Documente Academic

Documente Profesional

Documente Cultură

A Cry Lo Nit Rile

Încărcat de

Rani Dewi AyuningtyasDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Cry Lo Nit Rile

Încărcat de

Rani Dewi AyuningtyasDrepturi de autor:

Formate disponibile

ACRYLONITRILE Discovered in 1893 by the Frenchman Charles Moreu, acrylonitrile (d420) = 0.8061, mp = -83.5oC, bp1.013 = 77.

3C) remained a laboratory curiosity until the end of the First World War. Its industrial importance emerged around 1930, when it was used in Germany and the United States to manufacture nitrile rubber, Buna N, a copolymer of butadiene and acrylonitrile, displaying high resistance to hydrocarbons. Since then, its applications have expanded considerably, including textile fibers, synthetic resins, elastomers, and intermediates of organic syntheses. Nearly all the acrylonitrile produced worldwide is obtained by the ammoxidation of propylene. Furthermore, nearly 90 per cent of installed production capacities employ the Sohio process. This company has developed a whole series of increasingly betterperforming catalysts, with the first commercial achievement dating from 1960. The other technologies of this type offering an industrial character are those of Chemie Linz, OSW(Osterreichische Stickstoff Werke), Montedison/UOP(Universal Oil Products), SNAM (Societa Nazionale Metanodotti), Ugine/Distillers (PCUK/Distillers). The earlier methods were the following: (a) Addition of hydrogen cyanide to ethylene oxide to form cyanohydrin, which is then dehydrated to acrylonitrile. Developed by IG Farben, this process was adopted by American Cyanamid and Union Carbide, and then abandoned in 1965. (b) Reaction of hydrogen cyanide with acetylene, developed by Bayer, used by American Cyanamid, Du Pont, Monsanto until 1970. (c) Production of lactonitrile from acetaldehyde and hydrogen cyanide, and its dehydration to acrylonitrile. Developed and industrialized by Hoechst in Greisheim (Knapsack-Greisheim) until 1959, it is still partly used by the Japanese company Nusashino to manufacture lactic acid by lactonitrile hydrolysis. (d) Ammoxidation of propylene by nitrogen oxides, commercialized by Du Pont in Beaumont, Texas, until 1966. Many developments are currently under way to employ ethylene, propane and butane directly. 1. Acrylonitrile manufacture by ammoxidation of propylene Although a large number of its basic patents already lie in the public domain, the process commercialized by Sohio, concerning the ammoxidation of propylene, has acquired a virtual monopoly in view of the technological know-how accumulated in the past decade.

1

Specific gravity, 68.0/39.2

1.1 Transformation principle The formation of acrylonitrile by ammoxidation occurs according to the following highly exothermic reaction: CH2 =CH -CH3 + NH3 + 3/202 CH2 =CH -CN + 3H20 Ho298 =~-515 kJ/mol

It now'appears clear that this overall result can be explained by the production of acrolein as the main intermediate. In these conditions, the reaction scheme is as follows: CH2=CH-CH3 + O2 CH2=CH-CHO + H20 CH2=CH-CHO + NH3 CH2=CH-CH=NH + H20 CH2=CH-CH=NH + 1/202 CH2=CH-CN + H20 This transformation is also characterized by the importance assumed by degradation side reactions of propylene and of its oxygen and nitrogen derivatives, which lead simultaneously to the formation of hydrogen cyanide, acetonitrile, nitrogen, carbon monoxide and carbon dioxide: 2CH2 =CH-CH3 + 3NH3 + 302 3CH3CN + 6H20 CH2 =CH-CH3 + 3NH3 + 302 3HCN + 6H20 CH2=CH-CH3 + 302 3CO + 3H20 2CH2 =CH -CH3 + 902 6C02 + 6H20 Since these reactions are themselves highly exothermic, it is found in practice that the total exothermicity of acrylonitrile manufacture is higher than indicated by theory, and is as high as 650 to 670 kJ fmo\. A. Catalysts To offset the lower yield resulting from the development of side reactions, many catalyst formulations have been suggested, and their performance has steadily improved with time. They are allusing mixed oxides based on antimony, arsenic, bismuth, cobalt, tin, iron, molybdenum, nickel, phosphorus, rare earths, tellurium, uranium, vanadium, etc., with or without a support. The most signifIcant development was achieved by Sohio, who initially employed bismuth phosphomolybdate. This system was replaced in 1967 by a mixture based on oxides of antimony and uranium (catalyst 21). In 1972, Sohio then returned to an iron and bismuth phosphomolybdate (catalyst 41 (7)) doped by additions of cobalt, nickel and potassium, and achieving acrylonitrile productivity gains of 10 to 35 per cent. A fourth generation of catalysts (type 49) finally emerged in 1978, achieving a slight improvement in yield, but offering better mechanical properties.

