Documente Academic

Documente Profesional

Documente Cultură

How To Select A Heat Pipe

Încărcat de

Adrian NiżnikowskiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

How To Select A Heat Pipe

Încărcat de

Adrian NiżnikowskiDrepturi de autor:

Formate disponibile

How to Select a Heat Pipe?

Heat pipes are being used very often in particular applications when conventional cooling methods and heat sink designs are not suitable. Once the need for heat pipe arises, the most appropriate heat pipe needs to be selected. Often selecting an appropriate heat pipe is not an easy task, and the following needs to be considered. 1. Investigate and determine the following operational parameters for the heat pipe application: a. Heat load and geometry of the heat source. b. Possible heat sink location, the distance and orientation of the heat sink relative to the heat source. c. Temperature profile of the heat source, heat sink and ambient d. Environmental condition (such as existence of corrosive gas)

2. Select the heat pipe material, wick structure, and working fluid. (consult with an Shagal engineer or original heat pipe manufacturer to select the most appropriate heat pipe) a. Determine the heat pipe working fluid appropriate for your application b. Select heat pipe material compatible to the heat pipe working fluid c. Select heat pipe wick structure for the heat pipe operating orientation d. Decide on the protective heat pipe coating

3. Determine the heat pipe length, size of the heat pipe, and the shape of the heat pipe appropriate for your application (consult with Shagal engineer)

Figure 1 gives the heat pipe performance with heat pipe diameters ranging from 3 to 22.23mm.

What materials can be used to construct a heat pipe?

A particular heat pipe working fluid can only be functional at certain temperature ranges. Also, the particular heat pipe working fluid needs a compatible vessel material to prevent corrosion or chemical reaction between the fluid and the heat pipe vessel. Corrosion will damage the heat pipe vessel and chemical reaction can produce a non-condensable gas. Refer to Table 1. For example, the liquid ammonia heat pipe has a temperature range from -70 to +60C and is compatible with aluminum, nickel and stainless steel heat pipe vessel materials. Table 1. Typical Operating Characteristics of Heat Pipes

Temperature Range ( C) -200 to -80 -70 to +60 -45 to +120 +5 to +230 +190 to +550 +400 to +800 +500 to +900 +900 to +1,500 Heat Pipe Working Fluid Liquid Nitrogen Liquid Ammonia Methanol Water Mercury* +0.02% Magnesium +0.001% Potassium* Sodium* Lithium* Heat Pipe Vessel Material Stainless Steel Nickel, Aluminum, Stainless Steel Copper, Nickel, Stainless Steel Copper, Nickel Stainless Steel Nickel, Stainless Steel Nickel, Stainless Steel Niobium +1% Zirconium Measured axial(8) heat flux ( kW/cm2) 0.067 @ -163C 0.295 0.45 @ 100C(x) 0.67 @ 200C 25.1 @ 360C* 5.6 @ 750C 9.3 @ 850C 2.0 @ 1250C Measured surface(8) heat flux ( W/cm2) 1.01 @ -163C 2.95 75.5 @ 100C 146@ 170C 181 @ 750C 181 @ 750C 224 @ 760C 207 @ 1250C

1,500 + 2,000

Silver*

Tantalum +5% Tungsten

4.1

413

(8)Varies with temperature (x)Using threaded artery wick *Tested at Los Alamos Scientific Laboratory *Measured value based on reaching the sonic limit of mercury in the heat pipe Reference of "Heat Transfer", 5th Edition, JP Holman, McGraw-Hill The liquid ammonia heat pipe has been widely used in space and only aluminum heat pipe vessels are used due to lightweight. Water heat pipes, with a temperature range from 5 to 230C, are most effective for electronics cooling applications and copper heat pipe vessels are compatible with water. Heat pipes are not functional when the temperature of the heat pipe is lower than the freezing point of the heat pipe working fluid. Freezing and thawing of heat pipes is a design issue, which may destroy the sealed joint of a heat pipe when place vertically. Proper engineering and design can overcome this heat pipe limitation.

What are the four heat transport limitations of a heat pipe?

The four heat transport heat pipe limitations can be simplified as follows;

1. 2. 3. 4.

