Documente Academic

Documente Profesional

Documente Cultură

KATALYST On MirpurFurniturePlant

Încărcat de

Roman ZahanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

KATALYST On MirpurFurniturePlant

Încărcat de

Roman ZahanDrepturi de autor:

Formate disponibile

FEASIBILITY OF A WOOD SEASONING PLANT FOR THE MIRPUR FURNITURE CLUSTER 1.

0 INTRODUCTION Seasoning is one of the most important processing technologies prior to manufact ure of wood based products. It is an appropriate technology particularly for the furniture industr y, because it improves the quality of the furniture significantly. It increases physical and mechanical pro perties, dimensional stability, finishing, polishing painting and gluing capacity. It also saves timb er and its products like furniture from bio-deterioration by protecting from fungus and insect attacks. I t, thus, also enhances the service life of furniture. Because of these distinct advantages, a keen inte rest was observed among the owners of the furniture enterprises to have their own seasoning plants . But the individual enterprise is handicapped due to a large investment involved in adopting the tec hnology. This is why they have formed a Forum and have approached KATALYST to get the technical assis tances right from the feasibility study to installation, operation and training to improve th e quality of timber and its products. It aims at strengthening the furniture and sawmill industries. Initial ly, the feasibility aspect will be dealt with and after completion of this first phase, subsequent activiti es will be taken up. With this aim in view, the assignment was undertaken as per specific tasks contained in the Terms of Reference as mentioned in Annex-1. A list of the member enterprises of the Forum , Rokeya Sarani Furniture Development Industries is presented in Annex 2. The furniture enterprises and other organizations visited and personnel met in this respect are shown in Annex-3. A small number of big enterprises are already exporting furniture to different c ountries in a limited form. Some of the members of the Forum are planning to enter into the export are na with their products in the future. But it is a pre-requisite condition to manufacture furni ture from properly seasoned timber in case of export. They are fully aware of this aspect, which wa s evident during the discussion with them. This is another reason for the Mirpur furniture cluster to have its own seasoning plant. 2.0 METHODOLOGICAL APPROACH The study involved an initial discussion with the key personnel of the furniture and sawmill industries in Mirpur zone. The questionnaire survey method was used to know the state of ar t of 19 furniture enterprises comprising 22 members in the target area covering a broad range of a spects. For this, a structured questionnaire was prepared (Annex-4). The collection of reliable info rmation was

attempted through informal and friendly discussion with the entrepreneurs by rem oving their apprehension, misgiving and then convincing the importance of sustainability of the Forum which depends on their unreserved answers. Finally, all data were compiled and the fre quency analysis was performed on relevant information (Annexes: 5-14). Some related organizations we re visited, relevant documents were examined and all pertinent information were collected. F or procurement of wood seasoning kilns and basic woodworking machineries, detailed particulars wer e collected from the local and foreign sources through visits and correspondences. 3.0 FURNITURE INDUSTRY AND WOOD SEASONING PRACTICE 3.1 Furniture industry There is no reliable statistics about the furniture industry in the country. It is estimated that there are about 10,563 furniture enterprises in the country (Anon,1994, Kibria et al 2001) . Many of them, however, may not be in operation now, and some enterprises may have recently bee n established. There are about 200 furniture enterprises in the Mirpur zone, and in the Begum R okeya Sarani Road alone, over 100 such enterprises are located (Karim, 2004), which is the target area of the present study. 3.2.0 Wood seasoning practice It is considered pertinent to highlight the general information about wood seaso ning and then discuss the wood seasoning to fully understand the technology. 3.2.1 General information about seasoning Green timber contains a large amount of moisture content ranging from 50 to abov e 200%1 in its dry weight. Seasoning is removing this moisture by drying timber to a level which is in equilibrium with the atmospheric temperature and relative humidity. In Bangladesh, the average equili brium moisture content is 12 -14%2 and thus timber should be dried to this moisture content ran ge for proper seasoning (Anon, 1978). 3.2.2 Methods of seasoning There are various methods of seasoning of timber. Among them, the most common me thods of seasoning are air drying, kiln drying and solar drying. These are discussed brie fly. Air drying 1 Green timber contains moisture from 50 to 80% in its dry weight 2 In Northern Hemisphere like USA, Canada, EU, etc., the average equilibrium moi sture content is 6-8% 2

Air drying is the seasoning of timber by exposure in the direct sun or under a s hed following proper stacking of timber. It depends on natural flow of air, sunshine and rain. It is thus the most simple and inexpensive method. But it takes a long time and larger space and is not equally effective throughout the year (Sattar and Ali 1969). The investment on timber remains blocked for a l ong period which is another drawback of this method. Kiln drying Kiln drying is seasoning of timber in an enclosed chamber where there is full co ntrol of all the drying elements. Almost all commercial timbers of the world are seasoned by the kiln dr ying method. Timber can be dried to a lower level of moisture content in any time of the year. It is an efficient method, but expensive and complicated to both install and operate. Ideally, each piece of timber in a kiln should be subjected to a uniform flow of air at a predetermined temperature and humidity. For this it is necessary to control the following four essential drying elements: (i) heating, (ii) humidification, (iii) air circulation and (iv) ventilation. In the seasoning kilns there should be means to control these elements. Improper operation of the kilns may lead to serious drying defects resulting in even complete damage of ti mber. For this, the kiln drying schedules have been developed for the timbers of Bangladesh (Sattar, 1980). There are 55 conventional seasoning kilns in 20 organizations in the country. Th e total capacity of these kilns is about 0.71 million ft/annum. Due to various reasons, such as withd rawal of investment, lack of appropriate technical knowledge, improper maintenance, etc, these season ing plants are not fully utilized. Some of them are not in operation now (Sattar, 1988). Solar drying Solar drying is drying of timber in a totally enclosed structure which derives i ts energy from the solar radiation with the help of a heat absorber. The short wave solar radiation is tr ansmitted through the glazing material . The blackened sheet inside the solar kiln absorbs the radiati on, heated up and subsequently emits long wave radiation as heat energy. The glazing material is o paque to this radiation and thus it is trapped inside the solar kiln as heat energy. This heat is used for wood seasoning (Sattar, 1991). Prompted by satisfactory performance, ease of operation and economy, 22 solar ki lns were constructed both by public and private enterprises (Sattar, 1982, 1989). The tot al seasoning capacity was 36,000 ft/annum. But most of them are not now in operation, because these sol ar kilns have

completed their 10 years period which is their normal life of duration, and were not reconstructed. In stead, some of them, however, have constructed conventional seasoning kilns for more faster drying. 3

3.2.3 Wood seasoning practice Except for some enterprises of Bangladesh Forest Industrial Development Corporat ion (BFIDC) and a few private industries, there is no wood based industry that possesses facilitie s for timber seasoning (Sattar 1988). Unseasoned timber is thus being used in almost all cases. In this respect, a survey was conducted in seven major cities for a study in 1988. The condition of moistu re content (mc) in sawn timbers and manufactured furniture was ascertained. The result of three maj or cities is shown below (Table 1). Table 1 : Result of survey of furniture industries about seasoning Locality No. of industries Method Range of mc reached Sawn timber Manufactured Seasoning condition Dhaka Chittagong Khulna 30 2 30 4 30 1 Air drying Kiln drying Air drying Kiln drying Air drying Kiln drying 25- 50 18 - 35 16- 22 14 - 19 30- 60 22 - 45 15- 20 14 - 20 25- 50 18 - 24 15- 22 14 - 20 Partially dried Almost seasoned Partially dried Almost seasoned Partially dried Almost seasoned This survey was undertaken as long as 16 years back. The condition of seasoning practice has not improved during this period; it may have probably deteriorated further in some c ases. It is thus necessary to determine the moisture content of sawn timber as well as manufactur ed furniture to know the present condition of seasoning practice. 3.2.4 Wood seasoning practice in Mirpur zone The furniture industry is mostly concentrated in Mirpur area where about 200 sma ll to medium scale

furniture enterprises are clustered in this zone. But there is only one seasonin g plant consisting of two compartment type seasoning kilns in the area. This plant was constructed about 4 0 years back by the Bangladesh Forest Industries Development Corporation (BFIDC). The capacity of ea ch kiln is 1,000 ft per month. It caters the needs of its cabinet manufacturing plant. However, it offers seasoning facility to private enterprises on a very limited scale on payment. Proper maint enance and overhauling were not done either on the plant itself or on the boiler. This is w hy one seasoning kiln can run at a time which has made the plant uneconomic. It is difficult for furni ture enterprises to get their timber seasoned in time. On an average, this plant can season 100 ft of pri vate timber per month, whereas the need of the total seasoned timber for the 200 furniture enter prises is 37,400 ft/month in this area (Table- 2). Except Hatil Complex, three member enterprises claim that they get a part of the ir timber seasoned in the BFIDC plant. All other enterprises mention that they air-dry timber under th e sun or a shed for a 4

period ranging from 15 - 50 days. By adopting this practice, timbers are partial ly dried and only the surface moisture is removed as is evident from Tables-1. This means either unsea soned or partially seasoned timbers are used for making furniture in almost all cases. However, mos t of the enterprises also agree that they cannot achieve proper seasoning, and as such they are looki ng for kiln drying on collective basis (Annex- 9). 3.3 Demand of seasoned timber The average monthly utilization of sawn timber and demand for seasoning timber h ave been estimated through the survey in the Mirpur furniture cluster. The result is pres ented in Table- 2. Table- 2 : Sawn timber used and requirement for seasoning in Mirpur zone Sl. No. Amount of sawn timber and its requirement for seasoning/month Total amount/ month (ft) Average amount/month (ft) i) ii) Amount used by 21 enterprises (excluding Hatil Complex) Amount needed for seasoning by 21 enterprises (excluding Hatil Complex) 4,830 2,520 230 120 iii) iv) Amount used by all 22 member enterprises (including Hatil Complex) Amount needed for seasoning by these 22 enterprises (including Hatil Complex) 6,622 4,114 301 187 v) vi) Amount used by 200 furniture enterprises in Mirpur cluster (based on average of 22 enterprises) Amount needed for seasoning by these 200 enterprises in Mirpur cluster (based on average of 21 enterprises) 60,200 37,400 301 187

