Documente Academic

Documente Profesional

Documente Cultură

BLTN 03

Încărcat de

saji84Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BLTN 03

Încărcat de

saji84Drepturi de autor:

Formate disponibile

DUBAI MUNICIPALITY

ENVIRONMENT DEPARTMENT

ENVIRONMENT PROTECTION & SAFETY SECTION

CODE OF PRACTICE ON ABRASIVE BLAST CLEANING OPERATIONS IN DUBAI Adopted under the Local Order No. 61/1991 The Environmental Protection Regulations in the Emirate of Dubai Amended March 1996

The Code of Practice was prepared by Dubai Municipality and adopted under Local Order 61 of 1991 to control the air quality and occupational health issues associated with abrasive blasting. In addition, the Code seeks to reduce the problem of disposal of spent abrasive blasting media which is significant component of Dubais solid waste stream. A code of practice was seen as the best way of introducing fair consistent standards for this industry. All persons conducting abrasive blasting operations must comply with the requirements of the Code. Introduction and Scope 1. This code is adopted under Local Order 61 of 1991 The Environmental Protection and Safety Regulations in the Emirate of Dubai. The code has been prepared from a review of international practice and the experience of the EPSS with this industry in Dubai. The code applies to any abrasive blasting operation which is defined as the operation of cleaning any surface using a process of forcibly propelling a stream of abrasive materials against the surface. Abrasive blasting does not include hydroblasting where only high pressure water is used.

2.

3. Definitions: Blasting area for the purpose of this code means the site where abrasive blasting is taking place and the surrounding buffer area where the concentration of particulates is likely to be above the normal occupational acceptable/ prescribed levels Consumable abrasives (e.g. coal slag) are those abrasive media that are only used once or cannot substantially be recycled. Recyclable abrasives are those materials which can be reused several times with or without cleaning. Metallurgical abrasives are those derived from the primary metallurgy industry and which contain any heavy metal contaminants listed in column 1 of table 1 ,in total , exceeding 0.3% ( 3000 ppm by weight). Open blasting means any controlled process which is not enclosed by 4 walls and roof and vented through an air pollution control device and chimney. 4. Documentation 4.1. Any person or company responsible for the sale of use of any abrasive materials must be in possession of a recent test certificate from an accredited testing laboratory which contains the following information: - Physical properties (e.g. specific gravity, density, appearance, etc). - Heavy metal content. - Free silica content. - Disposal procedures in Dubai. - Personal protective equipment required. 4.2. 5. A test certificate must be made readily available to all parties purchasing the abrasive for use.

Prohibitions on Use of Abrasives 5.1 Sand or any abrasive blasting media containing more than 1% free silica shall not be used in abrasive blasting operations in Dubai. 5.2 All abrasive blasters operating in industrial areas shall use a recyclable nonmetallurgical abrasive material.

6.

Controls on the Use of Abrasives 6.1. The use of consumable abrasives in not favoured. Where practicable alternatives to the use of consumable abrasives such as high pressure water jetting or recyclable abrasives should be utilized. Dust from abrasive blasting must be contained at the work-site to the maximum feasible extent and should not result in off-site nuisance. Unless large items of work are involved all blasting operations must be done in enclosed blast cleaning machines, cabinets or rooms. Whenever abrasive blasting is done inside an enclosed room, this should be properly ventilated. Exhaust air from blast rooms or cabinets should be vented through appropriately designed dust collectors (e.g. filter bags, or similar equipment). The dust collector should be set up so that accumulated dust can be removed without generation of fugitive emissions and contaminating work areas. Portable blast - cleaning equipment used in the open by industrial establishments and construction sites should be provided with appropriate enclosures such as tarpaulin, screens to prevent dust migration and reduce hazards to adjacent workers and the general public. Companies using abrasives must take all practicable steps to minimize the loss of the materials to the environment, especially the drainage systems and marine waters. Abrasive blast cleaning of shiphulls must be off-water and should, where practicable, be appropriately provided with enclosures or catchment to prevent dust migration and waste falling into drains. Appropriate abrasive blasting technology or low dust abrasives must be used to control dust in the out door blasting of large items of work where off site impact and nuisance is likely.

6.2. 6.3. 6.4. 6.5.

6.6.

6.7.

6.8.

6.9

6.10 Where it is necessary to blast over water, only abrasives approved by the EPSS shall be used.

7.

