Documente Academic

Documente Profesional

Documente Cultură

Lekin

Încărcat de

Chintya Komala SariDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lekin

Încărcat de

Chintya Komala SariDrepturi de autor:

Formate disponibile

Automated Scheduling

Demonstration of LEKIN - Software System for Production Scheduling

Contents 1. Introduction to LEKIN 2. Machine environments 3. Methods 4. Criteria 5. Graphical user interface 6. Steps for generating a schedule 7. Examples: a single machine problem a flow shop problem

Planning and Scheduling in Manufacturing and Services Michael Pinedo, Springer Series in Operations Research and Financial Engineering, 2005, Chapter 5.6 or Operations Scheduling with Applications in Manufacturing and Services, Michael Pinedo and Xiuli Chao, McGraw Hill, 2000 Appendix C or Scheduling, Theory, Algorithms, and Systems, Michael Pinedo, Prentice Hall, Second Addition, 2002, 19.6

Introduction to LEKIN

Machine Environments

Single Machine Parallel Machines Flow Shop Job Shop Flexible Flow Shop Flexible Job Shop Generalisations: more than one machine of each type

Interactive scheduling system for machine

environments Useful for both research and teaching Graphical Interface Built in dispatching rules and simple heuristic methods User-defined algorithms can be added Developed at Stern School of Business, New York University + Columbia University The project has been directed by Professors M. Pinedo, X. Chao and J. Leung. Download (educational version): http://www.stern.nyu.edu/om/software/lekin up to 50 jobs, 100 machines, 20 work centres

Methods

Built-in Heuristics Dispatching Rules EDD (earliest due date), MS (minimum slack), LPT (longest processing time), SPT (shortest processing time), WSPT (weighted processing time) FCFS: (F)irst (C)ome (F)irst (S)erve CR : Critical Ratio rule Schedules jobs according to the ratio of the time left until the due date and the remaining processing time.

5

Shifting Bottleneck Heuristics Local Search Heuristic Hybrid Method: SB-LS: Combination of Shifting Bottleneck and Local Search heuristics

Prof S.Petrovic, School of Computer Science, University of Nottingham

Automated Scheduling

User-defined Heuristics Users can write new heuristics methods and use the plug-in feature Operate as external executables with standardised input and ouput parameters Allows researchers to test and develop new algorithms in an interactive environment. Facilitates comparison between various methods Makespan

Criteria

Cmax Tmax

Maximum Tardiness Total Number of Late Jobs Total Flow Time Total Tardiness Total Weighted Flow Time Total Weighted Tardiness

U C T w C

j j

w jT j

Graphical User Interface

Schedule

Job Pool Window Job statistics and settings

Machine Information

Job Information

9

Jobs

Sequence through machines and start and end 10 times for each machine

Sequence Window

Gantt Chart Window

Sequence of jobs through machine and start and end times

Jobs Machines (Work centres)

Machines (Work centres)

Time

11 12

Prof S.Petrovic, School of Computer Science, University of Nottingham

Automated Scheduling

Displaying schedules

Comparison between different schedules

Log of previous solutions

Various Solutions

Performance Criteria

13 14

Steps for generating a schedule

1. Enter Machine Information Number of Machines Availability Time Setup Time Information 2. Enter Job Information Number of Jobs Release Dates, Due Dates, Weight, and Route 3. Select a dispatching rule or heuristic and generate schedule

Examples

A single machine problem

jobs pj dj wj

1 10 4 14

2 10 2 12

3 13 1 1

4 4 12 12

15

16

Setting up the problem

4. For each job: Enter due date, processing time, and weight Click OK

1. Select single machine environment 2. Set number of machines (already set to 1) 3. Set number of jobs (4)

17 18

Prof S.Petrovic, School of Computer Science, University of Nottingham

Automated Scheduling

Environment display

Generated schedule

19

20

More solutions

EDD: (3214)

LPT: (3124)

J3

WSPT: J2 J1 J4

21

(4123)

22

Comparison between different schedules

EDD WSPT

23

LPT

24

Prof S.Petrovic, School of Computer Science, University of Nottingham

Automated Scheduling

A flow shop problem

Setting up the problem Machine (Workcenter) setup Establishing machine route for jobs

jobs p1j p2j p3j p4j

1 5 4 7 8

2 3 8 8 4

3 6 2 7 2

4 4 9 6 9

5 9 13 5 1

25

26

Schedule

Summary

Graphics based interactive machine shop scheduling system Ability to schedule a number of different machine environments Valuable as an educational and research tool Extendible with new heuristic techniques Manual Schedule Adjustment Large library of standard problems included in package Industrial version currently in development

