; Other waste are fixed The particles are sold out All types of waste and wrong production recomposed or reproduce. PLANNING FOR CONSUMPTION OF WASTE WATER SAFETY: In Europe there is the problem of space. In Jamshoro site treatment expense of wastewater is six paisa per liter. While in other places due to shortage of space Rs.10.00 per liter will be consumed on wastewater treatment plant. 6.11 6.12 PLANNING FOR PERSONNEL SAFETY: In order to prevent any impairment of health caused by the handling of hazardous of potent materials, manufacturing personnel wear head gear, full face mask mufflers, ear pin, respirators, apron dust mask, etc and such protective clothing remains in the area in which it is used. In some instances, it has been necessary to have restriction of the movement of personnel from special working areas.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

39 Clariant June July 2010

WAREHOUSE DEPARTMENT 7.1 Introduction:

It is defined as management for Receiving, storing, Accounting, issuing, and Supplying Materials. The purchase of D3 orders for raw material reaches the warehouse, the checking has been carried out against the purchase order. Raw materials are then transferred to quarantine area. From where the samples of raw material are sent to the quality assurance section for analysis, if the material is not approved then the material return back to the consignee, and destroyed if the period of return is expired. After the approval of raw material, the material is stored according to storage requirement. The particular material issuance is made according to formula, in the right proportion and is issued by the qualified person. The FIFO (first in first out) principle is followed.. 7.2 WAREHOUSE: The warehouse is categorized in four sub-warehouses, 1) Dyed Raw Material 2) Chemical Raw Material 3) Dyed Finished goods 4) Chemical Finished goods 7.2.1 Raw Materials: the 90% of the raw material for the both dyes and chemical are imported. Only 10% of raw material for the manufacturing of Dyed and Chemical purpose are local (Caustic Soda, Salt, and Potassium). As such batch of incoming raw material is receive, has given a receiving number by which it will be identified in subsequence operation. This number has distinguish characteristic which will prevent possible confusion with any number previously placed on the container by supplier. ISSUANCE OF RAW MATERIAL FROM BOUNDED WAREHOUSE: This warehouse involves the procedure to issue raw materials. All raw materials are issued through the warehouse on the documents. Materials are issued against manufacturing. The purchase order are liable to pay duty and charges on the imported raw materials, 7.3

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

40 Clariant June July 2010

comes out from the bounded warehouse. Now the warehouse Incharge issues the material to production section. Before issuing the material, re-check the container and liable to reassure the correct transfer to material.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

41 Clariant June July 2010

7.4 CAPACITIES AND CATEGORIZATION: There are four buildings consist the warehouse, seven shades and ten container of ten feet. There are 300 Ton capacity of ther warehous4e of the Jamshoro site. The material of the warehouse finally categorized each material form 1-10 categories. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. High Flammable Explosive Material Self-Reactive Substance Substance which reacts violently and produce Gas when it contacts with matter Oxidation Substance Flammable Liquids Flammable Solids Combustible Toxic Solids Combustible Solids (Liquids, Non, Liquids) Combustible Packing Material

7.5 BUSINESS PLANNING & CONTROL SYSTEM (BP & CS): The warehouse has seven multipurpose computer systems called Business Planning & Control System (BP & CS). In the IBM 400 latest system. VHF speed of that computer programmer is 9300bites per sec. The mian menu of BP & CS displays the following on the screen, Dyes Chemical & Master Batch BP & Cs non-inventory BP & CS Journal Ledger BP & CS Projects Project Monitoring System BP & CS Testing There are four-sub sections in BP & CS program. 1. Financial 2. Distribution 3. Manufacturing 4. System Application.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

42 Clariant June July 2010

7.6 PURCHASING RAW MATERIAL: The planning Department sends the forecast report for an other eight-month 7 indicates that which type of raw material is required, They send Such requirements to the purchase department when the purchase department approves it, then they send the purchase order to warehouse. Then warehouse manager imports all the described raw materials. 7.7 RULES TO KEEP WAREHOUSE: The Switzerland sends the guidelines, implementation for the warehouse. The rules are, Risk reduction Strategy Categorization of Stored goods Alarm & Emergency instructions Water & Soil Protection strategies and

