Documente Academic

Documente Profesional

Documente Cultură

G Codes and M Codes

Încărcat de

Harsh YadavDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

G Codes and M Codes

Încărcat de

Harsh YadavDrepturi de autor:

Formate disponibile

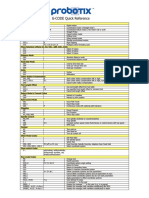

List of G-codes commonly found on Fanuc and similarly designed controls

Code G00 Description Milling Turning (M) (T) Corollary info On 2- or 3-axis moves, G00 (unlike G01) traditionally does not necessarily move in a single straight line between start point and end point. It moves each axis at its max speed until its vector is achieved. Shorter vector usually finishes first (given similar axis speeds). This matters because it may yield a dog-leg or hockey-stick motion, which the programmer needs to consider depending on what obstacles are nearby, to avoid a crash. Some machines offer interpolated rapids as a feature for ease of programming (safe to assume a straight line). The most common workhorse code for feeding during a cut. The program specs the start and end points, and the control automatically calculates (interpolates) the intermediate points to pass through that will yield a straight line (hence "linear"). The control then calculates the angular velocities at which to turn the axis leadscrews. The computer performs thousands of calculations per second. Actual machining takes place with given feed on linear path. Cannot start G41 or G42 in G02 or G03 modes. Must already be compensated in earlier G01 block. Cannot start G41 or G42 in G02 or G03 modes. Must already be compensated in earlier G01 block. Takes an address for dwell period (may be X, U, or P). The dwell period is specified in milliseconds. Uses a deep look-ahead buffer and simulation processing to provide better axis movement acceleration and deceleration during contour milling Uses a deep look-ahead buffer and simulation processing to provide better axis movement acceleration and deceleration during contour milling

Rapid positioning

G01

Linear interpolation

G02

Circular interpolation, clockwise Circular interpolation, counterclockwise Dwell

G03

G04 M T

G05 High-precision P10000 contour control (HPCC) G05.1 Q1. Ai Nano contour control

G07 G09 G10 G11 G12

Imaginary axis designation Exact stop check Programmable data input Data write cancel Full-circle interpolation, clockwise Full-circle interpolation, counterclockwise XY plane selection

M M M M M T T T Fixed cycle for ease of programming 360 circular interpolation with blend-radius lead-in and lead-out. Not standard on Fanuc controls. Fixed cycle for ease of programming 360 circular interpolation with blend-radius lead-in and lead-out. Not standard on Fanuc controls. On most CNC lathes (built 1960s to 2000s), ZX is the only available plane, so no G17 to G19 codes are used. This is now changing as the era begins in which live tooling, multitask/multifunction, and millturn/turn-mill gradually become the "new normal". But the simpler, traditional form factor will probably not disappearjust move over to make room for the newer configurations. See also V address. Somewhat uncommon except in USA and (to lesser extent) Canada and UK. However, in the global marketplace, competence with both G20 and G21 always stands some chance of being necessary at any time. The usual minimum increment in G20 is one ten-thousandth of an inch (0.0001"), which is a larger distance than the usual minimum increment in G21 (one thousandth of a millimeter, .001 mm, that is, one micrometre). This physical difference sometimes favors G21 programming. Prevalent worldwide. However, in the global marketplace, competence with both G20 and G21 always stands some chance of being necessary at any time. Takes X Y Z addresses which define the intermediate point that the tool tip will pass through on its way home to machine zero.

G13

M M

G17 G18

ZX plane selection

G19 G20

YZ plane selection

Programming in inches

G21 Programming in millimeters (mm) G28 Return to home position (machine zero, aka machine M T

reference point) G30 Return to secondary home position (machine zero, aka M machine reference point)

They are in terms of part zero (aka program zero), NOT machine zero. Takes a P address specifying which machine zero point is desired, if the machine has several secondary points (P1 to P4). Takes X Y Z addresses which define the intermediate point that the tool tip will pass through on its way home to machine zero. They are in terms of part zero (aka program zero), NOT machine zero.