Hatil Complex, one of the biggest furniture industries in the country, has three seasoning kilns at its factory site at Kasimpur. This industry seasons 90% of its monthly requirement o f 2,000 ft/month. It does not need any seasoning support. So, concern lies with the rest of 21 member furniture enterprises. These are small to medium sized industries which need a total of 2, 520 ft of timber to be seasoned per month. This is the estimated total demand of seasoned timber per mo nth, but in actual practice there may be a variation of the needs. Thus, provision should be made m inimum for 2,400 ft/month and maximum for 3,000 ft/month. 3.3.1 Timber species used by furniture enterprises There are about 26 conventional species which are commercially used in the count ry (Annex-15). In the Mirpur zone, four selective timber species are being used by the 22 enterpri ses as shown in Table-3. Teak, Chapalish, Gamar and Garjan are those species. Teak is predominan tly the main 5

timber species representing about 71% among the four timber species, the remaini ng 29% is almost equally shared by three species. 3.3.2 Price and thickness of timbers Teak is the costliest one, and its price averages Taka 1,300 per ft, while the av erage prices of other three species: Chapalish, Gamar and Garjan are Taka 877, 785, 836 per ft respecti vely (Table- 3). Because of its established better quality, furniture manufactured from Teak wood is preferred by the customers even with much higher price. The rest three species of timbers are com paratively costlier timbers than those of other commercial timbers. Various sizes of timber are used for different products. But it is the thickness of timber which matters for seasoning. So, different thicknesses that are used by the furniture enterpri ses have been ascertained (Table-3). It is evident from Table-3 that among the mostly used thi ckness class, the thickness of 0.75, 1.00 and 1.5 inches planks represent 46.2% 20.4% and 15.4% of the total. These thicknesses make 81.8%, and the rest 18.2% are 1.00, 1.25, 1.75. 2.00 and other special thickness. So, the planks representing 81.8% thickness class fall under priority group whic h needs to be seasoned. Table- 3 : Information regarding species, thickness and price of timbers a) Timber species Average percent Range of percent Frequency of industries Percent i) Teak (Tectona grandis) 70.8 40 85 22 100 ii) Chapalish (Artocarpus chaplasha) 11.5 5 20 20 90.9 iii) Gamar (Gmelina arborea) 8.6 6 30 18 81.8 iv) Garjan (Dipterocarpus spp.) 9.1 7 30 21 95.5 b) Price of timber species Average Price/cft (Tk) Price range Min. Max i) Teak 1300 1000 1500 ii) Chapalish 877 800 1000 iii) Gamar 785 700 850 iv) Garjan 836 750 900 c) Mostly used thickness of planks Thickness (inch) Percent Sawn timbers are obtained from Own sawmills Other sawmills i) 0.75 46.2 8 14ii) 1.00 20.2 (36.4%) (63.6%) iii) 1.25 6.5 iv) 1.50 15.4 v) 1.75 5.4

vi) 2.00 4.1 vii) Other thickness 2.2 Total number of enterprises 22 100 6

4.0 W0OD SEASONING KILNS There are different types of conventional seasoning kilns using different source of energy for heating. Some kiln uses electricity for heating and production of steam to humidify the k iln chambers as and when necessary. It is expensive due to consumption of a large amount of electric ity. Other conventional kilns have boilers for the production of steam which is used both f or heating and humidification. Again, the fuel used for the boiler may either be electricity, g as or waste wood. Among the three energy sources, the waste wood is obviously the cheapest one. The seco nd alternative energy source is gas which is comparatively cheaper than electricity, but costli er than waste wood. Since there will not be waste wood available for the kiln, gas should be preferr ed to other two sources of energy. 4.1 Quotations of wood seasoning kilns Keeping in mind the above type of seasoning kiln, specifications were prepared. The addresses of the suppliers and manufacturers were collected from the trade centres of Embassi es/High commissions. A large number of foreign manufacturers and suppliers of the follow ing countries were communicated through fax and e-mail : i) India, ii) China, iii) Taiwan, iv) Korea, v) Indonesia, vi) Japan, vii) UK, v iii) Ireland, ix) Italy and x) South Africa. Out of these countries, nine manufacturers/ suppliers responded initially. All o f them were requested to submit the price offers according to the specified requirements. Finally, two suppliers from India have submitted the quotatins of wood seasoning kilns with detailed specification s (Quotations: 1-2). These are all compartment type steam-heated kilns using gas as energy source for the boiler. One Italian manufacturer named, Coplan srl has also submitted a quotation for on e set of 550 ft capacity seasoning kilns and other relevant accessories (Quotation-3). It is als o of compartment type kiln using gas in the boiler. The suppliers from India have offered for 500 ft, 550 ft, 750 ft, and 1250 ft capaci ty seasoning kilns. It is always convenient to install a number of small capacity kilns rathe r than a single big kiln. It is thus convenient to install two units of compartment type seasoning kilns. The capacity of each unit may be 500 ft per charge. These two units will provide 2,400- 3,000 ft of seasoned timber per month. From the offers, the total costs of construction of two units of seasoning kiln of 500 ft capacity have

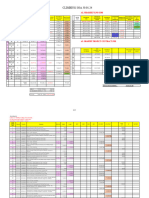

been estimated and a comparative statement is presented in Table-4. Table- 4: Comparative statement of two 500 ft capacity seasoning kilns as offered by different suppliers/ manufacturer Sl. Gangotri Impex Aditya Coplan srl 7

No. Items (India) Cost & Freight - Benapole (Taka) Casting Udyog (India): Cost only - Punjab (Taka) (Italy): Cost only (Ex-factory) (Taka) 1 Kiln equipments-fixed type 7,15,380 9,66,360 26,21,640 2 Boiler - 300kg/hr :complete set 9,66,900 8,99,400 3,30,780 (without accessories) 3 a) Freight upto Benapole (approx) b) Freight upto Chittagong port (approx) -50,000 1,20,000 4 a) Taxes & transport from Benapole to Dhaka b) Taxes & transport from Chittagong to Dhaka 2,00,000 2,00,000 3,90,000 5 Construction of 2 kiln chambers + boiler room + office room 5,50,000 7,00,000 3,00,000 6 a) Other works & materials b) Computer & printer 50,000 50,000 90,000 75,000 Sub-total 25,82,280 28,65,760 39,27,420 7 Water treatment plant 1,93,620 -Sub-total 27,75,900 28,65,760 39,27,420 8 Installation & commissioning charge including board & lodging 60,000 60,000 3,36,840 Total 27,35,900 29,25,760 42,64,260 4.2 Assessment of the quotations 4.2.1 Technical aspect (a) The Gangotri Impex has quoted for all relevant machineries and components in i ts offer. The full specifications of the machineries and components have also been mentioned (Quota tion-1). The capacity of each kiln is 500 and 750 ft per charge. Two boilers of 300 and 500 kg /hour capacity have

been offered. So, this offer may be considered as complete one. Since these are fixed type, the kiln chambers have to be constructed locally with brick and other materials. It has a lso offered one water treatment plant to supply iron-free water to the boiler. (b) The second offer is of Aditya Casting Udyog who has quoted for kilns of 500, 7 50 and 1250 ft capacity along with necessary components except the water treating plant (Quotat ion-2). Like Gangotri Impex, these are fixed type compartment kilns using gas in the boiler. The kiln chambers have to be constructed locally with brick and other materials. The specification s are not detailed ones, and so it is difficult to know exactly what they will supply. In this respect, t his offer cannot be termed 8

as fully complete one. It is also mentioned in the offer that these kilns are no t suitable for drying Teak wood using gas in the boiler. (c) The Coplan srl has offered a relatively sophisticated type of 500 ft capacity s easoning kiln using modular units (Quotation-3). The support of a computer will be taken for monitor ing the progress of drying. Gas will be used for production of steam for humidification. There is no mention of a water treatment plant in its offer. Technically, it will be difficult for the furnitur e enterprises to operate and maintain these seasoning kilns. 4.2.2 Financial aspect (a) The estimated total cost of two kilns of Gangotri Impex is Tk 27,35,900 incl uding a boiler of 300kg/hr (equivalent to 200 psi) capacity and a water treatment plant. The cost also includes installation and commissioning charge of the supplier (Table-4). Without a water treatment plant, the price is Tk 25,42,280. (b) The total cost of two kilns of Aditya Casting Udyog is estimated at Tk 29,25 ,760 without a water treatment plant. If the cost of a water treatment plant is included from the Gan gotri Impex s offer, the total cost becomes Tk 31,19,380 (Table-4). (c) The estimated total cost of Coplan s two kilns is Tk 42,64,260 including the a pproximate cost of freight from Italy to Chittagong port which was not included in the offer. It is the costliest among the three offers (Table-4). 4.2.3 Overall evaluation There were initially many responses for supplying seasoning kilns of different t ypes. But finally, offers of fixed type compartment kilns have been received. Among these offers, an appro priate seasoning kiln has to be selected. (a) Incoplan s kiln is sophisticated one and it will need qualified operators. Als o, it is the most expensive among the three offers. So this offer cannot be accepted.3 (b) The offer of Aditya Casting Udyog is not a complete one since it has not quo ted for a water treatment plant. Further, the supplier has mentioned that Teak wood cannot be se asoned with this kiln. The price is also higher than that of other remaining offer. So, this offe r cannot also be acceptable one. 3 Though Incoplan s Kiln might not be a good idea if the market is domestic, but f or export market this type of kiln drying is needed. 9

