Documente Academic

Documente Profesional

Documente Cultură

Cyclic Macro-Element For Soil) Structure Interaction: Material and Geometrical Non-Linearities

Încărcat de

Astrid AubryDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cyclic Macro-Element For Soil) Structure Interaction: Material and Geometrical Non-Linearities

Încărcat de

Astrid AubryDrepturi de autor:

Formate disponibile

* Correspondence to: CeH cile Cremer, GeH odynamique et Structure, Bagneux, France

Received 9 May 2000

Copyright 2001 John Wiley & Sons, Ltd. Revised 20 March 2001

INTERNATIONAL JOURNAL FOR NUMERICAL AND ANALYTICAL METHODS IN GEOMECHANICS

Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284 (DOI: 10.1002/nag.175)

Cyclic macro-element for soil}structure interaction: material and

geometrical non-linearities

CeH cile Cremer*, Alain Pecker and Luc Davenne`

GeHodynamique et Structure, Bagneux, France

`Laboratoire de MeH canique et de Technologie-ENS Cachan, Cachan, France

SUMMARY

This paper presents a non-linear soil}structure interaction (SSI) macro-element for shallow foundation on

cohesive soil. The element describes the behaviour in the near "eld of the foundation under cyclic loading,

reproducing the material non-linearities of the soil under the foundation (yielding) as well as the geometrical

non-linearities (uplift) at the soil}structure interface. The overall behaviour in the soil and at the interface is

reduced to its action on the foundation. The macro-element consists of a non-linear joint element, expressed

in generalised variables, i.e. in forces applied to the foundation and in the corresponding displacements.

Failure is described by the interaction diagram of the ultimate bearing capacity of the foundation under

combined loads. Mechanisms of yielding and uplift are modelled through a global, coupled plasticity}uplift

model.

The cyclic model is dedicated to modelling the dynamic response of structures subjected to seismic action.

Thus, it is especially suited to combined loading developed during this kind of motion. Comparisons of

cyclic results obtained from the macro-element and from a FE modelization are shown in order to

demonstrate the relevance of the proposed model and its predictive ability. Copyright 2001 John Wiley

& Sons, Ltd.

KEY WORDS: macro-element; soil}structure interaction; shallow foundation; plasticity; uplift

1. INTRODUCTION

Numerous studies have been performed on the bearing capacity of a shallow foundation under

inclined eccentric loading. Guided by experimental results, Meyerhof [1], Vesic [2], Butter"eld

and Gottardi [3] have proposed a solution for a shallow foundation lying on a sand layer. Later,

Salenion and Pecker [4,5], Paolucci and Pecker [6], Ukritchon et al. [7] and Houlsby and

Puzrin [8], have elaborated solutions for frictional and/or cohesive medium. The proposed

bounding surfaces allow the determination of the ultimate forces supported by the foundation,

but do not allow prediction of the amplitude of permanent displacements, which may in certain

cases become excessive and lead to instability of the structure.

M

H

V

B

(1- )B

e

x

e

z

x

z

Figure 1. System de"nition.

The concept of macro-element has been applied to the soil}structure interaction by di!erent

authors. They have especially studied the case of a foundation on sand. Among them, Tan [9],

Nova and Montrasio [10], Gottardi et al. [11] have performed a lot of experimental tests, for

di!erent monotonic loading paths, that guided them in the elaboration of a macro-element.

Martin [12] has applied the same concept, but for o!shore foundations on cohesive soil. These

models lead to a good prediction of plastic displacements, especially settlements, but only under

monotonic loading. Recently, Pedretti [13] has extended the Nova and Montrasio model to

cyclic loading using the hypoplasticity theory.

In this paper, we propose a new cyclic soil}structure interaction macro-element for a shallow

foundation on cohesive soil. Besides the plastic behaviour of the soil, the model takes into account

the non-linearities at the soil}foundation interface. Uplift has the e!ect of signi"cantly reducing

the forces in the structure. Di!erent studies have shown that it is a predominant factor at the base

of slender structures during seismic action [14]. This paper presents the cyclic plasticity-uplift

coupled model, and proposes a macro-element, which is rather easy to use and which represents

a very e$cient tool in designing a structure}foundation system.

2. BEHAVIOUR CHARACTERIZATION

2.1. System dexnition

Assuming that the foundation is a rigid body, its movement can be described with global

variables expressed at the foundation centre (Figure 1). The behaviour of the soil}foundation

system will thus be modelled through the forces applied at the base of the foundation (vertical

force <}horizontal force H}moment M) and through the corresponding kinematic displacements

measured at the centre (vertical displacement z}horizontal displacement x}rotation 0). The

separation ratio of the foundation of width B is noted as o; it is de"ned as the ratio of the length of

the foundation not in contact with the soil divided by the foundation width.

2.2. Numerical data base

Due to the di$culty and cost of carrying out experimental tests on a foundation lying on

a cohesive medium (mainly due to the di$culties of the model preparation due to clay consolida-

tion) for di!erent loading paths, the elaboration of a numerical data base allowed us to

1258 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 2. 2D "nite element mesh (parameters of the clay constitutive law: c"c

"

#Vg Z with c

"

"30 kPa

and Vg"3 kN/m`; G/c"1300 (G

"

"39 MPa); v"0.45; j"1.9 t/m`;

`

"0.016).

characterize the foundation behaviour and to identify the model parameters. These simulations

have been performed with the "nite element code Dyna-ow (PreH vost, version 1998), which

provides adequate constitutive laws for the description of the soil behaviour under cyclic loading.

The 2D numerical model (Figure 2) consists of a foundation lying on a largely discretized soil

medium, presenting a constant rate of increase of cohesion with depth. The contact elements at

the soil}foundation interface are governed by a no-tension criterion that allows separation

between the soil and the foundation.

For the soil modelling, the PreH vost [15] multi-yield constitutive law for cohesive soil is used.

This is an analytical model which describes the anisotropic, elastoplastic, path-dependent

stress}strain}strength properties of saturated clays under undrained loading conditions. The

failure is de"ned by the Von Mises criterion. The hardening is purely kinematic and is described

by successive yield surfaces translating inside the failure criterion. A plastic modulus is associated

with each of the yield surfaces, and an associative #ow rule is used to compute the plastic strains.

The cyclic behaviour is presented in Figure 3 for a triaxial compression and extension simulation.

The constitutive parameters have been identi"ed from experimental tests on undrained normally

consolidated saturated clay (plasticity index PI"20 per cent).

On the basis of these numerical simulations, carried out for a large number of di!erent loading

paths, the foundation behaviour has been interpreted.

2.3. Description of behaviour

Di!erent response diagrams M}0 (moment}rotation), H}x (horizontal force}horizontal displace-

ment), M}z (moment}vertical displacement) and M}o (moment}uplift ratio) are presented in

Figures 4}7 for a foundation with an ultimate vertical force equal to <

`

"2.4 MN. It is

subjected to a constant vertical force < (<"0.6 MN; </<

`

"0.25) and a cyclic radial loading

path in the M}H plane (M/H"10 m). The behaviour is strongly non-linear and highly

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1259

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 3. PreH vost's multi-yield model for anisotropic undrained clays (1978): Triaxial compres-

sion and extension stress}strain curves.

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-0.002 -0.0015 -0.001 -0.0005 0 0.0005 0.001 0.0015 0.002

(rad)

M

(

M

N

m

)

cyclic

monotonic

V=0.62MN

M/H=10m

Figure 4. Overturning moment}rotation.

dissipative. Non-linearities come from soil yielding but also from uplift at the interface. The non-

linearities due to uplift are partially recoverable (Figure 7), and thus clearly noticed in the

unloading part of the M}0 and M}z curves. Indeed, we observe in the unloading M}0 curve

(Figure 4), the increase in sti!ness due to restored contact of the foundation with the soil. In the

M}z diagram (Figure 6), which is dominated by the foundation settlement (increasing with

cycles), we note the e!ect of the lift-up of the centre of gravity during uplift and its lowering during

unloading.

2.4. Model design

From the observation of this kind of behaviour, it has been chosen to build the macro-element

around two di!erent models, one in plasticity and one in uplift, separated but coupled. Coupling

1260 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

-0.01 -0.005 0 0.005 0.01

x (m)

H

(

M

N

)

cyclic

monotonic

V=0.62MN

M/H=10m

Figure 5. Horizontal Force}horizontal displacement.

