Documente Academic

Documente Profesional

Documente Cultură

BP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-Pass

Încărcat de

OSDocs2012Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

BP America Gomx Deepwater Drilling MC 562 #1 Drilling Progra For 14-3/4"X16" By-Pass

Încărcat de

OSDocs2012Drepturi de autor:

Formate disponibile

Confidential

GOM

BP America

GoMX Deepwater Drilling

MC 562 #1 Drilling Program

For 14-3/4"x16" By-Pass

Procedures and Guidelines for Drilling Operations

EXHIBIT# lL r?a

WIT: __

BP-HZN-MBI 00034127

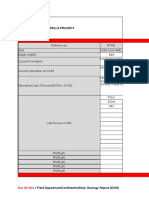

Approvals & Distribution

MC 562 ri I lsabeia Version I

Confidential

-- - - ~ -

Prepared by: ______________ _

Nicholas Lirette,

Drilling Engineer

Reviewed by: _______________ _

Bob Louviere

Sr. Drilling Engineer

Approved by: ______________ _

George Coltrin,

Team Leader

Approved by: ________ _____ _

David Sims,

Project Manager

Last revision 03121/2007

P a g ~ 2 of 17

!L'( Wdis Team

BP-HZN-MBI 00034128

Confidential

1. 13 5/8" Intermediate Drilling Liner Interval

Introduction

The objective of this section is to drill to 14,800' md and set the 13-5/8" liner shoe at

14,680' md to stay approximately 275' from the well control event experienced

previously. The 14-3/4"x16" hole interval will be drilled utilizing a rotary steerable

system for kicking off the cement plug just below the 16" shoe located at 12, 836' md

and to minimizing dog leg severity on kick off. The plan is to drill the entire section

with 11 .6 ppg mud weight since this mud weight was sufficient to get to 14,800' md on

the previous attempt to drill this hole section. Background LCM should be in the

system prior to exiting the 16" shoe. The directional plan is designed to stay a

minimum of 1 00' away from the previous wellbore at section TO with a goal of 150'.

Close attention to hole conditions will be necessary since the hole behavior is quite

unpredictable following the previous operations to gain control of the well.

Objective

1. Achieve Health, Safety, and Environmental (HSE) goals of No Accidents. No Harm

to People and No Damage to the Environment. HSE goals are measured by days

away from work, medical treatments and spills.

2. Kick off prior to 13,275' md, minimizing dog leg severity. Leaving 1 00' of plug if

second kick-off plug is necessary.

3. Drill hole section to TO and run 13-5/8" to 14,680' md.

4. Successful_ly cement 13-5/8" liner.

!VIC 562111 Isabda I Last 03/2112007

Page 3 of 17

IL'\ Wells Team

BP-HZN-M Bl 00034129

Concerns

Concern I Hazard

Well Control

Lost Circulation

Running 13-518"

Liner

Wellbore Instability

I Stuck Pipe

MC 562 #I lsabda

Confidential

Mitigation of Concern I Hazard

There is potential for a shallower sand to have been charged from the

bullheading done in the previous attempt to drill this hole section. Establish

flowback "fingerprinting" prior to drilling out and watch closely on each

connection. Closely monitor PWD. PVT, and al l other drilling parameters.

Watch for pressured shale coming over the shakers which could indicate an

underbalance situation or a wellbore instability issue.

Lost circulation due to weak fracture gradients from bullheading operation or

from the 12.lppg EMW shoe integrity. ECD's should be kept below 12.0ppg

in this hole section (ECD was l2.06ppg when kick was taken so ECD

shouJdn 't be a problem). Different particle size LCM (see MT mud rreatmenr

plan below) should be used in order to bridge off sands before fractures are

created. While drilling. monitor pit levels and returns for indications of lost

circulation. Implement lost circulation contingency plans if lost circulation

does occur.

Optimize running speeds to avoid sudden starts in stops while running string

and avoid surge pressures.

