Documente Academic

Documente Profesional

Documente Cultură

ADJUST FUEL TIMING

Încărcat de

Sanjay MadakaDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ADJUST FUEL TIMING

Încărcat de

Sanjay MadakaDrepturi de autor:

Formate disponibile

ADJUSTING FUEL TIMING Steps necessary for fuel timing: 1.

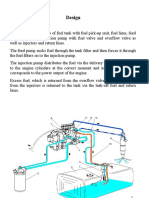

Remove air intake manifold so that the fuel injector pump can be removed without interference. 2. Set throttle lever at full speed. 3. Remove injector pump side cover. This will enable you to visually check to insure that the fuel rack pin inside the pump properly aligns with the opening in the top of pump housing when being removed to prevent binding or shearing of the pin. This pin is critical to proper pump operation and if damaged will require replacement of the complete pump. 4. The injector pump internal unit can now be loosened and removed. It may be necessary to remove fuel lines from injector nozzles to aid in pump removal 5. There are several shims located just below the pump top plate which will be used to adjust the timing. These shims are .006 inch thick and are equal to 1 or approximately 3116" of distance on the circumference of the flywheel. Addition of shims will retard the timing and removing shims will advance the timing. 6. If the mark on the flywheel is below the pointer, the fuel is being injected sooner than required and the fuel timing must be retarded. Shims must be added until the timing marks are aligned. The opposite is true if the flywheel mark is above the pointer. See image to the right. 7. If at all possible, it is better to operate the engine with the timing advance rather than retarded. 8. Replace fuel injector pump, making sure the fuel rack pin aligns with the housing opening and is properly inserted into the slotted arm. Tighten injector pump cover in place. Reconnect fuel line from fuel filter to pump. Repeat steps 2 thru 12 on engine timing.

9. If timing is satisfactory, then reassemble. Be certain that all plates, covers, fuel lines and connections are tight and free of leaks so that safe operation may be expected when the engine is started. Clean engine thoroughly. 10. Caution: Be sure all fuel lines and connections are kept clean during adjusting, to prevent fouling of nozzles when reassembled.

FUEL INJECTION TIMING: Unless major repair work is done on the engine, timing should not be required. Basic tools required: (A) - 10 MM Socket wrench (B) - 13 MM Socket wrench (C) - 17 MM Open end wrench (D) - 12 MM Box end wrench (E) - 27 MM Socket (1-1/16") Engine firing order - Two cylinder - 1 - 2 (Front V belt end) Three cylinder - 1 - 2 - 3 Four cylinder - 1 - 3 - 4 - 2 1. Remove fuel lines from injector pump fittings on injector pump (Tool C). 2. Pull decompression lever so that it will remain in the decompression position. No decompression lever on Model-i 2. 3. Open throttle fully. 4. Energize electric fuel pump and turn engine over with starter to ensure that fuel is coming out of each injector pump opening. Have clean rags around opening to soak up fuel. 5. Wipe off any fuel on injector pump body and the top of each injector opening. 6. Turn crankshaft over by hand, being careful not to damage spline on end of crankshaft. Engine rotation will be clockwise. STOP IMMEDIATELY at the first sign of fuel movement in the injector pump fuel fitting, for whichever injector pump is being checked. (No. 1 injector pump is the closest to the V-belt end of the engine). 7. Remove cover from flywheel timing mark inspection hold located inside of left engine mount (Tool B). 8. Check alignment of mark on flywheel with the timing pointer on the wall of the inspection hole. The 1-Fl mark on the flywheel represents fuel injection of No. 1 cylinder. 2-Fl represents No. 2 cylinder, etc. 9. If timing pointer and the flywheel marking 1-Fl is aligned then No. 1 cylinder is properly timed for fuel injection and should require no adjustment. The same will be true for No. 2, No. 3 and No. 4 cylinders if the above steps are followed. 10. In order to determine if timing is off, or if the injection pump is faulty, it is necessary to recheck the timing for each cylinder two or three times. 11 If there are variations in repeatability in the alignment of pointer and timing mark, a faulty

fuel injector pump may be suspected. 12. If timing marks repeat to same location but are off 3/16" or more above or below the pointer, this indicates that the engine must be retimed. If alignment of the timing mark is not within 3/16" above or below the pointer, the above steps must be taken to time the engine, If the timing is found to be satisfactory, then reconnect all fuel lines and fittings and tighten. The fuel system must be bled before the engine will operate properly. (See fuel bleeding instructions else where in this manual).

