Documente Academic

Documente Profesional

Documente Cultură

VP Manufacturing Operations in Orange County CA Resume Harry James

Încărcat de

HarryJames1Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

VP Manufacturing Operations in Orange County CA Resume Harry James

Încărcat de

HarryJames1Drepturi de autor:

Formate disponibile

HARRY K.

JAMES

Orange, CA 92869 (714) 318-1338 hkjames@aol.com C. P. A., CANDIDATE, STATE OF CALIFORNIA M. B. A., UNIVERSITY OF PITTSBURGH B. S. E. E., CARNEGIE-MELLON UNIVERSITY B. S. PHYSICS, CARNEGIE-MELLON UNIVERSITY QUALIFICATIONS: Experienced technical and managerial problem solver with a successful history of executive leadership roles in technology-based companies characterized by a primary focus on profitability. PROFESSIONAL EXPERIENCE: VICE PRESIDENT, MANUFACTURING ASSEMBLY, TEST AND SYSTEMS Oct. 2010 to Sept. 2011 Semicoa Corporation, Costa Mesa, CA (Reconstituted after US Dept. of Justice forced divestiture; see below.) Ramped production capacity to meet demand for three (3) new product design families. Implemented disciplined procedure for non-production utilization of manufacturing capacity to avoid misstatement of manufacturing cost. Reduced scrap lots due to manufacturing process deficiencies by 90%. Reduced customer RMAs to less than 1%. Initiated/achieved ITAR registration as Empowered Official assuring compliance to export rules. VICE PRESIDENT OF TOTAL QUALITY Aug. 2009 to Oct. 2010 Semicoa Corporation, Costa Mesa, CA (Reconstituted after US Dept. of Justice forced divestiture; see below.) Achieved successful AS9100 certification three (3) times. Succeeded with 18 of 18 customer and agency (Defense Logistics Agency-DSCC) audits. Achieved State licensing and DSCC certification of Kr 85 Radiflo leak detection system. INDEPENDENT CONSULTANT (Selected Clients) Sept. 2008 to Aug. 2009 Champion-Arrowhead, LLC, Alhambra, CA. Established cost for lead-free plumbing valve configurations. Bodycote Thermal Processing Corp., Huntington Park, CA. Reduced in-process idle-time by 30%. Pyramid Technologies, Irvine, CA. Expert witness to testing excessively moisture-exposed stored devices. DIRECTOR OF TOTAL QUALITY May 2008 to Sept. 2008 Semicoa Semiconductors, Costa Mesa, CA (Military Qualified Discrete Transistor and Diode Manufacturer. Reported to CEO.) Directed corporate-wide implementation of four new military qualified products. Cut quality deficiencies and resolution timelines in half. Prepared for sale of company to its chief competitor. ENTERPRIZE RESOURCE PLANNING SYSTEM IMPLEMENTATION Feb. 2007 to Mar. 2008 Champion-Arrowhead, LLC, Alhambra, CA (Irrigation and Plumbing Component Manufacturer. Under contract to Robert Half International; reported to CFO.) Validated historical and current manufacturing labor and overhead rates. Delineated complex manufacturing processes to create part numbering system and appropriate indented Bills-ofMaterials. Implemented Great Plains System Inventory, Manufacturing and Material Resource Planning Modules. Acted as internal resource providing requested assistance to outside auditors. SABBATICAL LEAVE Dec. 2001 to Feb. 2007 Primary caregiver to my special-needs daughter and son. Resolved the brain biochemistry dysfunction for my children and promoted the correct medication intervention to provide an opportunity for normal lives.

DIRECTOR OF OPERATIONS Oct. 1999 to Dec. 2001 Xenonics, Inc., Carlsbad, CA (High-intensity hand-held light. Reported to the President.) Established disciplined operations infrastructure, documenting all processes and training production personnel to meet customer demand and quality requirements achieving successful production ramp-up. Reduced cost, relocating manufacturing capacity, personally laying out production floor, warehouse, production control and administrative offices while achieving zero defects with 100% on-time delivery. Assured scheduled customer delivery and product profitability, personally negotiating supplier payment schedules to assure component delivery and production continuity in order to be 100% on-time. Prepared for a reverse merger into a public shell, reconstructing inappropriately altered accounting records and identifying steps to bring financial statements into 100% conformance with GAAP. VICE PRESIDENT, MANUFACTURING Masimo Corporation, Irvine, CA (Medical pulse-oximeter devices. Reported to the President.) Jul. 1997 to Jul. 1998

Ended outside contract assembly, renovating the facility for long-term in-house automated assembly capacity, growing volume from zero to 20K units/month while saving contractor costs of over $1M. Created a formal five-year manufacturing business plan, capturing revenue projections and articulating the manufacturing strategies and tactics necessary, assuring gross margin profitability. Assured profitability in a competitive, market-price driven environment, personally negotiating purchase agreements, for immediate savings of $1.5M and savings over 24 months totaling $5.7M. Completed customer and regulatory agency required medical manufacturing certification, facilitating ISO-, FDA- and CE-markregistrations, all within 90 days.