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

43 Clariant June July 2010

8.1 CONCLUSIONS: At the completion of internship the internee has drawn the conclusion that are presented in the following order. 1. 2. 3. 4. 5. There papers a shortage of skilled personal related to production. Product promotional policies seem to be ineffective locally. Out dated equipment seems to be used. The pace of research is little slower than required. The production management seem not following the JIT concepts religiously. Suggestions:

8.2

On the basis of conclusion drawn, the internee recommends the following suggestion. 1. The production management requires recruiting and training the personnel as to increase the efficiency & performance of the organization as whole. it is desirable to improve the product promotional polices for the betterment of the product locally. It may be more productive to introduce new equipment & advanced technology to save the time memory. it seems that there is dire need for more research. it appears that there is need to adopt the JIT concept in order to get the return immediately.

2. 3. 4. 5.

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

44 Clariant June July 2010

BIBLIOGRAPHY 1. 2. 3. 4. William G.Zikmund, Business Reseacrch Methods (third edition), 1991 page-06 C. William Emory, Business (revised edition), 1994 page-17 Research Methods

Norman A. Polansky. Social Work Research, The University Chicago Press, Chicago, 1974 Page-02 Melvin Crask, Rechord J. Fox, Roy G. Gtout: Marketing Research Principle & Applications (copy rights 1995) , Prentice Hall, page-15 to 17 Recce/o Grady, Business Fourth Edition 1994

5.

REFERENCES: Clariant Web Site Clariant Annual Report 2003-2004 Clariant Annual Report 2004-2005 Quarterly Report Clariant April-2003 to June-2003 Business Analysis Report Clariant March-2002 Manager Personal & Admin, Clariant, Jamshoro Manager Engineering Clariant, Jamshoro Manager Quality Control Clariant, Jamshoro Director Production Chemicals Clariant, Jamshoro Manager Warehouse Clariant, Jamshoro

Submitted by: Syed Wali Shah(2k8/BBa/175) 1/7/2012

45 Clariant June July 2010

S-ar putea să vă placă și

- How to Apply Marketing Theories for "The Marketing Audit": 27 Theories Practical Example insideDe la EverandHow to Apply Marketing Theories for "The Marketing Audit": 27 Theories Practical Example insideÎncă nu există evaluări

- How To Identify MQ Client Connections and Stop ThemDocument26 paginiHow To Identify MQ Client Connections and Stop ThemPurushotham100% (1)

- ChemicalsDocument92 paginiChemicalsBrian KawaskiÎncă nu există evaluări

- Playful Homeschool Planner - FULLDocument13 paginiPlayful Homeschool Planner - FULLamandalecuyer88Încă nu există evaluări

- Marketing Management Worked Assignment: Model Answer SeriesDe la EverandMarketing Management Worked Assignment: Model Answer SeriesÎncă nu există evaluări

- Training & Development in An OrganizationDocument77 paginiTraining & Development in An OrganizationuccvandanaÎncă nu există evaluări

- From Philo To Plotinus AftermanDocument21 paginiFrom Philo To Plotinus AftermanRaphael888Încă nu există evaluări

- ColgateDocument28 paginiColgateAsifshaikh7566Încă nu există evaluări

- Methods of Recording Retruded Contact Position in Dentate PatientsDocument15 paginiMethods of Recording Retruded Contact Position in Dentate PatientsYossr MokhtarÎncă nu există evaluări

- E Flight Journal Aero Special 2018 Small PDFDocument44 paginiE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Hey Friends B TBDocument152 paginiHey Friends B TBTizianoCiro CarrizoÎncă nu există evaluări

- Production and Operation Management ReportDocument33 paginiProduction and Operation Management ReportSM0008100% (1)