Sonic limit - The rate that vapor travels from heat pipe evaporator to condenser Entrainment limit - Friction between heat pipe working fluid and vapor that travel in opposite directions

Capillary limit - The rate at which the heat pipe working fluid travels from heat pipe condenser to evaporator through the wick Boiling limit - The rate at which the heat pipe working fluid vaporizes from the added heat

What is the common heat pipe wick structure?

There are four common heat pipe wick structures used in commercially produced heat pipes; groove, wire mesh, powder metal and fiber/spring. Each heat pipe wick structure has its advantages and disadvantages. There is no perfect heat pipe wick. Refer to Figure. 2 for a brief glance of actual test performance of four commercially produced heat pipes. Every heat pipe wick structure has its own capillary limit. The groove heat pipe has the lowest capillary limit among the four, but works best under gravity assisted conditions where the condenser is located above the evaporator.

Figure 2. The Actual Test Results of Heat Pipe with Different Wick Structure at Horizontal and Vertical (Gravity Assisted) Orientations. The rate of vapor traveling from the heat pipe evaporator to the condenser is governed by the difference in vapor pressure between them. It is also affected by the diameter and the length of the heat pipe. In the large diameter heat pipe, the cross sectional area will allow higher vapor volume to be transported from the heat pipe evaporator to the condenser than in a small diameter heat pipe. The cross sectional area of a heat pipe is the direct function for both the sonic limit and entrainment heat pipe limit.

Figure 3 compares the heat transport of heat pipes with different diameters. Also, the operational temperature of a heat pipe affects the sonic limit. We can see, in Figure 3, the heat pipes transport more heat at higher operational temperatures. The rate of heat pipe working fluid return from the condenser to the evaporator is governed by capillary limit and is the reciprocal function of the heat pipe length. A longer heat pipe transports less heat versus the same heat pipe with a shorter length. In Figure 3, the unit of the Y-axis is QmaxLeff (W-m) representing the amount of heat a heat pipe can carry per meter length. If the heat pipe is half a meter long, it can carry approximately twice the wattage as a meter long heat pipe.

Figure 3. The Performance of Various Groove Wick Copper Water Heat Pipes

S-ar putea să vă placă și

- V370Document30 paginiV370ulfatÎncă nu există evaluări

- AESW011Document50 paginiAESW011Arputharaj Maria LouisÎncă nu există evaluări

- Formal Quote SUB: - Extend Consultancy For The SS Selection and Fabrication. We Are Looking For A Manual That Will Include The Following As ScopeDocument1 paginăFormal Quote SUB: - Extend Consultancy For The SS Selection and Fabrication. We Are Looking For A Manual That Will Include The Following As Scopesathi11189Încă nu există evaluări

- 30 Ncmer037Document16 pagini30 Ncmer037Arslan ArshadÎncă nu există evaluări

- Damage Investigation On Welded TubesDocument6 paginiDamage Investigation On Welded TubesOmarÎncă nu există evaluări

- CHECK-LIST PL-01 Pipeline Material Selection Report - Fr.enDocument4 paginiCHECK-LIST PL-01 Pipeline Material Selection Report - Fr.enYousef SalahÎncă nu există evaluări

- CBI Welding Journal Vert Plate Apr04Document0 paginiCBI Welding Journal Vert Plate Apr04Mahendra RathoreÎncă nu există evaluări

- BASF - Hose Inspection Frequency TableDocument1 paginăBASF - Hose Inspection Frequency Tablepablo fornesÎncă nu există evaluări

- Bar Chart For E-302 B Shutdown REV.05Document7 paginiBar Chart For E-302 B Shutdown REV.05saadpervaiz14Încă nu există evaluări

- Selection of Materials For Chemical Engineering EquipmentDocument4 paginiSelection of Materials For Chemical Engineering EquipmentJak AshishÎncă nu există evaluări

- Tank Bottom Plate CorrosionDocument5 paginiTank Bottom Plate CorrosionShaalan AI-ZuhairiÎncă nu există evaluări

- Nondestructive TestingDocument27 paginiNondestructive Testingapi-3764139Încă nu există evaluări

- Fired Heater Optimization - AmteckDocument12 paginiFired Heater Optimization - Amteckbazil17Încă nu există evaluări