Cooperation between Distillers and PCV K, followed by Border Chen/ita/s, was oriiginally based on the development of a two-step process. In the fIrst step, propylene was converted to acrolein on a catalyst based on selenium and copper oxides, and, in the second step, ammonia reacted in the presence of a system including MoO) and various other compounds. A single-step technology was subsequently developed, involving the use of molybdenum oxide promoted by caustic soda, or cobalt molybdate and tellurium oxide, followed by the use of systems of antimony and tin oxides. The best results are now obtained with formulations based on cohalt, iron and molybdenum. While SN AM dcveloped mixtures based on the use of bismuth and vanadium commpounds, MOllte-elisOIl, whose exclusive operating license was acquired in 1975 by VOP, prcferred a supported cat~lIyst bascd on oxides of cerium, molybdenum and tellurium on silica. OSW employs a mixture of mctallic bismuth and molybdenum deposited on a support. _ The latest developments in catalysts for manufacturing acrylonitrile are those of the Japanese firm Nitto Chemical, which commercialized a system in 1974 based on doped antimony and iron, called NS 733A or catalyst 13, offering higher productivity in commparison with Sohio catalyst 41, as well as lower production of acetonitrile and hydrogen cyanide by-products. These formulations. which operate in the yapor phase, are preferably used in a nuidized bed, to facilitate the removal of the heat generated by the reaction, the homogenization of the thermal level within the reaction medium, beller temperature control and hence superior ca"ialyst performance (Sohio, III olltedisollf VO P, Nitto, etc.). However, this arrangement implies improved mechanical properties. Fixed beds have also been used (PCVKfDistillersfBorder. SNAM. Chelllie-Lif/:, etc.), the main problem being the need to withstand a thermal gradient, and possibly the existence of hot points causing the (7) Sohio's catalyst 41 formulation is as rollows: CO . 5 Fe Niu Bi PO.5 Ko.o ~'OI2 0B....... 82.5 per cent weight Si02. . . ............... 17.5 per cent weight accelerated deslruction of the catalyst due to the migration of active phases and lo allrition. Apparent residence times range from :2 to 15 s, and catalyst lifc is generally betwL:en one and three years, and possibly more with the latest formulations. B. Operating conditions As a rule, the ammoxidation of propylene takes place in the presence of a slight excess of ammonia and oxygen in comparison with stoichiometry. The purity of the