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

0 0.002 0.004 0.006 0.008 0.01 0.012

z (m)

M

(

M

N

m

)

cyclic

monotonic

V=0.62MN

M/H=10m

Figure 6. Overturning moment}vertical displacement.

between both submodels accounts for the in#uence of plastic yielding on uplift and vice versa, of

uplift on plastic yielding. Indeed, the reduction of the foundation width in contact during uplift

induces an increase of the stresses under the foundation. This leads to a larger soil yielding, which

itself modi"es the uplift behaviour of the foundation. Following this philosophy, the (z, x, 0)

displacements calculated for a given (<, H, M) forces vector are obtained by summing the

di!erent components, i.e. the elastic and plastic displacements issued from the plasticity model,

and the uplift displacement issued from the uplift model:

u

tot

"u

el

#u

pl

#u

up

The assumption that the global behaviour of the foundation behaves purely elastically during

unloading, allows one to assign all the non-linear e!ects visible on the unloading part of the

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1261

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-60 -40 -20 0 20 40 60

Uplift (%)

M

(

M

N

m

)

cyclic

monotonic

Uplift

left side

Uplift

right side

virgin loading

unloading-reloading

V=0.62MN

M/H=10m

Figure 7. Overturning moment}uplift.

curves to geometrical non-linearities. They are all gathered into the uplift model. These are

associated with the rotation and the vertical displacement (lift-up and lowering of the gravity

centre) induced exclusively by uplift. These expressions are "rst deduced from an uplift model for

an elastic soil. They are further modi"ed to take into account the coupling with plasticity. One

consequence of that coupling is that uplift becomes partially irreversible and that the moment

M for which it is initiated becomes a function of the foundation bearing capacity.

The plasticity model includes all the other non-linearities. These come from soil yielding under

the dead weight, under the increase in loads and also under the increase in stresses in the soil

during uplift. The e!ect of uplift is introduced by a failure criterion which corresponds to

a soil-failure mechanism for a foundation with uplift. The hardening law is also deduced from the

observation of the uplift behaviour. Finally, all the plastic parameters are identi"ed from

the plastic displacements from which the non-linear uplift components have been previously

subtracted.

This substructure approach decomposes a highly non-linear, coupled problem in order to

study each nonlinear e!ect separately, but without dismissing any coupling.

3. MODELLING

3.1. Plasticity model

3.1.1. Constitutive laws. The constitutive law is written as

F "K: (u !u

pl

) (1)

where u "u

el

#u

pl

with u

el

being the increment of elastic reversible displacement, u

pl

the

increment of plastic permanent displacement.

1262 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 8. Failure overturning mechanism with uplift.

The global variables (forces and displacements) have been rendered dimensionless to work with

a systemindependent of the foundation width B and of the plastic properties of the soil (cohesion):

F,

<'

H'

M'

"

1

<

`

<

H

M/B

, u,

z'

x'

0'

,

1

B

z

x

B0

(2)

where K is the dimensionless elastic sti!ness matrix (see Section 3.1.2), <

`

"q

`

B, with

q

`

being the foundation ultimate pressure under vertical centred load [16] or [17].

The plastic displacement increment is de"ned by the tensor

u

pl

"zQ ,P (3)

where P de"nes the #ow direction of plastic displacements in the forces' space, zQ is the plastic

multiplier; zQ ,"zQ if zQ *0, else zQ ,"0.

3.1.2. Elastic stiwness matrix. The dimensionless elastic sti!ness matrix is written as

K,

K'

XX

0 0

0 K'

VV

0

0 0 K'

FF

with K'

XX

"

K

XX

q

`

, K'

VV

"

K

VV

q

`

, K'

FF

"

K

FF

B`q

`

(4)

This is a diagonal matrix where the diagonal terms K

XX

, K

VV

, K

FF

correspond to the real part of the

static impedances of a shallow strip foundation, de"ned for instance by Gazetas [18]. They are

functions of the geometrical properties of the foundation (width B) and of the elastic properties of

the soil (shear modulus G, Poisson's ratio v).

Following the common practice for surface foundations, the o!-diagonal terms have been

neglected because they are very low with respect to the diagonal terms and do not signi"cantly

in#uence the foundation response.

3.1.3. Failure criterion. Bearing-capacity solutions, under any loading (combination of <, H, M),

for a strip foundation lying on a homogeneous cohesive half-space, have been proposed by

Salenion and Pecker [4,5] and Pecker [19] for a soil obeying the Tresca criterion with and

without tensile strength. These solutions have been obtained within the framework of the yield

design theory with static and kinematic approaches (Figure 8).

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1263

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 9. Bounding surface for cohesive soil.

For a homogeneous cohesive soil without tensile strength, the equation of the bounding surface

is (Figure 9)

f"

H'

a<'A(1!<')B

`

#

M'

b<'C(1!<')D

`

!1"0 (5)

with the coe$cients (values given in Table I):

E

a and b that de"ne the size of the bounding surface of elliptic shape in a (H', M') plane;

E

c, d and e, f that de"ne the parabolic shape of the bounding surface in the (<', H') and (<', M')

planes, respectively.

These coe$cients have been determined from the curves proposed by Ukritchon et al. [7] who

have derived solutions for a heterogeneous cohesive soil pro"le, exhibiting a constant gradient of

cohesion with depth [20]. The coe$cients are thus functions of q

`

/q

"`

, where:

E

q

`

is the foundation ultimate bearing capacity for a soil pro"le with cohesion c

"

at the surface,

exhibiting a gradient of cohesion, constant with depth;

E

q

"`

is the ultimate bearing capacity of the same foundation for a homogenous soil pro"le with

cohesion c

"

.

3.1.4. Loading surfaces. Knowing the failure criterion, one has now to determine the evolution of

the loading surface, dragged by the forces point, towards the failure surface when the forces

increase. The choice has been guided by the need for reproducing the behaviour of the soil and

foundation, initially submitted to the weight of the structure, and then solicited along any loading

path. Since the macro-element is built with the ultimate aim of modelling soil}structure interac-

tion under seismic action, loading paths followed by the structure under seismic conditions have

been favoured. If it is assumed that the dynamic gravity centre of the structure varies only slightly

(one predominant mode in the response), the paths are mainly radial in the (H, M) plane, with

a vertical force being almost constant (Figure 10). The model will be particularly well adapted for

these paths (parameters identi"cation).

1264 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

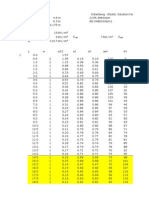

Table I. Proposed relationships for the parameters determination without any test.

Parameter Relationship

Elastic

Static sti+ness for a shallowstrip foundation on a heterogeneous soil medium with a gradient

of shear modulus constant with depth [18]:

K

XX

, K

VV

, K

VV

K

XX

"

0.73

1!v

G

"

(1#2:); K

VV

"

2

2!v

G

"

1#

2

3

:

; K

FF

"

2(1!v)

G

"

B

2

`

1#

1

3

:

where : de"nes the G shear modulus gradient following:

G"G

"

(1#:) and "

2z

B

with z, the depth, G

"

, the shear modulus at depth z"0, G, the shear modulus at depth z,

v, the Poisson ratio, B, the foundation width

Plastic

;ltimate bearing capacity of a shallow strip foundation for a vertical centred loading on

a cohesive soil [17]):

q

"`

Homogeneous soil with constant cohesion c

"

:

q

"`

"5.14c

"

Heterogeneous soil with a gradient of cohesion constant with depth:

q

`

q

`

"j

c

"

5.14#

VgB

4c

"

where Vg de"nes the c cohesion gradient following c"c

"

#Vgz

with z, the depth, c

"

, the cohesion at depth z"0, c, the cohesion at depth z, B, the width

of the foundation, j

, coe$cient depending on VgB/c

"

and on B/h, with h, the height of

the soil layer. Diagrams of j

are given in Matar and Salenion [17]

a, b, c, d, e, f Coe.cients of the failure criterion [20];

a"0.32/c; b"0.37/c"`; c"0.25; d"0.55; e"0.8; f"0.8;

where c"q

`

/q

"`

, Parameters of the plastic potential:

+0.23; +0.18

;plift

Moment for which the uplift is initiated, as a function of <':

M'

"

M'

"

"0.25<' exp``4

Magnifying unloading factor to apply to the loading slope of the (M'/<', o) relationship:

p p"4!3 exp(!4<' )

During the initialization phase of the gravity loads (Figure 11), the loading surface is reduced to

a straight line segment along the <'-axis (M'"H'"0):

f"<' with <'3[0, ,] and ,3[0, 1]. (6)

At the end of the initialization, <'","N/<

`

, where N is the weight of the structure.

