Documente Academic

Documente Profesional

Documente Cultură

Textile Chemicals

Încărcat de

Syed Inamullah ShahDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Textile Chemicals

Încărcat de

Syed Inamullah ShahDrepturi de autor:

Formate disponibile

Textile Chemicals

During the process of manufacturing, textile has to go through a long process of chemical and non chemical treatments. The Textile finishing procedure includes preparation and pretreatment, dyeing, printing and refinement of fabrics. Certain Textile Chemical Products are highly specialized chemicals such as biocides, flame retardants, water repellents and warp sizes. Others are relatively simple chemicals or mixtures such as emulsified oils and greases, starch, sulfonated oils, waxes and some surfactants. Over sixty distinct textile chemical product classes are used in yarn formation, fabric pretreatment and finishing, textile laminating and coating, and other miscellaneous applications. Textile Chemicals - Categories and Subcategories Textile Chemicals During the process of manufacturing, textile has to go through a long process of chemical and non chemical treatments. The Textile finishing procedure includes preparation and pretreatment, dyeing, printing and refinement of fabrics. Certain Textile Chemical Products are highly specialized chemicals such as biocides, flame retardants, water repellents and warp sizes. Others are relatively simple chemicals or mixtures such as emulsified oils and greases, starch, sulfonated oils, waxes and some surfactants. Over sixty distinct textile chemical product classes are used in yarn formation, fabric pretreatment and finishing, textile laminating and coating, and other miscellaneous applications. Textile Chemicals - Categories and Subcategories From pretreatment of textile to its finishing, there are various categories and subcategories of textile chemicals : Pretereatment Chemicals scouring agents, low foam scouring agents, wetting agents, low foam wetting agents, sequestering agents, mercerising agents, peroxide stabilisers, peroxide killers, neutralizers Textile Dyeing Chemicals Solubalisers & dispersents, levelling agents, soaping agents, dyeing agents. Dyeing & Printing Chemicals vat levelling agents, thickners, binders, stain removers, anti back staining agents Finishing Chemicals cationic softners flakes/ paste, nonionic softners flakes/ paste, anionic softners flakes/ paste, reactive softners, cold water soluble softner flakes Antistatic Agents spin finishes, spining aids Other Speciality Chemicals. Chemical Based Procedures of Textile Manufacturing Various processes are carried by the textile production units where different chemicals find their usage. These processes include, Scouring, Bleaching, Desizing, Softening, Mercerization, Dyeing, etc. Scouring Raw textile materials, in their natural form,haveadditives, dirt, soil and other impurities that are not suitable for clothing materials. Pesticides, fungicides, worm killers, etc are also there in these raw materials. The removal of these matters is called scouring. It is done by adding suitable wetting agents, alkali or other chemical or non chemical materials. After scouring, the fabric gives better wetting and penetration properties. This makes the subsequent bleach process easy resulting in better dye uptake. Sodium hydrosulphite, Sodium hydrosulphite, Bleaching If cloth is to be finished white or is to be given serface ornamentation, all natural colours must be removed. This process of decolorization of raw textile material is bleaching. Bleaching is

classified in to oxidative bleaching and reductive bleaching. Generally oxidative bleaching is carried out using sodium hypochlorite, sodium chlorite or hydrogen peroxide. Natural fibres like cotton, ramie, jute, wool, bamboo are all generally bleached with oxidative methods. Reductive method of bleaching is done with Sodium hydrosulphite, a powerful reducing agent. Fibers like Polyamide, Polyacrylics and Polyacetates are generally bleached using reductive bleaching technology. After scouring and bleaching, Optical Brightening Agents (OBA), avaialable in different tints such as blue, violet and red, are applied to give the textile material a brilliant white look. Bleach Clean up Bleaches are highly reactive chemicals and any such chemicals left on the fabric can hinder the process of dyeing. Thus cleaning of bleach is also done. The bleach is neutralized with a precisely controlled reducing agent. Desizing During weaving, specially for the fabrics made from cotton or blends, the warp threads are coated with an adhesive substance known as 'size'. This is done to prevent the threads from breaking during weaving. Starch and its derivatives are the most common sizing agents. After weaving, the 'size' is removed again in order to prepare the fabric for dyeing and finishing. This is called Desizing. It is done by treating the fabric with chemicals such as acids, alkali or oxidising agents. Fabric softening Fabric softener also called Fabric Conditioner is used to prevent static cling and make fabric softer. Their use may however reduce the water absorption capabilities of the fabric. Fabric softeners work by coating the surface of the cloth fibers with a thin layer of chemicals. These chemicals have lubricant properties and are electrically conductive, resulting in smoother feel and preventing the buildup of static electricity. It also increases resistance to stains and reduces wrinkling. Mercerization In this process, textiles (typically cotton) are treated with a caustic solution for improving properties such as fiber strength, shrinkage resistance, luster, and dye affinity. Higher-end fabrics may be double or triple mercerized for added benefits. The treatment consists of dipping the yarn or fibre in a solution of sodium hydroxide and then treating the material with water or acid to neutralize the sodium hydroxide.