reactants employed is generally high (ovet90 per cent weight for propylene, and 99.5 per cent weight for ammonia). With certain catalyst systems, especially the fIrstgeneration systems, the addition of steam raises selectivity and limits the conversion of ammonia to nitrogen. However, the current trend, due to the improvement in catalyst performance and the advances in metallurgy, is to eliminate this water hold-.up to achieve better optimization of the energy balance of the operation. Table 11.12 lists a number of typical molar feed compositions depending on catalyst type. Experience shows that the acrylonitrile yield increases with the NH3/propylene ratio. In practice, however, stoichiometry is approached as closely as possible (ratio of I), and, in certain cases, operations are even conducted at sub-stoichiometric values (;:;0 0.8). This is because the reaction is normally incomplete, and the ammonia remaining in the reactor exit gases, independent of the initial excess, gives rise to side reactions. These can be avoided by rapidly neutralizing it by sulfuric acid. Thus increasing the NH;/proopylene ra tio results in needless losses of ra w materials, with repercussions at the economic . level. From this standpoint, research projects under way are directed both for the developpment of better-performing catalysts and the development of ammonia recovery techniq ues, which allow for its recycling while maintaining high acrylonitrile selectivity. The reaction temperature usually ranges between 400 and sooDe and pressure remains below 0.3. J0/, Pa absolute. The acrylonitrile/acetonitrile molar ratio rises rapidly above 400"C. and rcaches a peak around 470 to 480"C. C. PClformance Once-through conversion of propylene is virtually complete, that of ammonia is higher in a fluidized bed (over 95 per cent) than in a fixed bed (~85 per cent). Selectivity, and consequently the acrylonitrile transformation yield, is very sensitive to . ,the type of catalyst and to the operating condition's, especially the residence time, which must remain above 1 s. The yield may be as high as 72 to 75 molar percent with the latest catalyst systems operating in a fluidized bed, and nearly 78 molar per cent with those operating in a fIxed bed . Table 11.l3 olTers some indications about the typical.emuent compositions leaving the propylene ammoxidation reactor according to the technology implemented. It also reveals the high proportion of by-products, whose utilization after separation and puriification can influence the economics of the operation considerably. Thus the acetonitrile, which could be used as a butadiene extraction solvent, is. usually burned. Another possibility is to convert it to acrylonitrile by the following reaction:

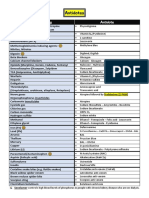

This reaction takes place in the presence of a supported potassium bromide-based catalyst. Hydrogen cyanide serves for the synthesis of methacrylic acid, methionine, etc. In many cases, however, it is also incinerated, minimizing the risks of pollution and accidents. With the Sohio technology, fluidized catalyst bed processes represent the most widespread industrial method. Lying far behind in the number of units installed, the PCUK/Distillers fixed bed technique is nevertheless the most widely used of competing processes. TYPICAL ~IOLAR COMPOSITION OF REACTOR fEED FOR THE PRODUCTION OF ACRYLONITRILE BY PROPYLENE A~l:vtOXIDATION I L. _ j Propylene Component .. T-------:--_~----:-, Ammonia! Air Sohio . Sohio . PCUK/Distillcrs . 1.5 to 2 1.05 to 1.2 1.1 to 1.2 10 to 20 10 to 15 12 to 15 I\tRYtf)"ITRIl.E 1'f!OI1l'c.-r10N IIY rf!I)PYI.I.NE A~l~lOXmATII)N. TYPKAL CO~lf'()Srnl1:-;s OF REM,oR EFFLlIE:-;T (./~ vol) C I I I ata yst processing. . . . . . . . . . . . . . . . . . .. ! Fluidiled bed I Fixcd ~cd ------_.-----;. ---- ----i--------i-_-- .. ---- .... - - --Catalyst i Sohio 41 ! Nitto IJ peu KiDistillcrs . -

._----+--_.! j!I i 5.3 I I g:r 'I i 29 :I i Emuent composition Acrylonitrile . Hydrogen cyanide . Acetonitrile . Carbon monoxide . Carbon dioxide . Higher nitriles .. . . Heavy products :- . Propane . Propylene . Water . Ammonia . Oxygen . Nitrogen . E 0.8 I

0.5 , 26.3 i 0.2 1 2.2 I ! 59.7 I !------ .!-------~ ----~-------r. 0.8 0.2 25.2 1.0 1.8 60.8 0.6 0.3 33.6 1.1 4.0 53.1 Residual gases (incineration) Indirect Quenching II Ammoxidation A. Propylene ammoxidation in fluidized bed, Sol,;o process The flowsheet of this type of installation (Fig. 11.19) comprises the following ma~n; operations: The reaction itself: this takes place in a specific vessel (Fig. 11.20) at the base of which a mixture of air compressed to between 0.15 and 0.3 . 106 Pa absolute and fertilizer grade ammonia is introduced, previously vaporized and preheated to between' 150 and 200C by passage through heat exchangers. This feed first crosses a distribution plate and then reaches the catalyst bed, which' it fluidizes. Chemical grade propylene To quenching and absorption Height of fluidized cata Iyst bed

