Documente Academic

Documente Profesional

Documente Cultură

Yarn Spinning For Beginners

Încărcat de

Soumen ChowdhuryDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Yarn Spinning For Beginners

Încărcat de

Soumen ChowdhuryDrepturi de autor:

Formate disponibile

Yarn Spinning | For Beginners

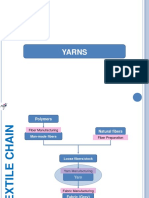

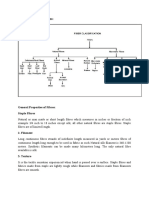

Yarn Spinning Combining staple fibers into yarns Spinning Systems Spinning systems- produce a yarn based on fiber characteristics of fiber Cotton System (staples less than 2.5 inches) Opening Carding Picker: Fibers made parallel, oriented. Short fibers removed. Blending can take place here. Layer pulled into SLIVER Cotton System Combing Drawing Redrawing This is an optional step. Only used in making certain cotton yarns. Fibers made more parallel. Short fibers removed. Smoother, superior yarns result. Several card slivers combined for uniformity. Fibers made more parallel Slivers combined for uniformity Cotton System Roving (twisting) Spinning Sliver attenuated (drawn out to finer diameter) and twisted. ROVING Roving attenuated and twist inserted Combed/Carded Yarns Yarns made with the combing step included are called Yarns made with the combing step Combed yarns are of higher quality, and are more expensive than carded yarns. Combing is not necessary Combed/Carded Yarns In a combed polyester/cotton blend yarn, only the cotton portion needs to be combed. A 50/50 polyester/combed cotton yarn is of higher quality than a 50/50 polyester/cotton yarn. Combing is necessary for the production of high-count (fine) cotton yarns, like those used in pin point oxford cloth, but is not necessary for low-count cotton yarns, like those used in denim. Spinning Depending upon the direction of rotation of the spindle during yarn manufacture, yarns may have either S-twist (left hand twist) or Z-twist (right hand twist). Single yarns, either combed or carded, may be combined by twisting two or more together, to produced plied yarns. The ply twist is usually opposite the yarn twist.

Ring Spinning any staple fibers <2.5 size="+3">Newer Spinning Processes Two more modern spinning processes have been increasing in popularity, because they produce yarn at a faster, more economical rate: Open-End Spinning Also called break spinning, this process produces yarns at least 3X faster than ring spinning, depending upon the fineness of the yarn. Carded Omits roving formation. Open-End Spinning Compared to an equivalent size ring-spun yarn, open-end spun yarn is weaker but more uniform. The yarn has a smooth even surface. bulkier, rougher, more absorbent, more uniform in strength, less likely to pill Only low and medium-count yarns can be made by this process. Open-end Ring spun Air-Jet Spinning Production rate is up to 10X that of ring spinning, and at least 2X that of open-end spinning. Sliver is Air-Jet Spinning Medium to Air-jet yarns are weaker than either ring spun or open- end spun yarns. Long staple spinning systems Two spinning systems exist for the spinning of the long staple (2 to 10) fibers into yarn. Worsted System (fibers 2-10 long) Machinery is different, but process is similar to combed cotton production. Fibers are highly parallelized prior to twisting into yarn. Yarns are used for slacks, sport coats, suits, overcoats, some sweaters, and carpet. They are stronger and firmer Woolen System Totally different Yarns are softer, warmer, bulkier, and weaker than worsted yarns. Woolen/Worsted Yarns The warmth of any apparel or textile product is mainly due to its ability to maintain dead-air space within the yarns. Because of the high degree The worsted spinning of wool fibers does achieve good alignment, but at a much higher cost than in woolen spinning. Examples of Cotton System Yarns: 100% Cotton, for denim 100% Combed Cotton, for Blouses 65% Polyester/35% Cotton, for Slacks 50% Polyester/50% Combed Cotton for Shirts 50% Polyester/50% Rayon, for Shirts 70% Polyester/30% Acrylic, for Knits Examples of Woolen System Yarns: Examples of Worsted System Yarns: 100% Wool, for Suits 55% Polyester/45% Wool, for Suits 65% Polyester/20% Rayon/15% Acrylic, for Slacks 100% Nylon, for Carpet 100% Polyester, for Carpet

Different fibers are present in the same yarn in planned proportions

Mixture Mixture- yarns (warp of one type, fill of another)

Combinations CombinationsWhy Blend Fibers Fabrics have a better combination of performance characteristics- Improve spinning, weaving, finishing, uniformity To obtain better fabric appearance- rabbit hair for certain appearance To minimize fiber costTo obtain unique color effects-