- Itoro Johnny Liquid Soap Business PlanDocument19 paginiItoro Johnny Liquid Soap Business PlanMAVERICK MONROE100% (1)

- SM ReportDocument8 paginiSM ReportAbhijit DharÎncă nu există evaluări

- Hima OPC Server ManualDocument36 paginiHima OPC Server ManualAshkan Khajouie100% (3)

- Strategic Management AssignmentDocument26 paginiStrategic Management Assignmenttoufiq111193% (27)

- Benevisión N15 Mindray Service ManualDocument123 paginiBenevisión N15 Mindray Service ManualSulay Avila LlanosÎncă nu există evaluări

- ICI ProjectDocument27 paginiICI ProjectWaheed ZafarÎncă nu există evaluări

- Principles of ManagementDocument12 paginiPrinciples of ManagementNadya AyasamyÎncă nu există evaluări

- "Analyzing The Strategic HR Environment Analysis of Keya Cosmetics LTD Under Keya Knit Composite DivisionDocument25 pagini"Analyzing The Strategic HR Environment Analysis of Keya Cosmetics LTD Under Keya Knit Composite DivisionOntor OmiÎncă nu există evaluări

- Fatima Group - Docx (Ethics Proposal)Document5 paginiFatima Group - Docx (Ethics Proposal)Salman MunawarÎncă nu există evaluări

- Strategic Analysis of PidiliteDocument20 paginiStrategic Analysis of PidiliteAbhijit DharÎncă nu există evaluări

- Profil EngDocument52 paginiProfil EngReza RhiÎncă nu există evaluări

- BASF - Company Profile: BASF at A GlanceDocument5 paginiBASF - Company Profile: BASF at A GlancemuzaffarnazishÎncă nu există evaluări

- IOCL Full Organizational AnalysisDocument13 paginiIOCL Full Organizational AnalysisShyamSundarÎncă nu există evaluări

- HR Policies and Its Implementation at Deepak NitriteDocument86 paginiHR Policies and Its Implementation at Deepak NitriteTahir HussainÎncă nu există evaluări

- Business Plan Chapter 1Document5 paginiBusiness Plan Chapter 1Nikki LabialÎncă nu există evaluări

- Tata Chemicals Yearly Reports 2018 19 PDFDocument62 paginiTata Chemicals Yearly Reports 2018 19 PDFAKHILÎncă nu există evaluări

- Final Project Ratio AnalysisDocument60 paginiFinal Project Ratio AnalysissatishgwÎncă nu există evaluări

- Packages FinalDocument17 paginiPackages FinalAysha AhmedÎncă nu există evaluări

- Business Strategy ACI BangladeshDocument2 paginiBusiness Strategy ACI BangladeshRamu Bannurkar100% (1)

- ChemRez Inc. - Company Analysis - Organizational BehaviorDocument23 paginiChemRez Inc. - Company Analysis - Organizational BehaviorMNLphÎncă nu există evaluări

- Business Ethics Governance and Risk unT2v2WlAhbjDocument4 paginiBusiness Ethics Governance and Risk unT2v2WlAhbjbhawnaÎncă nu există evaluări

- Strategic ManagementDocument34 paginiStrategic ManagementAnimalaRamachandran100% (1)

- Soumya Agrawal BV1Document19 paginiSoumya Agrawal BV1Soumya AgrawalÎncă nu există evaluări

- Sip Report On Customer Preferance For Vimal Ice CreamDocument53 paginiSip Report On Customer Preferance For Vimal Ice CreamSohel Shaikh100% (1)

- Dividend Policy of ACI LimitedDocument21 paginiDividend Policy of ACI LimitedNazmul Amin Aqib100% (1)

- Marketing Mix (4P's) Analysis and Competitors Evaluation: A Study On Advanced Chemical Industries (ACI)Document21 paginiMarketing Mix (4P's) Analysis and Competitors Evaluation: A Study On Advanced Chemical Industries (ACI)Arafat RahmanÎncă nu există evaluări

