Documente Academic

Documente Profesional

Documente Cultură

Thomas Coskeran Waste Mapping

Încărcat de

DaisyDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Thomas Coskeran Waste Mapping

Încărcat de

DaisyDrepturi de autor:

Formate disponibile

Thomas Coskeran: Waste mapping 4.4.

2006

Waste mapping and

waste minimisation

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Overview

• Nature of waste mapping

• Reasons for waste mapping

• Methodology of waste mapping

– Envirowise guide ET219: Waste

Mapping

• Examples

• Exercise

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 1

Thomas Coskeran: Waste mapping 4.4.2006

What is waste mapping?

• A recognised way to identify where

waste is occurring

• Often the first step towards tackling

waste problems

• Helps to build up picture of where actual

resource use is taking place

• Can identify the savings in wastes

arising that can be made

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

What is waste mapping?

• Not just mapping the production process

– Should go right across all activities in the

organisation

• Used in more than just industrial and

commercial organisations

• Being applied in the public sector in the UK:

National Health Service and Higher

Education

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 2

Thomas Coskeran: Waste mapping 4.4.2006

Waste mapping in UK

Higher Education

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Waste Mapping and Waste

Minimisation

• Will start the waste minimisation effort of the

business

– Part of the assessment phase

• Mapping is key to finding opportunities to

prevent or cut waste arising

• Will also highlight where re-use, recycling and

recovery can be conducted within the

organisation

• Focus on waste creation points

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 3

Thomas Coskeran: Waste mapping 4.4.2006

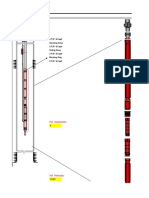

Steps In Waste Minimisation

COMMITMENT

ASSESSMENT

PHASE

RANKING OF

FEEDBACK OPTIONS

REVIEW AND FEASIBILITY

AUDIT ASSESSMENT

IMPLEMENTATION

AND MANAGEMENT

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Why use waste mapping?

• Simple process that easily understood

by non-specialists

• Can be implemented in an organisation

without high levels of technical

competence in waste management

• Easy to apply in the first instance

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 4

Thomas Coskeran: Waste mapping 4.4.2006

Why use waste mapping?

• Gives clear overview of where waste is

being generated

• Can reveal waste disposal being

handled by different contracts

– Scope for cost savings

• Can work out why waste is occurring

• Assists in calculating costs of waste to

the organisation

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Direct economic benefits of

mapping waste

• Reduces overheads and increase

competitiveness and profitability

– All companies produce waste, even the

efficient ones

– Companies of all sizes underestimate the

costs of waste

• Improves environmental performance and

so enhance image with customers

– increased sales

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 5

Thomas Coskeran: Waste mapping 4.4.2006

Direct economic benefits of

mapping waste

• Helps organisation to comply with legislation

and avoid potential lawsuits

• Reduces insurance premiums

• Improves workplace environment and worker

productivity

• Reduces UK Landfill Tax liability (currently

£21 per tonne for active waste; £2 per tonne

for inert waste)

