Documente Academic

Documente Profesional

Documente Cultură

Template Chapter1

Încărcat de

Tony OngDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Template Chapter1

Încărcat de

Tony OngDrepturi de autor:

Formate disponibile

CHAPTER ONE INTRODUCTION

1.1 General The most commonly used surfacing material for roads in Malaysia is asphaltic concrete. Other materials used include macadams, stone mastic asphalt, porous

asphalt and surface dressing or chip seals. Unlike asphaltic concrete, porous asphalt is relatively new in the Malaysian context. Porous asphalt was developed in the 1950s on British airport runways to improve the safety of fast moving aircraft traffic. The material later found its usage for roads on similar traffic safety grounds. A

characteristic feature of porous asphalt is its high void content, typically in excess of 20 per cent. This stems from the aggregate gradation which consists of predominantly coarse aggregate fraction but lower sand fraction and filler proportions.

To take advantage of its ability to eliminate ponding water, porous asphalt is normally used for the wearing course. As in conventional mixes, it supports vehicle loads and transfers them to the underlying layers though its structural contribution is low. Other terminologies associated with porous asphalt include drainage asphalt, whispering asphalt, ecophalt, pop-corn asphalt or pervious asphalt. asphalt will be widely used in this thesis. The terminology porous

1.2 Problem Statement Every year, the number of registered vehicles on Malaysian roads increases steadily. According to the Highway Planning Unit (2002), there are 12 million units of registered vehicles in the year 2002 which is about half of the total Malaysian population. The high increase in the number of vehicles annually has partly 1

contributed to the increase in the number of road accidents. However, there are also several pavement factors that have contributed to the increase in road accidents. Current pavement mix such as asphaltic concrete has been acknowledged for its ability and durability in terms of its life-span. However, on wet roads, this conventional material is undesirable to users in terms of splash, spray that results from ponding water.

This research focus on porous asphalt pavement due to its ability to reduce the potential for hydroplaning, improves visibility during wet weather apart from decreasing traffic noise levels. However, the performance of porous asphalt is Therefore, an additional

hampered due to its poor resistance to disintegration.

additive, Drain Asphalt Modified Additive (DAMA) has been added in different percentages to improve its performance. DAMA is intended to improve the resistance to disintegration of the porous asphalt by enhancing the bond between aggregate particles and binder. This is reflected from its better resistance to abrasion loss in the Cantabrian test.

In Malaysia, porous asphalt was first applied about 14 years ago and took place along Jalan Cheras-Beranang. In 1996 there were 16 locations along the Federal Routes that had been resurfaced with porous asphalt and another 25 locations in 1997 that had been identified for implementation. These efforts are to ensure rainwater do not form puddles on road surface and guarantee improved riding comfort to road users (HPU, 1998).

Other sites where porous asphalt have been applied include Jalan Tebrau in Johor Bharu, the Federal Highway, the Kerinchi Link and numerous patchy applications along the North-South Highway.

Porous asphalt is not as durable as dense mix. However, this can be improved through the use of modified mixes. Therefore, this research explores the possibility of

improving porous asphalt performance by incorporating DAMA. The presence of DAMA is hoped to increase the bonding between the aggregate and bitumen and overall improvement in mix durability. For comparative purposes, a commonly used polymer modified bitumen, namely Styrene Butadiene Styrene (SBS), is also studied.

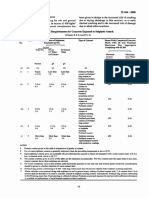

1.3 Objectives The objectives of this research are listed below: 1. To modify the gradation developed by Darin Tech, Korea, to suit to the Malaysian quarry practice. 2. To determine the design binder content of the modified gradation mix prepared using a conventional base bitumen grade 60/70, SBS modified bitumen and 60/70 pen bitumen with varying percentages of DAMA. 3. To characterize the engineering properties of mixes prepared using various percentage of DAMA dry mixed with 60/70 pen binder. 4. To evaluate performance of porous mixes incorporating DAMA compared with conventional and SBS modified mixes.

1.4 Scope of Work The scope of work focuses on porous asphalt performance prepared at varying percentages of DAMA. The aggregate grading used was a modification to the

gradation used in Korea. The basic tests on aggregates and binder were initially conducted to ensure conformity to the specifications. The binders used were a

conventional bitumen grade 60/70 and SBS modified binder while the aggregates used were from the granitic group.

The design binder content was determined based on the Cantabrian and binder drainage tests. Material characterization tests conducted at the design binder content include Marshall stability, resilient modulus, dynamic creep and wheel tracking.