Safety of Workers 7.1. Appropriate WARNING signs shall be posted in a conspicuous place in the work areas to warn workers about the hazards and specify personal protective equipment (e.g. respirators). Personnel involved in abrasive blasting must wear a blasters helmet with impact protection cover, fresh air supply and inside collar, suits made of hard-wearing material, leather gloves and safety shoes. The fresh air supply should not permit passage of dust particles less than 10 microns. The air quality should be suitable for breathing purposes satisfying the breathing air quality specifications detailed in the Technical Guideline No. 21. The occupier shall test the breathing air quality once in 3 months, and maintain a record. Measures must be taken to ensure that personal protective equipment are kept separately from other clothing belonging to employees, and outside the working area in special changing rooms. Respirable particulate outside of the abrasive blast cleaning area shall not exceed 50 ug/m3 (micrograms per cubic meter) - 8 hours time weighted average (TWA). In open blasting all workers within the blasting area must wear appropriate personal protective equipment. Workers should not eat, drink or use tobacco products in the blasting areas. Workers should wash their hands and face before eating, drinking and smoking. The employer should provide facilities for workers to take a shower before leaving the worksite. Workers engaged in abrasive blasting must be instructed on the health risks and on the use of appropriate personal protective equipment. All workers engaged in abrasive blasting activities shall be medically examined annually and given a chest x-ray. A file and records of each such staff member shall be submitted to Environmental Protection and Safety Section.

7.2.

7.3.

7.4.

7.5.

7.6. 7.7. 7.8. 7.9. 7.10. 7.11.

8.

Waste Disposal 8.1. Waste abrasives exceeding the limits specified in columns II and III or contaminated TBTO based paint residues or any other residue considered hazardous to the environment by Dubai Municipality are hazardous wastes in Dubai and must be disposed of in accordance with the procedures specified in Technical Guidelines No. 26 and 27.

Table 1

I Contaminant Arsenic Lead Cadmium Chromium Copper Nickel Mercury Zinc Tin Selenium II Total Concentration mg/kg 500 3000 50 3000 1000 1000 50 5000 500 100 III Leachable Fraction (*) mg/l 5 5 0.50 5 10 2 0.1 50

* Refer to approved leachate test outlined in Technical Guideline Number 23.

8.2.

Disposal of wastes to approved reuse schemes ( i.e cement products or similar ) is encouraged provided that this is conducted in accordance with conditions specified by Dubai Municipality. Any abrasive blasting wastes which are non-hazardous under the above definition and which are not reused may be disposed of as inert solid waste in Dubai.

8.3.

S-ar putea să vă placă și

- Alex Eubank GGIIDocument40 paginiAlex Eubank GGIIOliver Sleiman94% (16)

- Safe Blasting ProceduresDocument4 paginiSafe Blasting Proceduressajay2010Încă nu există evaluări

- UK Tax SystemDocument13 paginiUK Tax SystemMuhammad Sajid Saeed100% (1)

- Demolition & Excavation EnglishDocument64 paginiDemolition & Excavation EnglishRamon FrillesÎncă nu există evaluări

- OSHAD-SF - Elements v3.1 EnglishDocument64 paginiOSHAD-SF - Elements v3.1 EnglishMohammedJunaid100% (2)

- A Critical Appreciation of Ode To NightingaleDocument3 paginiA Critical Appreciation of Ode To NightingaleBaloch Karawan100% (2)

- Sand BlastingDocument2 paginiSand Blastingdipilkumar100% (1)

- How To Import Medical Devices Into The USDocument16 paginiHow To Import Medical Devices Into The USliviustitusÎncă nu există evaluări

- ISO 45001:2018 & OHSAS 18001:2007 Clause-Wise Comparison MatrixDocument3 paginiISO 45001:2018 & OHSAS 18001:2007 Clause-Wise Comparison MatrixvenkatesanÎncă nu există evaluări

- Cleanroom Technology: Fundamentals of Design, Testing and OperationDe la EverandCleanroom Technology: Fundamentals of Design, Testing and OperationÎncă nu există evaluări

- Decommissioning Oil Storage TanksDocument12 paginiDecommissioning Oil Storage Tankssmithwork100% (2)

