Documente Academic

Documente Profesional

Documente Cultură

350 - Survey ULJ S50C 03 1

Încărcat de

Gaurav WaliaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

350 - Survey ULJ S50C 03 1

Încărcat de

Gaurav WaliaDrepturi de autor:

Formate disponibile

ONBOARD NOx VERIFICATION PROCEDURES PARAMETER CHECK METHOD

PROCEDURE

Action by Onboard verification survey

Review of existing certificates and Technical File Review of the record book of engine parameters and components 3 Parameter and setting check (as considered necessary) 4 Submission of the check result 5 Issue (or renewal) IAPP certificate (or certificate of Statement of Compliance for NOx emission of the engine)

1 2 A/C Administration/Class EM Engine manufacturer O Owner Y Yard sea trial A/C N/A Y (+ EM & A/C, as necessary) Y A/C interm. & periodical surveys A/C A/C O (+ A/C, as necessary) O A/C

Remark

MAN B&W Diesel A/S

Onboard verification procedure, v5-1.1 Parameter check method TRUE

Licensee: Engine Definition

Engine type MCR Engine group No.: Parent engine No.:

Uljanik Strojogradnja d.d.

Uljanik

6S50MC-C 9480 ULJ-S50C-03-1 348

kW at

127

rpm

Parent engine data (reference values from Tech File, Table 1.3)

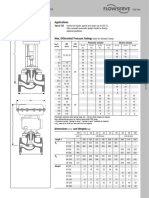

NOx corrected to ISO ambient and ref. Perf. (g/kWh) 12.24 13.75 15.29 18.21 13.72 Tscav (degC) 37 32 28 33 Tscav Max. Tolerance 6 3 3 3 Limit Max. NOx Pmax (barabs) 152.4 131.3 104.5 76.6 17 14.77 Pmax Max. Tolerance 3 3 3 3 IMO g/kWh Pback (mmWC) 300 179 86 25 Pback (max values) 450 340 225 115 Pcomp (barabs) 130 101 70 40 Pcomp Min. Tolerance 2 2 2 2 Tamb (degC) 25 Pamb (mbar) 1000

FALSE

Load (%) 100 75 50 25 IMO NOx

Choices

Cooling

Sea Water Central cooling Fixed temp *)

Cyclus

E2 E3

36

*) Fixed scavenge air cooler inlet te...

FALSE

MAN B&W Diesel A/S

Onboard verification procedure, v5-1.1 Parameter check method

ID Numbers - Parent engine (From Tech File, Table 1.1)

MAN B&W and Uljanik IMO ID No

3170262-7 1158704-5 1150972-0 1171182-5 1170729-8 1171906-5 1173321-5 ABB TPL CT70 TF20,TT40 CA17,CT70 TA23,TT40 1173320-3 VESTAS AIRCOIL LKMY LYNGSO

Settings - Parent engine (From Tech File, Table 1.2)

(Original input from test-bed adjustment (average for all cylinders))

Combustion chamber

Cylinder liner Piston crown Cylinder cover Fuel pump plunger

Compression ratio (shims) Fuel pump shims (if applicable) Fuel pump orifice (if applicable) Fuel valve opening/closing pressure Fuel cam lead angle Fuel cam lead lift Exhaust valve lead angle Exhaust by-pass (orifice diameter)

mm mm mm bar deg. CA (b.TDC) mm deg. CA (b.BDC) mm

6 8 N/A 350 11.4 13.6 -3.5 N/A

Fuel injection equipment

Fuel pump barrel Fuel nozzle Fuel cam T/C Compressor

T/C

Turbine Diffuser Nozzle ring Exhaust cam Scav. air cooler Governor Aux. blower

Other

FLAKT OY WOODS

MAN B&W Diesel A/S

ONBOARD NOx VERIFICATION PROCEDURES PARAMETER CHECK METHOD

Estimated NOx emission

30

NOx (as NO2) - g/kWh

350 STENA CONCEPT FALSE

25

Load (%)