S-ar putea să vă placă și

- Diesel Fuel Injection PumpsDocument10 paginiDiesel Fuel Injection PumpsRsjBugtong100% (1)

- 05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateDocument16 pagini05 - B - RTA 8 Series RTA 2 Series Fuel Pump UpdateGiovanniJara100% (1)

- Inline Injection Pump Removal, Installation and Timing Required MaterialsDocument2 paginiInline Injection Pump Removal, Installation and Timing Required MaterialsNati Man DejeneÎncă nu există evaluări

- Fuel Injection Pump - InstallDocument8 paginiFuel Injection Pump - Installedwin100% (1)

- Caterpillar Sleeve Metering Fuel System ExplainedDocument6 paginiCaterpillar Sleeve Metering Fuel System ExplainedJosephÎncă nu există evaluări

- High Pressure Injection System 01Document58 paginiHigh Pressure Injection System 01Orlando GalvanÎncă nu există evaluări

- Caution: Counterclockwise, As Viewed From TheDocument19 paginiCaution: Counterclockwise, As Viewed From TheanilÎncă nu există evaluări

- 01.main Engine ManualDocument64 pagini01.main Engine ManualwilfredÎncă nu există evaluări

- Injection SystemDocument75 paginiInjection SystemSlobodan100% (1)

- Fuel Injection Pumps, In-LineDocument24 paginiFuel Injection Pumps, In-LineJose Luis CristanchoÎncă nu există evaluări

- TICS Pump Electrical Part Resistance For HINODocument35 paginiTICS Pump Electrical Part Resistance For HINOBala Equal BalanceÎncă nu există evaluări

- Fuel Pump PDF FINALDocument5 paginiFuel Pump PDF FINALravidra markapudiÎncă nu există evaluări

- Code 368 PDFDocument2 paginiCode 368 PDFesquisof0% (1)

- Code 386 RepairDocument12 paginiCode 386 RepairCarlos A RomeroÎncă nu există evaluări

- Dismantling Process of Fuel Injection PumpDocument47 paginiDismantling Process of Fuel Injection PumpJonoAlexisDang-awanQuibanÎncă nu există evaluări

- Valve and Valve AdjustmentsDocument18 paginiValve and Valve Adjustmentsgillian marbebeÎncă nu există evaluări

- Manual Del Estudiante D8T - 12Document14 paginiManual Del Estudiante D8T - 12David CeronÎncă nu există evaluări

- Chapter Electric Fuel Injection SystemDocument92 paginiChapter Electric Fuel Injection Systemcamionetanissanz20Încă nu există evaluări

- Stanadyne DB2 and DB4 Pump Installation and RemovalDocument4 paginiStanadyne DB2 and DB4 Pump Installation and RemovalDenisGutierrezÎncă nu există evaluări

- Basic FuelDocument30 paginiBasic FuelMulyadi Tarchani100% (1)

- Disassembly and Assembly of Vehicular Engine Fuel Injection PumpDocument9 paginiDisassembly and Assembly of Vehicular Engine Fuel Injection PumpHammam al HammamÎncă nu există evaluări

- Operation 1Document9 paginiOperation 1Wbamlak AshebrÎncă nu există evaluări

- Fuel Injector Testing ReportDocument12 paginiFuel Injector Testing ReportZeke KazamiÎncă nu există evaluări

- D399 Industrial Engine Troubleshooting GuideDocument49 paginiD399 Industrial Engine Troubleshooting GuideMohamed SaiedÎncă nu există evaluări

- EX-2 Fuel Pump Timing Setting and AdjustmentDocument2 paginiEX-2 Fuel Pump Timing Setting and AdjustmentAayush Agrawal100% (1)

- 05 Fuel Injection SystemDocument42 pagini05 Fuel Injection SystemVishal JohaheerÎncă nu există evaluări

- Engine 3306 (Calibracion Valvular) PDFDocument1 paginăEngine 3306 (Calibracion Valvular) PDFJulito Santa Cruz100% (1)

- SmokeDocument2 paginiSmokeJoeÎncă nu există evaluări

- Instalacion Bomba Delphi DP210Document3 paginiInstalacion Bomba Delphi DP210Martina FambÎncă nu există evaluări

- 2 - Introduction To The ME Engine PDFDocument14 pagini2 - Introduction To The ME Engine PDFVikash Khaliyav Yadav50% (2)

- Fuel Injection Control Linkage - InstallDocument5 paginiFuel Injection Control Linkage - InstallPutra JawaÎncă nu există evaluări

- WMC568Document30 paginiWMC568vali_ecsÎncă nu există evaluări

- Fuel Injection System Project ReportDocument15 paginiFuel Injection System Project Reportgurudatt.kulkarni100% (2)