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1265

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

CG

h

m

B

M

H

h

1

h

2

h

3

h

4

for a constant V

Figure 10. Type of loading paths preferentially developed during seismic action for a structure

with one predominant mode.

0 1

V

Figure 11. Initialization under vertical load.

Figure 12. Hardening rule: evolution of the loading surface.

For any loading, the surface, initially reduced to a straight line segment, is dragged along by the

forces point F. It simultaneously undergoes an isotropic growth and a kinematic translation of

the ellipse centres in the (H', M') plane, with a movement of the extreme point P along the <'-axis

(Figure 12). This point moves in such a way that, when point F reaches the failure surface, point

P simultaneously reaches the extreme failure point <'"1.

To describe this evolution, the loading surfaces are written as

f"

H'!:I

A

&

jIA

&

`

#

M'![IA

+

jIA

+

`

!1"0 with A,

0

I

A

&

I

A

+

0

a<'A(!<')B

a<'C(!<' )D

(7)

and

",#(1!,) ( j#t)

1266 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 13. Relationship between isotropic and kinematic parameters.

E

,

0

:

[

is the kinematic hardening vector, with t"( : )`"(:`#[`;

E

j is the isotropic hardening parameter.

The condition ",#(1!,)( j#t) ensures that point P moves from<'", to 1 as a function of

the j and t hardening parameters. Under the assumption of a radial loading path in the (H', M')

plane, it may be veri"ed that point F reaches the failure surface for j#t"1. At that moment, the

extreme point P of the loading surface reaches point <'"1.

3.1.5. Hardening laws. The hardening laws describe the evolution of the j and t parameters, so

that the model correctly reproduces the foundation behaviour under cyclic loading as well as

under monotonic loading. These laws are deduced from three relationships: (a) the relationship

that will link the isotropic parameter to the kinematic which is determined from the observation

of the foundation behaviour during uplift; (b) the criterion of non-interpenetration of the failure

surface by the loading surface which will allow us to de"ne the direction of the kinematic

hardening vector, a criterion that is commonly used in multi-surface plasticity models (see for

instance Prevost, Mroz); (c) the consistency rule which will determine the amplitude of the

kinematic hardening vector.

For that, it will be posed that

"tR

(8)

where tR that de"nes the amplitude of the kinematic increment and / its direction.

(a) Relationship between jR }tR: It is observed for the M'}0' relationship that loading of the

foundation on one side almost does not in#uence its behaviour on the other side. This is easily

explained by considering the role of uplift. The soil area located under the edge of the foundation,

which has been strongly solicited and has yielded during loading in one direction, does not

contribute, if uplift occurs, to the foundation response during loading in the opposite direction.

The behaviour for the evolution of the loading surfaces (Figure 13) is expressed by imposing the

condition that point F, representative of the forces state reached during loading in one direction,

becomes a "xed point of the loading surface during loading in the opposite direction.

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1267

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 14. Non-interpenetration criterion.

This condition is written as (for a radial path)

jR "tR (9)

(b) Criterion of non-interpenetration of the failure surface by the loading surface: Following the

philosophy of Prevost's tangent rule [15], this criterion ensures an evolution of the loading

surface such that, at failure, the representative point of the forces state coincides with the meeting

point of the loading surface with the failure surface.

The vector direction representing the increment of the kinematic hardening vector / is

calculated by imposing the condition that the next forces point F

G>

(Figure 14) lies along the

segment de"ned by F

G

F

D

, with F

D

belonging to the failure surface, such that O

G

F

G

//OF

f

.

The following equations are obtained:

,

0

I

&

cos !H'

I

A

&

I

+

sin !M'

I

A

+

, "a tan

&

I

+

M'![I

+

H'!:I

&

(10)

where I

&

, I

+

are equivalent to I

A

&

, I

A

+

but de"ned for the failure surface, i.e. for "1

,

0

I

&

I

0

a<'A(1!<' )B

a<'C(1!<' )D

(c) Consistency rule: The consistency rule

fQ"0 (11)

1268 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

determines the amplitude tR of the kinematic hardening incremental vector. By introducing

Equations (8) and (9) into the consistency rule, and noting that

zQ "

1

h'

Q: dF (12)

tR"!zQ ,

h'

cf/c : / #cf/cj

(13)

Determination of the plastic modulus h' from the M'}0' relationship: The plastic modulus h'

describes the evolution of the force}plastic displacement relationship for monotonic loading. As

we are mainly interested in the rotational foundation behaviour, h' is identi"ed with the M'}0'

relationship.

By introducing relationships (12) and (18) into (3) and then (3) into (1), and by isolating the h'

parameter in the rotational component, it is given by

h'"

K'

FF

(dM'/d0')

K'

FF

!(dM'/d0')

2M'

`

cf

c<'

d<'

dM'

#

cf

c<'

d<'

dM'

#

cf

cM'

(14)

By identifying the M'}0' relationship, it is proposed for dM'/d0' that

dM'

d0'

"K'

FF

exp(!K'

FF

0'/M'

`

) with M'

`

: moment corresponding to failure. (15)

Determination of the initial settlement of the foundation under the weight of the structure

(initialization phase under gravity): For the calculation of the foundation settlement under

a vertical centred load, the relationship proposed by Nova and Montrasio [10] has been chosen:

<'"1!exp) XXX (16)

3.1.6. Flow rule. The choice of a plastic potential g di!erent from the loading surface f (non-

associated model) is, in this particular case, required to correctly model the evolution of the

plastic displacements.

The plastic potential g has been chosen as

g"

H'

`

#

M'

`

#<'`!1"0 and P"

cg

cF

(17)

with

cg

c<'

"2<',

cg

cH'

"

2H'

`

,

cg

cM'

"

2M'

`

(18)

It describes an ellipsoid centred at the axes origin (<', H', M').

The choice of a non-associated model is justi"ed because the outer normal to the yield surface

is not convenient for de"ning the direction of the plastic displacements u

pl

. This is particularly

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1269

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 15. Non-associated model. External normals of the loading surface and of the plastic potential.

-0.0045

-0.004

-0.0035

-0.003

-0.0025

-0.002

-0.0015

-0.001

-0.0005

0

0 0.0005 0.001 0.0015 0.002 0.0025

p

l

FE results

model

M/H=2

M/H=20

M/H=5

M/H=10

x

pl

Figure 16. Plastic #ow: plastic rotation}horizontal displacement.

obvious for loading with a small <' (Figure 15). In that zone (i.e. for <' smaller than the value

corresponding to the summit of the parabola in the (H', <') or (M', <') plane), the component

along <' of the outer normal to the yield surface n

D

is always negative whatever the loading is (and

particularly even if <' increases). The choice of an ellipsoid centred at the axes origin as plastic

potential allows for increasing plastic vertical displacements, even in this zone.

This potential linearizes the relationship between the plastic displacements for a radial loading

path of the corresponding forces. Figure 16 shows that this choice, when compared to FE

simulations, is acceptable.

For this example (radial loading path in the (H', M') plane for a constant <' ), we have (from

Equations (3) and (18))

0Q ''

xR ''

"

`

`

M'

H'

(19)

1270 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

M

M

0

=VB/4

0

M

C

=VB/2

Figure 17. Moment}rotation (elastic soil).

3.1.7. Elasto-plastic tangent stiwness matrix. In the previous chapters, all the components re-

quired to de"ne a plasticity model have been set. The terms of the elastic sti!ness matrix

correspond to the static sti!nesses of a shallow strip foundation. The interaction diagram of the

foundation bearing capacity (limit analysis for an overturning failure mechanism with uplift) has

been chosen for the failure criterion. The evolution of the loading surface and the hardening rule

has been expressed to describe the cyclic behaviour of the foundation specially under seismic

loading. Finally, the choice of the plastic potential leads to a linearization of the relationships

between plastic displacements for a radial path of the corresponding forces.