PRESIDENT Jan. 1995 to Jul. 1997 XCEL Arnold Circuits, Inc., La Habra, CA (Rigid multilayer PCBs. Reported to the Board of Directors.) Increased manufacturing capacity, directing a $1.5 million capital expansion and equipment upgrade, resulting in an additional unit capacity of 50%. Created a unified sales strategy, consolidating disparate, segmented sales representative organization, resulting in a six-month sales increase of 25%. Accomplished customer required ISO registration, guiding the team that achieved registration, gaining an initial 25% increase in sales from existing customers while avoiding revenue loss of over $10M. Expanded revenue to other niches of the printed circuit board marketplace, targeting and acquiring a wholly-owned subsidiary that increased revenue by 35% and profitability by 10%. SR. VICE PRESIDENT & GENERAL MANAGER Sept. 1989 to Jan. 1995 XCEL Corporation, Digitran Division, Ontario, CA (Electromechanical subsystems. Joined as Vice President and Director, Engineering; concurrent assignment as Vice President and Chairman of the Technology Council. Reported to the CEO/COB.)

Avoided forced receivership by assuring sufficient working capital income to operate in a changing marketplace, establishing predictable month-by-month revenue and profits with 100% accuracy. Stabilized critical business revenue and volume over several years, converting from military to commercial sales, analyzing markets and R&D priorities, while maintaining revenue and volume. Improved profitability, relocating corporate headquarters and division operations, contributing annualized bottom-line profits of $3.5M.

VICE PRESIDENT, OPERATIONS Cal Flex Inc., Anaheim, CA (Flexible printed circuits. Reported to the President.)

Jan. 1988 to Sept. 1989

Reduced numerous errors and unnecessary levels of scrap costs, improving production release system, reducing quality rejections by 35%. Gained manufacturing consistency, establishing manufacturing discipline and formalizing scheduling, reducing delinquent backlog to zero. Eliminated inefficient documentation, installing a LAN and training staff, tripling office efficiency in processing purchase orders, interoffice mail and report distribution and financial report preparation. Avoided misstating balance sheet and P&L due to improper valuation, properly evaluating inventory, saving a $250K balance sheet write-down and P&L hit. HARRY JAMES Page 2

INDEPENDENT CONSULTANT (Selected clients:) Jul. 1985 to Jan. 1988 Polar Spring, Menlo Park, CA. Established capacity plan for purified water system. Rugged Digital Systems, Sunnyvale, CA. Created manufacturing ground rules for ruggedized PC. Read-Rite Corporation, Milpitas, CA. Merged the read/write head operations from Cybernex. Magnesys, Santa Clara, CA. Established production pilot line for bubble memory systems. DIRECTOR, DIVISION OPERATIONS Mar. 1983 to Jul. 1985 Apple Computer, Inc., Accessory Products Group, Garden Grove, CA (Injection molding and full electronics assembly/test for input devices; responsible for R&D and Marketing. Reported to Group VP.) Increased output 500%, automating manufacturing plant, increasing revenue over 18 months to $80M. Improved margins in a 1400-employee plant, installing 23 robots, cutting labor costs in half. Provided conscious, formal coaching to upgrade skills, leading my direct staff, creating and articulating a formal site Strategic Charter and Tactical Plan covering a planned business expansion of 500%. Reduced product defect levels, implementing statistical process control techniques, reducing defect levels from 10% to zero-defects, allowing ship-to-stock status with our principal customer. Improved materials and inventory control, establishing purchasing and storage discipline, reducing costs 10%, doubling turns and holding book-to-physical variance at $320 on an inventory base of $10M. MANUFACTURING MANAGER Mar. 1982 to Mar. 1983 Apple Computer, Inc., Peripheral Systems Division, San Jose, CA (Floppy/hard disk drives and all Apple diskette duplication. Reported to Division Operations Manager.) Achieved volume and quality goals, creating a training program and installing disciplined line controls, producing 350K/mo. diskette duplication volume with less than 0.5% in-house defect level. Coached and consciously fostered upgrading of staff supervisory skills, developing a career assessment technique for all subordinate staff members, resulting in adoption as a corporation standard. PERTINENT PRIOR EXPERIENCE: DEVELOPMENT ENGINEERING MANAGER (Signetics Corp.) SENIOR PROCESS ENGINEER (Hewlett-Packard) MANUFACTURING MANAGER (Fairchild Semiconductor) SENIOR PROCESS ENGINEER (Fairchild Semiconductor) PRODUCTION PLANNER (Fairchild Semiconductor) DEV. ENGINEER / PROJ. ENGINEER / PROD. PLANNER (Texas Instruments) May, 1978 to Mar. 1982 Apr. 1975 to May 1978 Oct. 1974 to Apr. 1975 Mar. 1973 to Oct. 1974 Oct. 1972 to Mar. 1973 Aug. 1969 to Oct. 1972