G31

Skip function (used for probes and tool M length measurement systems) Single-point threading, longhand style (if not using a cycle, e.g., G76) Constant-pitch threading Single-point threading, longhand style (if not using a cycle, e.g., G76) Variable-pitch threading Tool radius compensation off M M T Cancels G41 or G42. Milling: Given righthand-helix cutter and M03 spindle direction, G41 corresponds to climb milling (down milling). Takes an address (D or H) that calls an offset register value for radius. Turning: Often needs no D or H address on lathes, because whatever tool is active automatically calls its geometry offsets with it. (Each turret station is bound to its geometry offset register.) Similar corollary info as for G41. Given righthand-helix cutter and M03 spindle direction, G42 corresponds to conventional milling (up milling). Takes an address, usually H, to call the tool length offset register value. The value is negative because it will be added to the M Some lathe controls assign this mode to G33 rather than G32. T Similar to G01 linear interpolation, except with automatic spindle synchronization for single-point threading.

G32

G33 G33

G34 G40 G41

Tool radius compensation left

G42 Tool radius compensation right G43 Tool height offset compensation negative M T

gauge line position. G43 is the commonly used version (vs G44). G44 Tool height offset compensation positive G45 G46 G47 G48 G49 G50 Define the maximum spindle speed Scaling function cancel T Axis offset single increase Axis offset single decrease Axis offset double increase Axis offset double decrease M Takes an address, usually H, to call the tool length offset register value. The value is positive because it will be subtracted from the gauge line position. G44 is the seldomused version (vs G43).

M M M M Cancels G43 or G44. Takes an S address integer which is interpreted as rpm. Without this feature, G96 mode (CSS) would rev the spindle to "wide open throttle" when closely approaching the axis of rotation.

Tool length offset M compensation cancel

G50

M Position register is one of the original methods to relate the part (program) coordinate system to the tool position, which indirectly relates it to the machine coordinate system, the only position the control really "knows". Not commonly programmed anymore because G54 to G59 (WCSs) are a better, newer method. Called via G50 for turning, G92 for milling. Those G addresses also have alternate meanings (which see). Position register can still be useful for datum shift programming. Temporarily shifts program zero to a new location. This simplifies programming in some cases. Takes absolute coordinates (X,Y,Z,A,B,C) with reference to machine zero rather than program zero. Can be helpful for tool changes. Nonmodal and absolute only. Subsequent blocks are interpreted as "back to G54" even if it is not explicitly programmed.

G50

Position register (programming of vector from part zero to tool tip)

G52

Local coordinate system (LCS)

G53 Machine coordinate system

G54 to G59 Work coordinate systems (WCSs) M T

Have largely replaced position register (G50 and G92). Each tuple of axis offsets relates program zero directly to machine zero. Standard is 6 tuples (G54 to G59), with optional extensibility to 48 more via G54.1 P1 to P48. Up to 48 more WCSs besides the 6 provided as standard by G54 to G59. Note floating-point extension of G-code data type (formerly all integers). Other examples have also evolved (e.g., G84.2). Modern controls have the hardware to handle it.

G54.1 P1 to P48

Extended work coordinate systems

G70

Fixed cycle, multiple repetitive cycle, for finishing (including contours) Fixed cycle, multiple repetitive cycle, for roughing (Z-axis emphasis) Fixed cycle, multiple repetitive cycle, for roughing (X-axis emphasis) Fixed cycle, multiple repetitive cycle, for roughing, with pattern repetition Peck drilling cycle for milling - highspeed (NO full retraction from pecks) Peck drilling cycle for turning Tapping cycle for milling, lefthand M thread, M04 spindle direction Peck grooving cycle for turning Fine boring cycle for M milling Threading cycle for turning, multiple

G71

G72

G73

G73

Retracts only as far as a clearance increment (system parameter). For when chipbreaking is the main concern, but chip clogging of flutes is not. T

G74

G74 G75 G76 G76

repetitive cycle G80 Milling: Cancels all cycles such as G73, G83, G88, etc. Z-axis returns either to Zinitial level or R-level, as programmed (G98 or G99, respectively). Turning: Usually not needed on lathes, because a new group-1 G address (G00 to G03) cancels whatever cycle was active. No dwell built in Dwells at hole bottom (Z-depth) for the number of milliseconds specified by the P address. Good for when hole bottom finish matters. Returns to R-level after each peck. Good for clearing flutes of chips.