Dyeing water are used. are used during chemically the dye soluble so applied directly to

While dyeing, large volume of dyestuff, thickening agent and small amount of Many textile chemicals like Dispersing agent, Leveling agent, Acid buffer etc the process. The dyestuff have to be either fermented (for natural dye) or reduced ( for synthetic vat and sulfur dyes) before being applied. This makes that it can be absorbed by the fiber. Direct dyes are water soluble and can be the fiber from an aqueous solution. Most other classes of synthetic dyes, other than vat and sulfur dyes, are also applied in this way.

Printing Dyeing decorates fabric by imparting colours which can further be enhanced by printing colour designs on the finished cloths. Many kinds of dyes are used for printing including vat, reactive, naphthol, disperse and pigment colours among others. These are fixed to the fiber by means of resins. Sometimes cheap prints are also made with basic colours mixed with tartar emetic and tannic acid. Silk is usually printed with acid colours. Wool is treated with chlorine to make it more receptive to colours and to prevent shrinking and is printed with acid or chrome dyes. Fabics made of synthetic fibers are generally printed with disperse and cationic dyes. Problems in Finishing Processes and their Solutions It has been found that 70% of the problems in finishing processes are due to poor treatment of the fabric. Thus it becomes essential to give emphasis on right kind of chemicals and process control parameters right from pretreatment to ultimate dyeing and printing steps for getting best finished textile. Some of the faults due to poor pretreatment can be listed as poor absorbency, catalytic damage or poor fluidity, stains , Moire effect, shade change from selvedge to selvedge, shrinkage/distortion, creasing/chafe marks, inferior brightness/luster, cloudy dyeing, skitteriness, pale areas, darkspots, ropemarks etc. Most of these faults can be easily corrected with certain precautions like use of specialty chemicals, suitable heat setting temperatures, thorough relaxation of the material, controlled tension and uniformity of batching during pretreatment and

checking for rough patches in the machine. While dyeing, selection of dyes with better dispersion stability, use of efficient dispersants, controlled heating when the dye exhibits a particularly high rate of exhaustion, use of anti foamers and special chemicals like welting agent or defoamer combinations etc. can give the best results.

From pretreatment of textile to its finishing, there are various categories and subcategories of textile chemicals : Pretereatment Chemicals scouring agents, low foam scouring agents, wetting agents, low foam wetting agents, sequestering agents, mercerising agents, peroxide stabilisers, peroxide killers, neutralizers Textile Dyeing Chemicals Solubalisers & dispersents, levelling agents, soaping agents, dyeing agents. Dyeing & Printing Chemicals vat levelling agents, thickners, binders, stain removers, anti back staining agents Finishing Chemicals cationic softners flakes/ paste, nonionic softners flakes/ paste, anionic softners flakes/ paste, reactive softners, cold water soluble softner flakes Antistatic Agents spin finishes, spining aids Other Speciality Chemicals. Chemical Based Procedures of Textile Manufacturing Various processes are carried by the textile production units where different chemicals find their usage. These processes include, Scouring, Bleaching, Desizing, Softening, Mercerization, Dyeing, etc. Scouring Raw textile materials, in their natural form,haveadditives, dirt, soil and other impurities that are not suitable for clothing materials. Pesticides, fungicides, worm killers, etc are also there in these raw materials. The removal of these matters is called scouring. It is done by adding suitable wetting agents, alkali or other chemical or non chemical materials. After scouring, the fabric gives better wetting and penetration properties. This makes the subsequent bleach process easy resulting in better dye uptake. Bleaching If cloth is to be finished white or is to be given serface ornamentation, all natural colours must be removed. This process of decolorization of raw textile material is bleaching. Bleaching is classified in to oxidative bleaching and reductive bleaching. Generally oxidative bleaching is carried out using sodium hypochlorite, sodium chlorite or hydrogen peroxide. Natural fibres like cotton, ramie, jute, wool, bamboo are all generally bleached with oxidative methods. Reductive method of bleaching is done with Sodium hydrosulphite, a powerful reducing agent. Fibers like Polyamide, Polyacrylics and Polyacetates are generally bleached using reductive bleaching technology. After scouring and bleaching, Optical Brightening Agents (OBA), avaialable in different tints such as blue, violet and red, are applied to give the textile material a brilliant white look. Bleach Clean up Bleaches are highly reactive chemicals and any such chemicals left on the fabric can hinder the process of dyeing. Thus cleaning of bleach is also done. The bleach is neutralized with a precisely controlled reducing agent. Desizing During weaving, specially for the fabrics made from cotton or blends, the warp threads are coated with an adhesive substance known as 'size'. This is done to prevent the threads from breaking during weaving. Starch and its derivatives are the most common sizing agents. After weaving, the 'size' is removed again in order to prepare the fabric for dyeing and finishing. This is called Desizing. It is done by treating the fabric with chemicals such as acids, alkali or oxidising agents. Fabric softening Fabric softener also called Fabric Conditioner is used to prevent static cling and make fabric softer. Their use may however reduce the water absorption capabilities of the fabric. Fabric softeners work by coating the surface of the cloth fibers with a thin layer of chemicals. These chemicals have lubricant properties and are electrically conductive, resulting in smoother feel and preventing the buildup of static electricity. It also increases resistance to stains and reduces wrinkling. Mercerization In this process, textiles (typically cotton) are treated with a caustic solution for improving properties such as fiber