(c) The offer of Gangotri Impex is the only one which has fulfilled all requirem ents. Its price is also the lowest among the three offers. It may be mentioned that two seasoning kilns of each 750 ft capacity are being installed by a member enterprise at Kashimpur near Savar. It will be advantageous to the member enterprises to visit the plant and see the performance of this typ e of kilns before purchase. So, the offer of Gangotri Impex is acceptable one. Two seasoning kilns of capacity 500 ft each using gas as heat energy in the boile r as offered by Gangotri Impex are thus suitable for the furniture enterprises. The boiler of 30 0 kg/hour (200 psi) capacity is recommended. These fixed type kilns are comparatively simple to inst all and operate. Generally, the life of this compartment type seasoning kiln is about 50 years. For the fixed type seasoning kilns, the superstructure needs to be constructed w ith brick and other materials. So, the seasoning plant preferably be installed in own land. In case it cannot have its own land, it should be rented for a long term basis, say at least for 10 years. 5.0 ECONOMIC ASPECTS OF STEAM HEATED KILNS The costs of seasoning per cubic feet of Teak and Chapalish timbers of 1.0 inch and 1.5 inch thick have been calculated for both 500 and 750 ft capacity seasoning kilns as shown in Tables- 5(a & b). The details of the calculation are given in Annexes- 19(a & b). The total costs of construction of two fixed type seasoning kilns of Gangotri Impex have been taken as basis of the cos t of the kilns. Table-5(a): Seasoning cost of Teak and Chapalish timbers and other economic aspects using two 500 ft capacity steam heated seasoning kilns Sl. . Items 2 units of 500 ft 1.0-inch timbers 2 units of 500 ft 1.5-inch timbers 1 Output of seasoned timber per annum 44,000 ft ( 44 charges: 7 days/charge) 28,000 ft ( 28 charges: 12 days/charge) 2 Total recurring expenditure (land rent + gas + electricity + operation + loading & unloading + water + maintenance) 14,48,884 14,91,556 3 Total capital investment (initial installation + working capital) 30,98,121 31,08,789 4 Total cost (recurring exp + interest on total capital investment + depreciation) 19,55,539 19,99,704

5 Kiln seasoning cost per ft = Total cost/output Tk 44.4 Tk 71.4 6 Return on investment 89.4 % 29. 3% 7 Pay back period 18.4 months 56.0 months 10

Table-5(b): Seasoning cost of Teak and Chapalish timbers and other economic aspects using two 750 ft capacity steam heated seasoning kilns Sl. . Items 2 units of 750 ft 1.0-inch timbers 2 units of 750 ft 1.5-inch timbers 1 Output of seasoned timber per annum 66,000 ft ( 44 charges: 7 days/charge) 42,000 ft ( 28 charges: 12 days/charge) 2 Total recurring expenditure (land rent + gas + electricity + operation + loading & unloading + water + maintenance) 17,60,472 19,24,416 3 Total capital investment (initial installation + working capital) 35,19,160 35,60,146 4 Total cost (recurring exp + interest on total capital investment + depreciation) 23,14,735 24,84,417 5 Kiln seasoning cost per ft = Total cost/output Tk 35.1 Tk 59.2 6 Return on investment 139.1 % 52.4% 7 Pay back period 8.6 months 21.6 months 5.1 Seasoning cost of steam heated kilns From Table-5(a), it is apparent that seasoning cost for 1.0-inch Teak and Chpali sh will be about Tk 44.4/ ft, whereas for 1.5-inch Teak and Chapalish it will be about Tk 71.4/ ft for 500 ft capacity seasoning kilns. If one kiln chamber seasons 1.0-inch timber and another kiln ch amber seasons 1.5inch timber simultaneously, then the combined seasoning cost will become (Tk 44.4/ ft + Tk 71.4/ ft)/2 = Tk 57.9/ ft. If two 750 ft capacity kilns are installed, then the combined seasoning cost will be less, i.e. (Tk 35.1/ ft +Tk 59.2/ ft)/2= Tk 47.2/ ft. It may be mentioned here that the lowest current cost of commercial seasoning is Tk 110 per ft of BFIDC plant, whereas it is charged at Tk 250 per ft in some private wood seasonin g plant. 5.2 Pay back period of steam heated kilns It is seen from Table- 5(a) that the initial investment of Tk 27,35,900 for two 500 ft kilns will be paid back in 18.4 months for drying 1.0-inch Teak and Chapalish timber, and for 1.5-i nch Teak and Chapalish it will be in 56.0 months. But for combined seasoning, the pay back pe riod will become (18.4+ 56.0)months/2 = 37.4 months, i.e. in about 3 years.

11

If two 750 ft kilns are considered, the combined pay back period will be only (8. 6+21.6)months/2= 15.1 months (Table-5b). 5.3 Increase in cost of furniture due to seasoning There will be increase in cost of production of furniture due to added cost of s easoning of timbers. It is found that if 1.0-inch timber is seasoned in one kiln chamber and another kiln c hamber seasons 1.5inch timbers simultaneously, then the combined seasoning cost will be Tk 57.9/ ft for 500 ft capacity seasoning kilns. Now, if a furniture like chest of drawer is made from seasoned Teak wood using 8 ft wood. The cost of seasoning this amount of timber will be Tk 463. If the cost of the furniture is Tk 25,000, then Tk 463 have to be added to it. So the total cost of the furniture b ecomes Tk 25,463. For this, the increase in cost of production will be only 1.8% for Teak furniture. I f the same furniture is made from Chapalish, the cost of production will be about Tk 18,000. If seasonin g cost of Tk 463 is added to it, the cost will be increased by 2.5%. It was observed during survey that if the customers are fully convinced that the furniture are made from properly seasoned timber, they are prepared to pay higher price compared to furniture made from rather unreliable seasoned timber or partially dried timber. This fact is w ell demonstrated in the products of Hatil Complex. So, there will not be any problem in fetching reasona bly higher price due to increased cost for seasoning. The owners are aware of this attitude of the cu stomers (Annex- 10). 6.0 RELEVANT ASPECTS OF KILN INSTALLATION AND OPERATION 6.1 Requirement of area of land The requirement of land for both fixed and portable seasoning kilns is not much. An area of about (25 x 25 ) = 625 sft will be required for two fixed type kilns. A boiler and a wate r treatment plant will need an additional area of about 600 sft. Timbers will have to be kept near the kilns for some times prior to and after seasoning. A small office room will also be required for the Kiln operators and Boilermen. For these purposes, another 800 sft will be needed. Combining all the se requirements, it becomes 2025 sft. So, the preferable area for the installation of the seasoning plant will be about 3,600 sft which is equivalent to 5 katha of land. 6.2 Requirement of time to raise fund It is difficult to estimate the time frame for the Forum to raise required amoun t of fund for the plant. The Forum consists of 22 members who pay Tk 110,000 per month. If they collect u sual amount of monthly subscription @ Tk 5,000, it may take more than 24 months. After 24 month s, the total 12

amount will be Tk 26,40,000. But it is learnt that they are planning to raise a large amount of fund at a time from each member so that they can establish a seasoning plant within 9- 12 months. 6.3 Seasoning of different species Four timber species, namely Teak, Chapalish, Gamar and Garjan are used by the me mber enterprises. Chapalish can be seasoned with minimum time and Teak takes normally one day more than Chapalish timber. Garjan does not pose any difficulty, but dries a little b it slowly. Gamar is a problematic species which is the slowest among the commercial timber species and takes about three times longer than that of Teak and chapalish (Sattar et al . 1991). Ideally, one species of same size of timber should be dried in a single charge i rrespective of using gas or electricity as a source of energy. If it necessitates drying more than on e species, then a special kiln drying schedule has to be employed (Sattar, 1980). For this, appropriate ki ln drying schedules have to be developed for the particular type of wood seasoning kilns. 6.4 Seasoning of different sizes of timber It is apparent from Table-3 that the thickness of 0.75, 1.00 and 1.5 inches plan ks are the mostly used sizes. These thicknesses make about 81.8%, and the rest all other sizes make 18. 2% of the use. So, the planks representing 81.8% thickness class fall under the priority group whic h needs to be seasoned. Like timber species, it is also an ideal condition to season different sizes of timber separately. But, if necessary, it is possible to season two or three sizes of ti mber together following a appropriate kiln drying schedule. 6.5 Time to install a seasoning plant The supplier has mentioned that the machineries will be delivered within 3- 4 mo nths from the date of receipt of a firm order along with an advance of 40% of the order value. The kil n chambers need to be constructed locally. This can be done after getting the structural design from t he supplier within two months. So, the total time will be about 5- 6 months. 6.6 Technical support from the supplier The supplier will provide technical support in respect of installation and opera tion of seasoning kilns and other machineries. The services for this will be charged which will include per diem for the engineer/technician, to and fro expenses from Kolkata and local conveyance plus lodging and boarding. The total expenses may be about Tk 60,000 for the Indian supplier. 13