Air/ammonia/ steam mixture Fig. 11.20. Schematic diagram of Sohio reactor for acrylonitrile production by nuidil.ed bed ammoxidation of propylene. (> 95 per cent weight) is introduced separately above the previous distributor. after fIrst having been vaporized and preheated to around 200"C. The fluidization height- is 7 to 8 m. A set of immersion tubes with internaI"boiler feed water circulation is placed within the catalyst bed. This serves to 'remove the heat generated by the reaction and to control the temperature at between 420 and 480C. while producing high-pressure steam (over 3 . lab Pa absolute). Cyclone separators are installed in the upper part of the reactor to retain catalyst particles entrained in the gaseous emuents . Quenching of the products obtained: to prevent any side reactions in the emuents, especially the addition of hydrogen cyanide to acrylonitrile and the formation of polymers which cause a drop in yield. the gases leaving the top of the reactor are rapidly cooled. They are first sent to a quench boiler for the production of low-pressure steam. and then to a direct contact cooling tower. which lowers their temperature to about 80 to 8SOC. This operation takes place in the lower part of the tower by means of a solution of sulfuric acid or acidified ammonium sulfate, designed to neutralize the ammonia present. Water scrubbing in the upper section removes the residual acidity. This treatment is accompanied by the production of a side stream of ammonium sulfate solution. which is then stripped of the organic compounds it contains. Product recO\wy: after additional cooling to between 40 and 45"C by indirect heat 'exchange. the neutralized gases arc sent to an absorber operating in the presence of cooled water (5"CI, to recover the maximum of hydrogen cyanide, acetonitrile, ac,ylonitrile and the heavier components. The residual gaseous emuents, which still have very low . contents of certain nitriles and hydrocarbons, are incinerated. Since acetonitrile and acrylonitrile have comparable boiling points (bplo13 = 81.6 and n.3C respectively). and ., also form azeotropes with comparable characteristics with water, their separation is '. relatively diffIcult, requiring about 70 to 80 trays. The heteroazeotrope obtained at the . _ top, after settling, yields an aqueous phase used as reflux, and an organic phase rich in . acrylonitrile and hydrogen cyanide, which is sent to the purifIcation step. The aqueous acetonitrile recovered at the bottom is enriched to over 97 per cent weight by azeotropic distillation (60 trays). The residual water is used as an absorption liquid after cooling to 5C. Acrylonitrile purification: this operation comprises a series of distillations for the following in succession:

(a) Separation of hydrogen cyanide (40 to 50 trays). (b) Removal of carbonylated impurities (acetone, acetaldehyde, propionaldehyde, acrolein, etc., 50 to 60 trays). (c) Vacuum purifIcation of acrylonitrile (25 to 30 trays). The presence of cyanohydrin, which is liable to decompose into HCN and carbonyllated compounds, and to lower the purity of the fmal product, makes it necessary to operate in the presence of a stabilizer (oxalic acid), in addition to a polymerization inhibitor added at various stages of the treatment scheme for ammoxidation emuents. Acrylonitrik to specifications is obtained in a side stream. Residual hydrogen cyanide is separated at the top and recycled to the previous column. The polymers withdrawn at thc bottom arc stripped to recover the acrylonitrile they contain and thus to improve the overall conversion yield. B. Fixed hed propylene ammoxidation, PCUK/Distillers process The flowsheet (Fig. 11.21) of plants operating with a fIxed bed displays the following main characteristics: Reaction: it takes place on a feed preheated to around 220C of ammonia, propylene and compressed air (0.3 . 106 Pa absolute) in controlled proportions. It takes place in a mnlti-tube reactor (catalyst tube dimensions: inside diameter 25 to 30 m!Tl, height 3 to 3.5 m), with shell-side circulation of a bath of molten salt intended to remove the heat generated by the reaction, and which is then cooled to produce high-pressure steam. Cooling: the gases leaving the ammoxidation reactor are quenched at about 380 to 400C, first in a boiler designed to produce low-pressure steam, and then by direct contact in a tower operating in the presence of sulfuric acid at the bottom zone to neutralize the residual ammonia, and water in the top section. The ammonium sulfate withdrawn can be treated subsequently to extract the organic compounds which it contains. Separation: transformation product r overy is also similar to that of the Sohio process, with cooling to about' 40C, partial condensation, absorption of nitriles and ~: ij j ,.\ Ii ' ,1 heavier compounds bv coolt:d waler (S"e). and incincr' t' f h 'd I H .... - '. d Ion 0 t e res 1 ua gases. etero-

