Documente Academic

Documente Profesional

Documente Cultură

Ian 48

Încărcat de

springtide2722Descriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ian 48

Încărcat de

springtide2722Drepturi de autor:

Formate disponibile

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

VOLUME 2 HIGHWAY STRUCTURES: DESIGN (SUBSTRUCTURES AND SPECIAL STRUCTURES) MATERIALS SECTION 1 SUBSTRUCTURES

INTERIM ADVICE NOTE IAN 48/03 MEASURES TO MINIMISE THE RISK OF SULFATE ATTACK (INCLUDING THAUMASITE) NEW CONSTRUCTION AND STRUCTURES UNDER CONSTRUCTION

SUMMARY This Interim Advice Note provides information for the design and construction of buried concrete to minimise the risk of sulfate attack. INSTRUCTIONS FOR USE This IAN supersedes IAN 25/99.

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

INTERIM ADVICE NOTE 48/03 DMRB VOLUME 2: SECTION 1: SUBSTRUCTURES MEASURES TO MINIMISE THE RISK OF SULFATE ATTACK (INCLUDING THAUMASITE) NEW CONSTRUCTION AND STRUCTURES UNDER CONSTRUCTION

1. 1.1

GENERAL Interim Advice Note 25 (reference 5.1.1) was published in March 1999 to provide details of the actions that were required to be taken by designers to deal with the potential effects of the thaumasite form of sulfate attack in new construction buried concrete and to take account of the publication of the Thaumasite Expert Group Report (reference 5.1.2). This Interim Advice Note supersedes IAN 25, to take account of the publication of Building Research Establishment Special Digest SD1 (reference 5.1.3), which implements and extends the recommendations of the Expert Group Report. It includes measures to minimise the risk of all forms of sulfate attack (including thaumasite), and applies to all new buried concrete. The recommendations of SD1 are incorporated in an amendment to the Specification for Highway Works Series 1700 (reference 5.1.4) and to the Notes for Guidance Series 1700 NG (reference 5.1.5) issued in May 2002. The nature of the thaumasite form of sulfate attack and its chemical and physical effects are presented in Chapter 2 of the Expert Group Report. A concise account is given in Part 1 of SD1. It should be noted that the Expert Group Report defines the thaumasite form of sulfate attack (TSA) when there is significant damage to the matrix of concrete as a consequence of replacement of cement hydrates by thaumasite. Thaumasite may also be found in pre-existing voids and cracks, but without necessarily causing deterioration of the concrete. In this case, the term thaumasite formation (TF) has been used instead of TSA. BACKGROUND Before the discovery of TSA-affected structures on the M5 Motorway in 1998, there was little published information and few recorded and documented cases. Following this discovery, the Highways Agency implemented measures for new construction in Interim Advice Note 15 (reference 5.1.6). At the same time, an Expert Group was established by the then Minister for Construction under the Chairmanship of Professor Les Clark of the University of Birmingham. This Expert Group was charged with developing advice and guidance on the implications for existing structures and recommendations for new construction in the UK. The Report of the Expert Group was published in January 1999 and the guidance and recommendations were implemented by the Highways Agency in Interim Advice Note 25, which also provided further advice for highway structures on Trunk Roads and Motorways. Prior to the publication of the Expert Group Report, guidance on measures to mitigate the effects of sulfate attack was contained in BRE Digest 363 Sulfate and acid

1.2

2. 2.1

2.2

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

resistance of concrete in the ground (reference 5.1.7). Subsequent to the publication of the Expert Group Report, an ad hoc BSI Panel, chaired by BRE, was established to draft an amendment (reference 5.1.8) to BS 5328 Concrete to take account of the Report. This Panel went on to advise on the revision of Digest 363, ensuring compatibility with the draft BS 5328 amendment. This revision resulted in the publication, in September 2001, of BRE Special Digest SD1 Concrete in aggressive ground which superseded Digest 363. Therefore where references are made to BRE Digest 363 in other Highways Agency documents in current usage for the design and construction of highway structures, henceforth reference should be made to SD1, to the May 2002 amendment to SHW and to this Interim Advice Note. Whilst the guidance in the Expert Group Report has also been superseded by that in SD1, nevertheless the Report does provide a full account of the nature and risk of TSA, the most likely geographical locations and geological conditions for occurrence, discussion of geotechnical investigations and testing and details of case studies. 2.3 TSA can occur in buried concrete structures, sub-surface structural elements and foundations when the following conditions are present:a) b) c) d)