7.0 MANAGEMENT OF THE FORUM AND THE SEASONING PLANT 7.1 Management of the Forum For any collaborative effort, the principal concern lies with its sustainability . There are many people in it, and it is natural that they have conflicting opinions about the management a nd activities. These may even threaten the existence of the forum. But all these need to be handled r ationally with proper management. There is no alternative than capable and committed leadership for its success. T he owners of the member enterprises expressed high priority on this aspect during discussion with them. They have also stressed the importance on other personal qualities of management personnel in addition to financial dealings (Annex-14). Considering all these, the member enterprises hav e formed a Forum with the following structure: a) Convener - 1, b) Secretary -1, and c) the rest 20 are general members. Within this framework, certain policies have been adopted for its management whi ch are as follows: i) Monthly subscriptions will be collected @ Tk 5,000 per member. ii) There will be a meeting in every month with all members. All issues regardin g the Forum will be discussed and decision should be taken in the meeting. iii) There will not be any withdrawal of fund within a year. It is learnt that the members are thinking to raise a large amount of fund at a time from each member so that they can establish a seasoning plant within 9- 12 months. For proper management of the Forum, it should be registered as a limited company with the proper authority. It will be then easier for them to arrange bank loan for installing t he seasoning plant, if there is any shortage of fund. The management committee of the limited company w ill be responsible for managing the seasoning plant. 7.2 Management and operation of the seasoning plant A seasoning plant is meant for drying of sawn timbers up to certain thickness cl ass to a desired 12% moisture content. It is equipped with some specialized equipments depending on t he type and design of seasoning kilns. The steam heated compartment type is comparatively cheaper a nd easier than other modern designs. As mentioned earlier, this design is considered for the fo rum. For its management, the following structure is recommended : 14

7.2.1 Personnel4 For this type of seasoning kiln, one boiler is needed for the production of stea m which provides both heat and humidification to the kiln. There will be boiler man for this purpose. There will be electric motors, compressor, other electric accessories, etc which will necessitate an el ectrician. Above all, there will be kiln operators to run the seasoning plant. Considering the economy of the forum, the following employees are suggested : a) b) c) d) e) Kiln operator/Foreman -One : Regular Kiln operator/cum Electrician -One : Regular Boilerman -One : Regular Boilerman Associate -One : Regular Kiln operator Associate -One : Regular

d) Labourer - Four : Occasional 7.2.2 Qualification, salary and other facilities a) The Kiln operator/ Foreman should be at least SSC and Trade Certificate holder i n mechanical works and should have some experience in the line. His salary may be fixed up according to his experience, but it may be around Tk 5,000 - 8,000. b) The Kiln operator cum Electrician should preferably be SSC and Trade Certificate holder in Electrical works and some experience in the line. His salary may be fixed up at Tk 4,000 6,000. c) The Boilerman should preferably be SSC and Trade Certificate holder in boiler works with some experience in the line. His salary may be fixed up at Taka 4,000 - 6,000. d) The Boilerman Associate should be Trade Certificate holder in boiler works wh o has read upto at least class VIII. His salary may be fixed up at Tk 3,000- 5,000. e) The Kiln operator Associate should be Trade Certificate holder in mechanical/ electrical works who has read upto at least class VIII. His salary may be fixed up at Tk 3, 000- 5,000. The seasoning plant will run 24-hour a day till the end of seasoning of timber w hich may take 7 15 days. For this, the employees have to work on two- three shifts basis. Two emplo yees, one kiln operator and another boilerman, can do this job at a time. The Associates will a lso work as Kiln operator and Boilerman. It will be convenient for both the employees and the emp loyer if there is a provision for residential accommodation for at least two persons. Then, they can be summoned as and when needed.

7.2.3 Practical training on operation 4 This number of personnel is not required to run the kiln drying. The owner can run it with less number of people efficiently 15

These employees will have basic vocational training on specific fields, but will not have experience on kiln operation. So, a thorough practical training need to be imparted to all of them. The Kiln operators and Assiciates are also required to be trained on boiler operation. It means, in the absence of some one, other employee should be able to do the job properly. 7.2.4 Maintenance of machineries The operational and maintenance guidelines will be provided by the manufacturers for the seasoning kilns and boiler. These guidelines should be followed properly. Maintenance of t hese machineries will involve mechanical, electrical and boiler works for which one of them will be ab le to perform the particular job. Once they are accustomed to these, there will be no problem to d o the regular maintenance work. It is also expected that the manufacturer will provide some in itial maintenance training. 8.0 ALTERNATIVE OPTION FOR STEAM HEATED SEASONING 8.1 Solar seasoning It is already mentioned that the members of the Forum are very keen to establish a seasoning plant for seasoning timbers. But if it takes a long time to raise the required amount of fund for the steam heated kilns, then an alternative option may be considered. For the interim peri od, solar seasoning is that option. It has been discussed earlier (Section 3.2.2) that commercial solar kilns were installed by public and private enterprises because of good performance, easy operation an d low cost of construction. It may also be mentioned here that solar kilns can be constructed using all local materials (Sattar,1991). 8.2 Economic aspects of solar seasoning The most advantage of the solar kiln is its economic aspects. The cost of constr uction of two 200 ft capacity solar kiln is estimated at Tk 160,000 (Annex- 20). The cost of seasonin g of 1.0-inch and 1.5-inch Teak/Chapalish timbers has also been estimated. It is presented in Tabl e-6. The details of the calculation are shown in Annex-21. 16

If the economic aspects are considered, solar drying is very lucrative. The cost of seasoning per ft is only Tk 37.4 for 1.0-inch timber and Tk 52 for 1.5-inch timber. So, it is the ch eapest one. More interesting is its pay back period. It is found that the investment of Tk 160,00 0 for two solar kilns can be paid back in only 6.3 months for combined drying. It may be mentioned that th e life of a solar kiln is 10 years. Table- 6: Seasoning cost of Teak and Chapalish timbers and other economic aspects using 200 ft capacity solar kilns Sl. No. Particulars Timber of 1.0- inch thick Timber of 1.5inch thick 1 Output of seasoned timber per annum 3,600 ft 18 charges: (18 days/charge) 2,400 ft (12 charges: 28 days/ charge) 2 Total recurring expenditure (land rent+ electricity+ operation+ loading & unloading) 111,600 101,940 3 Total capital investment (initial investment+ working capital) 107,900 105,485 4 Total cost (recurring exp+ interest on total capital investment + depreciation) 134,706 124,708 5 Solar seasoning cost/ ft = Total cost/output Tk 37.4 Tk 52.0 6 Return on investment (%) 281.7% 144.0% 6 Pay back period 4.3 months months 8.3 Other aspects of solar seasoning From the past experience it is found that solar drying is technically sound and economically viable technology (Sattar, 1987, 1991). But its only drawback is its drying time compar ed to conventional steam heated drying. It takes a long time to fully season the timber round the y ear. Normally, it takes about double time during the winter and pre-/post- winter periods (Sattar 1994). During rainy season, solar kiln absorbs whatever solar radiation available, and dries timber, but ver y slowly. This is why the average drying time is long. 9.0 WOODWORKING MACHINERIES Woodworking machineries are used for preparing the sawn planks into different sh apes and sizes prior to manufacture products. There are various types of them, but the main mac hineries include

planer, circular saw, jointer, moulder, mortiser, rip saw, turning lathe, router , etc. Each machine has 17

its own specific function. So, these machines are used for making furniture and related products in medium to big furniture enterprises. The Forum has fund constraint at this initial stage and thus cannot afford to pr ocure all of them involving quite a substantial amount of money. So, their acquisition of machiner ies is considered to be restricted to basic ones. These are as follows : 1) Circular saw, 2) Thickness planer, 3) Jointer and 4) Moulder 9.1 Quotations of woodworking machineries The specifications of these four types of machineries were prepared. The local s uppliers as well as foreign suppliers and manufacturers were contacted. They were requested to submi t the quotations in respect of these machineries within the scheduled time. Initially there were man y responses, but finally the following local and foreign suppliers/manufacturer have submitted qu otations : a) Galaxy Electro Power Ltd, 119- 200 Nawabpur Road, Dhaka has submitted two pri ce lists, one of Japan and another of Italy made various machineries (Quotations- 4). These are s mall woodworking tools suitable for the individual purposes or small individual enterprises. For collective use, heavy duty machineries are needed. So, none of these are suitable one, and as such are not included in the comparative statement. b) Abedin Equipment Ltd, B-52 Kemal Ataturk Avenue, Banani, Dhaka has quoted dif ferent woodworking machineries (Quotation-5). Except one model of circular saw , others are also small tools, and are not meant for heavy works. These are available from the ready sto ck. The offer of circular saw is included in the comparison. c) Aziz Machinery & Tools, 64 Nawabpur Road, Dhaka has quoted for different comb ined woodworking machineries (Quotation- 6). All these are available from the ready s tock. These are included in the comparison. d) Luna Enterprise, 91 Nawabpur Road, Dhaka has submitted a quotation of four ba sic woodworking machineries (Quotation- 7). These are included in the comparative statement. e) One leading manufacturer from India, namely Jai Industries , Ahmedabad has quote d for four basic wood working machineries (Quotation- 8). These are included in the compara tive statement. f) Another supplier from India, namely Gangotri Impex has quoted for some machiner ies (Quotation9). The relevant machineries are included.