- Orient Garment in Sri LankaDocument13 paginiOrient Garment in Sri LankaKanishka PeellawattageÎncă nu există evaluări

- Soumya Agrawal PRN No: 20020942063 Business Valuation AssignmentDocument19 paginiSoumya Agrawal PRN No: 20020942063 Business Valuation AssignmentSoumya AgrawalÎncă nu există evaluări

- FSA Group Assignment, Group-01Document20 paginiFSA Group Assignment, Group-01Heena MoorpanaÎncă nu există evaluări

- Pidilite Industries Limited FinalDocument28 paginiPidilite Industries Limited FinalrgogariÎncă nu există evaluări

- Vijaya Bank Single FileDocument55 paginiVijaya Bank Single Filedivya ReddyÎncă nu există evaluări

- Project Report On Inventory MnagementDocument109 paginiProject Report On Inventory MnagementLavkeshhÎncă nu există evaluări

- Raju Seen ChemicalDocument21 paginiRaju Seen ChemicalTaseen AhmeedÎncă nu există evaluări

- Lucky Cement Strategic OptionsDocument5 paginiLucky Cement Strategic OptionsFahim QaiserÎncă nu există evaluări

- Transpek IndustryDocument9 paginiTranspek IndustryPARTH PALRECHAÎncă nu există evaluări

- Daffodil International University: AssignmentDocument12 paginiDaffodil International University: AssignmentNasim AliÎncă nu există evaluări

- Mission StatementsDocument5 paginiMission StatementsAssignment WriterÎncă nu există evaluări

- Business Environment: 1 Semester BBM 2011 - 2012Document64 paginiBusiness Environment: 1 Semester BBM 2011 - 2012Sai KiranÎncă nu există evaluări

- History of Pidilite1Document13 paginiHistory of Pidilite1Shubhankar VaishÎncă nu există evaluări

- Marketing EnvironmentDocument53 paginiMarketing EnvironmentDiponker Saha SonchoyÎncă nu există evaluări

- PSO ProjectDocument29 paginiPSO ProjectJanhanwar KhanÎncă nu există evaluări

- Project MaricooDocument38 paginiProject MaricooRajesh NayakÎncă nu există evaluări

- Marico AssignmentDocument46 paginiMarico AssignmentRafiqul Awal0% (2)

- DPC CaseDocument32 paginiDPC CasechastincoÎncă nu există evaluări

- DR ReddyDocument8 paginiDR ReddyBiswajit SarmaÎncă nu există evaluări

- Cleanaway Waste Limited ReportDocument9 paginiCleanaway Waste Limited Reportkarma SherpaÎncă nu există evaluări

- Enterprise Solutions To Scale: Lessons Learned in Catalysing Sustainable Solutions To Global Development ChallengesDocument60 paginiEnterprise Solutions To Scale: Lessons Learned in Catalysing Sustainable Solutions To Global Development ChallengesAkhandal MohantyÎncă nu există evaluări

- Ujian Tengah Semester Matakuliah Manajemen Stratejik: Nama: Goutami Paxia 125170288Document20 paginiUjian Tengah Semester Matakuliah Manajemen Stratejik: Nama: Goutami Paxia 125170288Goutami PaxiaÎncă nu există evaluări

- Operations Management XYZ Co. For Alkyd Resin Student # Module #Document40 paginiOperations Management XYZ Co. For Alkyd Resin Student # Module #mokbelÎncă nu există evaluări

- Term Paper: Quality ImprovementDocument28 paginiTerm Paper: Quality ImprovementBinsentcaragÎncă nu există evaluări

- Wacc - DesconDocument5 paginiWacc - DesconYumna AzharÎncă nu există evaluări

- An Assignment On: Business Plan of "Seen Chemical Industry LTD."Document20 paginiAn Assignment On: Business Plan of "Seen Chemical Industry LTD."Taseen AhmeedÎncă nu există evaluări