Cancel canned cycle M

G81 G82

Simple drilling cycle M Drilling cycle with dwell M

G83

Peck drilling cycle (full retraction from M pecks) Tapping cycle, righthand thread, M03 spindle direction Tapping cycle, righthand thread, M03 spindle direction, rigid toolholder M

G84

G84.2

G90

Absolute programming

T (B)

Positioning defined with reference to part zero. Milling: Always as above. Turning: Sometimes as above (Fanuc group type B and similarly designed), but on most lathes (Fanuc group type A and similarly designed), G90/G91 are not used for absolute/incremental modes. Instead, U and W are the incremental addresses and X and Z are the absolute addresses. On these lathes, G90 is instead a fixed cycle address for roughing. When not serving for absolute programming (above) Positioning defined with reference to previous position. Milling: Always as above. Turning: Sometimes as above (Fanuc group type B and similarly designed), but on most lathes (Fanuc group type A and similarly designed), G90/G91 are not used

G90 G91

Fixed cycle, simple cycle, for roughing (Z-axis emphasis)

T (A)

Incremental programming

T (B)

for absolute/incremental modes. Instead, U and W are the incremental addresses and X and Z are the absolute addresses. On these lathes, G90 is a fixed cycle address for roughing. G92 Position register (programming of M vector from part zero to tool tip) Same corollary info as at G50 position register. Milling: Always as above. Turning: Sometimes as above (Fanuc group type B and similarly designed), but on most lathes (Fanuc group type A and similarly designed), position register is G50.

T (B)

G92 G94

Threading cycle, simple cycle Feedrate per minute M Fixed cycle, simple cycle, for roughing (X-axis emphasis) Feedrate per revolution Constant surface speed (CSS) M

T (A) T (B) T (A) T (B) On group type A lathes, feedrate per minute is G98. When not serving for feedrate per minute (above) On group type A lathes, feedrate per revolution is G99. Varies spindle speed automatically to achieve a constant surface speed. See speeds and feeds. Takes an S address integer, which is interpreted as sfm in G20 mode or as m/min in G21 mode. Takes an S address integer, which is interpreted as rev/min (rpm). The default speed mode per system parameter if no mode is programmed.

G94 G95 G96

G97 Constant spindle speed G98 G98 G99 M T

Return to initial Z M level in canned cycle Feedrate per minute (group type A) Return to R level in canned cycle Feedrate per revolution (group type A) M T (A) Feedrate per revolution is G95 on group type B. T (A) Feedrate per minute is G94 on group type B.

G99

List of M-codes commonly found on Fanuc and similarly designed controls

Code M00 Compulsory stop M01 M02 M03 Optional stop End of program M M M T T T Description Milling Turning (M) (T) Corollary info Non-optionalmachine will always stop upon reaching M00 in the program execution. Machine will only stop at M01 if operator has pushed the optional stop button. No return to program top; may or may not reset register values. The speed of the spindle is determined by the address S, in surface feet per minute. The right-hand rule can be used to determine which direction is clockwise and which direction is counter-clockwise. Spindle on (clockwise rotation) M T Right-hand-helix screws moving in the tightening direction (and right-hand-helix flutes spinning in the cutting direction) are defined as moving in the M03 direction, and are labeled "clockwise" by convention. The M03 direction is always M03 regardless of local vantage point and local CW/CCW distinction. See comment above at M03.