strength, shrinkage resistance, luster, and dye affinity. Higher-end fabrics may be double or triple mercerized for added benefits. The treatment consists of dipping the yarn or fibre in a solution of sodium hydroxide and then treating the material with water or acid to neutralize the sodium hydroxide. Dyeing While dyeing, large volume of dyestuff, thickening agent and small amount of water are used. Many textile chemicals like Dispersing agent, Leveling agent, Acid buffer etc are used during the process. The dyestuff have to be either fermented (for natural dye) or chemically reduced ( for synthetic vat and sulfur dyes) before being applied. This makes the dye soluble so that it can be absorbed by the fiber. Direct dyes are water soluble and can be applied directly to the fiber from an aqueous solution. Most other classes of synthetic dyes, other than vat and sulfur dyes, are also applied in this way. Printing Dyeing decorates fabric by imparting colours which can further be enhanced by printing colour designs on the finished cloths. Many kinds of dyes are used for printing including vat, reactive, naphthol, disperse and pigment colours among others. These are fixed to the fiber by means of resins. Sometimes cheap prints are also made with basic colours mixed with tartar emetic and tannic acid. Silk is usually printed with acid colours. Wool is treated with chlorine to make it more receptive to colours and to prevent shrinking and is printed with acid or chrome dyes. Fabics made of synthetic fibers are generally printed with disperse and cationic dyes. Problems in Finishing Processes and their Solutions It has been found that 70% of the problems in finishing processes are due to poor treatment of the fabric. Thus it becomes essential to give emphasis on right kind of chemicals and process control parameters right from pretreatment to ultimate dyeing and printing steps for getting best finished textile. Some of the faults due to poor pretreatment can be listed as poor absorbency, catalytic damage or poor fluidity, stains , Moire effect, shade change from selvedge to selvedge, shrinkage/distortion, creasing/chafe marks, inferior brightness/luster, cloudy dyeing, skitteriness, pale areas, darkspots, ropemarks etc. Most of these faults can be easily corrected with certain precautions like use of specialty chemicals, suitable heat setting temperatures, thorough relaxation of the material, controlled tension and uniformity of batching during pretreatment and checking for rough patches in the machine. While dyeing, selection of dyes with better dispersion stability, use of efficient dispersants, controlled heating when the dye exhibits a particularly high rate of exhaustion, use of anti foamers and special chemicals like welting agent or defoamer combinations etc. can give the best results.

S-ar putea să vă placă și

- Types of Dyeing ProcessesDocument5 paginiTypes of Dyeing ProcessesSyed Inamullah ShahÎncă nu există evaluări

- Surfactants: Types, Properties, and UsesDocument2 paginiSurfactants: Types, Properties, and UsesSyed Inamullah ShahÎncă nu există evaluări

- Steam: Dry and Wet SteamDocument6 paginiSteam: Dry and Wet SteamSyed Inamullah ShahÎncă nu există evaluări

- Roving FrameDocument8 paginiRoving FrameSyed Inamullah Shah0% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Raw Materials AssuranceDocument57 paginiRaw Materials Assuranceស្រី ស្រស់Încă nu există evaluări