- Clariant Corporation Case: Submitted By: Nisha ThakkarDocument16 paginiClariant Corporation Case: Submitted By: Nisha ThakkarAshwin GanatraÎncă nu există evaluări

- Components of The Capstone Project: New York Institute of TechnologyDocument27 paginiComponents of The Capstone Project: New York Institute of TechnologyVINIT MEHTAÎncă nu există evaluări

- Commodity Branding PracticeDocument36 paginiCommodity Branding PracticeSakhawat HossainÎncă nu există evaluări

- Model Answer: Launch of a laundry liquid detergent in Sri LankaDe la EverandModel Answer: Launch of a laundry liquid detergent in Sri LankaÎncă nu există evaluări

- Business Plan 3.3Document2 paginiBusiness Plan 3.3Rojin TingabngabÎncă nu există evaluări

- Activity # 1 (DRRR)Document2 paginiActivity # 1 (DRRR)Juliana Xyrelle FutalanÎncă nu există evaluări

- Retailing in IndiaDocument11 paginiRetailing in IndiaVinod MalkarÎncă nu există evaluări

- Ob NotesDocument8 paginiOb NotesRahul RajputÎncă nu există evaluări

- Broken BondsDocument20 paginiBroken Bondsapi-316744816Încă nu există evaluări

- Partes de La Fascia Opteva Y MODULOSDocument182 paginiPartes de La Fascia Opteva Y MODULOSJuan De la RivaÎncă nu există evaluări

- Work ProblemsDocument19 paginiWork ProblemsOfelia DavidÎncă nu există evaluări

- Application Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostDocument19 paginiApplication Activity Based Costing (Abc) System As An Alternative For Improving Accuracy of Production CostM Agus SudrajatÎncă nu există evaluări

- OZO Player SDK User Guide 1.2.1Document16 paginiOZO Player SDK User Guide 1.2.1aryan9411Încă nu există evaluări

- Electives - ArchitDocument36 paginiElectives - Architkshitiz singhÎncă nu există evaluări

- On Derridean Différance - UsiefDocument16 paginiOn Derridean Différance - UsiefS JEROME 2070505Încă nu există evaluări

- Android Developer PDFDocument2 paginiAndroid Developer PDFDarshan ChakrasaliÎncă nu există evaluări

- Chapter 2 ProblemsDocument6 paginiChapter 2 ProblemsYour MaterialsÎncă nu există evaluări

- Talking Art As The Spirit Moves UsDocument7 paginiTalking Art As The Spirit Moves UsUCLA_SPARCÎncă nu există evaluări

- Agco Serie 800 PDFDocument24 paginiAgco Serie 800 PDFJohnny VargasÎncă nu există evaluări

- Chemistry: Crash Course For JEE Main 2020Document18 paginiChemistry: Crash Course For JEE Main 2020Sanjeeb KumarÎncă nu există evaluări

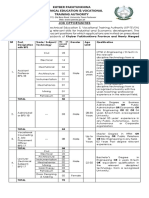

- KP Tevta Advertisement 16-09-2019Document4 paginiKP Tevta Advertisement 16-09-2019Ishaq AminÎncă nu există evaluări

- A Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDocument110 paginiA Case Study of Coustomer Satisfaction in Demat Account At: A Summer Training ReportDeepak SinghalÎncă nu există evaluări

- Objective & Scope of ProjectDocument8 paginiObjective & Scope of ProjectPraveen SehgalÎncă nu există evaluări

- SSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationDocument41 paginiSSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationPrachita AgrawalÎncă nu există evaluări

- The Doshas in A Nutshell - : Vata Pitta KaphaDocument1 paginăThe Doshas in A Nutshell - : Vata Pitta KaphaCheryl LynnÎncă nu există evaluări

- Classifications of AssessmentsDocument11 paginiClassifications of AssessmentsClaire CatapangÎncă nu există evaluări