azeotroplc dlstJllallon (20 to 30 trays) then elIminates a hm.e p'l t f th - b h' ". I" - ,~ ,r 0 e water, ot In - the wlthdra ,\',\!. whIch IS then used as a quench and absorption fluid, and in the distillate .' after settling of an aqueous phase employed as renux, and of an organic fraction, whid~ is sent to the next fractionation step . purification: this step features the second innovation of the process which, to eliminate the by-product acrolein, favors the formation of cyanohydrin by means of the hydrogen cyanide which is also present. This operation takes place at low temperature (20C) .. in agitated reactors, either continuously in the presence of a copper-based catalyst, or , semi-continuously with a reaction phase in basic medium (caustic soda addition), followed by a neutralization period (sulfuric acid addition). The cyanohydrin obtained is then removed by vacuum distillation. The withdrawal may be sent to a thin layer evaporator lO recover entrained acrylonitrile. These treatments must be conducted in the presence of a polymerization inhibitor and at a temperature below 55"C to prevent the redecomposition of cyanohydrin. Subsequent operations on the distillate are morc conventional. Distillation is used "lo sepanite the following in succession: (a) Hydrogen cyanide (40 to 45 trays). (b) Acetonitrile, in two columns, whose operation is based on the separation of heteroazeotropes between water and, on the one hand, acrylonitrile at the top of the first column (45 to 50 trays), and, on the other, acetonitrile at thc top of the st:cond (60 to 65 trays), and the wakr withdrawn is recycled to the first distillation. (c) Light compounds and rcsidual water at atmospheric pressure (50 to 60 trays). (d) Heavy compounds under vacuum (25 to 30 trays), with an impure acrylonitrile distillate recycled to the light-ends separation column, and a side stream uf acrylonitrile meeting commercial sreciflcations. A. Passage through ethylene cyanohydrin The following reactions are involved: CH2-CH, + HCN -+ CH,OH-CH2-CN ""-. / - o

CH20H-CH2-CN --+ CH2=CH-CN + H20 The preparation of cyanohydrin was described in connection with the synthesis of acrylates (see Section 11.3.2.2). As for dehydration, this can be conducted in the liquid phase, around 200C, in the presence of a soluble catalyst based on magnesium formate or carbonate, or in the vapor phase between 250 and 350C, by passage over alumina. The molar yield is 90 per cent. B. Addition of hydrogen cyanide to acetylene This highly exothermic reaction: HC=CH + HCN -+ CH2=CH-CN has been conducted industrially in the liquid phase, in the presence of a catalyst consisting of cuprous chloride and ammonium chloride in solution in hydrochloric acid. A large excess of acetylene is used (6 to 15 mol/mol HCN) at a pressure slightly above 0.1 .106 Pa absolute and a temperature of 80 to 90C. The molar yield is up to 90 per cent in relation to hydrogen cyanide, and 75 to 80 per cent in relation to acetylene. The main by-products are acetaldehyde, vinylacetylene, divinylacetylene, vinyl chloride, cyanobutene. lactoonitrile, methyl vinyl ketone, etc. The same reaction can be conducted in the vapor phase (Goodrich) around 500 to 600C, on charcoal impregnated with caustic soda and cyanides. C. Passage through lactonitrile The raw material is acetaldehyde. converted in two steps to acrylonitrile: (a) In the first step, lactonitrile is formed by the addition of hydrogen cyanide to acetaldehyde: This reaction. which is highly exothermic and very fast. takes place hetween 10 and 20ne. at pH between 7 and 7.5, with a molar yield of 97 to 9X per cent. (b) In the second step. the lactonitrilc is dehydrated to acrylonitrih.:: CH,I-O-{OH -CN -+ CH2 =CH -CN + H20 To prevent redecomposition into acetaldehyde and hydrogen cyanide. the reaction takes place with a large excess of phosphoric acid (three times by volume) by spraying at 600 to 700"C in a reactor in which the lactonitrilc is placed in contact with a hot, oxygen-free inert gas. during an interval shorter than 3 s. The total molar yields are about 90 per cent in relation to acetaldehyde and 92 per cent in relation to hydrogen cyanide.