– But set to rise to £35 per tonne for active waste

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Waste mapping in the

organisation

Purchase

Process

Package

Store

Use

Disposal

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 6

Thomas Coskeran: Waste mapping 4.4.2006

Waste mapping in the

organisation: potential problems

Purchase

Process

Package

Store

Use

Disposal

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Identifiable Waste Sources

• Raw materials and other consumables

• Packaging

• Solid: off-cuts and defective products

• Water/other liquids

• Gaseous including VOCs (volatile organic

compounds) and combustion emissions

• Materials covered by Special Waste

Regulations

• Solvents

• Energy

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 7

Thomas Coskeran: Waste mapping 4.4.2006

How to map waste

• Vital to get senior management commitment

• Set up company team to tackle the project

• Appoint project “champion” and publicise

• Draw up map of company site

– Can be simple or complex depending on scale of

problems faced

– Complexity can increase with each iteration of the

map

• Combine with symbols to identify waste

points

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Symbols for Waste Map

Source: ET219

Waste Mapping

• Not an exhaustive list nor is it compulsory

• Can be modified to reflect situation within the

organisation

• Note Labour as source of potential waste

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 8

Thomas Coskeran: Waste mapping 4.4.2006

How to map waste

• Begin with walk around site to identify

sources of waste

• ET219 Guide provides examples of

types of waste to consider

• Focus at outset should be on potentially

important sources of waste

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

How to map waste

• Look for wastes produced at each stage of

production

– from delivery to despatch

• Talk to employees involved in the production

process

• Use representatives from other departments

within the organisation when considering

waste sources

– they may see things differently

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 9

Thomas Coskeran: Waste mapping 4.4.2006

Investigating inputs and

outputs

• Need to know all inputs, outputs and

associated levels of waste for different

operations within the organisation

– NB again: not just production processes

• Consider areas where raw materials

and finished products are stored

• Also examine storage areas for waste

generated during production process

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Waste Mapping Activities

Inputs Processes Outputs

• Materials • Production • Packaging

• Energy • Storage and • Special

• Water materials wastes

• Packaging handling • Effluent

• Product design • Emissions

• Transport and • Spills/leaks

distribution • Energy

• Office-based

activities

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 10

Thomas Coskeran: Waste mapping 4.4.2006

Stage 1 - Site Level

LABOUR DEGREASER

CHEMICALS OILS ENERGY PLATING SOLUTION

CAST

CASTIRON

IRON PISTON RING PISTON

PISTON

POT

POT COMPANY RINGS

RINGS

PACKAGING HEAT DUST SCRAP SWARF

REJECT EFFLUENT

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Stage 2 – Detailed Level

CAST

CASTIRON

IRONRINGS

RINGS

INPUTS OUTPUTS

GOODS INWARDS

WASTE OIL

LABOUR WATER/OIL MIX

COOLANTS COOLANT

ENERGY CUTTING PROCESS

SWARF

OILS SCRAP

TOOLING REJECTS

HEAT TREATMENT

GRINDING & TURNING WATER

GASES

SOLVENTS

DUST

DRY BLASTING

REJECT RINGS

LABOUR

COATING ANODES

TOOLING

SCRAP

CHEMICALS

FILTER CAKE

INSPECTION & PACKAGING

DISPATCH

PACKAGED RINGS

PACKAGED RINGS

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 11

Thomas Coskeran: Waste mapping 4.4.2006

Example Waste Map

Source:

Envirowise ET219

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Calculating cost of waste

• Once map drawn with types of waste

indicated, can identify costs of wastes

on map for each waste point

• Necessary to convert to a common unit

• Aim to measure first the total mass input

to the production process

• Then assess mass output of product

and known wastes

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 12

Thomas Coskeran: Waste mapping 4.4.2006

Calculating cost of waste

• Apply relevant weights to conversion

factors

– 40 kg per cubic metre is industry standard

in the UK for waste produced

• Try to account for all losses from each

process

• Does not have to be highly accurate

• Can refine estimates over time

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Sources of information

• Site and process maps

• Company records and reports

• Meter readings and energy bills

• Water readings and water energy bills

• Waste disposal contractor bills

• Permits drawing up inventories of

inputs, processes and outputs

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 13

Thomas Coskeran: Waste mapping 4.4.2006

Recording Information

• Raw materials - tonnes/year

• Water use and effluent – m3/year

• Gas and electricity – kWh/year

• Fuel use – litres/year

• Solid waste – tonnes/year

• Solvent use and emissions –

tonnes/year

• Rejects – number/year, percentage

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Identifying Processes

Source: Envirowise publication GG280: Reducing water and waste costs in fruit and

vegetable processing

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 14

Thomas Coskeran: Waste mapping 4.4.2006

Identifying Inputs

Source: Envirowise publication GG280: Reducing water and waste costs in fruit and

vegetable processing

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Identifying Outputs

Source: Envirowise publication GG280: Reducing water and waste costs in fruit and

vegetable processing

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 15

Thomas Coskeran: Waste mapping 4.4.2006

Inventories of Inputs and

Outputs: examples

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Waste minimisation

• Once map defined with costings can

focus on how to minimise waste

• Envirowise has large number of

suggestions and publications

– industry-based

– case studies

– particular types of waste

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 16

Thomas Coskeran: Waste mapping 4.4.2006

Reducing Solid Waste

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Envirowise guides

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 17

Thomas Coskeran: Waste mapping 4.4.2006

Prioritising Strategy

• Draw up plan to tackle obvious sources of

waste

• Address easiest and lowest cost actions first

• Set waste and energy reduction targets for

tackling waste

• Costings obtained in waste mapping will be

important in determining which areas to

address

• Identify monitoring requirements

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Prioritising Strategy

• As problems are dealt with other waste

sources will become apparent

• Review progress against targets and

publicise results

• As problems are dealt with other waste

sources will become apparent

• After initial map drawn, produce detailed site

map to help indicate problem areas more

clearly

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 18

Thomas Coskeran: Waste mapping 4.4.2006

Conclusion: a continuous

process

• As waste is tackled and reduced, the waste

map (like all maps) will change

• Regular review of the map will be needed to

keep it relevant to the organisation

• Changes to the map will record achievements

in cutting waste and prioritise areas for further

action

• The map should not become a theoretical

exercise but should help to direct waste

strategy within the organisation

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

Sources of Assistance

• Envirowise web-site

http://www.envirowise.gov.uk

• Envirowise publications

• Good Practice Guide (GG174) Profiting from

Practical Waste Minimisation: Running a workshop

to maintain the momentum

• Good Practice Guide (GG38C) Cutting Costs by

Reducing Waste: A self-help guide for growing

businesses

• Case Study (GC16) Sites Set on Cost Savings

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 19

Thomas Coskeran: Waste mapping 4.4.2006

Sources of Assistance

• Case Study (GC20) Environmental Review

Helps Raise Profits

• Case Study (GC22) Simple Measures

Restrict Water Costs

• Finding Hidden Profit: 200 Tips for Reducing

Waste (ET30)