HARRY JAMES Page 3

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Model Risk TieringDocument32 paginiModel Risk TieringGabiÎncă nu există evaluări

- Product Costing and Cost Accumulation in A Batch Production EnvironmentDocument15 paginiProduct Costing and Cost Accumulation in A Batch Production EnvironmentKatCaldwellÎncă nu există evaluări

- Determinants of Effective Capacity PlanningDocument3 paginiDeterminants of Effective Capacity Planningkhatorbhai86% (7)

- Guesstimate & Case Interview ExamplesDocument10 paginiGuesstimate & Case Interview ExamplesVishwadeep Mishra100% (2)

- Designing Distribution Networks and Applications To Online Sales-Supply ChainDocument56 paginiDesigning Distribution Networks and Applications To Online Sales-Supply ChainArjun DasÎncă nu există evaluări

- Carrefour Project ReportDocument17 paginiCarrefour Project ReportAmitava Manna100% (1)

- Q1 Reconciliation by SKUsDocument38 paginiQ1 Reconciliation by SKUsErineÎncă nu există evaluări

- Bachelor of Logistics and Supply Chain Management PDFDocument93 paginiBachelor of Logistics and Supply Chain Management PDFquinter moraaÎncă nu există evaluări

- DMH Auditors Management Letter 1998Document38 paginiDMH Auditors Management Letter 1998williamblue100% (2)

- The Main Pillars of Good Governance - CooperativeDocument45 paginiThe Main Pillars of Good Governance - CooperativeEron Roi Centina-gacutan100% (1)

- Example:: Basis Assets LiabilitiesDocument23 paginiExample:: Basis Assets LiabilitiesAmbika Prasad ChandaÎncă nu există evaluări

- Subhiksha-Crm-Prm Case Study Iim Indore PGCRM BinduDocument17 paginiSubhiksha-Crm-Prm Case Study Iim Indore PGCRM BinduBindu Rathore100% (1)

- Exploiting Discrete Event Simulation To Improve A Chicken Supply ChainDocument11 paginiExploiting Discrete Event Simulation To Improve A Chicken Supply ChainBOHR International Journal of Advances in Management ResearchÎncă nu există evaluări

- Lesson 6 - Inventory CycleDocument42 paginiLesson 6 - Inventory CycleUnnamed homosapienÎncă nu există evaluări

- 1534 AsrDocument37 pagini1534 AsrElena JelerÎncă nu există evaluări

- Joint Cost QuizzerDocument5 paginiJoint Cost QuizzerxjammerÎncă nu există evaluări

- Market Research and Overall Performance of J&K Cements in Srinagar, KashmirDocument49 paginiMarket Research and Overall Performance of J&K Cements in Srinagar, KashmirDeepak Singh Bisht100% (2)

- DocumentDocument8 paginiDocumentmohab abdelhamedÎncă nu există evaluări

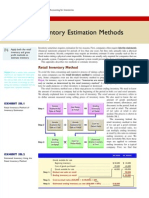

- Methods of Estimating InventoryDocument46 paginiMethods of Estimating Inventoryone formanyÎncă nu există evaluări

- BKAL1013 A201 Tutorial 3 333Document6 paginiBKAL1013 A201 Tutorial 3 333yussuf mohamedÎncă nu există evaluări

- The American Marketing Association Defines A Brand As ADocument12 paginiThe American Marketing Association Defines A Brand As AVish LalzareÎncă nu există evaluări

- LQMS 3.equipmentDocument14 paginiLQMS 3.equipmenttahir UddinÎncă nu există evaluări

- 05 Activity 2Document1 pagină05 Activity 2Febe Anne AglangaoÎncă nu există evaluări

- Guimbungan, Core Competency Module 1 - Part 3 PDFDocument11 paginiGuimbungan, Core Competency Module 1 - Part 3 PDFSharlyne K. GuimbunganÎncă nu există evaluări

- Income Statements For Group and SegmentsDocument24 paginiIncome Statements For Group and SegmentsADITYA VERMAÎncă nu există evaluări

- DellDocument2 paginiDellDeepan Chakravarthy KothandapaniÎncă nu există evaluări

- Centre of Information and TechnologyDocument8 paginiCentre of Information and TechnologyDanyal ChaudharyÎncă nu există evaluări

- Accounting ExamDocument7 paginiAccounting Examjerrytanny100% (1)

- Inventory EstimationDocument4 paginiInventory EstimationShy Ng0% (1)

- Obateru Adeyanju (Curriculum Vitae)Document2 paginiObateru Adeyanju (Curriculum Vitae)Adeyanju IsaiahÎncă nu există evaluări