- 01 Saip 38Document14 pagini01 Saip 38Arjun RawatÎncă nu există evaluări

- Communications Management QuestionsDocument2 paginiCommunications Management QuestionsMohamed AfsalÎncă nu există evaluări

- Case Study - Amine Regeneration ColumnDocument2 paginiCase Study - Amine Regeneration ColumnAshfaq Anwer100% (2)

- PWTH RequirementDocument2 paginiPWTH Requirementveeru290683_20976731Încă nu există evaluări

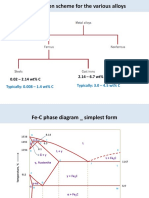

- Classification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CDocument19 paginiClassification Scheme For The Various Alloys: 0.02 - 2.14 WT% C 2.14 - 6.7 WT% CAlex HalesÎncă nu există evaluări

- Repair Procedure For Rubber LiningDocument1 paginăRepair Procedure For Rubber LiningChuah Cheong JinÎncă nu există evaluări

- Asmepcc 2repairleaks Article 4Document23 paginiAsmepcc 2repairleaks Article 4amalhaj2013Încă nu există evaluări

- Condition Assessment Programme (CAP) : An Introduction To CAP HullDocument79 paginiCondition Assessment Programme (CAP) : An Introduction To CAP Hullkoib789Încă nu există evaluări

- Shell and Tube Ref - AnandDocument6 paginiShell and Tube Ref - Anand7761430Încă nu există evaluări

- What Is PWHTDocument2 paginiWhat Is PWHTShaik ShahÎncă nu există evaluări

- FAC Maintenance Program PDFDocument38 paginiFAC Maintenance Program PDFMuhammad ArslaanÎncă nu există evaluări

- Pressure Points: Ask The EngineerDocument5 paginiPressure Points: Ask The EngineerMario MolinaÎncă nu există evaluări

- Effect of Metallurgy On Pygas Fouling PDFDocument6 paginiEffect of Metallurgy On Pygas Fouling PDFstreamtÎncă nu există evaluări

- Shell Corrosion Under InsulationDocument16 paginiShell Corrosion Under InsulationDavide CongiuÎncă nu există evaluări

- Investigation and Repair of H (1) - E.R Flange LeakDocument19 paginiInvestigation and Repair of H (1) - E.R Flange LeakriysallÎncă nu există evaluări

- 4.2.1 Graphitization 4.2.1.1 Description of DamageDocument3 pagini4.2.1 Graphitization 4.2.1.1 Description of DamageAjmi HmidaÎncă nu există evaluări

- Corrosion Damage in Waste Heat Boilers Major Root Causes and RemediationDocument10 paginiCorrosion Damage in Waste Heat Boilers Major Root Causes and Remediationvaratharajan g rÎncă nu există evaluări

- 32 Samss 019Document17 pagini32 Samss 019Moustafa BayoumiÎncă nu există evaluări

- Abilene, Inc.: An Introduction To Boiler MaintenanceDocument19 paginiAbilene, Inc.: An Introduction To Boiler MaintenanceSubbarayan SaravanakumarÎncă nu există evaluări

- ASME B 31.3 Process Piping - 1 PDFDocument9 paginiASME B 31.3 Process Piping - 1 PDFRamesh BaluÎncă nu există evaluări

- Effects of PWHT Temperature On Mechanical Properties PDFDocument11 paginiEffects of PWHT Temperature On Mechanical Properties PDFA K SinghÎncă nu există evaluări

- Ethylene Furnance InspectionfgDocument6 paginiEthylene Furnance InspectionfgThomas TuckerÎncă nu există evaluări

- A Guide To Failure Analysis For The Oil and Gas IndustryDocument6 paginiA Guide To Failure Analysis For The Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- API 510 PC 5mar05 Case Study 2 Thickness CalculationsDocument3 paginiAPI 510 PC 5mar05 Case Study 2 Thickness CalculationsSameh AminÎncă nu există evaluări

- Guide To Prepare WPQR According To Asme Section IxDocument5 paginiGuide To Prepare WPQR According To Asme Section IxHoque AnamulÎncă nu există evaluări