27

28

Prof S.Petrovic, School of Computer Science, University of Nottingham

S-ar putea să vă placă și

- Introduction To LEKIN: Gareth BeddoeDocument30 paginiIntroduction To LEKIN: Gareth BeddoeAlexander GomezÎncă nu există evaluări

- Pro in CDocument111 paginiPro in CkhairulfikhriÎncă nu există evaluări

- GFGHDGH KKDocument98 paginiGFGHDGH KKGabriella WidjajaÎncă nu există evaluări

- Title of SubjectDocument2 paginiTitle of Subjectloki654321Încă nu există evaluări

- Scheduling Job Shop - A CasestudyDocument8 paginiScheduling Job Shop - A Casestudyabbas6063Încă nu există evaluări

- Cocomo ModelsDocument37 paginiCocomo ModelsnareeeeÎncă nu există evaluări

- Materials Today: Proceedings: Suthep Butdee, Siridech KunhirunbawonDocument6 paginiMaterials Today: Proceedings: Suthep Butdee, Siridech KunhirunbawonDániel TokodyÎncă nu există evaluări

- 11 ProjectManagement COCOMODocument55 pagini11 ProjectManagement COCOMOMicky MElongaÎncă nu există evaluări

- Lectura 2 - SecuenciamientoDocument6 paginiLectura 2 - Secuenciamientofrancisco_mateoÎncă nu există evaluări

- Che 184 BDocument4 paginiChe 184 BzarceloÎncă nu există evaluări

- Project Time Cost Management 3Document51 paginiProject Time Cost Management 3AKHIL JOSEPHÎncă nu există evaluări

- Lec 1Document27 paginiLec 1RaftÎncă nu există evaluări

- Ppce Essay Two MarksDocument29 paginiPpce Essay Two Markskarthiksubramanian94Încă nu există evaluări

- Comparative Study of Two Scheduling Approaches To Resolve Scheduling Problem For A Wire and Cable Manufacturing ProcessDocument10 paginiComparative Study of Two Scheduling Approaches To Resolve Scheduling Problem For A Wire and Cable Manufacturing ProcesslsjayakumarÎncă nu există evaluări

- Software Project Management Class NotesDocument42 paginiSoftware Project Management Class NotesRohit BhardwajÎncă nu există evaluări

- CAPPDocument25 paginiCAPPshubham_arora_19Încă nu există evaluări

- Test Effort EstimationDocument31 paginiTest Effort EstimationJakeer Shaik SÎncă nu există evaluări

- CG5052 BPE 7.1 - Scheduling-Optimization-FlowsheetsDocument36 paginiCG5052 BPE 7.1 - Scheduling-Optimization-FlowsheetsRRÎncă nu există evaluări

- Me 6703-Cim-Mech-Viist-Au-Unit-IiDocument29 paginiMe 6703-Cim-Mech-Viist-Au-Unit-IiSiva RamanÎncă nu există evaluări

- Methodstudy (Compatibility Mode)Document32 paginiMethodstudy (Compatibility Mode)jimaerospace05Încă nu există evaluări

- RTS Slids Lec1Document11 paginiRTS Slids Lec1stephen562001Încă nu există evaluări

- Sem 2Document11 paginiSem 2jtsrinivasdownÎncă nu există evaluări

- Identify or Define: - Gantt Charts - Assignment Method - Sequencing Rules - Johnson's Rules - BottlenecksDocument13 paginiIdentify or Define: - Gantt Charts - Assignment Method - Sequencing Rules - Johnson's Rules - Bottlenecksrks32Încă nu există evaluări

- Time and Resource EstimationDocument15 paginiTime and Resource EstimationbdiitÎncă nu există evaluări

- Tinaporwal,+08 IJETMR19 A01 626Document11 paginiTinaporwal,+08 IJETMR19 A01 626Maimouna CoulibalyÎncă nu există evaluări

- Lab 6 Arena IIDocument8 paginiLab 6 Arena IIJunaidZafarÎncă nu există evaluări

- Abbas 2016 IOP Conf. Ser. Mater. Sci. Eng. 146 012052Document8 paginiAbbas 2016 IOP Conf. Ser. Mater. Sci. Eng. 146 012052jhun lopezÎncă nu există evaluări

- Gujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiDocument3 paginiGujarat Technological University Mechanical (Cad/Cam) (08) : Computer Aided Process Planning 2720813 Semester: IiGeorge CamachoÎncă nu există evaluări

- Computer Aided Process Planning For Milling Operation: PritiDocument8 paginiComputer Aided Process Planning For Milling Operation: PritiWahyu WidiantoÎncă nu există evaluări