sulfates and/or sulfides in the natural ground or manmade waste products mobile groundwater carbonate, generally in coarse and/or fine concrete aggregates low temperatures (generally below 15C) The amendments to the Specification for Highway Works and Notes for Guidance issued in May 2002 include requirements which are derived from SD1 for buried concrete exposed to sulfate and acid ground conditions. SD1 is extensively referenced as a supporting document for detail and for general background information. The requirements given in this amendment shall be fully adopted on all future Highways Agency Contracts, and this Interim Advice Note is intended to provide specific supplementary information.

2.4

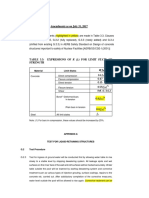

3. ACTIONS 3.1 New Construction 3.1.1 The Highways Agency has implemented revised precautionary measures to apply to all new construction involving buried concrete to minimise the risk of sulfate attack, and particularly the deleterious effects of the thaumasite form of sulfate attack (TSA). Henceforth the requirements in the May 2002 SHW amendment, and SD1 as appropriate, should be followed on all Highways Agency contracts. The approach taken by the amendment is to ensure the correct classification of the soil/groundwater regime in proximity to buried concrete. This is termed the Aggressive Chemical Environment for Concrete (ACEC) site classification. The ACEC Class is then considered together with the Structural Performance Level required for the structure and the concrete section thickness to give the Design Chemical (DC) Class and the required number, if any, of additional protective measures. A number of options are then recommended to provide the means to minimise the risks of TSA, including concrete mix design

3.1.2

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

requirements for each DC Class and a choice of additional protective measures where necessary. 3.2 Structures Under New Construction 3.2.1 Where foundations and other buried ground concrete structures and elements (including piling) are currently under construction, the work in progress should be reviewed on the basis of the SHW amendment and SD1. However if the design and construction requirements have been based on the recommendations and guidance of the Thaumasite Expert Group Report it will not be necessary to instigate any further changes. Where a reassessment is necessary, a review should be undertaken of the site sulfate classification, taking account of the total potential sulfate content that might result from oxidation of sulfide minerals such as pyrite following ground disturbance, and the groundwater condition (static, mobile or highly mobile). Based on the findings, the concrete proposed or being used may need to be reassessed. If necessary consideration should be given to using the additional protective measures listed in Table 17/8 of the SHW amendment (Part 2, Table 8 of SD1). This might result in one or more of the following:a) modification of the concrete mix design for the buried concrete by specifying an enhanced quality or by the use of Range B or C carbonate aggregates. b) using controlled permeability formwork where appropriate in order to enhance the in situ quality of the concrete in the cover zone. Any use of controlled permeability formwork should be in accordance with the manufacturers recommendations. c) using tankings or coatings to give protection to soil/structure interfaces of buried concrete. d) increasing the concrete section thickness to provide a sacrificial layer which can absorb aggressive chemicals. e) installing interceptor drains to channel groundwater seepages away from buried concrete. f) careful detailing and construction of carrier drains in proximity to buried concrete, to prevent possible contamination by sulfates in the drainage water. g) using alternative non-sulfate bearing backfills in proximity to sub-surface concrete (however care must be taken to avoid migration of sulfates present elsewhere into the uncontaminated backfill, and it may be necessary to utilise other measures in combination with non-sulfate bearing backfill). 3.2.3 The contractual implications of changes to the design or concrete mix should be assessed, and any necessary changes or variations made on the basis of practicality and cost, related to the risk of TSA. 3.3 Geotechnical Investigations 3.3.1 Part 1 Assessing the aggressive chemical environment of BRE Special Digest SD1 provides details of the geotechnical investigations and testing required to classify soils and groundwater. These requirements should be incorporated into existing Highways

3.2.2

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

Agency procedures contained in HD 22 Ground investigation and earthworks procedure for geotechnical certification (reference 5.1.9). All geotechnical investigation procedural statements and resultant testing regimes should consider the possibility of TSA and other forms of sulfate attack. Part 1 of SD1 provides further guidance on suitable procedures. 3.3.2 The main purpose of the geotechnical investigation should be to determine the correct ACEC classification of the soil and groundwater that will affect the buried concrete. This should recognise the existing conditions and also those that will appertain during and after construction. In particular, attention is drawn to the possibility of oxidation of sulfides such as pyrite under certain conditions, and to the potential method of construction which may increase the concentrations of sulfates. Correct assignment of groundwater mobility is also of paramount importance. Correct classification of the soils and groundwater will enable design options to be assessed to minimise the risk of sulfate attack.