Knowing all that, the expression of the elasto-plastic tangent sti!ness matrix K

elpl

can now be

derived:

F "

K!

1

h'#h

"

(K: P)(Q: K)

: u with h

"

"Q: K: P (20)

3.2. Uplift model

The uplift model for a foundation lying on an elastic soil is "rst presented. The expression of the

separation ratio o, as a function of the M/< ratio, is given, as well as the evolution of the

rotational and vertical components of displacement due to uplift. Then the in#uence of soil

yielding on the uplift behaviour is studied. Indeed, yielding modi"es the stress distribution under

the foundation and a!ects the value of the soil resisting forces for a given uplift. An uplift surface,

moving in the forces space with the loading history, is proposed. The expressions of the rotation

and vertical displacement of the elastic model are adapted to take into account the coupling with

plasticity.

3.2.1. Uplift model for an elastic soil [21]

Determination of the percentage of uplift width o for a (M, <) forces couple: For a shallow (perfectly

rigid) foundation lying on an elastic, homogeneous soil medium, under the assumption of an

actual, vertical stress distribution under the foundation (vertical stresses tending towards in"nity

at the edges of the foundation), CreH mer [21] proposed the following relationships (Figure 17):

Before uplift M(M

"

, M"K

FF

0

Uplift onset M"M

"

, M

"

"K

FF

0

"

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1271

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

M

C

=VB/2

M

0

=VB/4

M

0

1

0.5

M

0

1

Figure 18. Moment}uplift (elastic soil).

During uplift M'M

"

,

M

M

"

"2!

0

"

0

(21)

0"

0

"

1!o

(22)

with M

"

"<B/4, where M

"

is the moment for which uplift is initiated, 0

"

is the rotation

corresponding to M

"

.

M

"<B/2, where M

is the critical moment for which the structure overturns (o! centre vertical

force of a half foundation width).

From these relationships (Equations (21) and (22)), it results that the length Bo along which

separation occurs is a linear function of the ratio M/< (Figure 18) and is written as

o"

M

M

"

!1 with M

"

"<B/4 (23)

Note: It should be noticed that the vertical stress distribution at the soil}foundation interface is

very slightly in#uenced by the soil pro"le (layer of limited depth, constant gradient of the elastic

properties with depth). Figure 19 compares the vertical stress distribution under vertical loading

for an homogeneous soil pro"le (Poulos and Davis [22] analytical solution) and for a pro"le with

a linearly increasing elastic sti!ness, corresponding to the reference case of Figure 2 (Dyna#ow

FE simulations). However, for a layer of very limited depth or for strong gradient, the in#uence of

uplift on the horizontal degree of freedom may no longer be neglected.

Calculation of the components in rotation 0" and vertical displacement z" induced by uplift: Setting

0"0'#0" and M"K

FF

0' during uplift, the expression of 0", the rotational component

coming exclusively from uplift, is computed as

0""0

"

o`

1!o

(24)

By writing the purely kinematic relationship existing between rotation and vertical displacement

of the foundation centre, the expression of the vertical displacement due to uplift can also be

1272 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

0

0.5

1

1.5

2

2.5

3

3.5

4

z

z

/

z

z

m

e

a

n

linearly increasing stiffness (numerical

solution)

homogenous soil (analytical solution)

-B/2 0 B/2

Figure 19. Vertical stress distribution at the soil}foundation interface for a vertical loading.

computed. This is found by calculating "rst the in"nitesimal increment dz at the foundation

centre produced by an increment d0, under the assumption of a vertically "xed point located at

the centre of the foundation of reduced width (1!o)B. By integrating dz from 0

"

to 0, and by

replacing 0 by its o expression (Equation (22)), it "nally gives

z""

B0

"

2

o

1!o

#ln (1!o)

with o'0 (25)

Note: All the equations discussed above will be, for the elasto-plastic model, expressed in

the dimensionless variables ( ' ) of our system in order to include the e!ect of the bearing

capacity <

`

.

3.2.2. Uplift surface for an elasto-plastic soil. In the plasticity model, a loading surface growing

inside the failure criterion and referring to a certain yielding level has been proposed. Following

the same idea, an uplift surface moving inside an uplift domain de"ning the magnitude of

soil}foundation separation is built. This uplift surface is expressed in the forces space.

As for an elastic soil, it is observed that o is only a function of the M' and <' variables, and it

may be assumed that it is independent of the H' force. For this reason, the following developments

will be made in the (<', M') plane, for a given H'. The surfaces of &iso'-separation (same separation

ratio) are presented in Figure 20, superimposed with the failure criterion. Their shapes have been

deduced from Dyna-ow numerical simulations. Those surfaces de"ne, in the forces plane, an uplift

domain limited between the 0 and the 100 per cent separation surfaces.

The slopes at the origin of the surface corresponding to the onset of uplift (o"0 per cent) and

that corresponding to maximum separation (o"100 per cent) are

dM'

d<'

4"

B" ' "'

"

"

and

dM'

d<'

4"

B"" ' "'

"

`

(26)

which is consistent with the uplift behaviour of the foundation on elastic soil.

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1273

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

Figure 20. &Iso'-uplift surfaces and failure criterion in the (M', <') plane.

M/V

M

0

/V

1/4

V <

V >

elastic

1

Figure 21. Evolution of the uplift for di!erent values of <'.

The only values of separation, which may be reached during loading, are de"ned by the area of

the uplift domain located inside the failure criterion. Thus it is obvious that, with plasticity, soil

failure occurs before uplift has led to 100 per cent separation between the soil and the foundation.

The greater the <' force, the smaller the maximum separation reached at failure.

3.2.3. Evolution of the uplift surface

Monotonic loading: The moment M'

"

for which uplift is initiated is not (contrary to the elastic case)

a linear function of <' (see M'

"

curve in Figure 20). Its variation may be approximated by

a function of form

M'

"

"

<'

4

exp4 where A is a parameter to identify (27)

Moreover, it is observed that separation is still a linear function of the M'/<' ratio (Figure 21)

with the same coe$cient, whatever the yielding level. By applying the uplift results in elasticity

(Equation (23)), a coe$cient of

"

is found for the slope.

The separation evolution is then de"ned by

o"

4

<'

(M'!M'

"

) (28)

1274 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

M /V

M

0

(0)

p

(1)

/4

1

1

1/4

M

0

(1)

M

0

(2)

/ V

M

p

(1)

M

p

(2)

p

(2)

/ V

/ V

/ V

/ V

Figure 22. Uplift irreversibility (cyclic loading).

Knowing the expression of the surface at the onset of uplift and knowing also that separation is

a linear function of the M'/<' ratio, the evolution of the uplift surface is, in the (M', <') plane,

entirely de"ned for a monotonic loading.

Cyclic loading: For an elasto-plastic soil, uplift is no longer totally reversible (Figure 7). During

cyclic tests, it is observed that, after some cycles, soil yielding, located around the edges of the

foundation, leads to a bumping of the interface, and then to the appearance of holes at each edge.

This additional permanent non-linearity is visible on the (M'/<'!o) curve where the slope

during unloading and reloading (till the previously applied loading has been reached) is signi"-

cantly increased with respect to the original loading one (Figure 22).

This behaviour leads to a division of the uplift domain into an elastic}uplift and a plastic}uplift

domain. The elastic domain de"nes the set of forces that have already been applied to the

foundation. The plastic domain covers the set of forces that have not yet been reached during the

loading history. The surface, which separates the two domains, is nothing but the loading

surface of the plasticity model. Each domain is characterized by a di!erent slope in the

(M'/<'}o) diagram. The plastic domain has a slope of

"

. The elastic domain has a larger slope

p/4, where p is a magnifying factor (ranging from 1 for an elastic soil to about 4 for a highly

plastic soil) depending on the yielding and thus on the <' force. The p parameter needs to be

identi"ed.

To summarize (Figure 23), for a given H' and <', uplift occurs if M''M''''

"

and:

E

if M''M''''

: o"

4

<'

(M'!M''"'

"

) with M''"'

"

"

<'

4

exp4 ,

E

if M')M''''

: o"

4

p<'

(M'!M''''

"

) M''''

"

"M''''

N

!

p<'

4

o'''

N

,

where M''''

is the moment belonging to the loading surface. It is calculated from Equation (10) for

the given H' and <', o'''

is the separation corresponding to M''''

through the equation

o'''

"(4/<') (M''''

!M''"'

"

).

