Documente Academic

Documente Profesional

Documente Cultură

M 6ib

Încărcat de

Ege UgurluDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M 6ib

Încărcat de

Ege UgurluDrepturi de autor:

Formate disponibile

M-6iB Series

Basic Description

The M-6iB series is FANUC Robotics latest-generation family of small robots. The series is offered in two sizes designed to approximate the reach of an operator. Feature-rich standard capabilities and options provide dexterity, reliability and high speeds to make the M-6iB the perfect solution for countless applications and working environments.

M-6iB Series, the Solution for:

I I I I I I I I

Machine tending Material handling Assembly Picking and packing

I

Material removal Cleanroom operations Testing and sampling Dispensing

I I

Pneumatic lines routed from J1 inlet to J3 outlet Compact size, slim wrist, and small footprint permit operation in tight work spaces Upright, angle, wall, or invert mounting for increased installation flexibility Robot can flip over backwards for a larger work envelope High joint speeds maximize throughput Fail-safe brakes and adjustable J1 hardstops increase safety, functionality, and control Absolute encoder positioning eliminates homing at power-up Same footprint and wrist bolt pattern as previous generation for easy upgrades

Color, graphical, networkready teach iPendant

Reliability

I

Features and Benefits

I I I I

Latest generation of a proven design RV reducer, gear and harmonic drivetrains eliminate unreliable belts, pulleys and chains while providing rigidity and performance in a compact package Grease fittings on all lubrication points for quick and easy maintenance Sealed bearings and brushless, maintenancefree AC motors provide protection and improve reliability

6 degrees of freedom 0.08 mm repeatability Up to 10 kg payload at wrist

Large wrist moments and inertias for real-world EOATs and workpieces Supplementary payload mount on J3 casting Yoked wrist structure for increased rigidity Pneumatic and electrical (8 DI/8 DO) connections for EOAT on J3

I I I

Robot and Controller Options

I

Larger variant for greater reach (M-6iB) Smaller variant for tight installations (M-6iB/6S) Class 100 variant for cleanroom use (M-6iB/6C; see Cleanroom Robots datasheet) Higher-speed variant for greater throughput (M-6iB/2HS) Solution arm variants minimize EOAT dress-out complexity and cost (for M-6iB/6S and M-6iB/2HS) Severe dust and liquid protection package for harsh environments J1/J2 motor cooling fans for sustained high-duty operation 360 J1 rotation eliminates rear dead zone Machine vision for guidance and inspection Up to 16 axes (robot + auxiliary) on same controller Extended communications capabilities: FTP, DeviceNet, A/B RIO, Profibus, Genius, FANUC Model A I/O rack, CC-Link, etc. Linear or circular conveyor tracking CE-Mark 14 m or 21 m controller-torobot cables Solution Arm features a hollow wrist flange and preengineered EOAT cabling to reduce dress-out cost, snag interference, and to increase durability.

I I

Unique Software Options

I I

Singularity avoidance AccuDeflash for plastic deflashing Internet connectivity KAREL programming language And over 40 other powerful software solutions Class 100 option brings off-the-shelf FANUC reliability to electronics, pharmaceuticals and other cleanroom manufacturing operations. M-6iB/6C shown invertmounted.

I I I

M-6iB Series Dimensions

Top

R951

R273 170

170

R1373

150

615

100

140

100 J5 AXIS ROTATION CENTER 430 100 172

100 600 360

450

Back

Side

Front

Footprint

308 260 150 153 150 23 (Mounting face) 23 150 153 260 150 FRONT (Mounting face) Rotation Center of J1 axis 10 4-18 THRU 26 C' BORE DP5

Isometric

10 15

Standard Wrist

50h7 25H7

4-M6 Depth 10 Equally spaced on circumference 40 6H7 Depth 10 Circumference 40

53 53 6 100

45

M-6iB/6S and /2HS

M-6iB

85

74

Note: Dimensions are shown in millimeters. Detailed CAD data are available upon request.