3.3.3

3.4 Buried Concrete 3.4.1 SD1 provides recommendations for concrete mix options which will minimise the risk of TSA and deterioration, when taken in combination with the additional protective measures recommended. It is intended that the designer should consider the implications of all possible options but the selection of the concrete mix, cement type and carbonate range of the aggregates will wherever possible be left to the concrete supplier (refer section 3.8).

3.5 Design Details 3.5.1 The Expert Group Report provided some guidance on design details that may be vulnerable to TSA and recommended that, where possible, such details should be avoided and be designed out. In offering guidance on the selection of Structural Performance Level (SPL) required for the structure, SD1 recommends that structures with vulnerable critical details such as slender structural elements, hinges and joints should be classified as High SPL. This implies the need for more onerous concrete mix requirements and/or additional protective measures than might otherwise be the case and is a further indication that it would be preferable, where appropriate, to design out such details.

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

3.6 Additional Protective Measures 3.6.1 SD1 recommends a series of additional protective measures (see 3.2.1 above). Table 17/7 of the SHW amendment (Part 2, Table 7 of SD1) gives the DC Class and the required number of additional protective measures, derived from the ACEC classification, the SPL and the section thickness. The options for these measures are given in Table 17/8 (Part 2, Table 8 of SD1) and may affect the selection of the concrete mix including the carbonate range of the aggregate to be used, the possible choice of controlled permeability formwork where appropriate, the need for coatings or tanking, the concrete section size if the option to provide a sacrificial layer is selected, and the design of the drainage in the vicinity of the buried concrete. Footnotes [1] and [5] to Table 17/7 indicate that the number of measures may be reduced if either surface carbonation of the concrete prior to exposure can be assured or the choice of aggregate carbonate range is restricted to those with lower carbonate contents. Footnote [2] requires an increase in the number of measures if there is a hydrostatic head of groundwater greater than five times the concrete section thickness. When considering the requirements for additional drainage around foundations and other buried concrete the designer should assess the existing and post-construction topography and the soil and groundwater regime (particularly the anticipated quantities and direction of flow). In general positive drainage is preferred, utilising piped systems connected to the main highway drainage system. Groundwater seepages should be intercepted before coming into contact with buried concrete or its surrounding backfill. Careful detailing will be required to ensure the effectiveness of these drainage systems, and that they can be maintained in the future. Designers will need to assess the effects of the drains on ground conditions, particularly stability and settlement, in proximity to the structures concerned. Coatings and tanking The general requirements for coatings and tanking required to provide additional protection to buried concrete are listed in Part 2, Section 5.5.1 of SD1. These will usually be commercially available materials and should be applied in accordance with the manufacturers instructions. Particular attention should be given to long term durability and possible susceptibility to bacterial attack. Although little research has been undertaken, two coats of cutback bitumen emulsion carefully applied to buried concrete surfaces will usually be sufficient to provide the additional protection required. Other materials such as rubberised bitumen emulsions may also be suitable. As an alternative a sacrificial layer of concrete, of a quality equal to or higher than that of the inner concrete and preferably made with Range C aggregate, could be considered. The deciding factors should be of practicality and cost. However, the use of a sacrificial layer of concrete as an additional protective measure is not appropriate where the surface of the concrete must remain sound to prevent loss of frictional resistance or settlement, for example for skin friction piles.

3.6.2

3.6.3

3.6.4 3.6.5

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

3.6.6

In general, it will not be necessary to additionally protect the underside of concrete foundations, providing that non-structural concrete blinding has been used to provide a base for the structural concrete work. Special consideration may need to be given to in situ concrete piles through made or weathered ground, to provide additional protection by means of sleeving. Specific recommendations for any protective measures required for precast concrete piles are given in Design Guides 3a and 3g (where the concrete is surface carbonated) of Part 3 of SD1.