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1275

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

surface

M M

=100%

V

1 0

Failure

p

(i)

max

M

c

M

max

M

0

(i)

M

0

(0)

M

p

(i)

Plastic

Elastic

Elastic Plastic

=0%

(0)

=0%

(i)

Figure 23. Coupling between plasticity and uplift.

3.2.4. Rotation 0'" and vertical displacement z'" induced by uplift. As noted just above, the

percentage of separation reached at failure is smaller than 100 per cent, depending on the applied

<'. Thus in order to ensure that 0'" tends towards in"nity when the soil fails under a purely

overturning mechanism (i.e. for H'P0), o is replaced, in Equations (24) and (25), by the ratio

o/o

`

. o

`

is the maximum percentage of separation width reached at failure for a given <' and

for H'"0 (Figure 20). Following Equation (28), we write

o

`

"

4

<'

(M'

`

!M'

"

) (29)

where M'

`

is the maximum moment reached at failure for a given <' and H'"0, i.e. (from

Equation (5))

M'

`

"b<'(1!<')' (30)

The expressions of 0'" and z'" are now written as

0'""(1!<' ) 0

"

(o/o

`

)`

1!o/o

`

(31)

z'SN"(1!<' )

0

"

2

o/o

`

1!o/o

`

#ln(1!o/o

`

)

(32)

In both of them, the (1!<' ) coupling coe$cient has been introduced because it is noted that, for

a given value of o/o

`

, the greater <' (the larger yielding), the smaller the 0'" and z'" uplift

components. This expression is consistent because for <'P0 (elastic soil), the coe$cient is equal

to 1 (no yielding) and for <'P1 (vertical force tending towards the ultimate bearing capacity of

the foundationPmaximum yielding and failure), the coe$cient is equal to 0 (no uplift).

3.2.5. Uplift tangent stiwness matrix. To summarize, knowing the current state of yielding (loca-

tion of the loading surface), the percentage of separation corresponding to the forces <', H', M'

can be calculated. Then, fromthe o value, the 0'" and z'" displacement components are obtained.

1276 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

dF, du

el

dF

du

tot

= du

el

+ du

pl

+

du

up

Elasticity

Plasticity

Uplift

dF, du

pl

dF, du

up

Modle de plasticit

dF=K

elpl

(du

el

+ du

pl

)

Plasticity model

dF=K

elpl

(du

el

+ du

pl

)

Uplift model

dF=K

up

du

up

dF=K

elplup

du

tot

Figure 24. Structure of the global model.

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-0.0008 -0.0006 -0.0004 -0.0002 0 0.0002 0.0004 0.0006 0.0008

(rad)

M

(

M

N

m

)

Figure 25. Plastic model (el. #pl. comp.).

By writing the "rst order Taylor development of 0'" and z'",

d0'""

c0'"

c<'

d<'#

c0'"

cM'

dM' and dz'""

cz'"

c<'

d<'#

cz'"

cM'

dM' (33)

the linearized terms of the compliance matrix can be computed. After inversion, the uplift tangent

sti!ness matrix K

up

is calculated.

3.3. Global model (plasticity#uplift)

The total displacement increment u '' experienced by a foundation submitted to a F forces vector

increment is simply obtained by summing the elastic, plastic and uplift components (Figure 24).

u

tot

"u

el

#u

pl

#u

up

(34)

Figures 25}27 show an example for the rotational component.

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1277

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-0.0003 -0.0002 -0.0001 0 0.0001 0.0002 0.0003

(rad)

M

(

M

N

m

)

Figure 26. Uplift model (up. comp.).

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-0.001 -0.0005 0 0.0005 0.001

(rad)

M

(

M

N

m

)

Figure 27. Global model (el. #pl. #up. comp.).

4. PARAMETER IDENTIFICATION

4.1. Tests required for the identixcation

Contrary to the parameter identi"cation of a material constitutive model, the identi"cation of

a macro-element may not be completed with one or two classical tests. The di$culty comes here

from the concept of the macro-element itself. As it describes the behaviour of a global system (and

not of a material), the identi"cation has to be carried out on the entire system (foundation#soil).

The complete identi"cation of all model parameters requires one con"guration of foundation

and soil (one material setting-up for experimental test or one mesh discretization for numerical

1278 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

simulation) for which it is necessary to carry out only one test consisting of two di!erent loading

phases.

E

First phase: Monotonic increase of the vertical centred force until the force reaches the weight of

the studied structure (P<}z).

E

Second phase: For the constant vertical force applied at phase 1, increase followed by decrease

of the moment and horizontal force in a constant ratio equal to the height of the gravity centre

of the studied structure (PH}x, M}0, M}z, M}o).

4.2. Identixcation procedure

Besides the parameters that de"ne the studied system, and which are considered to be known as

geometrical parameters of the foundation (width B) and material properties of the soil (shear

modulus G, the Poisson ratio v, cohesion c and their gradient with depth), the parameters to

identify are as follows

E

elastic parameters: elastic sti!nesses, K

XX

, K

VV

, K

FF

(Equation (4));

E

plastic parameters: parameters de"ning the plastic potential, and (Equation (17));

E

uplift parameters: plastic moment for which the uplift is initiated, M'

"

; magnifying factor p, to

apply to the loading slope of the relationship (M'/<', o).

Note: The parameters de"ning the shape of the failure criterion are considered to be constant

(c, d, e, f ) or a function of the q

`

/q

"`

ratio (a, b). They are given in Table I.

In agreement with the model development (Chapter 2.4), the identi"cation has to follow this

particular procedure. First the elastic parameters, then the uplift ones and "nally the plastic ones

should be identi"ed. Identi"cation of the uplift parameters has to precede that of the plastic

parameters and the latter ones have to be identi"ed on the plastic displacements from which the

uplift components are subtracted.

The K

XX

elastic sti!ness is "tted to the initial sti!ness of the curve (<, z) issued from the "rst test

phase. The K

VV

and K

FF

ones are similarly identi"ed on the H}x and M}0 curves of the second

phase. These sti!nesses are not purely elastic as the soil has already (depending on the applied

weight) yielded during the "rst phase. The purely elastic ones may be captured on the unloading

part when the uplift is zero.

The uplift M'

"

and p parameters are identi"ed from the (M}o) curve, which has been trans-

formed into the dimensionless variables (M'/<', o). For p, it is "rst veri"ed that the slope of the

loading part is in agreement with the elastic case (slope of about

"

) and the p magnifying factor,

which should be applied to the loading slope, is derived on the unloading part.

The and plastic parameters are derived from the relationships existing between the plastic

displacements (as shown in Chapter 3.1.6 for the (0'', z'') relationship). These are obtained from

the total displacements u'' from which the elastic u' and the uplift u" components are

subtracted. The elastic displacements are calculated with the elastic sti!nesses and the uplift ones

are computed following Equations (31) and (32) with o issued from the uplift identi"cation.

4.3. Proposed relationships for the parameters determination without test

As is known, carrying out experimental tests on a foundation lying on a cohesive soil is a tricky,

di$cult and costly task. Also, running numerical analyses on a largely discretized soil medium

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1279

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-0.0015 -0.001 -0.0005 0 0.0005 0.001 0.0015

(rad)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.6MN

M/H=10m

Figure 28. Overturning moment}rotation (<"0.6 MN).

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

-0.005 -0.004 -0.003 -0.002 -0.001 0 0.001 0.002 0.003 0.004

x (m)

H

(

M

N

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.6MN

M/H=10m

Figure 29. Horizontal force}horizontal displacement (<"0.6 MN).

with a suitable soil constitutive law and contact elements requires special capabilities and is time

consuming.

For these reasons, a set of relationships is proposed for the determination of the model

parameters allowing one to dismiss, if necessary, any identi"cation test. The relationships, for

some of them, are known expressions, coming from literature, and are regularly used in practical

applications. For the others, they have been "tted here from numerous FE simulations. For

a preliminary study, the use of these relationships (without any identi"cation test) may be

su$cient, depending on the required accuracy.

These relationships are given in Table I.

1280 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

-60 -40 -20 0 20 40 60

(%)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.6MN

M/H=10m

Figure 31. Overturning moment}uplift (<"0.6 MN).