M04

Spindle on (counterclockwise rotation) Spindle stop

M M

T T

M05 M06

Automatic tool change (ATC)

Many lathes do not use M06 because the T address itself indexes the turret. Programming on any particular machine tool requires knowing which method that machine uses. To understand how the T address works and how it interacts (or not) with M06, one must study the various methods, such as lathe turret programming, T (some- ATC fixed tool selection, ATC random times) memory tool selection, the concept of "next tool waiting", and empty tools. These concepts are taught in textbooks such as Smid,[1] and online multimedia (videos, simulators, etc); the latter are usually paywalled to pay back the costs of their development. They are used in training classes for operators, both on-site and remotely (e.g., Tooling University).

M07 M08 M09 M10 M11 M13

Coolant on (mist) Coolant on (flood) Coolant off Pallet clamp on Pallet clamp off Spindle on (clockwise rotation) and coolant on (flood)

M M M M M

T T T For machining centers with pallet changers For machining centers with pallet changers This one M-code does the work of both M03 and M08. It is not unusual for specific machine models to have such combined commands, which make for shorter, more quickly written programs. Spindle orientation is more often called within cycles (automatically) or during setup (manually), but it is also available under program control via M19. The abbreviation OSS (oriented spindle stop) may be seen in reference to an oriented stop within cycles.

M19

Spindle orientation

M21 M21 M22 M22 M23 M23 M24 M30 M41 M42 M43 M44 M48 M49

Mirror, X-axis Tailstock forward Mirror, Y-axis Tailstock backward Mirror OFF Thread gradual pullout ON Thread gradual pullout OFF

M T M T M T T T T T T T M T This rule is also called (automatically) within tapping cycles or single-point threading cycles, where feed is precisely correlated to speed. Same with spindle speed override and feed hold button. Also empty spindle. For machining centers with pallet changers

End of program with M return to program top Gear select - gear 1 Gear select - gear 2 Gear select - gear 3 Gear select - gear 4 Feedrate override allowed Feedrate override NOT allowed

M52 M60

Unload Last tool from spindle Automatic pallet

M M

change (APC) M98 Subprogram call M99 M T Takes an address P to specify which subprogram to call, for example, "M98 P8979" calls subprogram O8979. Usually placed at end of subprogram, where it returns execution control to the main program. The default is that control returns to the block following the M98 call in the main program. Return to a different block number can be specified by a P address. M99 can also be used in main program with block skip for endless loop of main program on bar work on lathes (until operator toggles block skip).

Subprogram end

S-ar putea să vă placă și

- G and M Codes For CNC LatheDocument8 paginiG and M Codes For CNC LatheLuis Gonzalo Castañeda GalindoÎncă nu există evaluări

- List of G Codes: SR - NO. Code Function 1. 2. 3. 4Document28 paginiList of G Codes: SR - NO. Code Function 1. 2. 3. 4pmagrawal100% (1)

- Mach4 Mill GCode ManualDocument60 paginiMach4 Mill GCode Manualsahiljain_146Încă nu există evaluări

- CNC Machine Language G Code ListDocument3 paginiCNC Machine Language G Code ListJules OlivierÎncă nu există evaluări

- BMW Coding Parameters - F36 - 2016 435xi Gran CoupéDocument4 paginiBMW Coding Parameters - F36 - 2016 435xi Gran CoupéPaco BonilloÎncă nu există evaluări

- Book by BMWDocument359 paginiBook by BMWQingchang Lu100% (1)

- Mach4 G and M Code Reference ManualDocument81 paginiMach4 G and M Code Reference ManualMegi Setiawan SÎncă nu există evaluări

- Chapter Two 2. Manual NC Part ProgrammingDocument33 paginiChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeÎncă nu există evaluări

- Manual Part Programming FormatsDocument22 paginiManual Part Programming FormatsSatish PathakÎncă nu există evaluări

- NC ProgrammingDocument23 paginiNC ProgrammingAkash Byju100% (1)