- Industrial Engineering and Management-PrintDocument55 paginiIndustrial Engineering and Management-PrintekstsalembaÎncă nu există evaluări

- Production Scheduling Using TWK and SLK Methods: January 2021Document8 paginiProduction Scheduling Using TWK and SLK Methods: January 2021Fadoua LahnaÎncă nu există evaluări

- Production AND Operation: Jonafe F. Gamer BSCM-3Document3 paginiProduction AND Operation: Jonafe F. Gamer BSCM-3jona gamerÎncă nu există evaluări

- Chapter5-Facility Layout - POMDocument34 paginiChapter5-Facility Layout - POMCOCONUTÎncă nu există evaluări

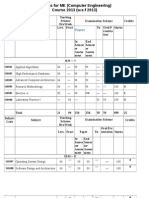

- Computer Science: E M S S SDocument34 paginiComputer Science: E M S S SWeb InaudioÎncă nu există evaluări

- ZooDocument98 paginiZooPankaj Rawat50% (2)

- Operating Systems: Literature Review On Scheduling Algorithms of Operating SystemDocument12 paginiOperating Systems: Literature Review On Scheduling Algorithms of Operating SystemTeja PeddiÎncă nu există evaluări

- Railway Management SystemDocument30 paginiRailway Management Systemrkjrocks0% (2)

- 00 Introdution To Programming (2022-1)Document22 pagini00 Introdution To Programming (2022-1)Attapon WaipripÎncă nu există evaluări

- VFFFXDocument40 paginiVFFFXxenon_9210Încă nu există evaluări

- Scheduling: Theory, Algorithms and Systems Development: January 1992Document9 paginiScheduling: Theory, Algorithms and Systems Development: January 1992Francesco BÎncă nu există evaluări

- ECSE-4790 Microprocessor Systems: Russell P. Kraft JEC 6028 Kraftr2@rpi - Edu Tel: 276-2765 Fax: 276-6261Document23 paginiECSE-4790 Microprocessor Systems: Russell P. Kraft JEC 6028 Kraftr2@rpi - Edu Tel: 276-2765 Fax: 276-6261reynelÎncă nu există evaluări

- Operations Management: Topic: Scheduling. DR - Nitin KubdeDocument31 paginiOperations Management: Topic: Scheduling. DR - Nitin KubdeSagar PhullÎncă nu există evaluări

- RTS Lec1Document11 paginiRTS Lec1Suraj KandpalÎncă nu există evaluări

- SchedulingDocument25 paginiSchedulingPrajyal SenguptaÎncă nu există evaluări

- System Life Cycle: Pertemuan 3 SIM by Eko DarwiyantoDocument39 paginiSystem Life Cycle: Pertemuan 3 SIM by Eko DarwiyantocchaniarÎncă nu există evaluări

- Unit-04 Production Planning and Control - PPTX'Document28 paginiUnit-04 Production Planning and Control - PPTX'Rupak KumarÎncă nu există evaluări

- Os Lab Manual - 0 PDFDocument56 paginiOs Lab Manual - 0 PDFVani BalamuraliÎncă nu există evaluări

- CPM/ PERT in Industrial EngineeringDocument80 paginiCPM/ PERT in Industrial EngineeringSuneel Kumar MeenaÎncă nu există evaluări

- MEDocument37 paginiMEMrunal UpasaniÎncă nu există evaluări

- More On Estimation: - in General, Effort Estimation Is Based On SeveralDocument20 paginiMore On Estimation: - in General, Effort Estimation Is Based On SeveralserachguruÎncă nu există evaluări

- Facility LayoutDocument23 paginiFacility LayoutJessie Radaza TutorÎncă nu există evaluări

- Aspen Plus - Module IDocument193 paginiAspen Plus - Module IHafeez Ahmad50% (2)

- Course SyllabusDocument2 paginiCourse SyllabusAayush KÎncă nu există evaluări

- Operating System Ch4Document56 paginiOperating System Ch4JustkelÎncă nu există evaluări

- M3 ILOC PM Planning Cost Estimation IIDocument37 paginiM3 ILOC PM Planning Cost Estimation II2020.dimple.madhwaniÎncă nu există evaluări

- COCOMO ModelDocument51 paginiCOCOMO ModelPrakhar RastogiÎncă nu există evaluări

- Syllabus Computational or CS IIIDocument3 paginiSyllabus Computational or CS IIISujan TimalsinaÎncă nu există evaluări

- Answer ALL Questions PART A - (10 2 20 Marks) : Answers Prepared by Me .So Pls Refer Book For Full Understanding .Document26 paginiAnswer ALL Questions PART A - (10 2 20 Marks) : Answers Prepared by Me .So Pls Refer Book For Full Understanding .Sagarias AlbusÎncă nu există evaluări