100 Ambient pressure Compression pressure Maximum pressure Compressor inlet temperature Scavenge air temperature Sea water inlet temperature Turbine back pressure Scavenging air pressure Power Engine speed Turbocharger speed Fuel pump index VIT index Date: mbar bar bar deg.C degC degC mmWC bar kW r/min r/min 1012 130.3 151 18 32 18 180 2.81 9486 127.0 15000 80.0 75 1012 103 131.6 17 26 18 120 2 7092 115.0 13000 65.0 50 1012 70.7 105 17 20 18 40 1.02 4739 101.0 10000 51.0 25 1012 45 75.5 16 24 18 20 0.3 2371 80.0 3500 36.7 100 1015 136 150 16 36 25 140 2.69 29420 76.0 9410 159.0 75

2003-03-28 2004-11-20 2004-11-20 2004-11-20 2004-11-20 2003-03-28

0 0 0 0

20 15 10 5 0 0 25 50

Engine Power - %

1015 109.7 134 15 30 25 108 1.96 22083 69.0 8400 134.0

75

100

83892740.xls

April 2002

MAN B&W Diesel A/S

Onboard NOx verification procedures, v5-1.1 ENCLOSURE 4 Parameter check method

Engine type: 6S50MC-C Vessel name: STENA CONCEPT Engine no: 350 Group no: ULJ-S50C-03-1

Table 1: Results

Estim. ISO amb. site NOx Parent engine ISO corr. NOx

Pmax NOx Tscav NOx Pback NOx Pcomp NOx

g/kWh g/kWh g/kWh g/kWh g/kWh g/kWh barabs barabs barabs %

100 11.77 12.24 -0.6129 -0.1120 -0.0480 0.3016 3.75 149.0 128.1 0.06

Load (%) 75 13.21 13.75 -0.1850 -0.1254 -0.0354 -0.1929 2.96 130.2 101.8 0.25

50 14.97 15.29 -0.0233 -0.1672 -0.0276 -0.1002 2.01 104.4 70.5 0.02

25 16.95 18.21 -0.2139 -0.1881 -0.0030 -0.8591 1.30 75.4 45.3 0.04

IMO NOx 13.19 13.72

Pscav Pmax Pcomp

Power

ISO ambient

Table 1.1: Exceeded tolerances

100 no no no no Load (%) 75 no no no no 50 no no no no 25 no no no no

Pmax tolerance Pback maximum Pcomp tolerance Power deviation >5%

Table 2: Input

Date Ambient pressure Compression pressure Maximum pressure Compressor inlet temperature Scavenge air temperature Sea water inlet temperature Turbine back pressure Scavenging air pressure Power Engine speed Turbocharger speed Fuel pump index mbar bar bar C C C mmWC bar kW r/min r/min Load (%) 100 75 50 25 2004-11-20 2004-11-20 2004-11-20 2004-11-20 1012 1012 1012 1012 130.3 103.0 70.7 45.0 151.0 131.6 105.0 75.5 18.0 17.0 17.0 16.0 32.0 26.0 20.0 24.0 18.0 18.0 18.0 18.0 180 120 40 20 2.81 2.00 1.02 0.30 9486 7092 4739 2371 127 115 101 80 15000 13000 10000 3500 80.0 65.0 51.0 36.7

02/07/2012

MAN B&W Diesel A/S

Onboard NOx verification procedures, v5-1.1 Parameter check method

Engine type: 6S50MC-C Vessel name: STENA CONCEPT Engine no: 350 Group no: ULJ-S50C-03-1

Estimated NOx emission

30

Row 4 25

Row 5

20

NOx (as NO2) - g/kWh

15

10

0 0 25 50 Engine power - % 75 100

02/07/2012

MAN B&W Diesel A/S

Onboard NOx verification procedures, v5-1.1 ENCLOSURE 4 Parameter check method

Engine type: 6S50MC-C Vessel name: STENA CONCEPT Engine no: 350 Group no: ULJ-S50C-03-1

Table 3: Components *)

MAN B&W and licensee IMO ID Cylinder liner

Combustion chamber

Actual part no

3170262-7 1158704-5 11550972 1171182-5 1170729-8 1171906-5 1173321-5 ABB TPL CT70 / TF20,TT40 CA17,CT70 / TA23,TT40 1173320-3