See appendix C in drilling program for "sloughing formation-tight hole'' and

"stuck pipe' ' decision tress.

Version 1 Last revision 03/21/2007

Page 4 of 17

!L'( Wdls Tc:un

BP-HZN-MBI 00034130

Confidential

HALLI BURTON

Sperry Drilling Servic:

Mlssissiopt Canyon 562(1SABEl..O,)

Site. OCS-G 19966

wen lsabi<la ILX

Nellbore: BP01

Design: Ver. 03-19-07

N"'"e

M5d

BP America

Reference Is Grid Nonn

WEI.L60RE TARGET DETAJLS(WJ' CO.OROIN.O.TESi

T'/0 .Nt-s EI-W Noi."'tino Sh;.,pe

-268.8! ...J.73 Citcle (RJdiiJ!.: :.:!00.00)

12400-

lrll<!re.opt80g5.00 -zo.n 1::30001.00 Po:>lnt

M55 1873500 .0.73 10323llC5.00 1:!3DIJQI.OO Circl ;RJdius: 200.00)

-4Q6.St 1::301=1.00 P:)int

12300-

:::---Tie-In to SUtVey at 12901.00' MD

13200-

13600-

1<!800-

=

0

0

co

515600-

c.

j 160001

16300-

17200-

17600-

13000-

18400-

1SSOO-

19200-

6

'

'

-... __

......

--.

'

BP01, Begtn Bui ld at 12936.00' MD

' ........... DLS=2.000./100.

End of Bui ld at 13061.57' MD

Hoid Angle at 3.00()'

West(-)/East(+) (400 ttlin)

Tie-lno to Survey at t2901 .oo MD BP01, Builct at 12936.oo MD

I

' I ...........

-

i.,,.-

Br.;,in Orop 3t 15003.57' MD

DLS=1.000'1100'

'2

:f:?oo-

8

,

___ -- Enct ot Build at 13061 57' r.o!D

+ Drop al 15003.57' MD

:!.

,

,

---

,'

End of Drop at 15303.57' MD

Hold An<Jie ar o.ooo

KOP, Bl'gin Build at 16763.04' MD

DLS=2.000'11 oo

---

-

------.::: - ------.EndofDrop a115303.57' M:)

z

:::.. M 56 ----

:J22oo- _. KOP, Begin Build at 16763.04' MD

5 .. ..

<n

-400-

600-

M 55

,

,

7

--

.... -- ......

--

M56 Intercept at 18142.43' MD

-

--

-... -.....

M55 Intercept at 18825.15' MD

.aoo- TO al19214.51. MD-19100.00. TVD

--

--

End of Build at 1 nso.75' MD

Hold Angle at 20.342'

'

' M561ntercept al18142.43' MD

'

'

'

'

'

'

M55

'

,

' ,

,

-..... ___ _

Si:C \10

I 12W11l0

"' 12'lle.oo

') 1306157

" 15003.57

6 1076:311<

7 17780 75

3 1814067

g 1614:!.43

10

1t 1Q214.51

Inc

0.!.:!0

0.!4S

3.Cl0

3.C<l0

0000

0.000

:!OZ42

M55 Intercept at 18825.15' MD

..;, T'IO

2' .... 320 1m : .23

::"ofo!.+IS

znoco !?0!0.73

270.000

il.OOO

J.OOO

li7!f. 88

:eo.343

1ac>..:.oo

1;.1c0.DD

S!OCTION C8'tLS

-NI.S -80-N

2!..30 !>.87

!-.37

t.7

-1-;..QO

-107 .75

20.08 107.75

14717

-30.88

-:e!.Sl !0.73

..;n.sl

CLog TFJce

0.000 c.ooo

2.000

0.000 0.000

I 000 1SC.OOO

o.ooc c.ooo

165.343

C.DDD 0.000

:.ceo :!C.Oilcl

0.000 c.ooo

C.OOC 0.000

IlSee

..