- Performance Evaluation by Simulation and Analysis with Applications to Computer NetworksDe la EverandPerformance Evaluation by Simulation and Analysis with Applications to Computer NetworksÎncă nu există evaluări

- CS308 Software Engineering and Project Management - Image.MarkedDocument3 paginiCS308 Software Engineering and Project Management - Image.MarkedVishnuraj Vishnu KrÎncă nu există evaluări

- 6es7134 4GB11 0ab0 PDFDocument24 pagini6es7134 4GB11 0ab0 PDFDeyanira Guzman EscobarÎncă nu există evaluări

- C# SerialDocument7 paginiC# SerialJuan ArevaloÎncă nu există evaluări

- FreeNAS 11.3 RELEASE User Guide - ScreenDocument375 paginiFreeNAS 11.3 RELEASE User Guide - ScreenTrifelonÎncă nu există evaluări

- All This Premium Accounts by PremiumDocument6 paginiAll This Premium Accounts by PremiumDon MorrisonÎncă nu există evaluări

- PANalytical SOP VDocument19 paginiPANalytical SOP VAzwan ShakraniÎncă nu există evaluări

- PS Vita Year OneDocument33 paginiPS Vita Year OnePatito0% (1)

- How Do I Stop JDLSDocument3 paginiHow Do I Stop JDLSEmmanuel Uchenna ChukwuÎncă nu există evaluări

- EC1 Preside PAPDocument90 paginiEC1 Preside PAPX19_fredÎncă nu există evaluări

- 50 TOP SAP ABAP Multiple Choice Questions and Answers PDF - SAP ABAP Interview Questions and AnswersDocument10 pagini50 TOP SAP ABAP Multiple Choice Questions and Answers PDF - SAP ABAP Interview Questions and Answersneschet0% (1)

- R - Manual NICRA ProjectDocument40 paginiR - Manual NICRA Projectherlambang rachmanÎncă nu există evaluări

- Hardware Information Guide: Emc Vnxe Series Vnxe3200Document65 paginiHardware Information Guide: Emc Vnxe Series Vnxe3200Anonymous n4NOOOÎncă nu există evaluări

- Software Engineering Lab Report (CS217)Document24 paginiSoftware Engineering Lab Report (CS217)Mayank PantÎncă nu există evaluări

- Church Motion Graphics Share5Document10 paginiChurch Motion Graphics Share5Willian PereiraÎncă nu există evaluări

- Archive Services For SAP Configuration Guide 6 5Document37 paginiArchive Services For SAP Configuration Guide 6 5jazarjaÎncă nu există evaluări

- Smart AppliancesDocument36 paginiSmart Appliancesju1976Încă nu există evaluări

- Varios TampermonkeyDocument53 paginiVarios TampermonkeyDaniel CardonaÎncă nu există evaluări

- SHDB Creare RecordingDocument9 paginiSHDB Creare RecordingElena PuscuÎncă nu există evaluări

- Career Cert Paths Poster PDFDocument1 paginăCareer Cert Paths Poster PDFI_ggizÎncă nu există evaluări

- Check SAP Tcode Authorisation Data Using SU53Document3 paginiCheck SAP Tcode Authorisation Data Using SU53Silvia BacchiniÎncă nu există evaluări

- The Story of Gary KildallDocument1 paginăThe Story of Gary KildallShubham LashkareÎncă nu există evaluări

- ICMS Substituicao TributariaDocument4 paginiICMS Substituicao TributariaTuaregue_BRÎncă nu există evaluări

- Research Paper Using SpssDocument9 paginiResearch Paper Using Spssfyrqkxfq100% (1)

- Salesoft Case Analysis: Group 1 - Section BDocument18 paginiSalesoft Case Analysis: Group 1 - Section BSaurabh Singhal100% (2)

- AIS Chapter 3 ReviewerDocument4 paginiAIS Chapter 3 Reviewerrex martin guceÎncă nu există evaluări

- Reliability Engineering: Kartik Gupta 2K13/PE/016Document15 paginiReliability Engineering: Kartik Gupta 2K13/PE/016Kartik GuptaÎncă nu există evaluări

- Mobile SpecificationsDocument38 paginiMobile SpecificationsrahulvaliyaÎncă nu există evaluări

- Daily Mis Report Format in ExcelDocument27 paginiDaily Mis Report Format in ExcelSahad MBÎncă nu există evaluări

- Cisco ePDG AdminDocument99 paginiCisco ePDG AdminChris HainesÎncă nu există evaluări

- INT I - Compiler - Set 1Document2 paginiINT I - Compiler - Set 1salajaÎncă nu există evaluări