- Inspection of Heat ExchangerDocument82 paginiInspection of Heat ExchangerBalaji VenkatesanÎncă nu există evaluări

- Isi Lesson 07 MaterialsDocument8 paginiIsi Lesson 07 MaterialsRizwan NazirÎncă nu există evaluări

- Chapter 3 - Corrosion ThermodynamicsDocument34 paginiChapter 3 - Corrosion ThermodynamicsEDU Academic Programs CoordinatorÎncă nu există evaluări

- MM435 - CDP-1 - 9 - Kinetics of PassivityDocument17 paginiMM435 - CDP-1 - 9 - Kinetics of PassivityAhmad JanÎncă nu există evaluări

- Tube Damage Mechanism and Repair Techniques PDFDocument16 paginiTube Damage Mechanism and Repair Techniques PDFArjed Ali ShaikhÎncă nu există evaluări

- EECE 574 - Adaptive ControlDocument73 paginiEECE 574 - Adaptive Controllamis rezkiÎncă nu există evaluări

- Basf - Ape SystemDocument44 paginiBasf - Ape SystemrendroedywibowoÎncă nu există evaluări

- Materials Selection Project PDFDocument14 paginiMaterials Selection Project PDFeddunbarÎncă nu există evaluări

- Unfired HRSGs For Solar TurbinesDocument2 paginiUnfired HRSGs For Solar Turbineshermit445350% (1)

- Acoustic Induced Vibration - Flare Systems PDFDocument2 paginiAcoustic Induced Vibration - Flare Systems PDFsri9987Încă nu există evaluări

- Investigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDFDocument10 paginiInvestigation of Weld Repair Without Post-Weld Heat Treatment For P91 PDF55312714Încă nu există evaluări

- What Is InspectionDocument6 paginiWhat Is InspectionRathnakrajaÎncă nu există evaluări

- Chapter 14 Boiler System Failures: Deaerator CrackingDocument22 paginiChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranÎncă nu există evaluări

- Comparative Analysis of Tear StrengthDocument6 paginiComparative Analysis of Tear StrengthLow Kah ZhoyÎncă nu există evaluări

- Delta FerriteDocument4 paginiDelta FerriteRavindra ErabattiÎncă nu există evaluări

- Exchangers: Repairing Cracks in Refinery HeatDocument4 paginiExchangers: Repairing Cracks in Refinery Heatramadoss_alwar7307Încă nu există evaluări

- Heat Pipe SelectionDocument6 paginiHeat Pipe SelectionSridhar RaoÎncă nu există evaluări

- Heat Pipes in Electronics (1) : 15.1 Components of A Heat PipeDocument10 paginiHeat Pipes in Electronics (1) : 15.1 Components of A Heat Pipekeerti06Încă nu există evaluări

- Heat PipeDocument27 paginiHeat Pipesaurabh maneÎncă nu există evaluări

- Advances Tube - enDocument9 paginiAdvances Tube - enAdrian NiżnikowskiÎncă nu există evaluări

- Catalogo - Produto RTAC (RLC PRC001B En) SmallDocument58 paginiCatalogo - Produto RTAC (RLC PRC001B En) SmallAdrian NiżnikowskiÎncă nu există evaluări

- Advances Tube - en PDFDocument8 paginiAdvances Tube - en PDFJai PatelÎncă nu există evaluări

- J Series ManualDocument201 paginiJ Series ManualAdrian NiżnikowskiÎncă nu există evaluări

- J Series ManualDocument201 paginiJ Series ManualAdrian NiżnikowskiÎncă nu există evaluări

- Inst Man L EnglishDocument21 paginiInst Man L EnglishAdrian NiżnikowskiÎncă nu există evaluări

- AuthorsDocument1 paginăAuthorsRaveena MathurÎncă nu există evaluări

- Sport of TodayDocument1 paginăSport of TodayAdrian NiżnikowskiÎncă nu există evaluări

- Tube Roller ExpansionDocument12 paginiTube Roller ExpansionTejaswiÎncă nu există evaluări

- LG Therma V MonoblocDocument47 paginiLG Therma V MonoblocMuhidin KozicaÎncă nu există evaluări