- Alugbati Plant Pigment Extraction As Natural Watercolor SourceDocument6 paginiAlugbati Plant Pigment Extraction As Natural Watercolor SourceMike Arvin Serrano100% (1)

- Confined SpaceDocument7 paginiConfined SpacearajanchabhadÎncă nu există evaluări

- Outlook 2Document188 paginiOutlook 2Mafer Garces NeuhausÎncă nu există evaluări

- Local Exhaust VentilationDocument25 paginiLocal Exhaust Ventilationfariyashoeb100% (1)

- Abrasive Blasting Safe Work PDFDocument2 paginiAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- Part II - 08 Abrasive BlastingDocument5 paginiPart II - 08 Abrasive Blastingsalah abddayemÎncă nu există evaluări

- GSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingDocument18 paginiGSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingRickz2k8100% (1)

- Aseptic Gowning WhoDocument17 paginiAseptic Gowning WhoMayson Bali100% (1)

- Refinería Kirkuk PDFDocument11 paginiRefinería Kirkuk PDFcesarinarragaÎncă nu există evaluări

- Cover Letter UchDocument1 paginăCover Letter UchNakia nakia100% (1)

- Abrasive BlastingDocument52 paginiAbrasive Blastinglwin_oo2435100% (1)

- Aseptic Techniques MFG IIDocument84 paginiAseptic Techniques MFG IIapi-197854430% (1)

- Lichens - Naturally Scottish (Gilbert 2004) PDFDocument46 paginiLichens - Naturally Scottish (Gilbert 2004) PDF18Delta100% (1)

- Kitain Mikhail Clean RoomDocument39 paginiKitain Mikhail Clean RoomshrinivastÎncă nu există evaluări

- Air and Noise: Abrasive Blast CleaningDocument5 paginiAir and Noise: Abrasive Blast CleaningBharathNaikPanjaÎncă nu există evaluări

- Safe Working Procedure For Abrasive Blasting: ObjectiveDocument4 paginiSafe Working Procedure For Abrasive Blasting: ObjectiveHari BabuÎncă nu există evaluări

- Occupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationDocument26 paginiOccupational Safety and Health Admin., Labor 1926.57: 1926.57 VentilationipliprensÎncă nu există evaluări

- Abrasive BlastingDocument2 paginiAbrasive BlastingHadrien FaryalaÎncă nu există evaluări

- 2-ABRASIVE-BLASTING ProcedureDocument4 pagini2-ABRASIVE-BLASTING ProcedureFaisal NadoÎncă nu există evaluări

- Guide FoundriesDocument13 paginiGuide Foundriesnadaf2Încă nu există evaluări

- A Guidance Note On The Best Practicable Means FOR Iron and Steel WorksDocument7 paginiA Guidance Note On The Best Practicable Means FOR Iron and Steel WorksVinod Kumar VermaÎncă nu există evaluări

- Safety PolicyDocument21 paginiSafety Policythewhitebunny6789Încă nu există evaluări

- Anup 018009Document7 paginiAnup 018009War ChildÎncă nu există evaluări

- DM-Envrt TG - 30 Paint Spray BoothsDocument6 paginiDM-Envrt TG - 30 Paint Spray Boothsaspire79Încă nu există evaluări

- FMA RegsDocument361 paginiFMA RegsJiong SoonÎncă nu există evaluări

- TG13 PDFDocument8 paginiTG13 PDFzahid_497Încă nu există evaluări

- Respiration Protection GROUP 1Document22 paginiRespiration Protection GROUP 1moyolisa0Încă nu există evaluări

- Factories and Machinery (Asbestos Process) Regulations 1986Document32 paginiFactories and Machinery (Asbestos Process) Regulations 1986Sam SiewÎncă nu există evaluări

- Lesson 7 Control of Hazardous MaterialsDocument6 paginiLesson 7 Control of Hazardous MaterialsSheena Ann StonehillÎncă nu există evaluări

- Regulation DD-24.0 Abrasive BlastingDocument3 paginiRegulation DD-24.0 Abrasive BlastingUsama TariqÎncă nu există evaluări

- Demolation Operation SafetyDocument17 paginiDemolation Operation SafetyLion DayÎncă nu există evaluări

- 8310 Guide ConcreteDocument6 pagini8310 Guide ConcreteMariana BeatrizÎncă nu există evaluări