-:M :!.6

.ae.u;

140 15

7i

::04.3f

0:')') ,23

1.15(

M5:'! lntuJ;:(Ip:

WELL DETAILS: lsaiJela ll.X I

- --TD at 19214.51' MD-19100.00' TVQ------------- -----------,

Verdcal Secuon at 174.25' (aoo Win)

Northing

10324403.8 r

War.er Depth 544.S.OO

Easong Launuce Longitude

1230091.7323' 26' 38 596 Nl8" 16.37 927 'N

MC 562 # I lsabda Vornion I L:tst rovision 03/21/2007

Page 5 of17

lL'< Wdls Team

BP-HZN-MBI 00034131

Confidential

o.o.

14.75"

9 .6.!5"

9S

6.7::"

9S

9.s"

9S

9S

14.:!5"

9.:;"

9 .5"

a

8.:!::"

a

..

8"

B.e1s

spe 11-,y-sun

O ... ILLING S'I!I ... VICSS

B HA Schematic

BP North America Explorat ion

lsabela WildCat

BHA 10 :r. 5

'14." X '16" GeoPilot Assemly

BHA Configuration

:co

10'

::.1'

::6.7'

:4.68'

s

T.S'

zo

s

60'

4'

7'

:ro

s:

SOD'

FulldrUt ton.g. PCC

Serle GeoPHo1

14 ,3/8" lnlegrol Blodo Stablll=cr

Flex Collar

Non Cro" Over Sub

'9-1/2" RLL w!ODS ... E'JVR PWO

9- I r- M ?T wiOir

14 SIS"' lntet;r:ll Bl.ede Stabili Zer

16" Rhmo Reomor

9 1/:C" Drill col l or

15 1 f2"' Concenu1c Slobll i=er

2 9 112" Drl ll col lar

Cro:3 Over Sub

J 's 0 1111 coil or

\Nea.r Sleewe- RunnmQ Toot

Over S\Jb

9 M HVIO"

rl E :tli thn9. Jar

20 'HWOP

BHA Discussion

X lS'"' GcoPHol/Re11mcr

L'II'O (PWOtGAMMAIR::SISnVJTY:

Dri ll ohead lo oet 13 S/8" Cooing at IS,SSS'

'A'OB 15-35,000 RPM 110-150

MC 562 Iii lsabda Vcr.;ion I

X H'.''/OP

Sox 6-518" FH

rl-E Drilling

Box 6-5/8. i'H

9 XHWDP

i3CY 6-51& FH

Over SIJb

Box 6518" Reg

3 X a Dnll coll ar

Sox 6-5/B" l'l.eg

Cro!ls Over Sub

L

L:..,;t 03i 21!2007

Page 6 of 17

1 1/2'" Concenwc

S:abW=er

9 112" Onll coll or

1o Rh1no Reamer

14 518" Jnte9ro1 61oce

S 1:tb1hzcsr

Bo:r l.j/8 .. Reg

9-11:2" MPf 11'Dir

112 '" Rll .u!OO$ ..

EWR +

Noo Mo!) Cross Ow!r

Sub

Elo> Rep

Flex Collar

14 3/8" lncegnl Blooe

Stabill:er

Elo> 5-518" Rep

9600 Seroe> GeoPolot

P!n 5-.518" R:c

Fulldrift lonQ c.;18U90:: POC

lL'\ Te:un

BP-HZNMBI 00034132

Confidential

5.581

32.67

37.71

0spiraled

209

50,524

1114-3/4" X 16" OH to 14800' MD/TVD; set 13-5/8" liner shoe@ 14680' (above 14-3/4" rathole).

I 5-1 /2" pipe shall be inspected to 90% RBW; all6-5/8" pipe inspected to 95% RBW.