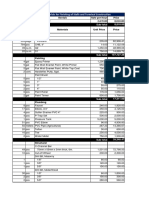

M-6iB Series Specifications

Items

Axes Payload at Wrist (kg) Supplementary Payload on J3 Casting1 (kg) Reach (mm) Repeatability2 (mm) Interference Radius (mm) Motion Range 3 (degrees) J1 J2 J3 J4 J5 J6 Motion Speed 4 (degrees/s) J1 J2 J3 J4 J5 J6 Wrist Moment (kgfcm) J4 J5 J6 Wrist Inertia (kgfcms2) J4 J5 J6 Mass (kg) Mounting Positions 5 Vibration (m/s2) Special Application Environments 6

M-6iB

6 6 12 1,373 0.08 273 340 250 315 380 280 720 150 160 170 400 400 520 160 100 60 6.4 2.2 0.62 138 Floor, angle, wall, inverted 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body

M-6iB/6C

Cleanroom

6 6 12 1,373 0.08 350 340 250 315 380 280 720 150 160 170 400 400 520 160 100 60 6.4 2.2 0.62 145 Floor, inverted 4.9 (0.5G) ISO Class 5 (Class 100 per U.S. Federal Standard 209E)

M-6iB/6S

6 kg Payload 7

6 6 12 951 0.08 273 340 250 310 380 280 720 200 200 260 400 400 720 160 100 60 6.4 2.2 0.62 135 Floor, angle, wall, inverted 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body

M-6iB/6S

10 kg Payload 7

6 10 6 951 0.08 273 340 250 310 380 280 720 200 200 200 400 400 520 160 160 70 6.4 3.7 0.65 135 Floor, angle, wall, inverted 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body

M-6iB/2HS

6 2 12 951 0.08 273 340 250 310 380 280 720 200 200 260 400 400 1,200 160 100 20 6.4 2.2 0.36 135 Floor, angle, wall, inverted 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body

M-6iB/6S

Solution Arm

6 4 12 951 0.08 273 340 250 310 240 110 720 200 200 260 400 400 1,200 140 80 36 6.2 2.0 0.37 140 Floor 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body (No IP rating for solenoid box)

M-6iB/2HS

Solution Arm

6 2 12 951 0.08 273 340 250 310 240 110 720 200 200 260 400 400 2,000 140 80 12 6.2 2.0 0.20 140 Floor 4.9 (0.5G) IP67 forearm and wrist / IP54 lower body (No IP rating for solenoid box)

Notes: (1) Payload on J3 casting is in addition to wrist payload capacity. (2) Repeatability per JISB8432. (3) 360 J1 rotation optional. (4) Higher sustained motion speeds available with High Duty option on all variants except M-6iB and M-6iB/6C. (5) J1 and J2 motion range de-rated when angle or wall-mounted. (6) IP67 forearm and wrist / IP55 body optional. Organic solvents, acids, alkalis and chlorine/gasoline coolants or any chemicals which may harm NBR (nitrile rubber) must not be used. See Cleanroom Robots datasheet for more information regarding M-6iB/6C. (7) M-6iB/6S default wrist payload is 6 kg. Included software permits toggling between 6 kg and 10 kg with no mechanical alterations required to mechanical unit. No motion restrictions in either mode.

FANUC Robotics America, Inc. 3900 W. Hamlin Road Rochester Hills, MI 48309-3253 (248) 377-7000 Fax (248) 276-4133

For sales or technical information, call:

Charlotte, NC (704) 596-5121 Chicago, IL (847) 898-6000 Cincinnati, OH (513) 754-2400 Los Angeles, CA (949) 595-2700

Toronto, Canada (905) 812-2300 Montral, Canada (450) 492-9001 Aguascalientes, Mexico 52 (449) 922-8000 Sao Paulo, Brazil (55) (11) 3619-0599

1-800-47-ROBOT

marketing@fanucrobotics.com www.fanucrobotics.com

2005 FANUC Robotics America, Inc.

Toledo, OH (419) 866-0788

FANUC ROBOTICS LITHO IN U.S.A. FRA-11/05

All rights reserved.