18

9.2 Assessment of the quotations A comparative statement of all the woodworking machineries has been prepared in order to assess them. Table-7 contains the comparative statement. Table- 7: Comparative statement of quotations of woodworking machineries Sl Type of machineries Abedin Equipments (Dhaka) Aziz Machinery (Dhaka) Luna Enterprise (Dhaka Jai Industries (India) Gangotri Impex (India) Total cost Total cost Total cost Total cost Benapole (from ready (from (import from (C&F + (C&F + stock) ready stock) India) taxes+ cost upto Dhaka) taxes+ cost upto Dhaka) 1. Circular saw Work table size 36 X24 5 HP (Heavy duty) Tk 40,000 2.38 HP (Germany) -Tk 65,000 Size-36 x19 Tk 57,880 (Model J-535H) 2 Thickness planer 18 , 5 HP, complete (Heavy duty) --Tk 92,000 Tk 74,020 (Model J-601 Tk 119,947 (Model J-601) 3. Moulder 3 HP, complete (Heavy duty) --Tk 97,000 Tk 70,240 Model J-504H

4. Jointer/ Surface planer 18 , 3 HP, complete (Model J- 118) --Tk 68,000 Tk 66,280 Tk 80,595 10 , 2 HP (ModelJ-116) Sub-total Tk 3,22,000 Tk 2,68,420 5. Combined woodworking m/c : Circular saw, Thickness/ Surface planer, Moulder, Scorer & Mortiser, (China) -Tk 2,20,000 (ModelML393C --6. Combined woodworking m/c : Circular saw, Thickness/Surface planer, Moulder, Mortiser, 1.5HP -Tk 140,000 (ModelML392E) --7. Planer & Jointer 12 , 3HP (China) -Tk 65,000 (ModelMJ300A) --9.2.1 Technical aspect The enterprises of the Forum need heavy duty type basic woodworking machineries. A single machine of each type should perform single function at a time continuously. Unli ke combined machines, this machine will allow different technicians to work simultaneously w ith their works without waiting for other to finish his work. With these specifications in mind, the mac hineries have been evaluated. 19

a) The local supplier, Galaxy Electro Power Ltd , has supplied two price lists of d ifferent kinds of tools and machineries, including some woodworking machineries. These are made of Italy and Japan (Quotation-4). These are also very small portable type equipments. Thus, none of these meet the requirements of the Forum. b) The local supplier, Abedin Equipments has offered for different machineries (Qu otation- 5). These are all good quality machineries of German made. But these are small proto-types and suitable for individual or very small enterprises. Thus, these machines are not suitable for large scale commercial application. However, one medium sized circular saw has been shown in the compar ison. c) The local supplier named, Aziz Machinery& Tools has submitted a quotation for t he combined woodworking machineries which consist of from circular saw, thickness planer, su rface planer, moulder , mortiser, scorer and planer to jointer (Quotation- 6). These are made in China. These are not as per requirements of the Forum. d) The local supplier, Luna Enterprise , has quoted for four machineries which are needed by the Forum(Quotation- 7). The quality of these machineries cannot be adequately judge d since no detailed specifications have been provided. e) One Indian manufacturer, Jai Industries has quoted for the circular saw, thickn ess planer, moulder and jointer (Quotation- 8). All of these are heavy duty type machines an d meet the requirements of the Forum. f) Another Indian supplier, Gangotri Impex , has quoted for some woodworking machin eries (Quotation- 9). Two relevant machines may be considered. 9.2.2 Economic aspect (a) The price of one circular saw has been quoted for Tk 40,000 by Abedin Equipm ents. This is of 2.38 HP capacity. The individual enterprise may consider this one, but not suita ble for the Forum. (b) The price of each set of combined machines offered by Aziz Machinery ranges from Tk 2,20,000 to Tk 65,000. Like other sets, the machine of the lowest price, i.e., Tk 65,000, is not heavy duty type (Table-7). These are not suitable for the Forum, but the individual enterprise m ay consider for its use. (c) The prices of machineries of Luna Enterprise are higher compared to those of Indian supplier, Jai Industries. The total cost is Tk 3,22,000 (Table-7). 20

(d) Jai Industries has offered the lowest prices for all basic machineries. Thes e are heavy duty and are meant for continuous use. The total price of these four machineries is Tk 2, 68,420 inclusive of taxes and transportation upto Dhaka (Table-7). (e) Gangotri Impex has mentioned the price of one Thickness planer as Tk 1,19,94 7 which is exactly the same type and model of Jai Industries. Jai Industries has quoted Tk 74,020 f or this machine. The price of a lower capacity Jointer (2 HP) has also been offered higher price than that of Jai Industries (Table-7). 9.2.3 Overall evaluation Considering technical and economic aspects, the tender submitted by Jai industrie s , Ahmedabad, India may be considered for purchase by the Forum. The machineries have met the technical requirements and also offered the lowest price. The cost of these machineries ha s been detailed in Annex-22. 10.0 RECOMMENDATIONS Based on the feasibility study, the following recommendations have been made for the Forum of furniture enterprises, Rokeya Sarani Furniture Development Industries : 1(a) Two compartment type seasoning kilns of 500 ft each using gas in the boiler be installed. A water treatment plant should be procured along with the kilns to supply iron-fre e water to the boiler. Thus, the quotation submitted by Gangotri Impex, 20B Nimtala Ghat Street, Kolkat a, India be accepted. (b) For these fixed type kilns, 5-katha land should preferably be owned by the F orum. If it is not possible, then the land should be rented for a long term basis, at least for 10 years. The pay back period of the initial investment is, however, less than three years. (c) If it takes a long time to raise sufficient fund for the steam heated kilns, then alternative option should be considered. It is recommended that at least two solar kilns of 200 ft c apacity be constructed. The initial investment of Tk 160,000 will be paid back in only 6.3 months. 2. The basic woodworking machineries quoted by Jai Industries, Ahmedabad, India ar e recommended to be purchased. These are heavy duty machines, and are suitable for simultaneous running for the member enterprises of the Forum. 21

11. 0 REFERENCES 1. Anon. 1991. Survey report on cottage industries of Bangladesh. BSCIC, Dhaka. 65 pp 2. Anon. 1978. Maximum permissible moisture content in timbers for making different products. Bangladesh Standard and Testing Institute, GOB. 10 pp 3. Ali, M.O. Sattar, M. A. and Talukdar, Y.A. 1980. Kiln drying studies on 1 -inch timber species of Bangladesh. For. Res. Inst. Bull. 6, Chittagong. 10 pp 4. Karim, B. 2004. Personal communication, Paris Furniture, Mirpur, Dhaka 5. Kibria, M.G., Sarker, D. C., and Islam, S. S. Forest Statistics of Bangladesh.20 01. Bulletin 4, Forest Economics Division, BFRI, Chittagong. 119 pp 6. Sattar, M. A. and Ali, M. A..1969. Air drying studies on 1" and 2" garjan timber . Forsetdale News. 2(1): 29-42 7. Sattar, M. A. 1980. Kiln drying schedules for indigenous timbers of Bangladesh. Bulletin No. 4, Wood Seasoning Series, BFRI, Chittagong. 11 pp 8. Sattar, M. A. 1982. Solar kiln for seasoning of timber in Bangladesh. For. Res. Inst. Bull. 8 (Wood Seasoning Series), Chittagong. 10 pp 9. Sattar, M. A. 1983. Properties and uses of teak wood. Bulletin No. 8, Timber Phy sics Series, BFRI, Chittagong. 7 pp 10. Sattar, M. A. 1987. Comparative studies on wood seasoning with a special referen ce to solar drying. Bano Biggyan Patrika. 16 (1&2) : 30-42 11. Sattar, M. A. 1988a. Lumber stacking and drying. In: South Asia workshops on sawmill productivity improvement. APFIDG., RAS/86/048, Chittagong, Bangladesh: 13-1-12 12. Sattar, M. A. 1988b. Prospects of wood seasoning in Bangladesh. Bano Biggyan Patrika. 17 (1&2) : 80-88 13. Sattar, M. A. 1989. Construction and operation of solar kilns for seasoning timber in Bangladesh. RERIC International Energy Jour. (Thailand). 11 (2) : 41-50 14. Sattar, M. A. 1991. Seasoning of timber by using solar energy. In : 10th Wor ld Forestry Congress, Paris, French : 327-332 15. Sattar, M. A., Sarkar, S.B. and Talukdar, Y.A.. 1991. Kiln drying of gamar (Gmelina arborea) using varying sticker thickness and drying schedule. Bangladesh Jour. of Forest Science. 20 (1&2) : 49-54 16. Sattar, M.A. 1994. Major energy saving by use of solar timber drying in deve loping countries. Renewable Energy(England). 5(1) : 457-464. 17.