Surveyor comments

3170262-7 1158704-5 1150972-0 1171182-5 1170729-8 1171906-5 1173321-5 ABB TPL CT70/TF20,TT40 CA17,CT70/TA23,TT40 1173320-3 VESTAS AIRCOIL LKMY

Piston crown Cylinder cover Fuel pump plunger

Fuel injection equipment T/C

Fuel pump barrel Fuel nozzle Fuel cam T/C Compressor/turbine Diffuser/nozzle ring Exhaust cam Scav. air cooler

Other

VESTAS AIRCOIL LKMY LYNGSO LYNGSO FLAKT OY WOODS FLAKT OY WOODS

Governor Aux. blower

*) Original input from the Technical File

Table 4: Settings **)

TF Compression ratio (shims) Fuel pump shims (if applicable) Fuel pump orifice (if applicable) Fuel valve opening/closing pressure Fuel cam lead angle Fuel cam lead lift Exhaust valve lead angle by-pass orifice diameter (if applicable) mm mm mm bar deg. CA (b.TDC) mm deg. CA (b.BDC) mm

6 8 N/A 350 11.4 13.6 -3.5 N/A

Actual

6 8 N/A 350 11.4 13.6 -3.5 N/A

**) Original input from test-bed adjustment (average for all cylinders, see individual in 4) Comments: When using the parameter check method for the on-board survey ( 3.2), a check of the fuel nozzle will usually be sufficient to verify compliance (provided that the record book shows the engine is kept as originally built,) where the component check method ( 3.3) usually is carried out during opening-up inspections and allow check of a complete cylinder unit. Adjustments of setting values are carried out to obtain the specified reference performance data (within the given tolerances) as specified in Table 1.3 - first on test bed but later as necessary. New setting values shall be stated in the record book for later reference 02/07/2012 1

MAN B&W Diesel A/S

Onboard NOx verification procedures, v5-1.1 ENCLOSURE 4 Parameter check method

Engine type: 6S50MC-C Vessel name: STENA CONCEPT Engine no: 350 Group no: ULJ-S50C-03-1

See additional comments in 3, on-board NOx verification procedures, and the flow chart in Fig. 1.

02/07/2012

S-ar putea să vă placă și

- 7S50MC-C7-TI TCA66-21 127.0 RPM 11060 KWDocument16 pagini7S50MC-C7-TI TCA66-21 127.0 RPM 11060 KWАлександр ТихомировÎncă nu există evaluări

- Leaflet H Cegielski-SERVICE New General LeafletDocument10 paginiLeaflet H Cegielski-SERVICE New General Leafletvangeliskyriakos8998Încă nu există evaluări

- 706 - Performance Evaluation and General Operation - 007Document72 pagini706 - Performance Evaluation and General Operation - 007Vignesh SivaÎncă nu există evaluări

- L23 30Document1.155 paginiL23 30Дима Скоробогатый100% (1)

- 701 Me DoosanDocument37 pagini701 Me DoosanRonald Sol Salen JordasÎncă nu există evaluări

- Rta-14 1Document8 paginiRta-14 1George DomusciuÎncă nu există evaluări

- Dimensi MesinDocument28 paginiDimensi MesinSyahrir QoimÎncă nu există evaluări

- L 48-60 Operating InstructionsDocument243 paginiL 48-60 Operating InstructionsdugouhaÎncă nu există evaluări

- Overhaul fuel valve kit for MAN Diesel & Turbo enginesDocument2 paginiOverhaul fuel valve kit for MAN Diesel & Turbo enginesFilipe FilipeÎncă nu există evaluări

- MAN B&W Two-Stroke MC Engine ReferencesDocument11 paginiMAN B&W Two-Stroke MC Engine Referenceshpss77100% (2)

- SL96-341 B&W Service LetterDocument4 paginiSL96-341 B&W Service LetterkamalÎncă nu există evaluări