S-ar putea să vă placă și

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe la EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsEvaluare: 5 din 5 stele5/5 (2)

- S 420i SerieDocument4 paginiS 420i SerieIbarra Aaron100% (2)

- LR Mate 100ibDocument2 paginiLR Mate 100iblnahoyosÎncă nu există evaluări

- Fanuc M-900ia SeriesDocument4 paginiFanuc M-900ia SeriesAxel GomezÎncă nu există evaluări

- M410 RJ3Document4 paginiM410 RJ3Ali Hernandez100% (1)

- C.Periodic Maintenance TableDocument2 paginiC.Periodic Maintenance Tableleonel mendieta100% (1)

- ARC Mate 120ic Series - 8Document2 paginiARC Mate 120ic Series - 8Joimir PerezÎncă nu există evaluări

- FANUC LR Mate 200ic DatasheetDocument1 paginăFANUC LR Mate 200ic DatasheetGodwin J. SobinÎncă nu există evaluări

- R 2000ic PDFDocument6 paginiR 2000ic PDFPRASADÎncă nu există evaluări

- Robot Manual HwashiDocument183 paginiRobot Manual HwashiDiogo CoelhoÎncă nu există evaluări

- Report On Basic Setups of Fanuc Robot: Difacto Robotics and AutomationDocument5 paginiReport On Basic Setups of Fanuc Robot: Difacto Robotics and AutomationAnil PandeyÎncă nu există evaluări

- Colchester LathesDocument7 paginiColchester LathesAndrew ParrottÎncă nu există evaluări

- AXstandardRev7+SafetyRev4 CombinedDocument125 paginiAXstandardRev7+SafetyRev4 CombinedJose Ernesto AcevedoÎncă nu există evaluări

- ABB Torch CleanerDocument44 paginiABB Torch CleanerAsim PedicÎncă nu există evaluări

- MR J3 TC E.pdf Meldas Servo MotorDocument227 paginiMR J3 TC E.pdf Meldas Servo Motorchidambaram kasiÎncă nu există evaluări

- Powerflex® 40P: Technical DataDocument36 paginiPowerflex® 40P: Technical DataPauli TaÎncă nu există evaluări

- M-900iA Serie 2 PDFDocument4 paginiM-900iA Serie 2 PDFFrancisco PedrozaÎncă nu există evaluări

- Mitsubishi Robot Catalog.L (NA) 09051ENG ADocument16 paginiMitsubishi Robot Catalog.L (NA) 09051ENG Ack_peyÎncă nu există evaluări

- M SeriesDocument47 paginiM SeriesMeet PAtelÎncă nu există evaluări

- RoboCare Manual enDocument17 paginiRoboCare Manual enVoxine OuscularenÎncă nu există evaluări

- As 117800 Iv-H2000ma Iv-H500ca Iv-H500ma Um 519GB WW GB 2031 8Document436 paginiAs 117800 Iv-H2000ma Iv-H500ca Iv-H500ma Um 519GB WW GB 2031 8Luis aÎncă nu există evaluări

- AR4 Robot Manul V1.5 PDFDocument292 paginiAR4 Robot Manul V1.5 PDFEusebio RivasÎncă nu există evaluări

- MELFA Works - Instruction Manual BFP-A8525-D (11.08)Document95 paginiMELFA Works - Instruction Manual BFP-A8525-D (11.08)Patran Valentin100% (1)

- NCU SinumerikDocument98 paginiNCU SinumerikSergeyÎncă nu există evaluări

- Urun KataloguDocument17 paginiUrun KataloguHaroun Al RachidÎncă nu există evaluări

- Quick Learn ManualDocument20 paginiQuick Learn ManualwalterazrÎncă nu există evaluări

- R 2000ic Operators PDFDocument222 paginiR 2000ic Operators PDFAdam ZiobrowskiÎncă nu există evaluări

- FANUC LR Mate 200ic DatasheetDocument1 paginăFANUC LR Mate 200ic DatasheetGodwin J. SobinÎncă nu există evaluări

- HW0483057.0 Trouble SchootingDocument142 paginiHW0483057.0 Trouble Schootingluho1979Încă nu există evaluări

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 paginiRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaÎncă nu există evaluări

- Robot Setup - ABBDocument24 paginiRobot Setup - ABBTrần Văn TrườngÎncă nu există evaluări