D. Nitric oxide with propylene This involves the following conversion: 4CH2 =CH -CH3 + 6NO -+ 4CH2 =CH -CN + 6H20 + N2 It takes place at atmospheric pressure, between 450 and 550C, in the presence of a siIYer oxide based catalyst deposited on silica or of earth alkali metal oxides. thallium and lead. and with excess propylene. An inert (nitrogen, steam, etc.) is used as diluent, in order to absorb the heat generated during the conversion, whose molar yield is 70 per cent in relation to propylene. These processes arc desi!!ncd to convert the hydrocarbons directly. particularl\' ethyylene and propylene, by the following main methods: Action of HC:" al high temperature (between 750 and 100()uC), in the absence of catalyst, to achieve previous ill situ dehydrogenation. Action of HCN in the presence of oxygen; Asuhi and Du POllt have developed a process for vapor phase ethylene conversion, between 330 and 360uC, on nickel- or palladium-based catalysts deposited on alumina (possibly acidified by the addition of hydrochloric acid) and doped by elements such as vanadium, cesium, etc: CH:,=CH:, + HCN + 1/20:, -+ CH3=CH-CN + H:,O The molar yields are in the neighborhood of 90 per cent. Ammoxidalion of paraffms: MOIl.';ullto and Po\\'cr Cus/lel have proposed processes employing propane instead of propylene: CH3-CH:, -CH3 + NH3 + 20:, -+ CH:, =CH -CN + 4H:,0 They operate around 480 to 520C, in the presence of a catalyst based on antimony, tungsten~ uranium, vanadium, etc. . TABLE I I. 14 ACKYL()~ITI(ILE I'IW[)Ut'lIUN. ECO:-<UMIC DA1A (France conditions mid-Il)~(,) /'i(OIlIXTIO'-: (.'AIA~Tf\ I UO.OOU tjYE,\H Consumption per ton of acrylonitrile: Raw materials Propylene (t) .

Ammonia (tl '.' . By-products Hydrogen cyanide (kg) . Acetonitrile (kg) . . . .. . . Utilities Steam (t) . Electricity (kWh) . Cooling water (m3) ................ Process 'water (m 3) . Cnemicals and catalysts (US$) Sulfuric acid (100%) (t) ................. Caustic soda (100%) (t) . Miscellaneous (US$) . 1.18 1.10 0.50 0.52 170 125 120 50 1.0 ! 0.5 270 I 250 400 I 500 5 I 5 0.05 I 0.30 -I 0.02 45 30 6 ! 6 I Table 11.14 g.ives tcchnico-economic data concerning the two principal processes for manufacturing acrylonitrile currently industrialized, and which involve the ammoxiidation of propylene in a Ouidized bed or a fIxed catalyst bed. Table J 1.15 lists the average commercial specifIcations of acrylonitrile and of the byyproducts formed in propylene ammoxidation (acetonitrile and hydrogen cyanide).

Table 11.16 lists the main applications of acrylonitrile in Western Europe, the United States and Japan, together with the production, capacity and consumption fIgures in these three geographic areas in 1984.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Antidotes and Its Clinical ApplicationsDocument26 paginiAntidotes and Its Clinical ApplicationsSubeesh KumarÎncă nu există evaluări

- Sodium AzideDocument8 paginiSodium Azidejohn100% (1)

- Mark Scheme Summer 2007 GCE Chemistry Paper 02Document11 paginiMark Scheme Summer 2007 GCE Chemistry Paper 02Darly SivanathanÎncă nu există evaluări

- Qualitative Inorganic Analysis of AnionsDocument90 paginiQualitative Inorganic Analysis of AnionsMahesh100% (1)

- Acid Leachability Copper Species PDFDocument10 paginiAcid Leachability Copper Species PDFJeyson Cornejo100% (1)