- Index - Vol.3-Đã G PDocument143 paginiIndex - Vol.3-Đã G Phuy huỳnhÎncă nu există evaluări

- Mb-4 Operation and DataDocument348 paginiMb-4 Operation and DataBorysÎncă nu există evaluări

- MAN B&W Fuel Pump PartsDocument22 paginiMAN B&W Fuel Pump PartsS SanchitÎncă nu există evaluări

- MAN B&W (L35MC S35MC) engine spare parts listDocument12 paginiMAN B&W (L35MC S35MC) engine spare parts listGales Sanowari Sakti100% (1)

- HIMSEN Catalog 2010Document46 paginiHIMSEN Catalog 2010A87_navjÎncă nu există evaluări

- MAN Hitachi S50MC C ManualsDocument7 paginiMAN Hitachi S50MC C ManualsVaibhav Sarda100% (2)

- G95me-C9 5Document361 paginiG95me-C9 5Pradeep AmmanamanchiÎncă nu există evaluări

- Ironpump PDFDocument14 paginiIronpump PDFrpicho0% (1)

- Man B&W 6S60MC 702Document6 paginiMan B&W 6S60MC 702Ishan Bhatnagar100% (1)

- MAN B&W 12S90ME-C9.2 diesel engine drawingsDocument1 paginăMAN B&W 12S90ME-C9.2 diesel engine drawingsSudarshan AgnihotriÎncă nu există evaluări

- Man B&W WarningDocument284 paginiMan B&W WarningMarcin SrokaÎncă nu există evaluări

- VOLUME.2 MaintenanceDocument600 paginiVOLUME.2 MaintenanceMyo Khant100% (1)

- RT Flex 05Document12 paginiRT Flex 05George Domusciu100% (1)

- S90me-C9 2Document367 paginiS90me-C9 2Htet Myat SoeÎncă nu există evaluări

- Mim Wingd x72Document172 paginiMim Wingd x72hihihi100% (1)

- 701Document35 pagini701tmtt44100% (1)

- l27-38 Genset Tierii Atualizado Joel MorelliDocument923 paginil27-38 Genset Tierii Atualizado Joel MorelliVictor NoschangÎncă nu există evaluări

- Fuel Injection Valve Condition: Service Letter SL2016-628/KELDocument4 paginiFuel Injection Valve Condition: Service Letter SL2016-628/KELVitalii KorolÎncă nu există evaluări

- K 98 Mec 7Document369 paginiK 98 Mec 7Luis MillerÎncă nu există evaluări

- OM RT Flex50 B - 2012 07Document454 paginiOM RT Flex50 B - 2012 07Igor SonÎncă nu există evaluări

- k90mcc6 PDFDocument381 paginik90mcc6 PDFTammy JohnsonÎncă nu există evaluări

- Gunclean Toftejorg 270FT Mark I, IM-TE102766-3-En10Document57 paginiGunclean Toftejorg 270FT Mark I, IM-TE102766-3-En10petrakou aglaia100% (1)

- Slide Type Fuel Valves PDFDocument5 paginiSlide Type Fuel Valves PDFThusith AlexanderÎncă nu există evaluări

- D628 Maintenance ScheduleDocument3 paginiD628 Maintenance ScheduleDPÎncă nu există evaluări

- B1 OperatingInstructionsDocument294 paginiB1 OperatingInstructionscengiz kutukcu100% (4)

- Maintaining Micro Pilot InjectorsDocument40 paginiMaintaining Micro Pilot InjectorsPeteÎncă nu există evaluări

- MAN L21 - 31 GenSet TierII-01 From MarekDocument1.412 paginiMAN L21 - 31 GenSet TierII-01 From MarekHatem GhabiÎncă nu există evaluări

- G90me-C10 5Document618 paginiG90me-C10 5GeorgeÎncă nu există evaluări

- Summary of MAN Service Letter 16/24: Technical Information L InformationDocument10 paginiSummary of MAN Service Letter 16/24: Technical Information L InformationPrinceSadhotraÎncă nu există evaluări