- Rotary Table Dynamic Fixture Offset Instruction 2Document5 paginiRotary Table Dynamic Fixture Offset Instruction 2diaboloboyÎncă nu există evaluări

- ABB IRB 6400 Calibration ManualDocument12 paginiABB IRB 6400 Calibration ManualAntonio SanchezÎncă nu există evaluări

- KR 10 R1100-2Document1 paginăKR 10 R1100-2Merced HernandezÎncă nu există evaluări

- Test Conditions For Machining Centres - Part 11: Noise TestsDocument13 paginiTest Conditions For Machining Centres - Part 11: Noise TestsbrunoagandraÎncă nu există evaluări

- Hyundai-robotics-Industrial Robot Series Eng 0802Document2 paginiHyundai-robotics-Industrial Robot Series Eng 0802jitender kumar0% (1)

- Leadwell NV-Serie 2015 PDFDocument8 paginiLeadwell NV-Serie 2015 PDFLevi BriceñoÎncă nu există evaluări

- Fanuc P50iBDocument2 paginiFanuc P50iBarmando rivera50% (2)

- Robot Series: Hyundai RoboticsDocument8 paginiRobot Series: Hyundai Roboticsjavier50% (2)

- Welding ShopDocument10 paginiWelding ShopAsifJavedÎncă nu există evaluări

- RV N e PDFDocument60 paginiRV N e PDFdavev2005Încă nu există evaluări

- Fanuc Arc Mate 100ib M-6ib Maintenance Manual B-81545en-01Document2 paginiFanuc Arc Mate 100ib M-6ib Maintenance Manual B-81545en-01TNasteca100% (1)

- LG CM4320Document63 paginiLG CM4320soms65Încă nu există evaluări

- S3 M93 Manual PDFDocument203 paginiS3 M93 Manual PDFgs100% (1)

- Fanuc 30ibDocument34 paginiFanuc 30ibthigale empireÎncă nu există evaluări

- FANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Document153 paginiFANUC ARC Mate 100ib - M-6iB - Maintenance Manual - B-81545EN-01Robert MegličÎncă nu există evaluări

- Dokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFDocument4 paginiDokumen - Tips - Fanuc Robotics System R j3 Controller S 430i Series Mechanical Unit Maintenance Manual Marm3s43009801e Rev B PDFMabrouk GuezatiÎncă nu există evaluări

- Fanuc DevicNet Printed From EDOCDocument118 paginiFanuc DevicNet Printed From EDOCIbarra AaronÎncă nu există evaluări

- 2414 2416 Installation ProcedureDocument4 pagini2414 2416 Installation ProcedureJames BondÎncă nu există evaluări

- Robacta Drive TwinDocument12 paginiRobacta Drive TwinAdina Claudia BesliuÎncă nu există evaluări

- V55 Maintenance 4Document5 paginiV55 Maintenance 4วรพงษ์ กอชัชวาลÎncă nu există evaluări

- Socket Screws MetricDocument32 paginiSocket Screws MetricBib GmzÎncă nu există evaluări

- TDS Sadechaf UVACRYL 2151 - v9Document5 paginiTDS Sadechaf UVACRYL 2151 - v9Alex MacabuÎncă nu există evaluări

- capto主轴标准Document87 paginicapto主轴标准中国心Încă nu există evaluări

- Comau High Payload ENG PDFDocument33 paginiComau High Payload ENG PDFDaniel DumitruÎncă nu există evaluări

- ROBODocument2 paginiROBODouglasRodriguesÎncă nu există evaluări

- Datos Técnicos Robot Industrial IRB 6600 03Document2 paginiDatos Técnicos Robot Industrial IRB 6600 03gussyÎncă nu există evaluări

- ArcMate 100ib.Document2 paginiArcMate 100ib.Kamy FoxÎncă nu există evaluări

- Fanuc R-2000iA Series PDFDocument4 paginiFanuc R-2000iA Series PDFAntonio RodriguezÎncă nu există evaluări

- Fanuc ARC Mate 100iDocument2 paginiFanuc ARC Mate 100icorneluts50% (2)