Compound and Fancy Yarns Complex Yarns (Novelty Yarns, Fancy Yarns) Complex yarns are used to provide visual interest and surface texture to a fabric. Only 5 to 10% of all yarns manufactured fall into this category. Complex yarns are Plied complex yarns usually include an effect yarn (E), a core yarn (C), and sometimes a binder yarn (B). Continued . . . . . Named Plied, but seldom add strength to fabric If used in only one direction they are used in the fill Usually the smaller the novelty effect the more durable the fabric (less effected by abrasion, less snagging) Tweed Flecks of short colored fibers twisted into the yarn, often wool WHY? Slub- single, spun, fancy yarns, varying yarn diameters along their length; these are usually singles. True slub- twist varied at regular intervals (thicker less twist) Elongated tufts of fiber into yarn at regular intervals with a core or binder yarn Types of complex yarns Thick and thin Chenille Resembles a caterpillar in appearance. Flock or flake, fleck

Types of complex yarns Spiral and Corkscrew Gimp and Ratin E and C are plied around each other; E is larger than in ratin than for gimp, effect ply is twisted around ground. At intervals the effect yarn kinks out and back on itself. Crepe highly twisted simple yarn Boucl, loop, and snarl

Compound or CompositeYarns Regular in appearance along length Covered Yarns: central yarn that is completely covered Core wrapped with 1 or more yarns Core Spun Yarns: Core wrapped with fiber

Yarn Quality Will it be strong enough to withstand the stress of the loom Better quality-

S-ar putea să vă placă și

- Classification of YarnDocument28 paginiClassification of YarnSofiane SouÎncă nu există evaluări

- YarnDocument37 paginiYarnMohammad HossainÎncă nu există evaluări

- Textile Yarn:: Types of Yarn - Characteristics of YarnDocument8 paginiTextile Yarn:: Types of Yarn - Characteristics of YarnHumaun Kabir100% (1)

- Yarns Fabric KnowledgeDocument15 paginiYarns Fabric Knowledgeishajain11Încă nu există evaluări

- Different Types of WeavesDocument6 paginiDifferent Types of WeavesShoaib ChaudhryÎncă nu există evaluări

- YarnsDocument38 paginiYarnsAbhinav VermaÎncă nu există evaluări

- R101 Lesson 7 Fabrics, Finishes and FurnishingsDocument44 paginiR101 Lesson 7 Fabrics, Finishes and FurnishingsAman KeltaÎncă nu există evaluări

- Fiber PropertiesDocument24 paginiFiber Propertiessatheeshpag12367% (3)

- Classification of Textiles PDFDocument52 paginiClassification of Textiles PDFsathish_201020100% (1)

- Yarn StudentsDocument32 paginiYarn Studentskartika ranaÎncă nu există evaluări

- Textile InternshipDocument62 paginiTextile InternshipNeetek SahayÎncă nu există evaluări

- SpinningDocument141 paginiSpinningKathirrveluSubramainanÎncă nu există evaluări

- 6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenDocument20 pagini6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenBebi WakaÎncă nu există evaluări

- Carpets: BY, Sushma RoyDocument34 paginiCarpets: BY, Sushma Royharshal kushwahÎncă nu există evaluări

- Terry Knit FabricsDocument45 paginiTerry Knit FabricsSaumya KharyaÎncă nu există evaluări

- SILK - An IntroductionDocument27 paginiSILK - An IntroductionGuneet KaurÎncă nu există evaluări

- YARN and ITS ConstructionDocument11 paginiYARN and ITS Constructionreshma_alexanderÎncă nu există evaluări

- YarnsDocument27 paginiYarnsnitishkohli75% (4)

- Properties Natural FibresDocument46 paginiProperties Natural FibresanishaÎncă nu există evaluări

- Cotton Spinning Lecture Notes For Students (07 Mart 2011)Document144 paginiCotton Spinning Lecture Notes For Students (07 Mart 2011)Onur ErbasÎncă nu există evaluări

- Yarn Numbering SystemsDocument10 paginiYarn Numbering Systemsdr tamerÎncă nu există evaluări

- Fibre To Fabric Notes 1Document3 paginiFibre To Fabric Notes 1Mohan Reddy KothapetaÎncă nu există evaluări

- Smart FabricsDocument16 paginiSmart FabricsVenkatesh Malpani100% (1)

- Advance Fibre and Yarn Testing InstrumentsDocument112 paginiAdvance Fibre and Yarn Testing Instrumentsmeghana raj100% (1)