- Mod 6Document4 paginiMod 6Althaf MlpmÎncă nu există evaluări

- Test 1 OshaDocument8 paginiTest 1 OshaFadzrul FaizÎncă nu există evaluări

- Temporary Permanent BPDocument18 paginiTemporary Permanent BPravinder277Încă nu există evaluări

- Factories and Machinery (Asbestos) Regulations, 1986 Ve - Pua289 - 1986Document11 paginiFactories and Machinery (Asbestos) Regulations, 1986 Ve - Pua289 - 1986Exsan OthmanÎncă nu există evaluări

- IR Ampling Nalysis: Neha Patel Associate Professor Civil Engineering Department B.V.M.Engineering CollegeDocument13 paginiIR Ampling Nalysis: Neha Patel Associate Professor Civil Engineering Department B.V.M.Engineering CollegeNeha PatelÎncă nu există evaluări

- BIS Standard For IlluminationDocument14 paginiBIS Standard For IlluminationbhaskarÎncă nu există evaluări

- 8426 Guide PressureDocument8 pagini8426 Guide PressurehainguyenbkvhvÎncă nu există evaluări

- Cms-2 Detector de MonoxidoDocument17 paginiCms-2 Detector de MonoxidoJORGEALEXERÎncă nu există evaluări

- Manual TolvaDocument30 paginiManual TolvaBraulio Candela NoriegaÎncă nu există evaluări

- Dish - Schedule of ChemicalsDocument15 paginiDish - Schedule of ChemicalsHimanshu PanchalÎncă nu există evaluări

- ETG22 - Safe Use of Industrial Organic SolventsDocument8 paginiETG22 - Safe Use of Industrial Organic SolventsRahul RamachandranÎncă nu există evaluări

- B3365 OSHA Silica Sand Rule Compliance Workbook With ChecklistDocument12 paginiB3365 OSHA Silica Sand Rule Compliance Workbook With ChecklistZeckÎncă nu există evaluări

- Control of Hazardous Dust During Tuckpointing: ControlsDocument4 paginiControl of Hazardous Dust During Tuckpointing: ControlsMarkÎncă nu există evaluări

- AHU System Installation Exploded and Catched FireDocument2 paginiAHU System Installation Exploded and Catched FireAbdul WafiyÎncă nu există evaluări

- EIA Module 6Document53 paginiEIA Module 6JayakrishnanÎncă nu există evaluări

- MSDS For CERAMIC MOULDDocument4 paginiMSDS For CERAMIC MOULDKukira KopiÎncă nu există evaluări

- Exposure Control Plan For Chip Hammering and Jackhammering: Protecting Workers When Chipping or Jackhammering ConcreteDocument6 paginiExposure Control Plan For Chip Hammering and Jackhammering: Protecting Workers When Chipping or Jackhammering Concreteritika5656Încă nu există evaluări

- Microbiological Safety CabinetsDocument3 paginiMicrobiological Safety CabinetsrunclechÎncă nu există evaluări

- Checklist For Powdercoaters - PowdercoatersDocument9 paginiChecklist For Powdercoaters - PowdercoatersParveen KohliÎncă nu există evaluări

- Control of Air Pollution: III Year / Semester VI Sch1310 - Environmental Pollution and Control Unit-IiDocument14 paginiControl of Air Pollution: III Year / Semester VI Sch1310 - Environmental Pollution and Control Unit-IiJuvilasri Vignesh NKÎncă nu există evaluări

- Art PlaybookDocument34 paginiArt PlaybookSen MuruÎncă nu există evaluări

- TG 11Document19 paginiTG 11Lorraine BautistaÎncă nu există evaluări

- White Paper - BSC - Safety Precautions For Biosafety Decontamination - 05 Jan 2012Document2 paginiWhite Paper - BSC - Safety Precautions For Biosafety Decontamination - 05 Jan 2012Sergey KafarovÎncă nu există evaluări

- Environmental PDFDocument8 paginiEnvironmental PDFLaiba AshrafÎncă nu există evaluări

- Art PlaybookDocument30 paginiArt Playbookkenneth.sinotccÎncă nu există evaluări

- Buildings Department 144 Practice Note For Authorized Persons and Registered Structural EngineersDocument8 paginiBuildings Department 144 Practice Note For Authorized Persons and Registered Structural Engineersspeedo3076Încă nu există evaluări