1.5

Justification of the Research

Roads in Malaysia are wet for a considerable duration in a year. Water on road surfaces can be hazardous to motorists because it causes skidding when skid resistance is reduced. The splash and spray produced by the tyres of moving vehicles reduce visibility and pose a danger to overtaking activity. These factors can be a source of road accidents. Among the measures taken in a Highway Planning Unit Report to the Economic Planning Unit to reduce road accidents include use of porous asphalt (HPU, 1998). The outcome of the investigation is expected to produce a durable porous asphalt that would reduce aquaplaning potential, improve skid resistance at high speed, reduce splash and spray, reduce traffic noise, reduce glare particularly on wet roads and improve stability of the construction. With the improved properties of porous asphalt, it is hoped that this material could be applied on a wider scale and contributes to reduce the number of road accidents in Malaysia.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Scaffolding PDFDocument80 paginiScaffolding PDFLeo Richmond75% (4)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Format Business LetterDocument1 paginăFormat Business LetterTony OngÎncă nu există evaluări

- Cuplok Product GuideDocument14 paginiCuplok Product Guideluiseduardo_plcÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Cuplok Scaffold System PDFDocument24 paginiCuplok Scaffold System PDFNestor Adolfo Freites PuelloÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Cuplok Scaffold System PDFDocument24 paginiCuplok Scaffold System PDFNestor Adolfo Freites PuelloÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- British Steel Universal Beams PFC Datasheet PDFDocument2 paginiBritish Steel Universal Beams PFC Datasheet PDFTony OngÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- RC ColumnsDocument42 paginiRC Columnsyenrai100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Cup Lock Technical Manual PDFDocument56 paginiCup Lock Technical Manual PDFTony OngÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Cuplok Product GuideDocument14 paginiCuplok Product Guideluiseduardo_plcÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- AFEO Criteria Asean Outstanding Engg Acheivement Awards V1.0Document5 paginiAFEO Criteria Asean Outstanding Engg Acheivement Awards V1.0Tony OngÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- StaadDocument7 paginiStaadTony OngÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Concrete DeteriorationDocument13 paginiConcrete DeteriorationTony OngÎncă nu există evaluări

- Scaffolding-Accessories (Huatraco) PDFDocument12 paginiScaffolding-Accessories (Huatraco) PDFTony OngÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Finite Element MethodDocument68 paginiFinite Element Methodpaulohp2100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- (FLYER) Structural Concrete RepairsDocument3 pagini(FLYER) Structural Concrete RepairsTony OngÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Jawi Map (From PG)Document1 paginăJawi Map (From PG)Tony OngÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Bulletin No. 1 - Call For Paper Final 1Document10 paginiBulletin No. 1 - Call For Paper Final 1Tony OngÎncă nu există evaluări

- Application Form-IPS Conference FundDocument7 paginiApplication Form-IPS Conference FundTony OngÎncă nu există evaluări

- Application Form-IPS Conference FundDocument7 paginiApplication Form-IPS Conference FundTony OngÎncă nu există evaluări

- Hilti Method (Scanned)Document8 paginiHilti Method (Scanned)Tony OngÎncă nu există evaluări

- PMP Boot Camp Time Table 201310Document1 paginăPMP Boot Camp Time Table 201310Tony OngÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Moment DesignDocument3 paginiMoment DesigndsureshcivilÎncă nu există evaluări

- Theory of StructuresDocument171 paginiTheory of StructuresTony OngÎncă nu există evaluări

- Sponsorship Letter (EcoWorld) - E-Finity Run 2016Document3 paginiSponsorship Letter (EcoWorld) - E-Finity Run 2016Tony OngÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Box Girder Model To MidasDocument1 paginăBox Girder Model To MidasTony OngÎncă nu există evaluări

- Properties of Steel Fibre in BendingDocument9 paginiProperties of Steel Fibre in BendingTony OngÎncă nu există evaluări

- Overfilled Arch BridgeDocument5 paginiOverfilled Arch BridgeTony OngÎncă nu există evaluări

- Detailed Description of Pre Stressed Cable AnchorDocument1 paginăDetailed Description of Pre Stressed Cable AnchorTony OngÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Plaxis Tutorial 01Document33 paginiPlaxis Tutorial 01drotostotÎncă nu există evaluări

- EUP 301 Lecture 8Document9 paginiEUP 301 Lecture 8Tony OngÎncă nu există evaluări

- BS 3958-5 PDFDocument10 paginiBS 3958-5 PDFAnitha MjÎncă nu există evaluări

- Case Study: Materials For Blood Bags: WWW - Blood.co - UkDocument6 paginiCase Study: Materials For Blood Bags: WWW - Blood.co - UkBijuChudraponvelilThomasÎncă nu există evaluări

- IS 456: 2000 8.2.4.2 Maximum Cement Content: Chss TypeDocument1 paginăIS 456: 2000 8.2.4.2 Maximum Cement Content: Chss Typesharath1199Încă nu există evaluări