- Injection Timing BTDCDocument4 paginiInjection Timing BTDCFilipposÎncă nu există evaluări

- Puncture ValveDocument1 paginăPuncture ValveAnkit DedhiyaÎncă nu există evaluări

- What is a Fuel Injection Pump? Its Parts, Working, Types and SymptomsDocument7 paginiWhat is a Fuel Injection Pump? Its Parts, Working, Types and SymptomsGANAPATHY MÎncă nu există evaluări

- Governor Adjust Idle SpeedDocument6 paginiGovernor Adjust Idle SpeeddarioÎncă nu există evaluări

- Kydr203cd-23 D.O Purifier Nanjing Luzhou MachineDocument48 paginiKydr203cd-23 D.O Purifier Nanjing Luzhou Machinekelvin100% (1)

- Common Rail Diesel Engine Management 1 PDFDocument13 paginiCommon Rail Diesel Engine Management 1 PDFMarranÎncă nu există evaluări

- Chequeo Tiempo Bomba de Inyeccion 3056 CATDocument10 paginiChequeo Tiempo Bomba de Inyeccion 3056 CATAlejandro ValenzuelaÎncă nu există evaluări

- Procedure for Overhaul of A/E GeneratorDocument20 paginiProcedure for Overhaul of A/E GeneratorKapil Verma100% (1)

- AVM2-PC EnglishDocument8 paginiAVM2-PC English賴小辰Încă nu există evaluări

- Injection Pump Removal Installation Timing AdjustmentDocument5 paginiInjection Pump Removal Installation Timing AdjustmentMimmo LeoneÎncă nu există evaluări

- Sensors System, Advanced Fuel Injection System, Computer Control SystemDocument34 paginiSensors System, Advanced Fuel Injection System, Computer Control SystemAdil RandhawaÎncă nu există evaluări

- VE Pump TrainingDocument36 paginiVE Pump TrainingNarendra FirmansyahÎncă nu există evaluări

- Diesel Injection Pump COVEC-FDocument36 paginiDiesel Injection Pump COVEC-FOlman Sandoval100% (1)

- Vp44 Injection Pump Repair ManualDocument2 paginiVp44 Injection Pump Repair Manualmarran almarranyÎncă nu există evaluări

- The Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsDocument2 paginiThe Delphi Advantage.: Remanufactured All Makes Diesel Fuel InjectorsEphrem MichaelÎncă nu există evaluări

- Fuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTDocument81 paginiFuel Valve, Fuel Pump, Relief Valve, Starting Air Valve, Air Distributor Automatic Valve, EXHAUSTsuraj0% (1)

- Fuel Injection Timing CheckDocument5 paginiFuel Injection Timing CheckSteven ManuputtyÎncă nu există evaluări

- Pge and Pgev Locomotive Governor Installation: Product Manual 54053 (Revision C)Document14 paginiPge and Pgev Locomotive Governor Installation: Product Manual 54053 (Revision C)Ahmad RagabÎncă nu există evaluări

- Timing Valves 6 CylindersDocument2 paginiTiming Valves 6 Cylindersmorrenita2003Încă nu există evaluări

- Diesel Fuel Injection Nozzle Operation & TestingDocument25 paginiDiesel Fuel Injection Nozzle Operation & TestingMoaed KanbarÎncă nu există evaluări

- Pistons and Connecting Rods - InstallDocument4 paginiPistons and Connecting Rods - InstallPutra Jawa100% (1)

- B Series Head Torque DataDocument21 paginiB Series Head Torque DataSpectrumRaijin100% (1)

- Original Series METAL Pumps: Simplify Your ProcessDocument47 paginiOriginal Series METAL Pumps: Simplify Your ProcessalexanderÎncă nu există evaluări

- Maintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingDocument12 paginiMaintenance and Repair of Fuel Suppply, Lubrication and Cooling System Fuel Pump TestingAdarsh AnilÎncă nu există evaluări

- Carburetor Troubleshooting Repair Guide For HondaDocument9 paginiCarburetor Troubleshooting Repair Guide For HondaRoyal EÎncă nu există evaluări

- Fuel PumpDocument4 paginiFuel PumpRajesh Kumar100% (2)

- Fuel Pump Replacement ManualDocument7 paginiFuel Pump Replacement Manualapi-542121636Încă nu există evaluări

- Deepwater Advanced 1 PDFDocument8 paginiDeepwater Advanced 1 PDFYadiiraaSagreeroÎncă nu există evaluări