- HalogenalkaneDocument4 paginiHalogenalkanePutri Nur SyafieqahÎncă nu există evaluări

- Purification and Characterisation TechniquesDocument10 paginiPurification and Characterisation TechniqueskrishnaÎncă nu există evaluări

- NH3 CNLeachPaperRevisedDocument17 paginiNH3 CNLeachPaperRevisedGeorgi Mitkov SavovÎncă nu există evaluări

- Chemistry of RileDocument34 paginiChemistry of RilechasadjeeÎncă nu există evaluări

- Co-Ordination and Organometallic CompDocument85 paginiCo-Ordination and Organometallic CompDr. Dhondiba Vishwanath100% (1)

- 5th International Seminar On Process HydrometallurgyDocument447 pagini5th International Seminar On Process HydrometallurgyCésar González Lagos100% (1)

- Sample PaperDocument17 paginiSample PaperagueromaÎncă nu există evaluări

- Environmentally Sound Gold Recovery ProcessDocument283 paginiEnvironmentally Sound Gold Recovery ProcessSumitShahÎncă nu există evaluări

- CLS Aipmt 18 19 XIII Che Study Package 6 SET 1 Chapter 20Document44 paginiCLS Aipmt 18 19 XIII Che Study Package 6 SET 1 Chapter 20sanika ///Încă nu există evaluări

- Hdpe Chem ResistanceDocument2 paginiHdpe Chem ResistanceMindy GuzmanÎncă nu există evaluări

- IddDocument15 paginiIddslidesputnikÎncă nu există evaluări

- Antidotes: Poison/Drug AntidoteDocument1 paginăAntidotes: Poison/Drug AntidoteAfsal Ur FriendÎncă nu există evaluări

- Practical Organic Chemistry For Advanced StudentsDocument306 paginiPractical Organic Chemistry For Advanced StudentsSamuel DinizÎncă nu există evaluări

- Organometallics FULL NOTESDocument349 paginiOrganometallics FULL NOTESBrian MachariaÎncă nu există evaluări

- Total and Amenable Cyanide by DistillationDocument10 paginiTotal and Amenable Cyanide by Distillationrnd labÎncă nu există evaluări

- Inorganic Chemistry Laboratory Ion TestDocument50 paginiInorganic Chemistry Laboratory Ion TestTrescia Mae EstilloreÎncă nu există evaluări

- WAD Cynoprobe PDFDocument9 paginiWAD Cynoprobe PDFGerehÎncă nu există evaluări

- Acute Cyanide PoisoningDocument18 paginiAcute Cyanide PoisoningRachman UsmanÎncă nu există evaluări

- Understanding Gold Plating Electrolytes and Deposition ProcessesDocument7 paginiUnderstanding Gold Plating Electrolytes and Deposition ProcessescicerojoiasÎncă nu există evaluări

- Jewellery Manufacturing ProcesDocument29 paginiJewellery Manufacturing ProcesDr. Neeru jain83% (6)

- Topinambur 1Document7 paginiTopinambur 1Ionela HoteaÎncă nu există evaluări

- Part - I: Practice Test-1 (Iit-Jee (Main Pattern) ) : MetallurgyDocument18 paginiPart - I: Practice Test-1 (Iit-Jee (Main Pattern) ) : MetallurgyGOURISH AGRAWALÎncă nu există evaluări

- Cyanide Method Picric Acid 1Document3 paginiCyanide Method Picric Acid 1Ferudun AkyolÎncă nu există evaluări

- 2224inst-Available Oia-1677 FIA (1) - CopiarDocument38 pagini2224inst-Available Oia-1677 FIA (1) - CopiarFranco A. ZavaletaÎncă nu există evaluări

- Nadia Chaouali Et Al. - Potential Toxic Levels of Cyanide in Almonds (Prunus Amygdalus), Apricot Kernels (Prunus Armeniaca), and Almond SyrupDocument7 paginiNadia Chaouali Et Al. - Potential Toxic Levels of Cyanide in Almonds (Prunus Amygdalus), Apricot Kernels (Prunus Armeniaca), and Almond Syrup897435hsdfÎncă nu există evaluări