- Cylinder Lubricator Unit: MAN B&W DieselDocument2 paginiCylinder Lubricator Unit: MAN B&W DieselFaustoJuniorÎncă nu există evaluări

- Spare Parts Listing with Codes and DescriptionsDocument5 paginiSpare Parts Listing with Codes and DescriptionsNeil GudiwallaÎncă nu există evaluări

- BT-69 MSDS EngDocument4 paginiBT-69 MSDS Engmehmet100% (2)

- Report: Crankshaft Deflections: Plate 70815-40FDocument1 paginăReport: Crankshaft Deflections: Plate 70815-40FwalleyranÎncă nu există evaluări

- Turbocharger Choices for MAN B&W S26MC EnginesDocument10 paginiTurbocharger Choices for MAN B&W S26MC EnginesyuniardimzÎncă nu există evaluări

- MAN B&W Diesel A/S: Licence LetterDocument3 paginiMAN B&W Diesel A/S: Licence Letterbhaswath2000Încă nu există evaluări

- 2007 - ΜΑΝ - ΣΤΟΙΧΕΙΑ ΚΙΝΗΤΗΡΑDocument14 pagini2007 - ΜΑΝ - ΣΤΟΙΧΕΙΑ ΚΙΝΗΤΗΡΑPariotis EfthimiosÎncă nu există evaluări

- G Type EnginesDocument16 paginiG Type Enginespavlo_790317697Încă nu există evaluări

- Bulletin D03 A EDocument4 paginiBulletin D03 A ETed PapasÎncă nu există evaluări

- Adjusting The Camshaft: Tion" in Chapter "Lower Valve Drive"Document25 paginiAdjusting The Camshaft: Tion" in Chapter "Lower Valve Drive"JavierÎncă nu există evaluări

- Brochure MT-50T SRH Eng PDFDocument2 paginiBrochure MT-50T SRH Eng PDFpramodtryÎncă nu există evaluări

- 2 Maintenance BDocument324 pagini2 Maintenance BPranav Shekhar100% (1)

- PG M-Iii L2131 PDFDocument488 paginiPG M-Iii L2131 PDFnavy4Încă nu există evaluări

- Man B&W Serv LTR Sl09-509-Sb-jDocument7 paginiMan B&W Serv LTR Sl09-509-Sb-jafsal999Încă nu există evaluări

- Hitachi Man-B&w Diesel Engine Service DataDocument4 paginiHitachi Man-B&w Diesel Engine Service Datar100% (2)

- L32-40CD B3-SparePartsCatalogueDocument254 paginiL32-40CD B3-SparePartsCataloguejamukanak pad100% (1)

- Pneumatic Fuel Valve Test Pump Type: VPU 1100.2 MKI/MKII: Instruction ManualDocument20 paginiPneumatic Fuel Valve Test Pump Type: VPU 1100.2 MKI/MKII: Instruction Manualvoldemar51rusÎncă nu există evaluări

- MV " Angela": Sietas Type 168a-Open Top Container VesselDocument2 paginiMV " Angela": Sietas Type 168a-Open Top Container VesselMery100% (1)

- Managing Fleet Performance 1.0Document16 paginiManaging Fleet Performance 1.0sayedmhÎncă nu există evaluări

- Boost Your Mental Ability with a FREE CourseDocument1 paginăBoost Your Mental Ability with a FREE CourseGaurav WaliaÎncă nu există evaluări

- Sewage Treatment PlantDocument3 paginiSewage Treatment PlantGaurav WaliaÎncă nu există evaluări

- Time and Work SuperDocument10 paginiTime and Work SuperGaurav WaliaÎncă nu există evaluări

- A Taste of TOEFLDocument9 paginiA Taste of TOEFLqutabshÎncă nu există evaluări

- The American Slang Dictionary - 9781440083433Document312 paginiThe American Slang Dictionary - 9781440083433Gaurav WaliaÎncă nu există evaluări

- meoekgIV 4003Document2 paginimeoekgIV 4003Gaurav WaliaÎncă nu există evaluări

- NPM pfcl25 SpecsheetDocument1 paginăNPM pfcl25 SpecsheetElectromateÎncă nu există evaluări