- Impact of Traditional Textile On The Gross Domestic Product - GDP of BangladeshDocument9 paginiImpact of Traditional Textile On The Gross Domestic Product - GDP of BangladeshInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- OE SpinningDocument12 paginiOE SpinningVijay KhoiwalÎncă nu există evaluări

- PTT Seminar WorkDocument28 paginiPTT Seminar WorkPiyush TakkarÎncă nu există evaluări

- Task 4.2 Worksheet Audreyna KeischaDocument2 paginiTask 4.2 Worksheet Audreyna Keischaaudreyna keischaÎncă nu există evaluări

- Presentation Sports WearDocument21 paginiPresentation Sports WearravibaroraÎncă nu există evaluări

- Making Crochet DollDocument20 paginiMaking Crochet Dollrodica144Încă nu există evaluări

- TTS BangladeshDocument15 paginiTTS Bangladeshpadhu_pÎncă nu există evaluări

- Presentation - MKT209m - Ao Dai Dan Phuong - FinalDocument24 paginiPresentation - MKT209m - Ao Dai Dan Phuong - FinalQuân NgôÎncă nu există evaluări

- LamiAid A For FIBC LaminationDocument1 paginăLamiAid A For FIBC LaminationvinchemÎncă nu există evaluări

- Survey explores consumer preferences for wrist watchesDocument14 paginiSurvey explores consumer preferences for wrist watchessyainsiÎncă nu există evaluări

- Entrepreneur ProfileDocument1 paginăEntrepreneur ProfilefarahÎncă nu există evaluări

- Guide To Dyeing WoolDocument18 paginiGuide To Dyeing WoolPenny Peden100% (2)

- Nikki Lissoni Fall Winter CollectionDocument6 paginiNikki Lissoni Fall Winter CollectionDarren McCormick JewelleryÎncă nu există evaluări

- PRE-PRODUCTION MANUAL With Annexures Draft 1Document25 paginiPRE-PRODUCTION MANUAL With Annexures Draft 1priyalÎncă nu există evaluări

- Lec 1-2 Overview of Textile EngineeringDocument13 paginiLec 1-2 Overview of Textile EngineeringMujahid MehdiÎncă nu există evaluări

- Moo Book WebDocument68 paginiMoo Book WebimeldarelixÎncă nu există evaluări

- Chapter 3 Introduction of Report No 1 of 2018 - Economic Sector Government of MaharashtraDocument66 paginiChapter 3 Introduction of Report No 1 of 2018 - Economic Sector Government of MaharashtraHarish Kumar.VÎncă nu există evaluări

- Handloom Industry and Its Economic Impact-A Study of Nagaon District With Special Focus On Gerjaipam VillageDocument13 paginiHandloom Industry and Its Economic Impact-A Study of Nagaon District With Special Focus On Gerjaipam VillageagrimaÎncă nu există evaluări

- Learning Outcome 2: Perform Simple CalculationsDocument22 paginiLearning Outcome 2: Perform Simple CalculationsLouiseÎncă nu există evaluări

- Zara's Supply Chain Structure and PerformanceDocument33 paginiZara's Supply Chain Structure and PerformanceSourav Kumar100% (1)

- Textile Contamination Removal: Removal of Polypropylene From The Knitted FabricsDocument1 paginăTextile Contamination Removal: Removal of Polypropylene From The Knitted FabricsMALIK ABDUL RAFAYÎncă nu există evaluări

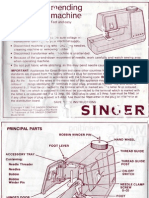

- Singer Magic Tailor ManualDocument10 paginiSinger Magic Tailor ManualManuel Fernández-Cuartero Luque50% (2)

- IM - LMW Rings R161 09-FEB-2021Document18 paginiIM - LMW Rings R161 09-FEB-2021pravat kumar routÎncă nu există evaluări

- C&A Purchase Order 72928220 Style 84759 159 11 860Document4 paginiC&A Purchase Order 72928220 Style 84759 159 11 860Tanvir SazzadÎncă nu există evaluări

- Greenland Playtime HoodieDocument3 paginiGreenland Playtime HoodiealexÎncă nu există evaluări

- Lavadora Secadora LG WD15EGS6 PDFDocument100 paginiLavadora Secadora LG WD15EGS6 PDFK-Search100% (1)

- PolyesterDocument20 paginiPolyesterShailendra MishraÎncă nu există evaluări

- Hemtextil 2011Document4 paginiHemtextil 2011ashish mishraÎncă nu există evaluări

- Sanitary Napkin - Low Investment ProjectDocument3 paginiSanitary Napkin - Low Investment ProjectsanjnuÎncă nu există evaluări