- Hass AnswersDocument7 paginiHass AnswersRelu ChiruÎncă nu există evaluări

- G Codes CommandsDocument45 paginiG Codes CommandsordamÎncă nu există evaluări

- Install: Windows: GRBL 1.1Document31 paginiInstall: Windows: GRBL 1.1Martas DeskÎncă nu există evaluări

- Cad Cam3 Unit NeelimaDocument96 paginiCad Cam3 Unit Neelimasatish86Încă nu există evaluări

- FANUC F0i-D Spec E-13 SpecificationsDocument14 paginiFANUC F0i-D Spec E-13 Specificationsmt7038Încă nu există evaluări

- Nexys4 PDM RefProj2 V2Document12 paginiNexys4 PDM RefProj2 V2Vale Conde Cuatzo100% (2)

- 05b4 E70 Adaptive Headlight SystemDocument33 pagini05b4 E70 Adaptive Headlight SystemAnirudhPandeyÎncă nu există evaluări

- BMW E6x Code ListDocument10 paginiBMW E6x Code Listtodor todorovÎncă nu există evaluări

- Job CNC MillDocument11 paginiJob CNC MillHerie KrisÎncă nu există evaluări

- G Codes PDFDocument1 paginăG Codes PDFKrocodileÎncă nu există evaluări

- Comparative Study of CNC Controllers Used in CNC Milling MachineDocument9 paginiComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALÎncă nu există evaluări

- Fanuc Lathe ProgramDocument93 paginiFanuc Lathe Programnguyenanhso100% (1)

- Application Note - PMC Axis ControlDocument14 paginiApplication Note - PMC Axis ControlAbhishek Chaubey100% (1)

- Grbl-Panel Wiki GitHubDocument3 paginiGrbl-Panel Wiki GitHubMarky Maypo100% (1)

- G and M Codes For CNCDocument2 paginiG and M Codes For CNCRajesh Kumar PÎncă nu există evaluări

- Important Tips On LED DriversDocument8 paginiImportant Tips On LED DriversRaja HafizuddinÎncă nu există evaluări

- Lazyturn Manual Rev 5Document49 paginiLazyturn Manual Rev 5s45rebatbnÎncă nu există evaluări

- Direct Drawing Dimension ProgrammingDocument6 paginiDirect Drawing Dimension ProgrammingVivekanand HasaraddiÎncă nu există evaluări

- G Code FanukDocument5 paginiG Code FanukCucoș Marius MarianÎncă nu există evaluări

- Heidenhain 920Document68 paginiHeidenhain 920Angel Alvarez CarrilloÎncă nu există evaluări

- Ibac-Services With OrdercodesDocument2 paginiIbac-Services With Ordercodesdradubuh002Încă nu există evaluări

- FANUC Series 0 - MF Plus Die Mould Functions (Procedures)Document20 paginiFANUC Series 0 - MF Plus Die Mould Functions (Procedures)Moaied MoaiedÎncă nu există evaluări

- BMW 10 OBD 11Document27 paginiBMW 10 OBD 11SalisburÎncă nu există evaluări

- Mazak Multiple Pull Transfer Example - Towmeup Console SwivelDocument3 paginiMazak Multiple Pull Transfer Example - Towmeup Console SwivelArturo LopezÎncă nu există evaluări

- LampMapping PDFDocument1 paginăLampMapping PDFGualberto Rocha100% (1)

- A Letter Engraving Custom MacroDocument15 paginiA Letter Engraving Custom Macrofirepower117Încă nu există evaluări

- P5 P7 DiameterDocument34 paginiP5 P7 DiameterThiago Abraao100% (1)

- Doosan G76Document17 paginiDoosan G76Pham LongÎncă nu există evaluări

- CNC English Code Controller SystemDocument17 paginiCNC English Code Controller Systemmarciano1980Încă nu există evaluări

