Documente Academic

Documente Profesional

Documente Cultură

Process Modeling Using Aspen HYSYS

Încărcat de

Linton WongDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Modeling Using Aspen HYSYS

Încărcat de

Linton WongDrepturi de autor:

Formate disponibile

Training Course Data Sheet

Page 1 of 2

Training Course Data Sheet

EHY101

Course Number: Duration: CEUs Awarded: Level:

EHY101 3 days 2.1 Introductory

Aspen HYSYS: Process Modeling

Former Course Title/Number

This course was previously known as Process Modeling Using Aspen HYSYS, EA1031

Who Should Attend

New engineering graduates/technologists who will be using Aspen HYSYS in their daily work Process engineers doing process design and optimization projects and studies Plant engineers checking plant performance under different operating conditions R&D engineers and researchers using Aspen HYSYS for process synthesis

Objectives

Learn to build, navigate and optimize process simulations using Aspen HYSYS Learn the efficient use of different HYSYS functions to build steady state process simulations

Course Benefits

Discover how the key features of Aspen HYSYS allow rapid flowsheet construction and its intuitive, bi-directional calculations Use the WorkBook and Process Flow Diagram (PFD) interfaces for quick and effective modeling Customize the WorkBook to track additional stream and operating parameters Investigate how templates and subflowsheets can streamline and organize simulation efforts Explore different means of reporting results, including the use of Microsoft Excel VB macros Preliminary Cost Estimation using Aspen Process Economic Analyzer from the Aspen HYSYS Environment Introduction to Aspen Simulation Workbook Evaluate the performance of existing equipment with the Rating function Improve the convergence performance of a simulation; troubleshoot common problems

Approach

Instruction on basic topics Experienced instructor will select an appropriate order in which to present the modules Discussion about the general approach and the key elements for successful simulations Instructor-guided demonstrations of features Hands-on workshops using examples from the natural gas processing industry Detailed course notes

Prerequisites

A background in chemical engineering or industrial chemistry

Suggested Subsequent Courses

EHY121 Aspen HYSYS: Using Aspen Simulation Workbook EHY201 Aspen HYSYS: Process Modeling Additional Topics

http://support.aspentech.com/supportpublictrain/classes/EHY101.htm

4/15/2009

Training Course Data Sheet

Page 2 of 2

EHY101 Aspen HYSYS: Process Modeling Course Agenda

Module: Getting Started Define a fluid package property package Select components, including hypotheticals Install streams and attach stream utilities Customize the Workbook Module: Propane Refrigeration Loop Add operations to build a flowsheet and use the

interface to manipulate flowsheets

Module: Natural Gas Dehydration with TEG Model a typical TEG dehydration unit Determine water dewpoint for a gas Estimate Process Capital Costs using Aspen

Economic Evaluation Tool

Module: Rating Heat Exchangers Use the Dynamic Rating method (by providing

heat exchanger geometry) to determine if an existing heat exchanger will meet process specifications

Understand forward-backward information Convert simulation cases to templates

Module: Refrigerated Gas Plant Install and converge heat exchangers Use logical operations: Adjust and Balance Use the Case Study tool to perform case studies

on your simulation

Module: CO2 Capture with MEA Define a fluid package in Aspen HYSYS using

Aspen Properties

Simulate electrolyte systems using Electrolyte NRTL

Module: NGL Fractionation Train Install columns by modeling a de-methanizer,

de-ethanizer, and de-propanizer column train

Module: Troubleshooting Recognize, interpret, and troubleshoot common

problem areas in Aspen HYSYS

Learn tips and tricks to ensure column convergence

Module: Oil Characterization Oil Characterization using boiling point assay

data and the Aspen HYSYS Oil Manager

Use of the Aspen HYSYS Spreadsheet to perform calculations

Module: Acid Gas Sweetening with DEA Simulate amine towers; supply tray dimensions Discuss efficiencies for amine towers Use the Set operation and the Spreadsheet Module: Reporting in Aspen HYSYS and Aspen Simulation Workbook Customize reports using the Report Manager Use XML to create an input data summary Run an Excel utilities to view workbook data Use Aspen Simulation Workbook to deploy

models in Microsoft Excel

Module: Gas Gathering System Use the pipe segment to model pipelines Module: Two-Stage Compression Use the Recycle operation in Aspen HYSYS Choose suitable tear locations for recycles Module: Compressor and Pump Curves Specify and attach single and multiple head and

efficiency curves to compressors and pumps

Aspen Technology, Inc. awards Continuing Education Units (CEUs) for training and development activities conducted by our organization in accordance with the definition established by the International Association of Continuing Education & Training (IACET). One CEU is granted for every 10 hours of class participation.

http://support.aspentech.com/supportpublictrain/classes/EHY101.htm

4/15/2009

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- List of B.tech CollegesDocument26 paginiList of B.tech CollegesShengavulaanushagmail.com AnushaÎncă nu există evaluări