MC 562 Il l Jsabcla V ~ r s i o n I Last rovision 03/21/2007

Page 7 of 17

BP-HZN-MBI 00034133

M<

Confidential

18''

1358'

11.75x13 'art

- -+- R3/IOM..FP

- rvcsrum..Y D.ffi3.R.E\J

. . . . . . . FR M:& ufq:jy Clnp::Ste Fia:

- M..S"ae&S:rd Res..re

83)

a:D

l.Of

AON6.e1s

. ,

'

.

.. .

8 9 10 11 12 13 14 15 16

.'!!am

BP-HZN-MBI 00034134

Confidential

General Hole Section Procedure

1. RIH with 14-3/4"x16" rotary steerable assembly and test BOP's per APD.

2. Once BOP's have been tested continue to RIH and tag cement at approxi mately

12,336' MD.

3. Drill cement from TOC to 16" shoe located at 12,836' MD. Prior to drilling past the

shoe ensure 11.6ppg MW with the proper LCM formulation is in the system as

prescribed below. . Watch for enlarged hole/cement sheaths/ sloughi ng shale

immediately below the 16" casing.

LCM Formulation:

7ppb- Safe Carb 40, 7ppb-Safe Carb 250, 7 ppb G-

Seal. Add 600 lb/hr of Safe Carb 250 at the hopper because the shakers will

strip this particle size out.

4. Control drill past the 16" shoe to kick off as soon as possible attempting to keep the

dog leg severity below 4 degrees/1 00' . Once kick off has been confirmed by 100%

cutti ngs return continue drilling ahead cautiously keeping EGO' s below 12.0ppg.

Note: if not kicked off by 13,275' MD, leave 1 00' of cement for isolati on and base

for another kick off p!ug.

5. Drill 14-3/4" hole until reamer and concentric stabil izer is safely out of shoe. Drop

ball and circulate down as per Smith procedures. Pressure up and open Rhino

reamer. Pull test against 16" shoe with 15K overpull to confi rm reamer blocks are

open. Drop second ball to convert stabilizer.

6. Continue drilling 14-3/4"x1.6" hole using the following parameters:

ROP ROP wi ll be based on PWD to keep ECD below 12.0ppg EMW.

ROP should not exceed 100 FPH in this section.

-------was Li mited by bitl torque:-vibratiorl:sHA

-------- RPM --1 00+ -------------------------------------------

- Torqlie-Mt)ratio-Monitor.thedifference betwe-en on a.n.doff-bottom .torque - Donot

n exceed the makeup torque of the weakest connection in the hole.

------------- -----------

Pump Rates 3-4 pumps with max flow rate given maximum allowable SPP and

ECD limits (Ensure MWD flow-ra!e are _ _ _

Mud Weight Monitor UNO, torque, drag, background and cnx gas, mud cut, _etc.

adjust mud wej_ght -----

ECD/ PWD Plot and track PWD/ECD measurements for future reference.

Monitor and record mud weight "in" and "out," funnel viscosity, and

sand content.

- - H"oieoeviation- Monitor inciTilation-ari-a

MC 562 Il l lsabda

_ _ _ ____

Vor.;ion I Last r<vision 03/21/2007

9 of 17

IL '\ W<lls To:u11

BP-HZN-MBI 00034135

Confidential

--

section TO Casing point is planned to be 14,800' minus needed rat hole unless

hole conditions prevent us from getting to this depth.

Record flow back "finger printing" on all connections to assist with kick detection.

Once fingerprinted, the mudlogging software should detect any deviation from a

normal connection flowback.

LCM Formulation:

7ppb - Safe Carb 40, 7ppb-Safe Carb 250, 7 ppb G-

Seal. Add 600 lb/hr of Safe Carb 250 at the hopper because the shakers will

strip this particle size out.

TO for this section is planned to be 14,800' MD. This depth is based on staying

approximately 275' from the well control event that was experienced previously.

If hole problems are experienced before this depth (i.e. pack-off, wel lbore

instability, loss circulation, well control) then TO will be re-evaluated.