- Most BusDocument20 paginiMost BusTBogdanMÎncă nu există evaluări

- Fanuc 15i AlarmsDocument17 paginiFanuc 15i AlarmsRevolusiSoekarnoÎncă nu există evaluări

- CNC Turn-Mill G and M CodesDocument51 paginiCNC Turn-Mill G and M CodespptmnltÎncă nu există evaluări

- Topswitch - GX: Flyback Quick Selection CurvesDocument12 paginiTopswitch - GX: Flyback Quick Selection Curvessteviej85Încă nu există evaluări

- Video Interface For AUDI 2009-2011 Model Years: Car SolutionsDocument25 paginiVideo Interface For AUDI 2009-2011 Model Years: Car Solutionsluso portuguesÎncă nu există evaluări

- Fanuc 0m-ADocument3 paginiFanuc 0m-ASanchai ProgaeewÎncă nu există evaluări

- f10 Line Departure CodingDocument3 paginif10 Line Departure Codingivo shterevÎncă nu există evaluări

- BMW EBA 361831 Rear View Camera Retrofit InstructionsDocument14 paginiBMW EBA 361831 Rear View Camera Retrofit InstructionsisoxÎncă nu există evaluări

- Siemens Parameter ListDocument4 paginiSiemens Parameter ListS.DharanipathyÎncă nu există evaluări

- CNC Mill ProgrammingDocument24 paginiCNC Mill ProgrammingZahidah AmaninaÎncă nu există evaluări

- ARM Robot Trainer SpecificationDocument1 paginăARM Robot Trainer SpecificationOmar Hs100% (1)

- Master List 10-26 PDFDocument12 paginiMaster List 10-26 PDFBloju Ionut AlexandruÎncă nu există evaluări

- D291M000UC - P7ME ManualDocument553 paginiD291M000UC - P7ME ManualConstantin DumitruÎncă nu există evaluări

- G CodeDocument9 paginiG CodeArga Rio MugafiÎncă nu există evaluări

- System Variables For 0iDocument17 paginiSystem Variables For 0iRonÎncă nu există evaluări

- G-Codes and M-Functions - MillingDocument1 paginăG-Codes and M-Functions - MillingJuan Carlos Cárdenas TufiñoÎncă nu există evaluări

- Enabling of Tire Pressure Monitoring System On A4 A5 b8Document5 paginiEnabling of Tire Pressure Monitoring System On A4 A5 b8costeniucÎncă nu există evaluări

- Fanuc 6M Alarm CodesDocument7 paginiFanuc 6M Alarm CodesKrassi GlogovskiÎncă nu există evaluări

- Code Description Milling (M) Turning (T) Corollary InfoDocument11 paginiCode Description Milling (M) Turning (T) Corollary InfoDilshad MalikÎncă nu există evaluări

- Code Description Milling (M) Turning (T) Corollary InfoDocument5 paginiCode Description Milling (M) Turning (T) Corollary InfoivtrubeljaÎncă nu există evaluări

- Code Description Milling Turning (M) (T) G00 Rapid Positioning M TDocument12 paginiCode Description Milling Turning (M) (T) G00 Rapid Positioning M TjokoÎncă nu există evaluări

- Technical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresDocument2 paginiTechnical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresFernando Cesar PérezÎncă nu există evaluări

- Use of Information Technology in The Flight Catering ServicesDocument32 paginiUse of Information Technology in The Flight Catering ServicesAbhiroop SenÎncă nu există evaluări

- The Rheological Properties of Ketchup As A Function of Different Hydrocolloids and TemperatureDocument8 paginiThe Rheological Properties of Ketchup As A Function of Different Hydrocolloids and TemperatureVicente WiethÎncă nu există evaluări

- A. Desplat: Godzilla (2014) - Film Score AnalysisDocument18 paginiA. Desplat: Godzilla (2014) - Film Score AnalysisR.PercacciÎncă nu există evaluări

- Festivals of IndiaDocument51 paginiFestivals of IndiaDhatchayani RamkumarÎncă nu există evaluări