- Prospectus 2010Document99 paginiProspectus 2010Sayyed Salman Mehdi MosviÎncă nu există evaluări

- THE Nano World: Group 7Document33 paginiTHE Nano World: Group 7Daniela Claire FranciscoÎncă nu există evaluări

- 16jul2014 04Document17 pagini16jul2014 04Jomin JosephÎncă nu există evaluări

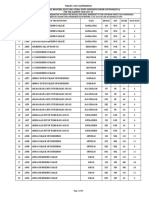

- B.E-Computer Science and Engg. Branch Name: Subject Code Subject Name Semester Exam Date Session DayDocument2 paginiB.E-Computer Science and Engg. Branch Name: Subject Code Subject Name Semester Exam Date Session DayvelsÎncă nu există evaluări

- Harry Okolo Jr. - CV 10th Jan 2013Document5 paginiHarry Okolo Jr. - CV 10th Jan 2013Nuno Sa PunsoÎncă nu există evaluări

- Placements 2017 18Document7 paginiPlacements 2017 18Kirti KumarÎncă nu există evaluări

- Problem 2 ReflectionDocument3 paginiProblem 2 ReflectionMegan MakelaÎncă nu există evaluări

- HCT Catalogue 1516 Programmes Cis 1Document12 paginiHCT Catalogue 1516 Programmes Cis 1api-354576162Încă nu există evaluări

- LICET Admissions2021-2022Document1 paginăLICET Admissions2021-2022MaheÎncă nu există evaluări

- Sociology in The Era of Big Data: The Ascent of Forensic Social ScienceDocument24 paginiSociology in The Era of Big Data: The Ascent of Forensic Social ScienceRodrigo FernandezÎncă nu există evaluări

- Karl Popper 1977 Normal Science and Its Dangers en Criticism and The Growth of Knowledge Imre Lakatos y Allna Musgrave EdsDocument7 paginiKarl Popper 1977 Normal Science and Its Dangers en Criticism and The Growth of Knowledge Imre Lakatos y Allna Musgrave EdsFatimah Ameer100% (1)

- Phase2ers ListDocument4 paginiPhase2ers Listabalos larryÎncă nu există evaluări

- Registered Engs, ETs, Firms & Labs May 05, 2021Document7 paginiRegistered Engs, ETs, Firms & Labs May 05, 2021Alfred PatrickÎncă nu există evaluări

- Aravind CV - For MergeDocument3 paginiAravind CV - For Mergek_parveen33Încă nu există evaluări

- Test2 Schedule 2020-21 Even SemDocument1 paginăTest2 Schedule 2020-21 Even SemkepoÎncă nu există evaluări

- PH.D Male TA Spring 2020Document3 paginiPH.D Male TA Spring 2020Srilalita ManasiÎncă nu există evaluări

- Evolution of Media GlobalizationDocument7 paginiEvolution of Media GlobalizationSearching AccÎncă nu există evaluări

- Loganathan Profile - May 2016Document2 paginiLoganathan Profile - May 2016dlogumorappurÎncă nu există evaluări

- Ieee 1138Document34 paginiIeee 1138Jose Antonio EstofaneroÎncă nu există evaluări

- Product Lifecycle Management: Dr. Michael Grieves Co-Director U of M PLM Development Consortium WWW - Plmdc.engin - Umich.eduDocument24 paginiProduct Lifecycle Management: Dr. Michael Grieves Co-Director U of M PLM Development Consortium WWW - Plmdc.engin - Umich.eduiwc2008007100% (1)

- Vanderlande Industries Software Private LimitedDocument2 paginiVanderlande Industries Software Private LimitedMudasir Ali BaigÎncă nu există evaluări

- T6 P8Document2 paginiT6 P8patilsharad3Încă nu există evaluări

- APQP Checklist Report - Version 1.1.Dtd. 13.11.08Document51 paginiAPQP Checklist Report - Version 1.1.Dtd. 13.11.08robbie86290% (10)

- IEC 61499 - Reference Model For Distributed AutomationDocument3 paginiIEC 61499 - Reference Model For Distributed Automationalonso_chicaÎncă nu există evaluări

- Statement of PurposeDocument2 paginiStatement of PurposePhortezzaÎncă nu există evaluări

- Complete List of Engineering Colleges in MUMBAI: Name & Address Activity Phone & Email Course OfferedDocument10 paginiComplete List of Engineering Colleges in MUMBAI: Name & Address Activity Phone & Email Course OfferedNilesh KordeÎncă nu există evaluări

- Saurabh Kumar Gautam-EntrepreneurDocument2 paginiSaurabh Kumar Gautam-Entrepreneurapi-240724695Încă nu există evaluări

- Dbms Placement QuesDocument27 paginiDbms Placement Quesachaparala4499Încă nu există evaluări

- George DantzingDocument5 paginiGeorge DantzingAnahazin SyanaÎncă nu există evaluări