3.6.7

3.7 Structural Performance Level 3.7.1 Table 17/6 of the SHW amendment (Table 5, Part 2 of SD1) sets out typical attributes of structures to assist with assigning the Structural Performance Level. In general, highway structures should be classed in the High SPL category.

3.8 Contractual Implications 3.8.1 Table 17/4 of the SHW amendment (Table 6, Part 2 of SD1) recommends a number of options for concrete mixes in each Design Chemical Class. Where possible, designers should include all options in Contracts to allow Contractors to price alternatives in the tender process. These options may also include different drainage, surface protection and other protective measures as part of the package to minimise the risk of TSA. An alternative approach which would be favoured is to use a Designated Outline for a Contractor-based design offering a complete package of measures to minimise the risks of TSA. A typical package would consist of a concrete mix to comply with the requirements of Table 17/4 of the SHW amendment (Table 6, Part 2 of SD1) and, where necessary, additional protective measures. If this approach is adopted then the compiler of the Contract documentation must include sufficient information about the design constraints to allow tenderers a fair opportunity to submit their detailed proposals and price the package.

3.8.2

4. APPLICATION 4.1.1 These requirements shall apply henceforth to buried concrete on all new structures planned or under construction on Trunk Roads and Motorways. It should be noted that this applies in all locations, not just in areas where there is a greater potential risk of TSA.

IA 48/03

January 2003

Volume 2 Section 1 Substructures

Interim Advice IA 48/03

5. REFERENCES 5.1.1 IAN 25 Measures to minimise the risk of sulfate attack (including thaumasite). New construction and structures under construction. 5.1.2 DETR The thaumasite form of sulfate attack: Risks, diagnosis, remedial works and guidance on new construction. Report of the Thaumasite Expert Group. January 1999. (Available from DfT Publications Sales Centre, Cambertown House, Goldthorpe Industrial Estate, Goldthorpe, Rotherham, S63 9BL. 5.1.3 Building Research Establishment Special Digest SD1, Concrete in aggressive ground, (2001). CRC Ltd, 151 Rosebery Avenue, London, EC1R 4GB. Also obtainable online from the BRE bookshop via the BRE homepage at www.bre.co.uk 5.1.4 Specification for Highway Works (MCHW Volume 1) Series 1700. Amendment May 2002. 5.1.5 Notes for Guidance on the Specification for Highway Works (MCHW Volume 2) Series NG 1700. Amendment May 2002. 5.1.6 IA 15 Thaumasite sulfate attack new construction and structures under construction. 5.1.7 Building Research Establishment Digest 363, Sulfate and acid resistance of concrete in the ground (1996). Out of print, superseded by Special Digest SD1. 5.1.8 British Standards Institution, BS 5328 Concrete, Amendment No 2 to BS 5328-1; Amendment No. 3 to BS 5328-2; Amendment No. 5 to BS 5328-3. BSI, 2002. 5.1.9 HD 22 Ground investigation and earthworks procedure for geotechnical certification.

IA 48/03

January 2003

S-ar putea să vă placă și

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceDe la EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceÎncă nu există evaluări

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeDe la EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeÎncă nu există evaluări

- Bs 8500 12006Document13 paginiBs 8500 12006hamzaali1976Încă nu există evaluări

- SANS 2001-CC1:2007: Construction Works Part CC1: Concrete Works (Structural)Document65 paginiSANS 2001-CC1:2007: Construction Works Part CC1: Concrete Works (Structural)Melvin Joseph88% (8)

- Sans SpecificationsDocument65 paginiSans SpecificationsOlona LonaÎncă nu există evaluări

- Implementation of BS 8500 2006 Concrete Minimum Cover PDFDocument13 paginiImplementation of BS 8500 2006 Concrete Minimum Cover PDFJimmy Lopez100% (1)

- Design Manualfor Roads and BridgesDocument39 paginiDesign Manualfor Roads and BridgesRonnie De Joya AguirreÎncă nu există evaluări

- Ts Ia 23 Revision 3 Implementation of Bs 8500 12006Document13 paginiTs Ia 23 Revision 3 Implementation of Bs 8500 12006Gaurav Ram TripathiÎncă nu există evaluări