Sattar, M. A. and Bhattacharjee, D. K. 1998. Physical and mechanical properties and uses of timbers of Bangladesh. Booklet, Bangladesh Forest Research Institute, Chittagong . 64 pp 18. Sattar, M. A. 2002. Review of marketing of wood in Bangladesh. Intercooperai on, Swedish Agency for Development and Cooperation. 65 pp 22

ANNEX - 1 TERMS OF REFERENCE (TOR) A. Background KATALYST is mandated to enhance the private sector in Bangladesh by improving th e capacity of the private sector to ameliorate its growth and competitiveness. Business-like i nterventions are needed to lead to a sustainable result without negative side effects. KATALYST o perates in several products and business service sectors of which furniture sector is one. The furniture industry is mostly concentrated in Mirpur area where about 400 sma ll to medium scale furniture and sawmill industries are clustered in one zone. But the most importa nt processing technology like seasoning is lacking in that area. As a result, either unseasone d or partially seasoned timbers are used for making end products in almost all cases. Seasoning is consi dered to be a vitally essential technology for the furniture industries, because it enhances the quali ty of the products by imparting improved physico-mechanical properties, increased service life and oth er favourable properties. Because of these distinct advantages, there is a growing interest to adopt this technology, but the individual enterprise is handicapped due to a large investment involved in adopting the technology. As a part of the activities, a vision workshop was organized by the Industry and Rural Services component of KATALYST where a tremendous enthusiasm was observed among the owner s of furniture and sawmill industries to have seasoning plants on collective basis. T hey have already formed a Forum and have started to raise fund for this purpose, and approached K ATALYST to offer the technical assistances right from the feasibility study to installation, oper ation, training and other relevant aspects of interest to improve the quality of timber and its products. The assignment aims at strengthening the furniture and sawmill industries in this respect. Initially, t he feasibility aspect will be dealt with and after completion of this first phase, subsequent activities will be taken up. It is very important that seasoning plant be a sustainable one despite the fact that the en trepreneurs are enthusiastic and find it profitable. Accurate information on demand and supply s ide would be proper indicators for this purpose. B. Objectives 1. Study the feasibility of installation of seasoning kilns through collective effo rt of the owners of

the furniture industries at Mirpur area; the feasibility must cover answer to th e following questions along with other related issues : What is the current demand? How the demand is met at present? What would be the approximate increase in cost if seasoning is done? Are the entrepreneurs ready to bear the cost? Would it be profitable enough for the manufacturers to use seasoned timber? What should be appropriate capacity of seasoning kiln to satisfy the collective demand? What if there are different types of timber or different sizes of planks? How long it may take to season to season a particular amount of planks? What may be a feasible type of kiln- electric, gas-fueled or solar? What would be a preferable area for the installation of a seasoning plant? What would be a dependable management and maintenance structure for the seasoning kiln? 2. Collect detailed information about the seasoning kilns from local and foreign so urces with specific information on the following aspects : What the different price-ranges offered by the suppliers for seasoning kilns of different capacity? Hong long it may take to install a seasoning kiln starting from placing an order for a kiln? How many people are required to run, operate and maintain a seasoning kiln? 23

Will the supplier provide any technical support in installation/ operation and maintenance of the plant? What might be the best offer from the dealers? 3. Collect detailed information about basic woodworking machinery from local and fo reign sources. C. Methodology and Activities 1. A 4- 5 member team will be formed comprising the representatives of the entrepre neurs; the consultant will work directly with them for the communication in the cluster; 2. Representative furniture and sawmill industries will be visited at Mirpur and key timber traders, sawmillers and furniture manufacturers will be consulted; 3. The right type, size and specifications of the seasoning kilns and basic woodwor king machinery required for the Mirpur area will be identified; 4. The mechanism and operation of different types of existing seasoning kilns at Sa var/ and Chittagong (BFRI and BFIDC complex) will be demonstrated to the members of the F orum (i.e. circular saw, jointer, thickness planer and moulder) will be collected fro m both local and through exposure visits; 5. Details of manufacturers and suppliers of the seasoning kilns and basic woodworking machinery foreign sources like India/China/Taiwan/Korea/Indonesia/other through visit to local agents and correspondences, and then proper specifications for seasoning k ilns and woodworking machinery will be finalized; D. Work Plan Activity No. Details of the works Tentative dates No. of days 1 Initial day-long discussion session with the key actors 25 July 2004 1 2. Formation of a core team, planning and discussion 2- 3 Aug 2004 2 3. Designing one set of interview guidelines for the furniture and sawmill industries and for the suppliers of seasoning kiln 6- 7 Aug 2004 2 5 Visit and interview with different types of furniture and sawmill industries at Mirpur and consult the key persons to collect requisite information 9- 12 Aug 2004 14-17Aug 2004 4 4 6. Assessment of the needs of the furniture and sawmill industries in respect of seasoning kilns and basic woodworking machinery

21-24Aug 2004 4 7 Testing the adequacy of the existing drying method adopted by the furniture industries 29-30Aug 2004 2 8. Collect relevant information, particulars and photographs of different types of seasoning kilns (electric, gas and solar heated) from BFRI and BFIDC at Chittagong 7- 9 Sep 2004 3 9. Collection of detailed information about the kilns and machinery from local and foreign sources through visits and correspondences 11-16Sep 2004 18-20Sep 2004 6 3 10 Collect relevant information of gas-fired seasoning kiln from Hatil Complex at Savar/ Kashimpur 23 Sep 2004 1 11. Identification of the proper specifications based on the needs and capability of the industries 25-28Sep 2004 4 12 Preparation of the final report covering the total activities/ works 10-12 Oct 2004 3 Total 37 24

E. Deliverables Deliverable Due date for submission The final report will contain details of survey findings on feasibility of the seasoning plant and also include type, size, price and origin of the machinery, and recommendation of proper specifications of seasoning kilns and basic woodworking machinery for the Forum 20 Oct 2005 Meeting minutes After each meeting on weekly basis ANNEX- 2 Rokeya Sarani Furniture Development Industries (RSFDI) Sl. No. Member enterprises Owner Address 1 Crystal Meubles Furniture Shop Mr. M. Quamrul Huda Convenor 218/6, West Kafrul, Begum Rokeya Sarani Road, Mirpur 2 Paris Furniture Mr. M. Bazlul Karim Secretary 607, Kazipara, Begum Rokeya Sarani Road, Mirpur 3 Rangamati Complex ( 2 members) Mr. M. Jalilur Rahman 494, North Kazipara, Begum Rokeya Sarani Road, Mirpur 4 Hatil Complex Mr. Selim H. Rahman 1243, East Monipur, Begum Rokeya Sarani Road, Mirpur 5 Dhaka Furniture Mr. S. M. A. Awal Plot # 13, Main Road, Begum Rokeya Sarani Road, Mirpur 6 Shital Complex Mr. M. Alamgir Prodhan 495/5, Monipur, Kazipara, Rokeya Sarani Road, Mirpur 7 Sandwip Complex Mr. M. Mainur Rahman 613/1, North Kazipara, Begum Rokeya Sarani Road, Mirpur 8 Bhai Bhai Furniture Mr. M. Jalilur Rahman 494, North Kazipara, Begum Rokeya Sarani Road, Mirpur 9 Decorus Furniture Mr. M. Fazlul Hoque 615, North Kazipara, Begum Rokeya Sarani Road, Mirpur 10 Furniture Garden Mr. M. Mesbahuddin 220, Kazipara, Begum Rokeya Sarani Road, Mirpur 11 Mamata Furniture (2 members) Mr. Habibur Rahman 218/6,West kafrul, Begum Rokeya Sarani, Mirpur 12 Hazrat Shah Paran Furniture Mr. M. Tofazzol 20//2/A, West Kafrul, Begum Rokeya Sarani Road, Mirpur 13 Dorian Furniture Mr. Aminul Islam 205/5, West Kafrul, Begum Rokeya Sarani Road, Mirpur 14 Shawdagar Complex Mr. M. Nurul Islam 604, Kazipara, Begum Rokeya Sarani Road, Mirpur 15 Rawshon Complex Mr. N. Islam Salim 618, Kazipara, Begum Rokeya Sarani Road, Mirpur 16 Furnitech Furniture Mr. Azazur Rahman Shuva

622, Kazipara, Begum Rokeya Sarani Road, Mirpur 17 Aleef Furniture (2 members) Mr. A. K. Azad 613/1, Kazipara, Begum Rokeya Sarani Road, Mirpur 25

18 Madina Furniture Mr. M. A. Hakim Sarkar 50, Sheorapara, Begum Rokeya Sarani Road, Mirpur 19 Khaleda Furniture Mr. M. A. Khair Molla 586/2, Sheorapara, Begum Rokeya Sarani Road, Mirpur ANNEX 3 Enterprises/ organizations visited and personnel met Sl. Personnel Enterprises/ organizations Address (a) Furniture Enterprises 1 Mr. M. Quamrul Huda Proprietor Crystal Meubles Furniture Shop 218/6, West Kafrul, Begum Rokeya Sarani Road, Mirpur 2 Mr. M. Bazlul Karim Managing Directir Paris Furniture 607, Kazipara, Begum Rokeya Sarani Road, Mirpur 3 Mr. M. Jalilur Rahman Director Business Dev. Rangamati Complex 494, North Kazipara, Begum Rokeya Sarani Road, Mirpur 4 Mr. N. M. S. Alam Director Ya Rab Complex 217/1, West Kafrul, Begum Rokeya Sarani Road, Mirpur 5 Mr. Selim H. Rahman Managing Director Hatil Complex 1243, East Monipur, Begum Rokeya Sarani Road, Mirpur 6 Mr. M. Mainur Rahman Proprietor Sandwip Complex 613/1 North Kazipara,Begum Rokeya Sarani Road, Mirpur 7 Mr. M. Israil Miah Director Bhai Bhai Furniture 494, North Kazipara, Begum Rokeya Sarani Road, Mirpur 8 Mr. M. Fazlul Hoque Proprietor Decorus Furniture 615, North Kazipara, Begum Rokeya Sarani Road, Mirpur 9 Mr. M. Solaiman Proprietor The National Furniture 315, East Monipur, Begum Rokeya Sarani Road, Mirpur 10 Mr. M. K. Akhtar Khan Proprietor Furniture Express 632, Kazipara, Begum Rokeya Sarani Road, Mirpur 11 Mr. Habibur Rahman Proprietor Mamata Furniture 218/6,West Kafrul, Begum Rokeya Sarani, Mirpur 12 Mr. M. Tofazzol Proprietor Hazrat Shah Paran Furniture 20/d/2/A, West Kafrul,Begum Rokeya Sarani Road, Mirpur