- Tunnelling For Randstadrail in RotterdamDocument9 paginiTunnelling For Randstadrail in RotterdamHarold TaylorÎncă nu există evaluări

- 8378 13800 1 SMDocument9 pagini8378 13800 1 SMSYIFA AULIA 1Încă nu există evaluări

- Reactivity Series QPDocument5 paginiReactivity Series QPSalman Farsi TaharatÎncă nu există evaluări

- PTS. 11. 15. 02 Steel StructureDocument20 paginiPTS. 11. 15. 02 Steel StructureSulist N Wahyudie67% (3)

- D 3301 - 94 RdmzmdetukveDocument7 paginiD 3301 - 94 RdmzmdetukveHernan MartÎncă nu există evaluări

- Chapter 3 Deep FoundationDocument2 paginiChapter 3 Deep FoundationTeaMeeÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Pipe Rolers and SupportDocument16 paginiPipe Rolers and SupportAhmed YousriÎncă nu există evaluări

- VCS STD 5711 102 09 2005 Method Statement PDFDocument4 paginiVCS STD 5711 102 09 2005 Method Statement PDFFadi MagdyÎncă nu există evaluări

- Grade 8, Quarter 3Document39 paginiGrade 8, Quarter 3Leisor Euqirdnam Oyacnub94% (16)

- ECCSCIB Joint Committee On Sandwich ConstructionsDocument93 paginiECCSCIB Joint Committee On Sandwich ConstructionsHuy Dao NgocÎncă nu există evaluări

- SteelBook Pipe PipeFittingsDocument28 paginiSteelBook Pipe PipeFittingsSumeet Sisir SarkarÎncă nu există evaluări

- Portable Dry Powder Fire Extinguisher Ms1539: FeaturesDocument6 paginiPortable Dry Powder Fire Extinguisher Ms1539: FeaturesVash HeroÎncă nu există evaluări

- Fiber Optics PPT 2Document14 paginiFiber Optics PPT 2Srijan pareekÎncă nu există evaluări

- Chapter 4 PDFDocument20 paginiChapter 4 PDFSiti Arbaiyah AhmadÎncă nu există evaluări

- Understanding The Differences in Base Oil GroupsDocument2 paginiUnderstanding The Differences in Base Oil Groupspriyagoswami100% (1)

- Effective Stiffness of Reinforced Concrete ColumnsDocument9 paginiEffective Stiffness of Reinforced Concrete ColumnsAlberto Ezequiel León TamayoÎncă nu există evaluări

- Standard Hooks Card-ASTM PDFDocument2 paginiStandard Hooks Card-ASTM PDFJose R Birmighan S100% (1)

- TWI CSWIP 3.2 WIS 10 Senior Welding Inspection Destructive Tests Section 5Document39 paginiTWI CSWIP 3.2 WIS 10 Senior Welding Inspection Destructive Tests Section 5JJÎncă nu există evaluări

- (Re) Coating of Pylons With ZINGAENDocument5 pagini(Re) Coating of Pylons With ZINGAENMarco Antonio MoncerrateÎncă nu există evaluări

- BRE 462 Steel Structures Supporting Composite Floor Slabs FireDocument12 paginiBRE 462 Steel Structures Supporting Composite Floor Slabs FireUmmar FarooqÎncă nu există evaluări

- Design and Analysis of Eot Crane Hook For Various Cross SectionsDocument6 paginiDesign and Analysis of Eot Crane Hook For Various Cross SectionsFiroz PawaskarÎncă nu există evaluări

- ERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsDocument31 paginiERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsMuhammed FuadÎncă nu există evaluări

- Mixed Flowing Gas (MFG) Tests For Electrical ContactsDocument11 paginiMixed Flowing Gas (MFG) Tests For Electrical ContactsEugene OgosiÎncă nu există evaluări

- 3 - MeroxDocument22 pagini3 - MeroxAn Lê TrườngÎncă nu există evaluări

- IRC 58 (Plain Jointed Rigid Pavements Design Highways)Document61 paginiIRC 58 (Plain Jointed Rigid Pavements Design Highways)herculesbhai73% (11)

- SPECIFICATION-FOR-ALUMINIUM-SULPHATE (Alum) Used For Potable Water SupplyDocument5 paginiSPECIFICATION-FOR-ALUMINIUM-SULPHATE (Alum) Used For Potable Water SupplyWeida KuchingÎncă nu există evaluări

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDocument6 paginiResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaÎncă nu există evaluări

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDe la EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialEvaluare: 3.5 din 5 stele3.5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (137)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDe la EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetEvaluare: 4.5 din 5 stele4.5/5 (10)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDe la EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesEvaluare: 5 din 5 stele5/5 (1)