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

0 0.002 0.004 0.006 0.008 0.01

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.6MN

M/H=10m

z (m)

Figure 30. Overturning moment}vertical displacement (<"0.6 MN).

5. COMPARISON MACRO-ELEMENT/FE MODEL

The comparison between the results obtained from the FE modelization (Dyna-ow) and from the

macro-element is presented in Figures 28}35. The same geometry and the same characteristics for

the soil as those presented in Figure 2 have been used, as well as the same loading path. The

parameters identi"cation has been carried out as described in Chapter 4.1.2. Results are presented

for three di!erent vertical loads (<"0.3, 0.6, 0.9 MN). From Figures 28}31 (<"0.6 MN), it may

be concluded that the cyclic behaviour of the foundation obtained from the macro-element

reproduces very well all the trends observed with the FE model. From Figures 32}35 (<"0.3

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1281

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-1.5

-1

-0.5

0

0.5

1

1.5

-0.0015 -0.001 -0.0005 0 0.0005 0.001 0.0015

(rad)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.3MN

M/H=10m

Figure 32. Overturning moment}rotation (<"0.3 MN).

-1.5

-1

-0.5

0

0.5

1

1.5

0 0.0005 0.001 0.0015 0.002 0.0025 0.003 0.0035 0.004

z (m)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.3MN

M/H=10m

Figure 33. Overturning moment}vertical displacement (<"0.3 MN).

and 0.9 MN), it is noticed that the model is better suited for describing moderate plasticity

behaviour, but with strong uplift.

6. CONCLUSION

A non-linear soil}structure interaction macro-element for a shallow strip foundation lying on

a cohesive medium has been proposed. Expressed in global variables, the macro-element

1282 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

-0.0015 -0.001 -0.0005 0 0.0005 0.001 0.0015

(rad)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.9MN

M/H=10m

Figure 34. Overturning moment}rotation (<"0.9MN).

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

0 0.005 0.01 0.015 0.02

z (m)

M

(

M

N

m

)

FE model

macro-element

B=10m

Vmax=2.4MN

V=0.9MN

M/H=10m

Figure 35. Overturning moment}vertical displacement (<"0.9 MN).

reproduces the cyclic behaviour of the foundation, including the e!ects of non-linearities occur-

ring in the near "eld. Yielding of the soil under the foundation is modelled through a global

plasticity model. The contact non-linearities induced by the uplift of the foundation are integrated

in an uplift model. Although developed separately, these two models remain strongly dependent

in order to take into account the coupling e!ect. This substructure approach allows the

decomposition of a highly non-linear, coupled problem, but without dismissing any couplings.

The comparison of the results obtained from the macro-element with those from an FE modelling

has enhanced the relevance of the proposed model.

It is well known that an alternative model of the foundation behaviour obtained by the "nite

element method with suitable non-linear soil constitutive laws and special contact elements,

CYCLIC MACRO-ELEMENT FOR SOIL}STRUCTURE INTERACTION 1283

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

requires a high degree of modelling competence and is time consuming. The macro-element

provides a practical and e$cient tool, which may replace e$ciently, in a "rst approach, a

costly FE soil model, and which ensures the accurate integration of the e!ect of soil}structure

interaction.

Specially developed for seismic loading, the macro-element will be adapted to a dynamic

behaviour. The radiation of waves in an in"nite half-space, as well as energy dissipation, will be

introduced by the concept of dynamic impedances.

REFERENCES

1. Meyerhof GG. The bearing capacity of foundations under eccentric and inclined loads. Proceedings of the hird

International Conference on Soil Mechanics Foundations Engineering, Zurich, vol. 1, 1953; 440}445.

2. Vesic AS. Bearing capacity of shallow foundations. In Foundation Engineering Handbook, Winterkorn HF, and Fang

H-Y (eds). van Nostrand Reinhold: New York, 1975; 121}147.

3. Butter"eld R, Gottardi G. A complete three-dimensional failure envelope for shallow footings on sand. Ge& otechnique

1994; 44:181}184.

4. Salenion J, Pecker A. Ultimate bearing capacity of shallow foundations under inclined and eccentric loads. Part I:

purely cohesive soil. European Journal of Mechanics, A/Solids 1995; 14(3):349}375.

5. Salenion J, Pecker A. Ultimate bearing capacity of shallow foundations under inclined and eccentric loads. Part II:

purely cohesive soil without tensile strength. European Journal of Mechanics, A/Solids, 1995; 14(3):377}396.

6. Paolucci R, Pecker A. Seismic bearing capacity of shallow strip foundations on dry soils. Soils and Foundations,

Japanese Geotechnical Society 1997; 37(3):95}105.

7. Ukritchon B, Whittle AJ, Sloan SW. Undrained limit analysis for combined loading of strip footings on clay. Journal

of Geotechnical and Geoenvironmental Engineering 1998; 124(3):265}276.

8. Houlsby GT, Puzrin AM. The bearing capacity of a strip footing on clay under combined loading. Proceedings of the

Royal Society of ondon A, 1999; 455:893}916.

9. Tan FSC. Centrifuge and theoretical modelling of conical footings on sand. PhD thesis, University of Cambridge,

1990.

10. Nova R, Montrasio L. Settlements of shallow foundations on sand. Ge& otechnique 1991; 41(2):243}256.

11. Gottardi G, Houlsby GT, Butter"eld R. Plastic response of circular footings on sand under general planar loading.

Ge& otechnique 1999; 49(4):453}469.

12. Martin CM. Physical and numerical modelling of o!shore foundations under combined loads. DPhil hesis,

University of Oxford, 1994.

13. Pedretti S. Nonlinear seismic soil-foundation interaction: analysis and modelling method. PhD thesis, Dpt Ing

Strutturale, Politecnico di Milano, 1998.

14. Psycharis IN. Dynamic behavior of rocking structures allowed to uplift. Journal of Earth Engineering and Structural

Dynamics 1983; 11:57}76 and 501}521.

15. PreH vost JH. Anisotropic undrained stress}strain behaviour of clays. Journal of the Geotechnical Engineering Division

1978; GT8:1075}1090.

16. Davis EH, Booker JR. The e!ect of increasing strength with depth on the bearing capacity of clays. Ge& otechnique

1973; 23(4):551}563.

17. Matar M, Salenion J. CapaciteH portante des semelles "lantes. Revue franmaise de Ge& otechnique 1979; 9:51}76.

18. Gazetas G. Foundations vibrations. In Foundation Engineering Handbook, Fang H-Y (ed.), Chapter 15. van Nostrand

Reinhold: New York 1991.

19. Pecker A. Analytical formulae for the seismic bearing capacity of shallow strip foundations. In Seismic Behaviour of

Ground and Geotechnical Structures, Seco e Pinto (ed.), Balkema: Rotterdam, 1997; 261}268.

20. CreH mer C, Pecker A, Davenne L. Elaboration d'un macro-eH leH ment d'interaction sol-structure avec prise en compte du

deH collement de la fondation. Proceedings of the <GC

&

KC Colloque National Afps, Cachan, vol. 1, 1999; 197}206.

21. CreH mer C. Elaboration of a soil}structure macro-element for foundation uplift. Me& moire de stage de DEA, ENS-

Cachan, 1998.