13 Mr. Aminul Islam Proprietor Dorian Furniture 205/5, West Kafrul, Begum Rokeya Sarani Road, Mirpur 14 Mr. M. Nurul Islam Proprietor Shawdagar Complex 604, Kazipara, Begum Rokeya Sarani Road, Mirpur 15 Mr. N. Islam Salim Proprietor Rawshon Complex 618, Kazipara, Begum Rokeya Sarani Road, Mirpur 16 Mr. M. Mesbahuddin Proprietor Furniture Garden 220, Kazipara, Begum Rokeya Sarani Road, Mirpur 17 Mr. Azazur Rahman Proprietor Furnitech Furniture 622, Kazipara, Begum Rokeya Sarani Road, Mirpur 18 Mr. A. K. Azad Proprietor Aleef Furniture 613/1, Kazipara, Begum Rokeya Sarani Road, Mirpur19 Mr. Shahjahan Kabir Director Business Dev Modern Furniture Complex 6, North Kazipara, Begum Rokeya Sarani Road, Mirpur 20 Mr. Arifur Rahman Proprietor Vienna Furniture 752/1, Sheorapara, Begum Rokeya Sarani Road, Mirpur 21 Mr. M. M. Alam Proprietor Woodman Furniture 1038, Sheorapara, Begum Rokeya Sarani Road, Mirpur 22 Mr. M. Zahirul Islam Baghdad Furniture 752, Sheorapara, Begum 26

23 23 25 26 29 (b) 30 31 32 33 34 35 (c) 36 37 38 39 40 41 42 43 44 Proprietor Mr. M. A. Hakim Sarkar Proprietor Mr. M. A. Kader Proprietor Mr. M. A. Khair Molla Proprietor Mr. S. M. A Awal Proprietor Mr. S.H. Rahman Proprietor Sawmills/ Timber traders Mr. B.M Jahurul Hoque Proprietor Mr. Siddiqur Rahman Proprietor Mr. Abu Bakar Siddique Proprietor Mr. M. Aminul Islam Director Mr. Rafiqul Islam Proprietor Mr. M. Nurul Islam Proprietor Other organizations Dr. M. Ashraful Haque Director Dr. N. A. Siddiqui Division Head Dr. M. Nazrul Islam Division Head Mr. M. A. Khaleque Division Head Mr. S. M. A. Rahman Asst General Manager Mr. S. M. A. Latif

Manager, Production Mr. M. Shakil Ahmed Asst General Manager Mr. M. Saiful Islam Asst General Manager Mr. Nurul Alam Sikdar Manager, Marketing Madina Furniture Long Life Furniture Khaleda Furniture Dhaka Furniture Shital Complex Sonali Timber Trade Sawmill Al Makka Sawmill Nesarabad Timber Popular Timber Traders National Timber Complex Uzzal Timber Bangladesh Forest Research Institute do do do Bangladesh Forest Industries Development Corporation do do do do Rokeya Sarani Road, Mirpur 50, Sheorapara, Rokeya Sarani Road, Mirpur 49, Sheorapara, Begum Rokeya Sarani Road, Mirpur 586/2, Sheorapara, Begum Rokeya Sarani Road, Mirpur Plot # 13. Main Road, Begum Rokeya Sarani Road, Mirpur 495/5, Monipur, Kazipara, Rokeya Sarani Road, Mirpur 168, Senpara, Begum Rokeya Sarani Road, Mirpur ?, Senpara, Begum Rokeya Sarani Road, Mirpur 152, Senpara, Begum Rokeya Sarani Road, Mirpur ? Senpara Begum Rokeya Sarani Road, Mirpur ? Begum Rokeya Sarani Road, Mirpur 167, Senpara, Begum Rokeya Sarani Road, Mirpur Sholashahar, Chittagong do do do Cabinet Manufacturing Plant, Section- 2, Mirpur doBFIDC Complex, Kalurghat

Do do 27

ANNEX- 4 QUESTIONNAIRE REGARDING FURNITURE INDUSTRY IN MIRPUR ZONE 1. a) b) c) d) e) 2. a) b) c) GENERAL INFORMATION Name of the industry : Address : Year of establishment : Owner/designation : Phone/e-mail address : TYPE OF INDUSTRY Fully mechanized/ Semi-mechanized/ Manual : (Tick) Medium/ Small/ Other : (Tick) Total number of employees :

3. MACHINERY a) Mention the major machinery and equipments : b) Mention the origin of the machinery/equipments : Local/ Foreign (India/ China / UK/ Germany/ Italy/ Other (mention ) : (Tick) c) If foreign products, how these were procured? : Local market/ Imported : (Tic k) 4. RAW MATERIALS a) What type of raw materials are used ? : Sawn timber/ Plywood/ Particle board : (Tick) -% b) ): c) of sawn timber used : Name the major timber species: Teak/ Chapalish/ Gamar/ Garjan/ Other (mention Tick) Price of sawn timber/cft: (Tk): Teak- , Chapalish- , Gamar-

Garjan-, Other (mention) d) Why the particular timber species are used ? : Easy availability/Cheaper/ Bet ter quality/ Preferred by the customers/ Other (mention) : (Tick) e) Mention the total amount of sawn timber used per month (in cft) : f) Indicate the amount of sawn timber actually be for seasoning (cft) : g) From what sources timbers are procured ? : Local market /Imported/ Both : (Ti ck) h) If imported, mention % of the total : i) Mention the country of origin : Myanmar/ Malaysia/ Nepal/Bhutan/ Indonesia/ Singapore/ Nigeria/ Other (mention) : (Tick) 28

5. SIZES OF TIMBER used a) Mention the sizes of timber which are commonly used (in inch) ? : 0.50/ 0.75/ 1. 00/ 1.25/ 1.50/ 1.75/ 2.00 : (Tick) b) What are the sizes used mostly ? : c) How these sizes are obtained ? : Converted from logs/squares in own sawmill/ In other sawmill/ Purchased required sizes from local market/ Purchased sizes from foreig n market: (Tick) 6. PROCESSING TECHNOLOGY a) What processing technology is adopted for timber prior to manufacture of product s ? : Seasoning/ Chemical treating / Other (mention)/ None : (Tick) b) If seasoning technology is adopted, what method is used ? Kiln drying/ Air dryin g/ Solar drying : (Tick) -Do you think that your adopted method is adequate for proper seasoning ?Yes/ No : (Tick) c) If you are not adopting proper seasoning , do you think it is due to the followi ng one or more reasons? : (Tick) -Lack of seasoning facility -Unable to install own seasoning plant -Increased seasoning cost involved -Lack of technical knowledge -Don t know about seasoning -Other (mention) : d) Do you know t hat the quality of timber and its products can be improved through seasoning? : Yes/ No : (Tick) e) Are you confident that better price and market can be fetched if products are made from seasoned timber? : Yes/ No : (Tick) f) Do you know that customers are increasingly interested in purchasing products manufactured from seasoned timber? : Yes/ No : (Tick) g) If yes, mention the percent of customers who are interested even with reasona bly higher cost : (%)

g) Do you know that it is pre-requisite condition to manufacture products from seas oned timber, in case of export ? : Yes/ No : (Tick) h) If ( d, e, f, g ) are yes, will you be interested in adopting the seasoning t echnology presently/ in the future? : Yes/ No : (Tick) 29

i) If yes, will you be ready to bear the additional cost involved in seasoning? :Yes/ No: (Tick) 7. MANUFACTURED PRODUCTS a) Name the major products : b) In what markets these are sold ? : Local market/ Foreign market/ Both : (Tick) c) Name the products which are exported, if any : -% of the total products : d) Name the products which are imported, if any : -% of the total products : e) If not exporting now, is there any planning for export in the future ? : Yes/ No : (Tick) f) Mention the problems /bottlenecks for not exporting the products presently: (i) Technical : (ii) Financial : (iii) Policy level : (iv) Other : 8. DESIGN OF PRODUCTS a) What designs of products are used : Local /Foreign/ Both : (Tick) b) If any foreign design is used, mention the reason : c) Mention the total foreign designs used (%) : d) How the foreign designs were obtained : Catalogues/ Foreign visit/ Imported item s/ / Other (mention) : (Tick) e) Are you interested in developing/obtaining improved designs ? : Yes/ No : (Ti ck) 30

9. COST OF PRODUCTS a) Mention the approximate cost of the manufactured products per month (in lakh) : (Optional) 10. SUGGESTIONS/ FURTHER NEEDS a) After completion of the feasibility study, do you need further technical assista nce ?: Yes/ No : (Tick) b) If yes, what specific assistance are needed ? : (Tick) (i) Full guidance/technical assistances including procurement, installation, trainin g, operation and developing proper seasoning schedules (ii) Training, operation and developing seasoning schedules (iii) Operation and developing proper seasoning schedules (iv) Only training of the operators (v) Only developing seasoning schedules (vi) None of these c) You have formed a forum specifically for installing a seasoning plant on collabo rative basis, what is your idea about ? (i) Management of the forum to run it on sustainable basis : (ii) Management of the seasoning plants to run it on sustainable basis : 31

ANNEX- 5 General information about the member furniture enterprises at Mirpur area Sl. No. Particulars Frequency Percent Cumulative percent a) Nature of industries: i) Mechanized 1 4.5 4.5 ii) Semi-mechanized 6 27.3 31.8 iii) Manual 15 68.2 100 Total number of industries 22 100 b) Size if industries : i) Big1 4.5 4.5 ii) Medium 12 54.6 59.1 iii) Small 9 40.9 100 Total number of industries 22 100 c) Type of machinery : i) Fully mechanized0 0 0 ii) Only hand tools 14 63.6 63.6 iii) Both hand/ machine 8 36.4 100 d) Place of procurement of machinery i) Local ii) Foreign Total number of industries using machinery 3 7 10 30 70 100 30 100 ANNEX 6