7. At 14,800' MD, circulate the hole clean and spot a 16.5ppg pill in rat hol e

equal to 1-1/2 times the calculated volume. Ensure proper yield point prior to

circulating BU to improve hole cleaning and cuttings suspension. POOH to the

last casing shoe. Monitor well for flow. If good hole conditions are observed,

POOH to run casing. If hole conditions are poor, trip to bottom and circulate

hole clean. POOH and continue making wiper trips until conditions are

sufficient for running casing.

8. While POOH the 15.25" wear sleeve will be left in the hole. Prepare to run the

13-5/8" liner and Weatherford hanger. See Weatherford program for detailed

running procedures.

MC 562 il l ls:tbd:t L:tsl re,ision 03121/2007

Page 10 of 17

BP-HZN-MBI 00034136

Confidential

Running and Cementing 13-5/8" Drilling Liner

Casing and Cementing Operation Preparation

The 00 of the 13-5/8" liner hanger is 14.44" and may not pass through the wear sleeve

unless it is the 15.25" wear sleeve. Check to ensure the hanger wi ll pass through the

wear sleeve, if not pull the wear sleeve.

Total string wt. (Casing+ OP = 545 kips).

Ensure that cement, additives, fresh and seawater samples are sent to the lab for final

lab testing.

Thickening time lab tests to be done with expected bottom hole temperature and second

parallel test with temperature 15 degrees higher than expected and results compared.

Model cement pumping rates based on ECOs and FGs.

Cement volumes should assume gauge hole + 25% excess.

Prepare the 13-5/8" casing tally, clean and inspect the casing threads and drift casing to

12-1/4".

Since the water depth exceeds the length of casing, (6533' wd > 2200' liner) a 13-5/8"

casing swedge will not be required on the rig floor in the open positi on.

Review swab/surge pressures from Ml Virtual Hydraulics and Allaman for various running

speeds. Select an acceptable running speed to ensure that the formation breakdown

pressure is not exceeded during TIH.

Rabbit the 6-5/8" landing string to a minimum of 2-5/8" on TOOH prior to runni ng the

casi ng.

Primary float equipment should be bucked up and thread-locked onto a joint of pipe prior

to shipment. Inspect the shoe and float collar joints for debris prior to picking up.

Make up cementing head pre-loaded with proper drill pipe dart.

MC 562111 lsabda Vorsion I l..:tSL rovision 03i21.'2007

Poge II of 17

IL'X Wells To:un

BP-HZN-MBI 00034137

Example

MC 562 Il l Jsabda l

Confidential

13-5/8" Liner Diagram

Wford Liner

Hanoer I Pkr

51

0.625"wall

Q-125

88.20#/ft

8- 50

All connections are SLX

7

6

Centralizer

5

0.625" wall

Q- 125

88.20 #/ft

Auto Fill Float Collar

Centralizer

3-4

0.625" wall

Q-125

88.20 #/ft

Centralizer

2

0.625"wall

HCQ-125

88.20 #/ft

Centralizer

1

0.625" wall

Q-1 25

88.20#/ft

Centralizer

Guide Shoe

r

Made up onshore

Made UP. onshore

-'"1

onshore

r

Made UP. onshore

""""1

onshore

Last 0312112007

12 of 17

Float Equipment and Centralizers

should already be on the pipe.

Protech centralizers should be mid

Assume shoe depth of 14,680' md

JL \: Wells Team

BP-HZN-MBI 00034138

Confidential

12.317

88.2

88.2

Qspiraled

. I

217

0

0'

477,947

544,510

689,510

I ' .. ,.

Readimg t1-1 ' ', ,,

I ' Ul o,l I I'""' l ' ' ' ' t'" .. ,

. , :'-ilj, i.'u ,-_., .. 1,167,457

14-3/4" X 16'' OH to 14800' MD/TVD; set 13-5/8" liner shoe @ 14680' (above 14-3/4" rathole ).

5-1/2" pipe shall be inspected to 90% RBW; all 6-5/8" pipe inspected to 95% RBW.