- Construction Exhibit Air QualityDocument3 paginiConstruction Exhibit Air QualityMarvin ParaynoÎncă nu există evaluări

- Ontario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair OperationsDocument19 paginiOntario Regulation 278/05 Designated Substance - Asbestos On Construction Projects and in Buildings and Repair Operationsparallax1957Încă nu există evaluări

- Workers Welfare Standards Qatar 2022 v2 PDFDocument111 paginiWorkers Welfare Standards Qatar 2022 v2 PDFaamed100% (1)

- ICV Scorecard - Tawteen - ICV Scorecard Submission Template Guidelines - Version 1 4Document60 paginiICV Scorecard - Tawteen - ICV Scorecard Submission Template Guidelines - Version 1 4saji84Încă nu există evaluări

- Workers Welfare Standards Qatar 2022 v2 PDFDocument111 paginiWorkers Welfare Standards Qatar 2022 v2 PDFaamed100% (1)

- Workers Welfare Standards Qatar 2022 v2 PDFDocument111 paginiWorkers Welfare Standards Qatar 2022 v2 PDFaamed100% (1)

- Radiological Incident: February 20, 1999Document10 paginiRadiological Incident: February 20, 1999saji84Încă nu există evaluări

- Acute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.DDocument12 paginiAcute Renal Failure in The Intensive Care Unit: Steven D. Weisbord, M.D., M.Sc. and Paul M. Palevsky, M.Dkerm6991Încă nu există evaluări

- Cadorna, Chesca L. - NCPDocument2 paginiCadorna, Chesca L. - NCPCadorna Chesca LoboÎncă nu există evaluări

- ATI Respiratory PowerpointDocument90 paginiATI Respiratory PowerpointAnn KelseaÎncă nu există evaluări

- Science 9 Q4 SML17 V2Document15 paginiScience 9 Q4 SML17 V2HotdogÎncă nu există evaluări

- Notes Marriage and Family in Canon LawDocument5 paginiNotes Marriage and Family in Canon LawmacÎncă nu există evaluări

- READING 4 UNIT 8 Crime-Nurse Jorge MonarDocument3 paginiREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANÎncă nu există evaluări

- Service Manual: Multifunction Electrical Tester CalibratorDocument106 paginiService Manual: Multifunction Electrical Tester CalibratorJuan Carlos Ferrer OrtizÎncă nu există evaluări

- CrewmgtDocument36 paginiCrewmgtDoddy HarwignyoÎncă nu există evaluări

- Mixed Topic Revision 4Document18 paginiMixed Topic Revision 4YaakkwÎncă nu există evaluări

- Exercises - Fluid MechanicsDocument3 paginiExercises - Fluid MechanicsgemnikkicÎncă nu există evaluări

- Food Processing NC II - SAGDocument4 paginiFood Processing NC II - SAGNylmazdahr Sañeud DammahomÎncă nu există evaluări

- Arsenal Strength Catalog 6.2-1Document41 paginiArsenal Strength Catalog 6.2-1Mohammed NavedÎncă nu există evaluări

- Ventricular Septal DefectDocument8 paginiVentricular Septal DefectWidelmark FarrelÎncă nu există evaluări

- 41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Document167 pagini41403A - Guide - Rev - 12-20-17 - With Edits - 2-16-18Ronald KahoraÎncă nu există evaluări

- Gender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaDocument53 paginiGender, Slum Poverty and Climate Change in Flooded River Lines in Metro ManilaADBGADÎncă nu există evaluări

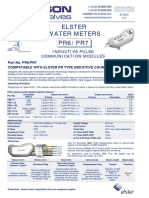

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 paginăData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaÎncă nu există evaluări

- Updoc - Tips Dictionar Foraj e RDocument37 paginiUpdoc - Tips Dictionar Foraj e RDaniela Dandea100% (1)

- Thanks For Visiting Our Page!: Hi Doc!Document15 paginiThanks For Visiting Our Page!: Hi Doc!bey luÎncă nu există evaluări

- Pip-Elsmt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetDocument11 paginiPip-Elsmt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetAjay BaggaÎncă nu există evaluări

- Chemical Reaction Engineering-II - R2015 - 10-04-2018Document2 paginiChemical Reaction Engineering-II - R2015 - 10-04-201818135A0806 MAKKUVA BHAVYAÎncă nu există evaluări