Information regarding raw materials, particularly timbers used by the furniture enterprises Sl. Type of raw material Average Range No. Percent Min. Max. a) i) Sawn timber 80.8 70 90 ii) Plywood 10.7 10 20 iii) Particle board 8.5 2 10 b). Type of timber species Av. Percent Range of use Frequency of industries Percent i) Teak 70.8 41 100 22 100 ii) Chapalish 11.5 6 30 21 95.5 iii) Gamar 8.6 8 20 18 81.8 iv) Garjan 9.1 9 30 22 100 c) Price of timber species Average Range Price/cft (Tk) Min. Max i) Teak 1300 1000 1500 ii) Chapalish 877 800 1000 iii) Gamar 785 700 850 iv) Garjan 836 750 900

32

ANNEX - 7 Information about thickness of timber mostly used and how these are obtained Sl. No. Mostly used thickness of planks (inch) Percent Timbers are obtained from Own sawmill Other sawmill i) ii) iii) iv) v) vi) vii) 0.75 1.00 1.25 1.50 1.75 2.00 Other thickness Total industries : 22 46.2 20.2 6.5 15.4 5.4 4.1 2.2 100 8 14 (36.4%) (63.6%) ANNEX- 8 Information regarding reason/s and amount of use of these timbers Sl. No. Why these particular timbers are used Frequency Percent a) i) Easy available ii) Cheaper iii) Better quality iv) Preferred by customers Total industries 22 0 22 22 22 100 0 100 100 100 b) Amount of sawn timber and its requirement for seasoning/month Average amount (cft) i) Total amount used

ii) Amount needed for seasoning iii) Source of procurement Total industries (excluding one big industry- Hatil Complex) 230 120 Local 21 ANNEX- 9 Information about the processing technology used by the enterprises Sl. No. Type of technology Frequency Percent Cumulative percent a) i) Seasoning ii) Chemical treatment iii) Other (Improper seasoning) Total industries 4 18 22 18.2 81.8 100 18.2 18.2 100 b) What method seasoning Frequency Percent Cumulative percent i) Kiln seasoning ii) Solar seasoning iii) Air seasoning Total industries 4 0 18 22 18.2 0 81.8 100 18.2 18.2 100 c) How they assess their method of seasoning Proper Inadequate Don t know Comments Total industries : 22 4 18 33

ANNEX - 10 Specific reasons for not adopting seasoning and awareness about it Sl. No. Reasons for not adopting proper seasoning method a No. of ind. replied Yes (%) No (%) 1. i) Lack of seasoning facility 21 (95.5) 1 (4.5) ii) Unable to install own seasoning kiln 21 (95.5) 1 (4.5) iii) Increased seasoning cost 1 (4.5) 21(95.5) iv) Lack of technical knowledge 21(95.5) 1 (4.5) v) Don t know about seasoning 0 22 Total number industries 22 (100) 2. i) Do they know/ think that by seasoning -Quality of timber and products can be increased 22(100) 0 -Better price can be fetched ii) Do they know/ think that : 22(100) 0 - Customers are increasingly interested 22(100) 0 -Customers are interested even with higher cost iii) Are the industries ready to : 22(53) 0 - Bear the cost for seasoning kiln/s 22(100) 0 Total number of industries 22(100) ANNEX- 11 Information regarding manufactured products Sl. No. Manufactured products/Marketing/Planning Frequency Percent 1. 2. 3. Products : i) Usual furniture items ii) Usual items with some special ones Marketing : i) Local market ii) Foreign market iii) Both markets Planning for export : i) Presently ii) In the future Total number of industries 22 2 22 0 0 0 20 22 100 9.0 100 0 0 0 90.9 100 ANNEX- 12 Problems/ bottlenecks hindering the present export potentials

Sl. No. Different aspects/ bottleneck Frequency Percent 1. 2. 3. 4. Technical : i) Lack of woodworking machinery ii) Lack of seasoning facility iii) Cannot cope up with local demand Financial : i) Financially not so solvent to expand and modernize the factory Policy : i) Not declared as an industry like garment industry ii) Bank loan not given without mortgaging any land Other : i) Not allotted any govt. plot like cottage industry Total number of industries 21 21 1 21 21 21 21 22 95.5 95.5 4.5 95.5 95.5 24 95.5 100 34

ANNEX - 13 Needs of the furniture industries regarding installation of seasoning plant Sl. No. Type of specific assistance needed Frequency Percent 1. 2. 3. 4. 5. 6. -Full guidance including procurement, installation, training, operation and developing drying schedules -Training, operation and developing drying schedules -Operation and developing drying schedules -Only training of the operators -Only developing drying schedules - None of these Total number of industries 22 22 ----100 ----ANNEX - 14 Suggestions regarding management of the Forum and the seasoning plant to make them sustainable Sl. No. Type of suggestions offered by the key actors Frequency Percent (a) 1 -Run through a management committee/ council 22 100 2 -Select active and capable persons 14 63.6 3 -Select sincere and honest persons 11 50 4 -Select sincere and committed persons 8 36.4 5 -Monthly regular meeting 18 81.8 6 -Decision after taking consent of each member 3 13.6 7 -Subscription be regular 10 45.5 8 -Increase subscription, if necessary 4 18.2 9 -Financial transaction be fair and transparent 4 18.2 10 - 10% extra seasoning charge be paid 3 13.6 11 -Three trusted members for financial operation 3 13.6 12 -Arrange bank loan after forming Ltd Co. 4 18.2 13 -No withdrawal of fund within 12 months 3 13.6 14 -Target installation within 9-12 months 4 18.2 Total number of industries 22 100 Suggestions offered by the key actors for the Plant (b) 1 -Run by a separate set of staff and supervised directly by the Forum 5 22.7 2 -Appoint technical staff for the plant 4 18.2 3 -Appoint a set of employees and train them properly 7 31.8 4 -Consultant will suggest the structure 11 50.0 Total number of industries 22 100 35

ANNEX - 15 Major commercial wood species with their origin and major uses Sl No. Common name Scientific name Occurance Major uses 1. Teak Tectona grandis Hill forests Furniture, construction, other 2. Garjan Dipterocarpus spp. do Construction, sleepers, other 3. Champa Michelia champaca do Furniture, cabinets, other 4. Chapalish Artocarpus chaplasha do Furniture, cabinets, other 5. Chickrassi Chickrassia tabularis do Furniture, construction 6. Gamar Gmelina arborea do Furniture, construction, other 7. Jarul Legerstroemia speciosa do Industrial, other 8. Sal Shorea robusta do Construction, other 8 Civit Swintonia floribunda do Plywood, other 10. Dhakijam Syzygium grandis do Construction, other 11. Telsur Hopea odorata do Construction, other 12. Batna Quercus sp. do Construction, other 13. Goda Vitex peduncularis do Construction, other 14. Sundri Heriteria fomes Mangrove Construction,hardboard, other 15. Gewa Exocaria agalocha do Newsprint, other 16. Kankra Brugera conjugata do Construction, other 17. Passur Xylocarpus mollocensis do Construction, other 18. Raintree Samanea saman All regions Furniture, light work, packing 19. Mango Mangifera indica do Furniture, packing, other 20 Mahogany Swentonia mahogoni Rajshahi region Furniture, construction 21 Silkorai Albizia procera All regions Matches, light work, packing 22 Babla Acacia nilotica North-west Machine formats, sp. work 23 Sissoo Dalbergia sissoo do Construction, other 24 Tentul Tamarindus indica All regions Construction, other 25 Jam Syzygium cumini do Furniture, doors/frames, boat 26 Kanthal Artocarpus heterophylllu do Furniture, construction, other 36

ANNEX- 16(a) Estimated cost of construction of two 500 cft capacity steam heated seasoning ki lns as quoted by Gangotri Impex, India Sl. No. Particulars CFR Benapole Taxes and transport charge from Benapole to Dhaka, etc Total cost 1(a) Kiln equipments Complete with 2 sets of blower fans, heating batteries, pipe line, top damper, motor, etc (without kiln chambers) *US $ 5,527x 2 = Tk 6,63,240 (b) Insulated door - 2 Nos. US $ 869 = Tk 52,140 3 (a) Boiler (Model BSPG-3) Complete package US $ 11,051 = Tk 6,63,060 (b) Interconnectivity from boiler to 2 kilns US $ 581 = Tk 34,860 4 (a) Chimney MS self/Guy wire supported US $ 2,381 = Tk 1,42,860 (b) Interconnectivity ducting from fan to chimney US $ 581 = Tk 34,860 Pipeline from boiler to 2 kilns US $ 1,521 = Tk 91,260 Sub-total US $28,038 = Tk 16,82,280 Tk 16,82,280 5 Construction of 2 kiln chambersCivil works & other costs (approx.)- local --Tk 5,50,000 Sub-total --Tk 22,32,280 6 Water treatment plant Complete with booster pump, materials, etc. excluding civil work, electrical, etc US $ 3,227 = Tk 1,93,620 Sub-total US $ 3,227 = Tk 1,93,620 Tk 1,93,620 Sub-total -Tk 2,00,000 Tk 2,00,000

7 Other civil works, electric, etc. local --Tk 50,000 Sub-total Tk 26,75,900 8 Installation & commissioning charge Including board & lodging Tk 60,000 Grand total Tk 27,35,900 * 1 US $ = Tk 60 37