- Is 3370 - 1Document20 paginiIs 3370 - 1Umesh ChikhlikarÎncă nu există evaluări

- IS 3370.2009 Part-1 PDFDocument20 paginiIS 3370.2009 Part-1 PDFnalla maheshÎncă nu există evaluări

- Grade of ConcreteDocument10 paginiGrade of ConcreterddlfcbeauditÎncă nu există evaluări

- 350R 89Document55 pagini350R 89DIDIER ANGEL LOPEZ RINCONÎncă nu există evaluări

- Is 3370 1 2009Document23 paginiIs 3370 1 2009ab5918590Încă nu există evaluări

- IS 3370 Part 2 - 2009-Readable PDFDocument14 paginiIS 3370 Part 2 - 2009-Readable PDFpradip ghodeswarÎncă nu există evaluări

- IS 3370 (Part2) 2009Document15 paginiIS 3370 (Part2) 2009AMAR HEBBAR V.PÎncă nu există evaluări

- Is 3370 2 2009Document13 paginiIs 3370 2 2009Abh AbhÎncă nu există evaluări

- ASD Unit 3 Code BookDocument15 paginiASD Unit 3 Code BookGurram AmarsaiÎncă nu există evaluări

- Corrections Within Design Manual For Roads and Bridges November 2002Document32 paginiCorrections Within Design Manual For Roads and Bridges November 2002mathewbasil22Încă nu există evaluări

- A A A A A A 10Document62 paginiA A A A A A 10firasslmnÎncă nu există evaluări

- Alkali Silica Reaction-Minimising The Risk of Damage To ConcreteDocument33 paginiAlkali Silica Reaction-Minimising The Risk of Damage To ConcreteRavi7654Încă nu există evaluări

- Guidance For Use of The BSH Standard Design of Offshore Wind Turbines"Document13 paginiGuidance For Use of The BSH Standard Design of Offshore Wind Turbines"paimpillyÎncă nu există evaluări

- BD 74 00 FoundationsDocument49 paginiBD 74 00 FoundationsShawn Mckenzie100% (1)

- Is 3370 2 2009Document18 paginiIs 3370 2 2009Manish AhujaÎncă nu există evaluări

- IS3370 (Part - I) 2009Document20 paginiIS3370 (Part - I) 2009amithcivil100% (1)

- Ian 95 - 07Document6 paginiIan 95 - 07BogdanBÎncă nu există evaluări

- BD 30 - 87Document14 paginiBD 30 - 87tpop1707Încă nu există evaluări

- Backfilled Retaining Walls and Bridge Abutments: The Highways Agency BD 30/87Document14 paginiBackfilled Retaining Walls and Bridge Abutments: The Highways Agency BD 30/87chitranjan4kumar-8Încă nu există evaluări

- 2 3 1 Overview of Geotechnical Design of Bridges and Provisions of UK National Annex For EN1997 1Document15 pagini2 3 1 Overview of Geotechnical Design of Bridges and Provisions of UK National Annex For EN1997 1Martha LacerdaÎncă nu există evaluări

- Permanent FormworkDocument13 paginiPermanent FormworkjimmydomingojrÎncă nu există evaluări

- Slurry Wall Construction - 2002 - : Section/Article DescriptionDocument14 paginiSlurry Wall Construction - 2002 - : Section/Article DescriptionMarwan MokhadderÎncă nu există evaluări

- 1881 208-96Document14 pagini1881 208-96bhagwatpatil100% (1)

- Future Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresDocument17 paginiFuture Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresSophia LiuÎncă nu există evaluări

- 03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Document34 pagini03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Oscar Mendoza100% (1)

- Inglés Estructuras No ConvencionalesDocument2 paginiInglés Estructuras No ConvencionalesMaria Paula Ballesteros GaleanoÎncă nu există evaluări

- 6.0 Geotechnical Department 6.1 Authority and GuidelinesDocument21 pagini6.0 Geotechnical Department 6.1 Authority and GuidelinesTaqiuddin MJÎncă nu există evaluări

- Guide Specifications For Seismic Isolation Design CONTENTSDocument9 paginiGuide Specifications For Seismic Isolation Design CONTENTSTianyouXie0% (1)

- WB 1399Document15 paginiWB 1399lamyuwangÎncă nu există evaluări

- WCC AIP To EC Temp WorksDocument26 paginiWCC AIP To EC Temp WorksnevillemukoroÎncă nu există evaluări