MC 562 Il l !,;,1bda I L:t.sl revision 03i21/2007

P:1ge 13 of 17

IL\: Wdls Team

BP-HZN-MBI 00034139

Confidential

13-5/8" Liner Running Operation

1. Ensure sufficient clearance thru the wellhead. The max 00 of the 13-5/8" liner

hanger is 14.44".

2. Ensure DP has been drifted to 2-518".

3. Rig up to run approximately 2, 144' 13-5/8" liner (based on 300' of liner lap) as

follows:

Note: Centralizers will be run on this liner string.

MC 562 ff l J.abda

One joint of 13-5/8", 88.20#, Q-125, Hydril SLX casing with guide shoe

(with up-jets), 1 centralizer.

Two joints of 13-5/8", 88.20#, Q-125, Hydril SLX casing, 1 centralizer per

joint.

One joint of 13-518", 88.20#, Q-125, Hydril SLX casing with Davis Lynch

Auto-Fill Float Collar I Landing Collar, 1 centralizer.

Note: Thread lock connections from the top of the landing collar down.

10 joints of 13-518", 88.20#, Q-125, Hydril SLX casing with one ( 1)

Protech Centerform centralizer each installed onto center of joint.

Remainder of 13-5/8", 88.20#, Q-125, Hydril SLX casing.

Weatherford 13-5/8", 88.20#, Q-125, Hydril SLX Hanger with Liner Top

Packer and 20' PBR and Weatherford Nodeco TDH top drive dual plug

launching cementing head with 3-1 /2" ball drop capability.

ATC Diverter sub should be placed 4 stands above the liner hanger.

A total of 10 Protech Centerform centralizers will be run on the first 10

joints.

Note: The connections from the top of the float collar joint down should

be thread locked including the centralizer subs.

4. Run the 13-5/8" casing with the blinds closed. Fill casing as necessary.

Continuously circulate the riser to warm the mud while running the casing.

Prior to opening the blinds, check for pressure below the blinds.

5. Casing information can be found in the Casing/Connector section of the

well program.

6. MU Hydril SLX connections to 48,000 ft-lbs. (Min I Opt I Max MU

torques 40K I 48K I 55K ft-lbs)

7. Limit the running speed to avoid surging formation. Actual running

speeds are to be based on hole conditions. Start and stop casing slowly.

V.:rsion I i..;LSt r.:vision 03i2!/2007

Page 14 of 17

IL'\ Wdls T.:am

BP-HZN-MBI 00034140

MC.: 562 Il l ls:obd :o

Confidential

8. Make up and install liner hanger, plug launching assembly and liner top

packer with 20' PBR. PU and install ATC Diverter Sub 4 stands above

the top of the hanger setting tool. Run the liner on DP. Confirm auto-fill

float equipment is functioning. If equipment is not functioning fill running

string every 10 stands.

9. RIH with 13-5/8" liner to the 16" shoe. Pri or to entering open-hole,

ensure casing is full. Get PU, SO and neutral weights.

10. When the liner is 15 stands off bottom drop the 1-7/8" wash-down

converter ball and continue to trip in the hole. Verify ball sizes and all

ID's on running assembly.

11. When liner is one stand off bottom, MU top drive and start washing down

slowly until liner is at setting depth.

12. Run the 13-5/8" liner to within 5' -1 0' from bottom of the underreamed

section.

13. Drop the 1-7/8" wash down ball. Circulate to close the ATC Diverter Sub.

Pressure up to 600 psi slowly and hold for 3 minutes. Continue to

pressure up to 1500 - 1800 psi to yield the seat and launch ball to

convert float equipment.

14. After yielding the ball seat, circulate at 15 spm and record pressure

once returns have stabilized (this pressure should be a minimum of 150

psi greater than previous recorded pump pressure at 15 spm). Do not

exceed 750 psi during this operation. The setting pressure for the

hanger is 1500 - 1800 psi. Verify all pressures for hydraulically

activated tools.