22. Poulos HG, Davis EH. Elastic Solutions for Soil and Rock Mechanics. Wiley: New York, 1974.

1284 CED CILE CREMER, ALAIN PECKER AND LUC DAVENNE

Copyright 2001 John Wiley & Sons, Ltd. Int. J. Numer. Anal. Meth. Geomech., 2001; 25:1257}1284

S-ar putea să vă placă și

- Theme - N 9Document5 paginiTheme - N 9Satya kaliprasad vangaraÎncă nu există evaluări

- Axial - Loaded Pile PLAXIS 2dDocument4 paginiAxial - Loaded Pile PLAXIS 2dMarko AdamovićÎncă nu există evaluări

- Integrated Imaging of the Earth: Theory and ApplicationsDe la EverandIntegrated Imaging of the Earth: Theory and ApplicationsMax MoorkampÎncă nu există evaluări

- Ijrras 16 3 06Document10 paginiIjrras 16 3 06Rajkumar KarmegamÎncă nu există evaluări

- Soil Paper Review July5Document15 paginiSoil Paper Review July5Christine Vel MarcianoÎncă nu există evaluări

- CH 373Document10 paginiCH 373RICHARD SEBASTIAN CHAVEZ CASTROÎncă nu există evaluări

- Pile Foundations Macro-Element - Ssilink2Document6 paginiPile Foundations Macro-Element - Ssilink2Structural SpreadsheetsÎncă nu există evaluări

- Etasr 5351Document8 paginiEtasr 5351pawan yadavÎncă nu există evaluări

- Drag Anchor FlukeDocument6 paginiDrag Anchor FlukesiswouÎncă nu există evaluări

- Monte Carlo Simulation of SSI Effects Using Simple Rheological Soil ModelDocument9 paginiMonte Carlo Simulation of SSI Effects Using Simple Rheological Soil ModelRui CbÎncă nu există evaluări

- Musso 2008Document15 paginiMusso 2008badisnoveÎncă nu există evaluări

- 7 Harshdeep BhatiyaDocument14 pagini7 Harshdeep BhatiyaINTERNATIONAL JOURNAL FOR EDUCATIONAL RESEARCH STUDIESÎncă nu există evaluări

- Numge2023 10Document7 paginiNumge2023 10WanÎncă nu există evaluări

- Dense Sand P-Y CurvesDocument8 paginiDense Sand P-Y CurvesBilal Adeel WithraÎncă nu există evaluări

- Behaviour of An Open Type Berthing Structure Under Earthquake Condition - A Numerical ApproachDocument5 paginiBehaviour of An Open Type Berthing Structure Under Earthquake Condition - A Numerical ApproachJagal UdayaÎncă nu există evaluări

- 1 s2.0 S0266352X0800030X MainDocument14 pagini1 s2.0 S0266352X0800030X Mainsam kowalskiÎncă nu există evaluări

- KauselDocument16 paginiKauselGaneshPaiÎncă nu există evaluări

- Pestana Et Al-1999-International Journal For Numerical and Analytical Methods in GeomechanicsDocument29 paginiPestana Et Al-1999-International Journal For Numerical and Analytical Methods in GeomechanicsVu Xuan BachÎncă nu există evaluări

- Soil-Pile Interaction Model For Earthquake Respnse Analysis of Offshore Pile FoundationsDocument18 paginiSoil-Pile Interaction Model For Earthquake Respnse Analysis of Offshore Pile FoundationspeckonetÎncă nu există evaluări

- Stability Analysis of Cellular Retaining Structure by PLAXIS Finite Element CodeDocument14 paginiStability Analysis of Cellular Retaining Structure by PLAXIS Finite Element Codevijjikewlguy7116Încă nu există evaluări

- Application of A Continuum Numerical Model For Pile Driving Analysis and Comparison With A Real CaseDocument13 paginiApplication of A Continuum Numerical Model For Pile Driving Analysis and Comparison With A Real Casebereket gÎncă nu există evaluări

- MS23 123Document7 paginiMS23 123BuiDucVinhÎncă nu există evaluări

- Manzari2001-On Integration of Cyclic Soil ModelDocument25 paginiManzari2001-On Integration of Cyclic Soil ModelsharikaÎncă nu există evaluări

- Modeling of Soil-Structure Interaction A PDFDocument5 paginiModeling of Soil-Structure Interaction A PDFTariq MahmoodÎncă nu există evaluări

- A Multiaxial Inertial Macroelement For Deep FoundationsDocument18 paginiA Multiaxial Inertial Macroelement For Deep FoundationsValerioÎncă nu există evaluări

- Material Damping vs. Radiation DampingDocument7 paginiMaterial Damping vs. Radiation DampingYang LuÎncă nu există evaluări

- Numerical Simulation of The Role of A Geocell Inclusion On Deformation Behavior of A Pavement Structure Laid On A Fissured Clayey SubgradeDocument4 paginiNumerical Simulation of The Role of A Geocell Inclusion On Deformation Behavior of A Pavement Structure Laid On A Fissured Clayey SubgradeEdwin Rodriguez GutierrezÎncă nu există evaluări

- Load Transfer Approach For Laterally Loaded PilesDocument29 paginiLoad Transfer Approach For Laterally Loaded Pileshectorru64Încă nu există evaluări

- GG 6 (1-3) 53-80 1987 by Rowe and Soderman PDFDocument28 paginiGG 6 (1-3) 53-80 1987 by Rowe and Soderman PDFpabulumzengÎncă nu există evaluări

- OTC 10996 Jackup Units On Clay: Structural Analysis With Realistic Modelling of Spudcan BehaviourDocument12 paginiOTC 10996 Jackup Units On Clay: Structural Analysis With Realistic Modelling of Spudcan BehaviourLTE002Încă nu există evaluări

- Modelling Liquefaction Effects - From Lateral Spreading To Soil-Structure InteractionDocument13 paginiModelling Liquefaction Effects - From Lateral Spreading To Soil-Structure InteractionCătălin CăpraruÎncă nu există evaluări

- On The Volumetric Deformation of Reconstituted Soils: Int. J. Numer. Anal. Meth. Geomech., 24, 101) 133 (2000)Document33 paginiOn The Volumetric Deformation of Reconstituted Soils: Int. J. Numer. Anal. Meth. Geomech., 24, 101) 133 (2000)a4abhirawatÎncă nu există evaluări

- CH150Document6 paginiCH150Toky NirinaÎncă nu există evaluări

- Seismic Earth Pressure On Deep Stiff Soil (Wagner, Sitar-UC Berkeley)Document10 paginiSeismic Earth Pressure On Deep Stiff Soil (Wagner, Sitar-UC Berkeley)Germar PorquerinoÎncă nu există evaluări

- P-Y MethodDocument10 paginiP-Y MethodJillian HowardÎncă nu există evaluări

- ChaztigogosxDocument30 paginiChaztigogosxFranco BrownÎncă nu există evaluări

- Rowe 1987Document28 paginiRowe 1987Luciano JuniorÎncă nu există evaluări

- 2D Numerical Analysis of Sao Paulo TunnelDocument6 pagini2D Numerical Analysis of Sao Paulo TunnelAnh DoÎncă nu există evaluări

- Taherzadeh2009 PDFDocument21 paginiTaherzadeh2009 PDFcharaf247Încă nu există evaluări

- Soil Constitutive Models and Their Application in Geotechnical Engineering A Review IJERTV7IS040129 PDFDocument9 paginiSoil Constitutive Models and Their Application in Geotechnical Engineering A Review IJERTV7IS040129 PDFgamidi67Încă nu există evaluări

- Vertical Drain 1Document12 paginiVertical Drain 1Dian_SipilÎncă nu există evaluări

- Kinematic Interaction in Pile Foundations: F. Dezi, S. Carbonari and G. LeoniDocument8 paginiKinematic Interaction in Pile Foundations: F. Dezi, S. Carbonari and G. LeoniroloheÎncă nu există evaluări

- Soil-Structure Interaction in Yielding Systems: Javier Aviles and Luis E. Perez-RochaDocument23 paginiSoil-Structure Interaction in Yielding Systems: Javier Aviles and Luis E. Perez-RochaBaban A.BapirÎncă nu există evaluări

- Mac FoundationDocument20 paginiMac FoundationsugyanibalaÎncă nu există evaluări

- Modeling and Analysis of Soil-Pile InteractionDocument21 paginiModeling and Analysis of Soil-Pile InteractionLhester NavascaÎncă nu există evaluări

- Soil Pile Interaction Pallavi Neelima ICETCE-14Document8 paginiSoil Pile Interaction Pallavi Neelima ICETCE-14Gizeth AguilarÎncă nu există evaluări

- Ceer2021 2 Boulkhiout CalkulatingDocument40 paginiCeer2021 2 Boulkhiout CalkulatingAyanShrivastavaÎncă nu există evaluări

- Poster TripodDocument1 paginăPoster TripodjoseÎncă nu există evaluări

- 2015 - Comparative Study of The Compression and Uplift of Shallow FoundationsDocument8 pagini2015 - Comparative Study of The Compression and Uplift of Shallow Foundationsweichenyao12138Încă nu există evaluări

- A Cyclic-Softening Macro Element Model For Mono-Bucket FoundationsDocument16 paginiA Cyclic-Softening Macro Element Model For Mono-Bucket Foundationsw2gxg558s6Încă nu există evaluări