- Fibre ScienceDocument38 paginiFibre ScienceVenkatesh Bairabathina100% (1)

- Sewing ThreadDocument55 paginiSewing Threadচৌদ্দগ্রাম পৌর আমজনতা0% (1)

- Factors Affecting Yarn StrengthDocument11 paginiFactors Affecting Yarn StrengthAbhishek ThakurÎncă nu există evaluări

- Textile Yarns PDFDocument35 paginiTextile Yarns PDFVu Ngo Tuan100% (1)

- Complete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Document98 paginiComplete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Muhammad IlyasÎncă nu există evaluări

- Non Woven Home FurnishingsDocument6 paginiNon Woven Home FurnishingsMuhammad Farooq KokabÎncă nu există evaluări

- New Fibres For Home TextilesDocument4 paginiNew Fibres For Home TextilesVasant KothariÎncă nu există evaluări

- Denim Fabric ManufacturingDocument22 paginiDenim Fabric ManufacturingFazley Elahi100% (2)

- Pilling of TextilesDocument16 paginiPilling of TextilesAthirah Mansor100% (2)

- Nannu Spinning Mills Limited Quality Control Department: Melange YarnDocument10 paginiNannu Spinning Mills Limited Quality Control Department: Melange YarnAhmed LikhonÎncă nu există evaluări

- Applications of Nonwovens in Medical TextileDocument17 paginiApplications of Nonwovens in Medical TextileDipesh JainÎncă nu există evaluări

- Woven Fabrics: W.I. Samarasinghe Sri Lanka Institute of Textile & ApparelDocument32 paginiWoven Fabrics: W.I. Samarasinghe Sri Lanka Institute of Textile & ApparelAjith SatyapalaÎncă nu există evaluări

- Principles of Knitting TechnologyDocument18 paginiPrinciples of Knitting Technologysaadbinazad100% (1)

- Yarn Manufacturing ProcessDocument92 paginiYarn Manufacturing ProcessUjjwal Anand50% (2)

- Btech Syllabus Textile EngineeringDocument68 paginiBtech Syllabus Textile EngineeringShubham BansalÎncă nu există evaluări

- Fibres To FabricDocument23 paginiFibres To FabricPallavi Luthra KapoorÎncă nu există evaluări

- Featureso of Different Weaves 13.10Document28 paginiFeatureso of Different Weaves 13.10Atik U BhuiyanÎncă nu există evaluări

- Recent Development of Circular KnittingDocument32 paginiRecent Development of Circular KnittingHarshitha A100% (1)

- What Is Sectional Warping?: Creel Drum BeamDocument6 paginiWhat Is Sectional Warping?: Creel Drum Beamamar9247Încă nu există evaluări

- Yarn Count Conversion CalculationDocument3 paginiYarn Count Conversion CalculationMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Textile Testing and Product EvaluationDocument64 paginiTextile Testing and Product EvaluationBhaswati PandaÎncă nu există evaluări

- WoolDocument69 paginiWoolnitishkohli100% (5)

- Textile-Yarns Lap FormationDocument21 paginiTextile-Yarns Lap FormationLAXMAN SINGH SANKHLAÎncă nu există evaluări

- Classification of FibresDocument12 paginiClassification of FibresARYAN RATHOREÎncă nu există evaluări

- Synthetic FibreDocument6 paginiSynthetic FibreswaroophoppyÎncă nu există evaluări

- Training Report of Gcti Tarinees MS WORDDocument55 paginiTraining Report of Gcti Tarinees MS WORDAakash NagpalÎncă nu există evaluări

- Agrotextiles - Study Material - 8th Semester BTech - 2023Document27 paginiAgrotextiles - Study Material - 8th Semester BTech - 2023Sanju100% (1)

- Textile ScienceDocument22 paginiTextile ScienceAbhinav VermaÎncă nu există evaluări

- Ramie PDFDocument6 paginiRamie PDFkabir_ce06038Încă nu există evaluări

- Cotton, Polyester & Cotton Polyester BlendDocument4 paginiCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Textur Game Engine ProgrammingDocument30 paginiTextur Game Engine ProgrammingSoumen ChowdhuryÎncă nu există evaluări

- Opera Mini 4.21 HUI200b4Document1 paginăOpera Mini 4.21 HUI200b4Soumen ChowdhuryÎncă nu există evaluări

- Thermodynamic CycleDocument13 paginiThermodynamic CycleAF EYah MalikÎncă nu există evaluări