Waste minimization and resources use optimization, University of Oulu, 3-7 April 2006

University of Oulu, Waste minimization

and resources use optimization course 20

S-ar putea să vă placă și

- The New Sharing EconomyDocument13 paginiThe New Sharing EconomyDaisy100% (4)

- Systems Intelligence 2004Document320 paginiSystems Intelligence 2004Daisy100% (1)

- Building Sustainability in An Urbanizing World - WB 2013Document216 paginiBuilding Sustainability in An Urbanizing World - WB 2013DaisyÎncă nu există evaluări

- Forty Rules of LoveDocument41 paginiForty Rules of LoveDaisy100% (8)

- Sustainable Everyday ENGDocument276 paginiSustainable Everyday ENGDaisy100% (4)

- Companion To Philosophy of ScienceDocument465 paginiCompanion To Philosophy of ScienceMario de Turey93% (15)

- Jessican Conrad Sharing RevolutionDocument81 paginiJessican Conrad Sharing RevolutionZaq MosherÎncă nu există evaluări

- How To Design Our World For HappinessDocument69 paginiHow To Design Our World For HappinessDaisy100% (1)

- ADB Green Growth Resources ResilienceDocument157 paginiADB Green Growth Resources ResilienceDaisyÎncă nu există evaluări

- ADB Climate Change Assessment CooDocument28 paginiADB Climate Change Assessment CooDaisyÎncă nu există evaluări

- Social Dimensions Climate ChangeDocument16 paginiSocial Dimensions Climate ChangeSamrerng KriengprathanaÎncă nu există evaluări

- ADB Flood Risk ManagementDocument206 paginiADB Flood Risk ManagementDaisyÎncă nu există evaluări

- Investing in Resilience: Ensuring A Disaster-Resistant FutureDocument188 paginiInvesting in Resilience: Ensuring A Disaster-Resistant FutureAsian Development BankÎncă nu există evaluări

- ADB Flood Risk ManagementDocument206 paginiADB Flood Risk ManagementDaisyÎncă nu există evaluări

- Global Food Policy Report 2012Document142 paginiGlobal Food Policy Report 2012DaisyÎncă nu există evaluări

- ADB Building Climate Resilience Agriculture SectorDocument322 paginiADB Building Climate Resilience Agriculture SectorDaisyÎncă nu există evaluări

- ADB Building Climate Resilience Agriculture SectorDocument322 paginiADB Building Climate Resilience Agriculture SectorDaisyÎncă nu există evaluări

- Soc Trang ICAM ReportDocument74 paginiSoc Trang ICAM ReportDaisyÎncă nu există evaluări

- Mekong Basin Planning Story 2013Document68 paginiMekong Basin Planning Story 2013DaisyÎncă nu există evaluări

- ADB Climate Change Assessment CooDocument28 paginiADB Climate Change Assessment CooDaisyÎncă nu există evaluări

- Paving The Way For Climate Resilient InfrastructureDocument148 paginiPaving The Way For Climate Resilient InfrastructureDaisyÎncă nu există evaluări

- Kelty - ProfToolkit - Healthy Living Healthy MindDocument149 paginiKelty - ProfToolkit - Healthy Living Healthy MindDaisy100% (2)

- Joy of Learning - Lesson Plans On Hygiene, Sanitation, Water, Health and EnvironmentDocument98 paginiJoy of Learning - Lesson Plans On Hygiene, Sanitation, Water, Health and EnvironmentDaisy80% (5)

- Family Toolkit Healthy LivingDocument73 paginiFamily Toolkit Healthy LivingDaisy100% (1)

- The Ecosystem Approach - 5 Steps To ImplementationDocument39 paginiThe Ecosystem Approach - 5 Steps To ImplementationDaisyÎncă nu există evaluări

- Pay - Establishing Payments For Watershed ServicesDocument105 paginiPay - Establishing Payments For Watershed ServicesDaisyÎncă nu există evaluări

- Value - Counting Ecosystems As Water InfrastructureDocument90 paginiValue - Counting Ecosystems As Water InfrastructureDaisyÎncă nu există evaluări

- Mekong Environmental Symposium 2013 - Abstract VolumeDocument282 paginiMekong Environmental Symposium 2013 - Abstract VolumeDaisy100% (1)