Note: See Weatherford procedures for detailed steps. Verify ball OD's,

ID' s and pressures with service company to ensure all tool s are

compatible.

15. Stage up pumps to 5 bpm and CBU if hole conditions all ow.

16. Pressure up as necessary to convert float equipment.

17. Proceed to set the liner hanger and release running tool.

Drop the 2 1 /8" setting ball for the liner hanger and pump same to

the diverter sub. Pressure up to 2,200 - 2,800 psi to bl ow ball

through the seat.

Let the 2-1/8" ball fall to the Li ner Hanger Running tool , pressure

up to 2000 psi setting the hanger per Weatherford's recommended

procedures.

V<rsion I L:osl revision 0312 1!2007

P ~ s 15 of 17

LL \: Wdls T<:un

BP-HZN-MBI 00034141

,'VIC 562 il l lsabda

Confidential

13-5/8" Cementing Operations

1. Hold pre-job safety meeting with all involved personnel prior to cement

job. Release liner running tool and position for cementing.

2. Rig up and test cementing lines to required pressure.

3. Mix and pump spacer and cement slurry as per the recommended

cementing program

a) Pump 75 bbls of 15ppg tuned spacer

b) Mix and pump of 115 bbls of 16.4ppg premium cement

(1 ,000' of fill with 25% excess and 200' shoe track).

Please note these volumes are not definite, we will

revisit prior to cement job.

4. Launch drill pipe wiper dart, and follow with 15 bbls 16.4 ppg premium

cement; displace cement with SSM at a minimum of 8-10 bpm. Displ ace

at maximum rate possible. Note pressures as dart passes through

various restrictions to confirm I recalculate displacement vol umes. 5 bbls

prior to reaching diverter sub with wiper dart, slow rate down to 3-4 bpm.

1,500-2,000 psi above circulating pressure will be necessary to release

the liner wiper plug. Bump wiper plug with 1,000 psi over differential

pressure.

Note: Include compressibility in displacement calculations.

Note: Do not overdisplace Y2 shoe track volume.

Note: It is the responsibility of the Driller, Mud Engineer and

Mud Logger to closely monitor and agree on the amount of mud

lost during the liner job. Report mud losses for the different

phases of the job as follows:

Bbls lost while PU and running the liner.

Bbls lost while RIH with liner on landing string

Bbls lost while washing the liner to bottom (if required)

Bbls lost while circulating, after the liner is landed

Bbls lost while pumping and displacing cement

Bbls left behind pipe.

5. After displacing the cement, verify floats are holding.

Note: If floats do not hold, bleed back no more than 1 0 bbls to snap

floats closed. If floats are stil l not holding, close annul ar, re-pressure

Vorsion I Last rovision 03i21/2()07

?ago 16 of 17

IL'\ Wdb 'J'oam

BP-HZN-MBI 00034142

MC 562 # I ls:tb.:la

Confidential

liner to the final displacement pressure or bump pressure and hold this

pressure based on the lab test results for thickening time. Monitor DP

and casing pressures. After two hours WOC, release pressure and

proceed with setting packer I testing operati ons.

6. Proceed to set the liner top packer and test per Weatherford' s

recommendations. Usually after setting the packer it' s tested to 1,000

psi. Pick up above PBR and circulate bottoms up. POOH and lay down

running tool.

7. Test the BOPs if required. See APD for permitted test requirements.

Version 1 La,;l r ~ v i s i o n 03i2 1/2007

Page 17 of 17

IL"\ Wells Team

BP-HZN-MBI 00034143

S-ar putea să vă placă și

- Montara H1 ST1 Well ReleaseDocument62 paginiMontara H1 ST1 Well Releasemack_eausÎncă nu există evaluări

- By-16 Drilling Monitoring Report 05.11.2012Document3 paginiBy-16 Drilling Monitoring Report 05.11.2012shuvo134Încă nu există evaluări