- Yunus Mujawar: Electrical EngineerDocument3 paginiYunus Mujawar: Electrical EngineerSuresh VanierÎncă nu există evaluări

- Solar CellDocument6 paginiSolar CellJonathan NandhikaÎncă nu există evaluări

- Solar Business Plan 1Document9 paginiSolar Business Plan 1shivanipoudwalÎncă nu există evaluări

- Engineering Units Converter (Version 1)Document23 paginiEngineering Units Converter (Version 1)segunoyesÎncă nu există evaluări

- IRENA IEAPVPS End-of-Life Solar PV Panels 2016 PDFDocument100 paginiIRENA IEAPVPS End-of-Life Solar PV Panels 2016 PDFAndre SÎncă nu există evaluări

- Understanding Telecom Power Components and SystemsDocument15 paginiUnderstanding Telecom Power Components and SystemsharkishanÎncă nu există evaluări

- Valve Failure Analysis: Read the CluesDocument5 paginiValve Failure Analysis: Read the CluesahmedalgaloÎncă nu există evaluări

- Emerson IF80 0471Document16 paginiEmerson IF80 0471Tekos7Încă nu există evaluări

- Important Questions CE 6451 Fluid MechanicsDocument4 paginiImportant Questions CE 6451 Fluid Mechanicsommech2020Încă nu există evaluări

- 6562 DuelfuelDocument2 pagini6562 DuelfuelAnonymous NUn6MESx100% (3)

- Department of Electrical EngineeringDocument39 paginiDepartment of Electrical EngineeringfdsafdsafasÎncă nu există evaluări

- 1000-1109 - Index 17 GE Jenbacher Gas EnginesDocument14 pagini1000-1109 - Index 17 GE Jenbacher Gas EnginesDavid PomaÎncă nu există evaluări

- Perovskite Solar CellDocument11 paginiPerovskite Solar CellOptimus Prime100% (2)

- Electric Arc Furnace Technology Enables Low-Cost Steel Production in Southeast AsiaDocument4 paginiElectric Arc Furnace Technology Enables Low-Cost Steel Production in Southeast AsiaBoy Trio ManikÎncă nu există evaluări

- Full ReportDocument57 paginiFull Reportapi-3756989100% (4)

- Transformations of Sound, Heat, Light and ElectricityDocument6 paginiTransformations of Sound, Heat, Light and ElectricityPrince Jallie Bien GuraÎncă nu există evaluări

- Design of 26m Precast Piles for Bangladesh Power PlantDocument6 paginiDesign of 26m Precast Piles for Bangladesh Power PlantcivixxÎncă nu există evaluări

- BAM 101 Introduction To Business Administration (Shakshi Shakshi)Document10 paginiBAM 101 Introduction To Business Administration (Shakshi Shakshi)shakshiÎncă nu există evaluări

- Ap18 FRQ Environmental Science PDFDocument6 paginiAp18 FRQ Environmental Science PDFadolecente venezolanoÎncă nu există evaluări

- Abound CdTe PDFDocument2 paginiAbound CdTe PDFKirsten HernandezÎncă nu există evaluări

- CHE2162 Week 9 Tutorial PDFDocument4 paginiCHE2162 Week 9 Tutorial PDFHua KhienÎncă nu există evaluări

- Oversizing of Solaredge Inverters, Technical NoteDocument1 paginăOversizing of Solaredge Inverters, Technical NoteMohammad HamamdÎncă nu există evaluări

- Advantages of Low Volatile Coals for PCIDocument24 paginiAdvantages of Low Volatile Coals for PCIKUNALJAYÎncă nu există evaluări

- CHPRCS01001 Prasad QuestionsDocument4 paginiCHPRCS01001 Prasad QuestionsAshish SrivastavaÎncă nu există evaluări

- 2,3l Motronic (AGZ) 1Document14 pagini2,3l Motronic (AGZ) 1Bernardo Verber100% (2)

- Applied Thermal Engineering: Jacek KalinaDocument12 paginiApplied Thermal Engineering: Jacek KalinaAle' AmoudiÎncă nu există evaluări

- Cable Trench Design Calculation for 50 MW Solar PlantDocument4 paginiCable Trench Design Calculation for 50 MW Solar PlantAmol ChavanÎncă nu există evaluări

- Air Intake Parts ListDocument42 paginiAir Intake Parts ListFrancisco RenteriaÎncă nu există evaluări

- Ammonia Gas Turbine Co-Generation Tech Reduces NOx EmissionsDocument6 paginiAmmonia Gas Turbine Co-Generation Tech Reduces NOx EmissionsMartin VidmarÎncă nu există evaluări