- Thermod 10Document13 paginiThermod 10Soumen ChowdhuryÎncă nu există evaluări

- Arts of Mindanao AttireDocument31 paginiArts of Mindanao AttireClaudette Gutierrez Caballa100% (1)

- Sewing Tools and Its UsesDocument10 paginiSewing Tools and Its UsesEllen BiescasÎncă nu există evaluări

- Newlong DN 2Document40 paginiNewlong DN 2garciac12Încă nu există evaluări

- OAKLEY Katalog OblečeníDocument236 paginiOAKLEY Katalog OblečenívladimirsalatÎncă nu există evaluări

- Kaitag - A Personal ViewDocument40 paginiKaitag - A Personal ViewR. John Howe100% (2)

- Lot Wise Packing ProductionDocument2 paginiLot Wise Packing ProductionMd. Mamunur RashidÎncă nu există evaluări

- Art Appreciation Book Final Pub. 2018 1Document83 paginiArt Appreciation Book Final Pub. 2018 1한서린85% (172)

- Application Form 2018 19Document3 paginiApplication Form 2018 19Sukriti MandalÎncă nu există evaluări

- ARCH121 Test 8Document5 paginiARCH121 Test 8Argian khairullahÎncă nu există evaluări

- Crochet Gingerbread Man Amigurumi Free PDF PatternDocument5 paginiCrochet Gingerbread Man Amigurumi Free PDF Patternsarah.rinearÎncă nu există evaluări

- History of FashionDocument23 paginiHistory of FashionRohit SinghÎncă nu există evaluări

- Handouts 4Document3 paginiHandouts 4Dexee Giel CanoyÎncă nu există evaluări

- 6136 26 Patron GratisDocument4 pagini6136 26 Patron GratisCarmen LuzónÎncă nu există evaluări

- Kansai DLR-1502V, 1501M, 1501MF, 1502T, 1502V-HD, 1502L, 1503V, 1503V-HD PDFDocument40 paginiKansai DLR-1502V, 1501M, 1501MF, 1502T, 1502V-HD, 1502L, 1503V, 1503V-HD PDFJhon GomezÎncă nu există evaluări

- BooksDocument10 paginiBooksPundeep ToorÎncă nu există evaluări

- DwadDocument2 paginiDwadPizza BoyÎncă nu există evaluări

- Winter Blanket KAL Knitting Pattern For Christmas in Debbie Bliss Rialto 2NDK 2Document9 paginiWinter Blanket KAL Knitting Pattern For Christmas in Debbie Bliss Rialto 2NDK 2alevegalv2Încă nu există evaluări

- Sipitaly Catalogue PS342-FG1SIPDocument2 paginiSipitaly Catalogue PS342-FG1SIPjhonatan garciaÎncă nu există evaluări

- Experiment No 1: Study On Yarn Path Diagram of A Shuttle Loom With Different PartsDocument13 paginiExperiment No 1: Study On Yarn Path Diagram of A Shuttle Loom With Different PartsRubel alamÎncă nu există evaluări

- LoomDocument23 paginiLoomAditi KÎncă nu există evaluări

- Crochet Pattern Naughty Monkey: Author - Juliia PyhaDocument16 paginiCrochet Pattern Naughty Monkey: Author - Juliia PyhaMayi Romero Chancafe100% (6)

- CPAR Lesson 2Document21 paginiCPAR Lesson 2Leoben Rey CagandeÎncă nu există evaluări

- Ballistic Protective ClothingDocument36 paginiBallistic Protective ClothingMukut Basu Badhan0% (1)

- Pfaff Creative 1371 Sewing Machine Instruction ManualDocument121 paginiPfaff Creative 1371 Sewing Machine Instruction ManualiliiexpugnansÎncă nu există evaluări

- Bunnypattern 1Document6 paginiBunnypattern 1Gyányi PanniÎncă nu există evaluări

- EuroPro Next 30 Sewing Machine Instruction ManualDocument35 paginiEuroPro Next 30 Sewing Machine Instruction ManualiliiexpugnansÎncă nu există evaluări

- C. To Congratulate Sonia For Her SuccessDocument12 paginiC. To Congratulate Sonia For Her SuccessIndra AzhaÎncă nu există evaluări

- How To Make Teddy BearsDocument68 paginiHow To Make Teddy BearsIsabel Arenilla JuanasÎncă nu există evaluări

- What Is Art Crafts?Document16 paginiWhat Is Art Crafts?John DiestroÎncă nu există evaluări

- Questionnarie Survey 1 PDFDocument17 paginiQuestionnarie Survey 1 PDFDevi Saranya SÎncă nu există evaluări