- Hitachi zw250 GBDocument20 paginiHitachi zw250 GBKhaleel100% (1)

- Thermo King Parts Manual CF-II M53 (uPA+) - P PDFDocument93 paginiThermo King Parts Manual CF-II M53 (uPA+) - P PDFSerhiiÎncă nu există evaluări

- Boiler MountingsDocument15 paginiBoiler MountingsBishwajit MahatoÎncă nu există evaluări

- Handbook Chapter15 DisplacementVentilationDocument41 paginiHandbook Chapter15 DisplacementVentilationJoao Sousa100% (1)

- Gestra v725 PDFDocument1 paginăGestra v725 PDFErdincÎncă nu există evaluări

- Cameron FLS Gate Valve - PDS0112Document2 paginiCameron FLS Gate Valve - PDS0112Karl TbsgÎncă nu există evaluări

- Tractor D10T PDFDocument213 paginiTractor D10T PDFCarlos Alberto Alvarado Loayza100% (1)

- Continuous Energy: Product CatalogDocument40 paginiContinuous Energy: Product CatalogNegash JaferÎncă nu există evaluări

- Ball Bearings CatalogueDocument40 paginiBall Bearings CatalogueCorneliu TocanÎncă nu există evaluări

- Earth Moving Machines-A GlanceDocument27 paginiEarth Moving Machines-A GlanceVinod YbÎncă nu există evaluări

- Machine Design IIDocument3 paginiMachine Design IIRushabh PatelÎncă nu există evaluări

- SCANIA Suspension BT200 Work DescDocument32 paginiSCANIA Suspension BT200 Work DescHeri Suryo0% (1)

- Overhauling Air Compressor On ShipsDocument12 paginiOverhauling Air Compressor On ShipsTun Lin Naing100% (3)

- Specific Fuel ConsumptionDocument2 paginiSpecific Fuel ConsumptionEko PurwantoÎncă nu există evaluări

- Lockout Tagout Equipment ProcedureDocument2 paginiLockout Tagout Equipment ProcedureMehara AmarzeetÎncă nu există evaluări

- Detriot Desiel s60 SensorsDocument8 paginiDetriot Desiel s60 SensorsEdgar Gerve25% (4)

- Allison HD4060 Service Manual PDFDocument83 paginiAllison HD4060 Service Manual PDFKyle Crandall100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 paginiInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Elie Abisaad100% (1)

- Acoplamento Hidrodinamicos VoithDocument150 paginiAcoplamento Hidrodinamicos VoithantonioÎncă nu există evaluări

- Diagnostic Trouble Codes (DTC) : DTC P0703 Brake Switch Circuit MalfunctionDocument3 paginiDiagnostic Trouble Codes (DTC) : DTC P0703 Brake Switch Circuit Malfunctionluis eduardo corzo enriquezÎncă nu există evaluări

- SERIES WIRING DIAGRAMDocument22 paginiSERIES WIRING DIAGRAMp_janko100% (1)

- Aftercooler CoreDocument6 paginiAftercooler CoreRichard ChuaÎncă nu există evaluări

- SW4S enDocument4 paginiSW4S engolden-eagleÎncă nu există evaluări

- ATA 24, 26, 29, 30, 36 Issue1Document62 paginiATA 24, 26, 29, 30, 36 Issue1shazia SyedÎncă nu există evaluări

- 3110 Installation InstructionsDocument2 pagini3110 Installation InstructionsmavefoxÎncă nu există evaluări

- IndexingDocument25 paginiIndexingJaymin PatelÎncă nu există evaluări

- Remove & Install Bucket CylinderDocument6 paginiRemove & Install Bucket CylinderKevin DayÎncă nu există evaluări

- Mtu 12V 16V4000M90 1DSDocument2 paginiMtu 12V 16V4000M90 1DSzaki100% (1)

- Crono 75 RG Motorhacke BJ 2011 AlpinaDocument7 paginiCrono 75 RG Motorhacke BJ 2011 AlpinaCipri RengleÎncă nu există evaluări