- Share - Managing Water Across Boundaries IUCN 2008Document97 paginiShare - Managing Water Across Boundaries IUCN 2008DaisyÎncă nu există evaluări

- Mangroves - Soldiers of Our CoastsDocument17 paginiMangroves - Soldiers of Our CoastsDaisyÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Via Fill PlugDocument7 paginiVia Fill PluganeeshdÎncă nu există evaluări

- C510WNDocument2 paginiC510WNEdgarDavidDiazCamposÎncă nu există evaluări

- Medellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFDocument16 paginiMedellin Castillo Zaragoza Siqueiros2019 - Article - DesignAndManufacturingStrategi PDFajay d1212Încă nu există evaluări

- Technical Summary: Semiconductor MC68HC11A8 MC68HC11A1 MC68HC11A0 8-Bit MicrocontrollersDocument45 paginiTechnical Summary: Semiconductor MC68HC11A8 MC68HC11A1 MC68HC11A0 8-Bit MicrocontrollersElias CoronelÎncă nu există evaluări

- Cloud Whitebook Cloud White BookDocument60 paginiCloud Whitebook Cloud White BookeevengÎncă nu există evaluări

- Risk Assesment-Rebar Loading & UnloadingDocument1 paginăRisk Assesment-Rebar Loading & Unloadingmainraj rajÎncă nu există evaluări

- Working Drawings: Key PlanDocument1 paginăWorking Drawings: Key PlanSharanyaÎncă nu există evaluări

- Breakwater Vertical BarriersDocument10 paginiBreakwater Vertical BarriersAlbert PranataÎncă nu există evaluări

- Broadcast BillDocument22 paginiBroadcast BillLidwin SoundariaÎncă nu există evaluări

- 13 - NM Electrical Stimulation in NeurorehabilitationDocument29 pagini13 - NM Electrical Stimulation in NeurorehabilitationvladÎncă nu există evaluări

- Drafting Technology Y2Document202 paginiDrafting Technology Y2Anderson MarantanÎncă nu există evaluări

- Quality Control Handbook Street LightingDocument36 paginiQuality Control Handbook Street LightingbalaafconsÎncă nu există evaluări

- Volvo (Dem) and Haldex: History, Function, Diagnosis and RepairsDocument6 paginiVolvo (Dem) and Haldex: History, Function, Diagnosis and RepairsNecsaszNorbertÎncă nu există evaluări

- 7749289-TheClandestineChemist 'Snotebook PDFDocument28 pagini7749289-TheClandestineChemist 'Snotebook PDFTonÎncă nu există evaluări

- List of Companies and E-Mail Id SL - No Company E-MailDocument4 paginiList of Companies and E-Mail Id SL - No Company E-MailRadheshyam Kushwaha75% (4)

- LIFIDocument7 paginiLIFIRajeshÎncă nu există evaluări

- Sample Letters To DEPDocument7 paginiSample Letters To DEPSJLibraryÎncă nu există evaluări

- Platespin User GuideDocument17 paginiPlatespin User GuideEbitomo Anthony TobiÎncă nu există evaluări

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 paginiData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Buckling Considerations in Pile Design: October 2005Document9 paginiBuckling Considerations in Pile Design: October 2005shashank sharmaÎncă nu există evaluări

- Class 10 Science (Physics) MCQs Chapter 11 QuestionsDocument28 paginiClass 10 Science (Physics) MCQs Chapter 11 QuestionsKSA TEXTILEÎncă nu există evaluări

- Composite For Innovative Wind TurbineDocument25 paginiComposite For Innovative Wind TurbineSuraj MoodÎncă nu există evaluări

- Digital Optical PyrometerDocument1 paginăDigital Optical Pyrometerlehdruk7100Încă nu există evaluări

- INFA3227 Esquema 01-MAR-2021Document9 paginiINFA3227 Esquema 01-MAR-2021sasgarisÎncă nu există evaluări

- Titus Slot DiffuserDocument4 paginiTitus Slot Diffuservico1982Încă nu există evaluări

- GROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 paginiGROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoÎncă nu există evaluări

- Cloud Infrastructure and ServicesDocument3 paginiCloud Infrastructure and ServicesShobha RaniÎncă nu există evaluări

- Robotic CafeDocument13 paginiRobotic CafeRana SaqlainÎncă nu există evaluări

- 6420 PHENOLS 6420 A. Introduction: 1. Sources and SignificanceDocument6 pagini6420 PHENOLS 6420 A. Introduction: 1. Sources and SignificanceNguyen Hien Duc HienÎncă nu există evaluări

- Leeson Speedmaster ManualDocument80 paginiLeeson Speedmaster ManualOrbán Árpád100% (1)