- Overall Heat Transfer CoefficientDocument8 paginiOverall Heat Transfer CoefficientSarthak DandareÎncă nu există evaluări

- Sea Level: Ashrae Psychrometric Chart No.3Document1 paginăSea Level: Ashrae Psychrometric Chart No.3Tran KieuÎncă nu există evaluări

- Thermal Insulation Investigation 1 Higher Practice Exam QuestionsDocument4 paginiThermal Insulation Investigation 1 Higher Practice Exam QuestionssayemaÎncă nu există evaluări

- Clean RoomDocument9 paginiClean Roomxyzscribd1988Încă nu există evaluări

- HVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningDocument20 paginiHVAC Basics: Hvac - Heating, Ventilation, Air-ConditioningAli GurselÎncă nu există evaluări

- PFD DPCU & GuidelineDocument2 paginiPFD DPCU & GuidelineTifano Khristiyanto100% (1)

- Quiz - Boilers and Thermic Fluid HeatersDocument3 paginiQuiz - Boilers and Thermic Fluid HeatersMohammad TachtouchÎncă nu există evaluări

- Pipe TermsDocument38 paginiPipe Termseuphris starfellÎncă nu există evaluări

- SPX Cooling TowerDocument2 paginiSPX Cooling Towertanveer ansariÎncă nu există evaluări

- Manual For Experimental Water Cooling TowerDocument7 paginiManual For Experimental Water Cooling TowerBalRam Dhiman100% (1)

- Modeling and Simulation of Chemical Process Systems (2019) PDFDocument519 paginiModeling and Simulation of Chemical Process Systems (2019) PDFĐức Lê100% (5)

- Steps of Hvac DesginDocument3 paginiSteps of Hvac DesginMo EmadÎncă nu există evaluări

- Heat Work and Internal EnergyDocument35 paginiHeat Work and Internal EnergyJesse EbreoÎncă nu există evaluări

- HW 7Document15 paginiHW 7r8chel100% (4)

- Thermal Comfort ConceptsDocument7 paginiThermal Comfort ConceptsSAPNA JAINÎncă nu există evaluări

- Sheet 2Document3 paginiSheet 2Ahmed Hamdy KhattabÎncă nu există evaluări

- HT Tutorial 2 QuestionsDocument14 paginiHT Tutorial 2 QuestionssairamÎncă nu există evaluări

- Failure Analysis of Heat Treated Steel Components (2008) PDFDocument636 paginiFailure Analysis of Heat Treated Steel Components (2008) PDFMohammed Ghisheer100% (3)

- Termokimia (Pertemuan 6)Document39 paginiTermokimia (Pertemuan 6)indah phebeÎncă nu există evaluări

- Evaporation PDFDocument74 paginiEvaporation PDFIshtiak HossainÎncă nu există evaluări

- A Thermal WheelDocument1 paginăA Thermal WheelrkibÎncă nu există evaluări

- Zone Sizing Summary For Chiller: Air System InformationDocument4 paginiZone Sizing Summary For Chiller: Air System InformationGior GioÎncă nu există evaluări

- 00 BLANK Pipe Size Calc Sheet HWS - CWSDocument9 pagini00 BLANK Pipe Size Calc Sheet HWS - CWSharoub_nasÎncă nu există evaluări

- Steam Tables Pressure Heat of VaporizatioDocument5 paginiSteam Tables Pressure Heat of VaporizatioMmmmohÎncă nu există evaluări

- High-Performance Building Envelopes: Design Methods For Energy Efficient FacadesDocument15 paginiHigh-Performance Building Envelopes: Design Methods For Energy Efficient FacadesHiddenKoalaÎncă nu există evaluări

- 4 Performance and Efficiency Test of A Refrigeration PlantDocument52 pagini4 Performance and Efficiency Test of A Refrigeration PlantIvy Joy UbinaÎncă nu există evaluări

- Combustion FundamentalsDocument40 paginiCombustion Fundamentalsbinu vaÎncă nu există evaluări

- Apricus Collector Installation ManualDocument68 paginiApricus Collector Installation ManualKCFUNGÎncă nu există evaluări

- ARI Standard 340 - 360Document20 paginiARI Standard 340 - 360riandikafakri0% (1)