- Manual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveDocument100 paginiManual MERCRUISER QSD 2.0L DIESEL ENGINE Service Repair Manual SN 88200000 and AboveWallace Ferlim100% (6)

- Regolatore Aspirazione Rh38EDocument2 paginiRegolatore Aspirazione Rh38EДжон ДиллинджерÎncă nu există evaluări

- N R P F W G: Direction of Impending MotionDocument28 paginiN R P F W G: Direction of Impending MotionAbdullah Ahsan AhmedÎncă nu există evaluări

- AG 200-800 Series PilotsDocument13 paginiAG 200-800 Series Pilotstxlucky80Încă nu există evaluări

- Tutorial 6Document1 paginăTutorial 6kishan shuklaÎncă nu există evaluări

- Replacement Parts BUSHDocument33 paginiReplacement Parts BUSHIsaac Rodríguez BetancourtÎncă nu există evaluări

- Pneumatic HammerDocument7 paginiPneumatic HammerShlok PatelÎncă nu există evaluări

- Unit 3Document29 paginiUnit 3ashok Pradhan100% (1)

- Piston Rings GuideDocument5 paginiPiston Rings GuideAshok BishtÎncă nu există evaluări

- Optimized Skid Design For Compressor PackagesDocument9 paginiOptimized Skid Design For Compressor Packagesmario_gÎncă nu există evaluări

- Cap 71 PW6000Document158 paginiCap 71 PW6000Luiz FerrazÎncă nu există evaluări

- Anchor BoltsDocument1 paginăAnchor BoltsBert EngÎncă nu există evaluări

- Control & On-Off Valve - Forbes MarshallDocument12 paginiControl & On-Off Valve - Forbes MarshallPraful Patil100% (1)

- 02 PDFDocument39 pagini02 PDFShishir Kumar NayakÎncă nu există evaluări

- BF08H00902 Components EngineDocument125 paginiBF08H00902 Components EngineHéctor Medina100% (1)

- King Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerDocument4 paginiKing Air 350 Limitations, Specs, and Study Guide N Compressor N PropellerMikeÎncă nu există evaluări

- JNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsDocument25 paginiJNTUK-DAP-Course Structure and Syllabus-B.tech (Mechanical Engineering) - II YEAR.R10 StudentsAnusha MylavarapuÎncă nu există evaluări

- Hipps: High Integrity Pressure Protection SystemsDocument9 paginiHipps: High Integrity Pressure Protection SystemsAndrew XuguomingÎncă nu există evaluări

- Mfe24pi1505 Design of Production Toolingdrill BushingsDocument14 paginiMfe24pi1505 Design of Production Toolingdrill BushingsSubrat pandaÎncă nu există evaluări

- Goodyear OTR Databook2009Document169 paginiGoodyear OTR Databook2009otr-tireman100% (1)

- Range Rover11 MainDocument19 paginiRange Rover11 Main15101980Încă nu există evaluări

- IVECO StralisDocument40 paginiIVECO StralismicakojicÎncă nu există evaluări

- C Chains APIDocument1 paginăC Chains APILuisSilvaÎncă nu există evaluări

- Gujarat Technological UniversityDocument2 paginiGujarat Technological UniversityMaulik PatelÎncă nu există evaluări

- PN1949 Perkins Irrigation Engine Ratings GuideDocument16 paginiPN1949 Perkins Irrigation Engine Ratings GuideMd ShÎncă nu există evaluări

- 3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionDocument2 pagini3 Hrs Motor Grader 2,670.00 8,010.00: Detailed Bill of Materials For Finishing of Stalls and Terminal ConstructionKris Aileen CortezÎncă nu există evaluări

- Catalogos BombasDocument12 paginiCatalogos BombasJose NavarreteÎncă nu există evaluări

- Performance Based Seismic Design of Reinforced Concrete Tall BuildingsDocument175 paginiPerformance Based Seismic Design of Reinforced Concrete Tall BuildingsPatrick CanceranÎncă nu există evaluări

- Fatigue Curve For SCM440Document6 paginiFatigue Curve For SCM440Nagaraj RaoÎncă nu există evaluări