- EM 1110-2-2000 - Standard Practice For Concrete For Civil Works StructuresDocument124 paginiEM 1110-2-2000 - Standard Practice For Concrete For Civil Works StructuresLuis Adrian SigchaÎncă nu există evaluări

- IStructE Recommendations For The Permissible Stress Design of Reinforced Concrete Building Structures PDFDocument131 paginiIStructE Recommendations For The Permissible Stress Design of Reinforced Concrete Building Structures PDFRajiv SawaruthÎncă nu există evaluări

- Indian Standard Is 456 2000 For Print SECTIONS 1 2 3Document42 paginiIndian Standard Is 456 2000 For Print SECTIONS 1 2 3Kalasekar M SwamyÎncă nu există evaluări

- Ufgs 03 30 00.00 10Document54 paginiUfgs 03 30 00.00 10Jorge Yitzhak PachasÎncă nu există evaluări

- 332R 84Document87 pagini332R 84DIDIER ANGEL LOPEZ RINCONÎncă nu există evaluări

- CH 2Document36 paginiCH 2rammirisÎncă nu există evaluări

- PTA Guidance Note GN02Document2 paginiPTA Guidance Note GN02Sheik Mohamed LiakathÎncă nu există evaluări

- Indian Standard - Retaining Wall For Hill Area-Guidelines Part 2 Selection of Type of WallDocument8 paginiIndian Standard - Retaining Wall For Hill Area-Guidelines Part 2 Selection of Type of WallSarmistha Patowary0% (1)

- Regdoc 0 TRSCDocument193 paginiRegdoc 0 TRSCAnil MehtaÎncă nu există evaluări

- Chp-20-Final - Depth of Fixity of PileDocument25 paginiChp-20-Final - Depth of Fixity of Pileprabhu81Încă nu există evaluări

- BD 30-87 Backfilled Retaining Walls and Bridge AbutmentsDocument14 paginiBD 30-87 Backfilled Retaining Walls and Bridge AbutmentsDavid Shanks 1100% (1)

- Design of Corrugated Steel Buried StructuresDocument64 paginiDesign of Corrugated Steel Buried StructuresAshaari Cha-eÎncă nu există evaluări

- Highway Structures: Approval Procedures & General Design Section 2 Other Procedural DocumentsDocument25 paginiHighway Structures: Approval Procedures & General Design Section 2 Other Procedural DocumentsZayyan RomjonÎncă nu există evaluări

- Ufgs 03 30 00.00 10 PDFDocument54 paginiUfgs 03 30 00.00 10 PDFjackcan501Încă nu există evaluări

- Coastal Engineering Manual: Overview And Coastal HydrodynamicsDe la EverandCoastal Engineering Manual: Overview And Coastal HydrodynamicsÎncă nu există evaluări

- Corrosion and its Consequences for Reinforced Concrete StructuresDe la EverandCorrosion and its Consequences for Reinforced Concrete StructuresÎncă nu există evaluări

- Brittle Fracture in Steel StructuresDe la EverandBrittle Fracture in Steel StructuresG.M. BoydÎncă nu există evaluări

- 2010 ADA Standards for Accessible DesignDe la Everand2010 ADA Standards for Accessible DesignEvaluare: 3 din 5 stele3/5 (1)

- Corrosion: Corrosion ControlDe la EverandCorrosion: Corrosion ControlL L ShreirEvaluare: 5 din 5 stele5/5 (1)

- The Fabrication of Materials: Materials TechnologyDe la EverandThe Fabrication of Materials: Materials TechnologyEvaluare: 5 din 5 stele5/5 (1)

- A State-of-the-Art Guide for Post-Installed ReinforcementDe la EverandA State-of-the-Art Guide for Post-Installed ReinforcementÎncă nu există evaluări

- Drainage GCDocument7 paginiDrainage GCVgkBharadwajÎncă nu există evaluări

- Excavating, Trenching and BackfillingDocument8 paginiExcavating, Trenching and Backfillingcharles IkeÎncă nu există evaluări

- Astm d2321Document10 paginiAstm d2321ALARCONISTAÎncă nu există evaluări

- BituBOND Manual DigitalDocument19 paginiBituBOND Manual DigitalisuruÎncă nu există evaluări