- Auto Repair and Car Wash Business PlanDocument31 paginiAuto Repair and Car Wash Business PlanKiraYagamiÎncă nu există evaluări

- Morning Star Cafe Menu Revised 08-14-2019 On Line Menu 1Document2 paginiMorning Star Cafe Menu Revised 08-14-2019 On Line Menu 1api-471935951Încă nu există evaluări

- Pakistan RailwayDocument38 paginiPakistan RailwayمحمودعليÎncă nu există evaluări

- Marine Upholstery SpecsDocument1 paginăMarine Upholstery SpecsRezza KurniawanÎncă nu există evaluări

- Drugs and Tinnitus - Neil Bauman PHD - April '09Document2 paginiDrugs and Tinnitus - Neil Bauman PHD - April '09DownTheTheRabbitHole108Încă nu există evaluări

- Assignment Oumh2103 English For Science Technical PurposesDocument12 paginiAssignment Oumh2103 English For Science Technical PurposesKhairul AnuarÎncă nu există evaluări

- Esab Ok 55 (3.2 MM)Document1 paginăEsab Ok 55 (3.2 MM)DHANEESH VELLILAPULLIÎncă nu există evaluări

- Tadabbur I Qur'ānDocument43 paginiTadabbur I Qur'ānamjad_emailÎncă nu există evaluări

- Evolution of Indian TolucaDocument28 paginiEvolution of Indian TolucaAlberto Duran IniestraÎncă nu există evaluări

- Airborne Doppler Radar Navigation of Jet Transport Aircraft-EftDocument10 paginiAirborne Doppler Radar Navigation of Jet Transport Aircraft-Eftjulio perezÎncă nu există evaluări

- INTERVIEW QUESTIONS - Verilog - PART-1Document9 paginiINTERVIEW QUESTIONS - Verilog - PART-1charan tejaÎncă nu există evaluări

- Ovonic Unified Memory OR Phase Change MemoryDocument37 paginiOvonic Unified Memory OR Phase Change Memoryrockstar_69Încă nu există evaluări

- Turnitin Originality ReportDocument20 paginiTurnitin Originality ReportNaomi Deirdre ReyesÎncă nu există evaluări

- DEH S4150BT Owners Manual PDFDocument96 paginiDEH S4150BT Owners Manual PDFfatih konaçoğluÎncă nu există evaluări

- Job Hazard Analysis Form: Section A: Task InformationDocument3 paginiJob Hazard Analysis Form: Section A: Task InformationHasnei NÎncă nu există evaluări

- English: Third Quarter - Module 3Document12 paginiEnglish: Third Quarter - Module 3Anna Agravante-SulitÎncă nu există evaluări

- Practice Tests - Tiếng Anh 7 I-learn Smart World TestDocument9 paginiPractice Tests - Tiếng Anh 7 I-learn Smart World TestnghiepÎncă nu există evaluări

- Industrial TYROLITc 21Document611 paginiIndustrial TYROLITc 21kamilÎncă nu există evaluări

- Types of Welding Defects PDFDocument12 paginiTypes of Welding Defects PDFDhiab Mohamed AliÎncă nu există evaluări

- Current Invoice No. 1: Enabling Works CeilingDocument1 paginăCurrent Invoice No. 1: Enabling Works CeilingEyad RefaiÎncă nu există evaluări

- Expansion ScrewsDocument32 paginiExpansion ScrewsJomar PortadoÎncă nu există evaluări

- 4mb/01r-Que-2023 Jun Edexcel PastpaperDocument24 pagini4mb/01r-Que-2023 Jun Edexcel Pastpaperaugust.shwanÎncă nu există evaluări

- LLM01v5 0Document12 paginiLLM01v5 0Alan LeungÎncă nu există evaluări

- GIRBESDocument6 paginiGIRBESMiguel LópezÎncă nu există evaluări

- All About CupcakesDocument4 paginiAll About CupcakesRevtech RevalbosÎncă nu există evaluări