- Aminaton Marto - Foundation Size Effect On Modulus of Subgrade Reaction On Sandy SoilsDocument8 paginiAminaton Marto - Foundation Size Effect On Modulus of Subgrade Reaction On Sandy Soilsmateus456Încă nu există evaluări

- Study of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3DDocument6 paginiStudy of Lateral Load Carrying Capacities of Piles in Layered Soils Using PLAXIS 3Dneerad mohan100% (1)

- Immediate Settlement CalculationsDocument4 paginiImmediate Settlement CalculationsgeminexÎncă nu există evaluări

- Comparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachDocument7 paginiComparison Study of Pile Foundation Using Eurocode 7 and Working Stress Design ApproachIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalÎncă nu există evaluări

- ViscousdampingformulationDocument37 paginiViscousdampingformulationRICHARD SEBASTIAN CHAVEZ CASTROÎncă nu există evaluări

- A Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Document25 paginiA Model With A Unified Kinematic Hardening Law For Cyclic Behavior of Stiff Clay-Tang-JMP-Cui-1Melete GashawÎncă nu există evaluări

- Mohammad I 2013Document10 paginiMohammad I 2013Carlos SantamariaÎncă nu există evaluări

- COMPLAS2013-87 - Recent Progress in MicroplaneDocument12 paginiCOMPLAS2013-87 - Recent Progress in Microplanefs jiÎncă nu există evaluări

- SPT Correlation n60 and n'60 To Odst As Per AashtoDocument4 paginiSPT Correlation n60 and n'60 To Odst As Per AashtoAstrid AubryÎncă nu există evaluări

- BG Timescale 2003Document1 paginăBG Timescale 2003Astrid AubryÎncă nu există evaluări

- ASTM G57-06 (R2012) Standard Test Method For Field Measurement of Soil Resistivity Using The Wenner Four-Electrode MethodDocument6 paginiASTM G57-06 (R2012) Standard Test Method For Field Measurement of Soil Resistivity Using The Wenner Four-Electrode Method曾乙申100% (9)

- BG Timescale 2003Document1 paginăBG Timescale 2003Astrid AubryÎncă nu există evaluări

- Joule To ForcesDocument1 paginăJoule To ForcesAstrid AubryÎncă nu există evaluări

- BG Timescale 2003Document1 paginăBG Timescale 2003Astrid AubryÎncă nu există evaluări

- Atterberg LimitsDocument2 paginiAtterberg LimitsAstrid AubryÎncă nu există evaluări

- Engineering Example of 3D Plate Materials: Sheet Pile Wall in BendingDocument2 paginiEngineering Example of 3D Plate Materials: Sheet Pile Wall in BendingAstrid AubryÎncă nu există evaluări

- HS Small StraimDocument9 paginiHS Small StraimAstrid AubryÎncă nu există evaluări

- Elastic ModuliDocument10 paginiElastic ModuliAtalanta PixmaÎncă nu există evaluări

- Elastic ModuliDocument10 paginiElastic ModuliAtalanta PixmaÎncă nu există evaluări

- SOUNDNESS of Rip RapDocument62 paginiSOUNDNESS of Rip RapAstrid AubryÎncă nu există evaluări

- AAstho Correlation Friction Angle and n'60 1631Document3 paginiAAstho Correlation Friction Angle and n'60 1631Astrid AubryÎncă nu există evaluări

- Atterberg Limit of The Whole SampleDocument5 paginiAtterberg Limit of The Whole SampleAstrid AubryÎncă nu există evaluări

- Lanye Laterla ScourDocument2 paginiLanye Laterla ScourAstrid AubryÎncă nu există evaluări

- All PileDocument20 paginiAll PileAstrid AubryÎncă nu există evaluări

- Basic Friction AngleDocument1 paginăBasic Friction AngleAstrid AubryÎncă nu există evaluări

- SAP2000 V 15Document1 paginăSAP2000 V 15Astrid AubryÎncă nu există evaluări

- Draft Reinforcement ArrangementDocument1 paginăDraft Reinforcement ArrangementAstrid AubryÎncă nu există evaluări

- Socketing Depth of Piles in RockDocument4 paginiSocketing Depth of Piles in RockNAUTILUS87100% (2)

- Brady and Kavanagh (2002) Analysis of The Stability of Masonry-Faced Earth Retaining WallsDocument44 paginiBrady and Kavanagh (2002) Analysis of The Stability of Masonry-Faced Earth Retaining WallsComrade Comrade Limbe100% (1)

- Experiment 13-Unconfined CompressionDocument13 paginiExperiment 13-Unconfined CompressionMuhammad LutfiÎncă nu există evaluări

- SOUNDNESS of Rip RapDocument62 paginiSOUNDNESS of Rip RapAstrid AubryÎncă nu există evaluări

- Map of JointsDocument1 paginăMap of JointsAstrid AubryÎncă nu există evaluări

- Presentation 14Document19 paginiPresentation 14Claudia DominoniÎncă nu există evaluări

- Priliminary Design Jurf Dam Typical Non-Overflow Section A - Alternative-1Document1 paginăPriliminary Design Jurf Dam Typical Non-Overflow Section A - Alternative-1Astrid AubryÎncă nu există evaluări

- Osterberg - Embankment - DykeDocument48 paginiOsterberg - Embankment - DykeAstrid AubryÎncă nu există evaluări

- Lugeon TestingDocument10 paginiLugeon TestingAstrid Aubry100% (3)

- Priliminary Design Jurf Dam Typical Non-Overflow Section A - Alternative-1Document1 paginăPriliminary Design Jurf Dam Typical Non-Overflow Section A - Alternative-1Astrid AubryÎncă nu există evaluări

- 3+200 - BHa 7 - 8-ModelDocument1 pagină3+200 - BHa 7 - 8-ModelAstrid AubryÎncă nu există evaluări

- IIT JAM Previous Year Paper Analysis (2018-2022)Document8 paginiIIT JAM Previous Year Paper Analysis (2018-2022)Anu P KumarÎncă nu există evaluări

- Action PlanDocument3 paginiAction PlanIvy BarnacheaÎncă nu există evaluări

- VMWare EBooks - VMware Workspace ONE - Deploy and Manage (V22.x) Student Lecture Manual1Document50 paginiVMWare EBooks - VMware Workspace ONE - Deploy and Manage (V22.x) Student Lecture Manual1Saeed NasharÎncă nu există evaluări

- Essay ReviseDocument4 paginiEssay ReviseHanifah IndrianaÎncă nu există evaluări

- TOPIC: Assessing The Knowledge and Attitude Towards Online Netiquette of High School Students of Mandaue City Comprehensive National High SchoolDocument12 paginiTOPIC: Assessing The Knowledge and Attitude Towards Online Netiquette of High School Students of Mandaue City Comprehensive National High SchoolMarjoe MejiasÎncă nu există evaluări

- Fluid 9ed Solution ManualDocument919 paginiFluid 9ed Solution ManualAmr f100% (1)

- ALFA ThermostatDocument1 paginăALFA ThermostatTamilarasi SambathÎncă nu există evaluări

- Experiment No 2 Flame TestDocument2 paginiExperiment No 2 Flame TestBalangÎncă nu există evaluări

- Week 1 - Iot - Assignment 1 - AnsDocument3 paginiWeek 1 - Iot - Assignment 1 - Ansdude RohitÎncă nu există evaluări

- HistoryDocument37 paginiHistoryThulaniÎncă nu există evaluări

- College For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityDocument2 paginiCollege For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityLove JcwÎncă nu există evaluări

- 9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityDocument3 pagini9801 Low-Shrinkage Camera Module Epoxy With LED and Heat-Cure CapabilityAchraf BouraÎncă nu există evaluări

- Shadows of Esteren Universe PDFDocument293 paginiShadows of Esteren Universe PDFThibault Mlt EricsonÎncă nu există evaluări

- Nadia Maharani Eka Suci: Education LevelDocument1 paginăNadia Maharani Eka Suci: Education LevelMICHELLE BENEDICTAÎncă nu există evaluări

- Stewart - Design of Piled Bridge Abutments On Soft Clay For Loading FromDocument9 paginiStewart - Design of Piled Bridge Abutments On Soft Clay For Loading FromMarcelaMarquesÎncă nu există evaluări