- School of Architecture in Karakorum International University Gilgit BaltistnDocument73 paginiSchool of Architecture in Karakorum International University Gilgit BaltistnGunjan UttamchandaniÎncă nu există evaluări

- 9203.392 2016 PDFDocument4 pagini9203.392 2016 PDFhoanam2009Încă nu există evaluări

- Bio-Engineering: BEG499BE Dr. Pradeep K. ShresthaDocument20 paginiBio-Engineering: BEG499BE Dr. Pradeep K. ShresthaPradeep ShresthaÎncă nu există evaluări

- Isricu I15889 001Document105 paginiIsricu I15889 001Josif KaevskiÎncă nu există evaluări

- InterchangeDocument57 paginiInterchangeNguyễn Văn CôngÎncă nu există evaluări

- Uganda Standards Series 2000 - DrainageDocument37 paginiUganda Standards Series 2000 - DrainageKintu Munabangogo100% (2)

- Drain DesignDocument14 paginiDrain DesignSneh KhandelwalÎncă nu există evaluări

- Dewpoint Drainage Pump DP-0521-B (Product Catalogue) 8-9-2021Document4 paginiDewpoint Drainage Pump DP-0521-B (Product Catalogue) 8-9-2021locoÎncă nu există evaluări

- Ireland EPADocument72 paginiIreland EPARajesh ShenoyÎncă nu există evaluări

- Retaining Wall TerminologyDocument2 paginiRetaining Wall Terminologyhammads88Încă nu există evaluări

- Dam - Foundation - Drains - Grout - Curtain - Design of GravitydamsDocument15 paginiDam - Foundation - Drains - Grout - Curtain - Design of GravitydamsAwais AliÎncă nu există evaluări

- Pelland Pumptrack2018Document60 paginiPelland Pumptrack2018ksnakaÎncă nu există evaluări

- Surface Water DrainageDocument8 paginiSurface Water DrainageronyÎncă nu există evaluări

- Repair Against Rain Water Leakages in Building: 18Cs27 - Maintenance and Rehabilitation of StructuresDocument28 paginiRepair Against Rain Water Leakages in Building: 18Cs27 - Maintenance and Rehabilitation of StructuresSWARNA GOWRI RÎncă nu există evaluări

- Statements of Purpose Guidelines and Sample EssaysDocument51 paginiStatements of Purpose Guidelines and Sample Essaysyawnbot botÎncă nu există evaluări

- Design of Storm Sewer System For The Bistekville 1 of Brgy. Payatas Quezon CityDocument77 paginiDesign of Storm Sewer System For The Bistekville 1 of Brgy. Payatas Quezon CityAnonymous fASKuwVÎncă nu există evaluări

- B HighHead IS115-ADocument2 paginiB HighHead IS115-AJOHNNY CALEROÎncă nu există evaluări

- ACO HexDrain Brickslot BrochureDocument2 paginiACO HexDrain Brickslot BrochureDmitrijus TruninasÎncă nu există evaluări

- Flush Thread PVC Well Screens, Casings and AccessoriesDocument12 paginiFlush Thread PVC Well Screens, Casings and AccessoriesWong Jian WenÎncă nu există evaluări

- Diseño de Sistemas de Drenaje y Facilidades de TratamientoDocument80 paginiDiseño de Sistemas de Drenaje y Facilidades de Tratamientolauraibc100% (1)

- Design Standards No. 13 Embankment DamsDocument100 paginiDesign Standards No. 13 Embankment Damsjnf100% (3)

- Landforms and ContoursDocument38 paginiLandforms and ContoursJuvilasri VigneshÎncă nu există evaluări

- Sarawak Building Works RateDocument55 paginiSarawak Building Works RateChaiYingH100% (1)

- Socio-Economic Impacts of Solar Pumping System in Term of Local Job and Value Creation in EgyptDocument110 paginiSocio-Economic Impacts of Solar Pumping System in Term of Local Job and Value Creation in EgyptJessa ArgabioÎncă nu există evaluări

- Opportunities and Challenges of Road Construction in NepalDocument7 paginiOpportunities and Challenges of Road Construction in NepalBharat upadhyayÎncă nu există evaluări

- Wavin QuickStreamDocument2 paginiWavin QuickStreamsk lukoÎncă nu există evaluări