- Chapter 2-J Positive Displacement MotorsDocument23 paginiChapter 2-J Positive Displacement MotorsFor Free Drilling Training CenterÎncă nu există evaluări

- Repair Side Tracking DL LGDocument74 paginiRepair Side Tracking DL LGeleceron7919Încă nu există evaluări

- Trex 01157Document17 paginiTrex 01157OSDocs2012Încă nu există evaluări

- Pos North1 - Basic WCR Rev0Document874 paginiPos North1 - Basic WCR Rev0Felipe RamírezÎncă nu există evaluări

- Anti CollisionDocument5 paginiAnti CollisionJaime A PolancoÎncă nu există evaluări

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikDocument2 paginiJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaÎncă nu există evaluări

- Goldenman Petroluem Equipment Co., Limited: Quotation ListDocument4 paginiGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoÎncă nu există evaluări

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 paginiKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedÎncă nu există evaluări

- SD-24P Bit Record 2Document1 paginăSD-24P Bit Record 2Them Bui XuanÎncă nu există evaluări

- HH 83-1D SurveyDocument3 paginiHH 83-1D SurveyMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Morning Report 19 - 24 April 2012Document3 paginiMorning Report 19 - 24 April 2012tolstoy potemkinÎncă nu există evaluări

- Dilution: 3 ExperimentDocument10 paginiDilution: 3 ExperimenthamaÎncă nu există evaluări

- SOP 829-019 Rig Out The Mud Tanks and Pumps.Document2 paginiSOP 829-019 Rig Out The Mud Tanks and Pumps.Anonymous XbmoAFtIÎncă nu există evaluări

- Make Up TorqueDocument1 paginăMake Up TorqueNicasio AlonzoÎncă nu există evaluări

- API-40-125-casing Setting Depth PDFDocument73 paginiAPI-40-125-casing Setting Depth PDFRahmi WandiÎncă nu există evaluări

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 paginăSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025Încă nu există evaluări

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 pagină16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroÎncă nu există evaluări

- String Diagram Toot Deep-1 OGDCL DST-6 - 3Document1 paginăString Diagram Toot Deep-1 OGDCL DST-6 - 3Aadil HaroonÎncă nu există evaluări

- Mizzen L-11 - End of Well Report - INV - 032042 642 PDFDocument1 paginăMizzen L-11 - End of Well Report - INV - 032042 642 PDFKevin MuellerÎncă nu există evaluări

- AFPC Lithology DescriptionDocument9 paginiAFPC Lithology DescriptionDaneskumar ManogaranÎncă nu există evaluări

- Copia de Bha de PozoDocument18 paginiCopia de Bha de PozoBertha Julieth Lopez ParraÎncă nu există evaluări

- JarBestPracticesv ImpppDocument35 paginiJarBestPracticesv ImpppShiela OÎncă nu există evaluări

- Notes 4Document18 paginiNotes 4Ruben ChirinosÎncă nu există evaluări

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument12 paginiKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedÎncă nu există evaluări

- Well #1 - Well #1 - PROFILE PDFDocument1 paginăWell #1 - Well #1 - PROFILE PDFHassan ZakeriÎncă nu există evaluări

- Amal-18 Sta DDR#20 02-03-2020Document30 paginiAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimÎncă nu există evaluări

- 2017-18 Drilling ProgrammeDocument32 pagini2017-18 Drilling ProgrammesmashfacemcgeeÎncă nu există evaluări

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedDocument1 paginăCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaÎncă nu există evaluări

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsDocument1 paginăTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaÎncă nu există evaluări

- Daily HSE Summary Report 28-03-2018Document1 paginăDaily HSE Summary Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Amal-18 Sta DDR#22 04-03-2020Document30 paginiAmal-18 Sta DDR#22 04-03-2020eng7mohamed7hashimÎncă nu există evaluări

- The Role of BP in The Deepwater Horizon Explosion and Oil SpillDocument254 paginiThe Role of BP in The Deepwater Horizon Explosion and Oil SpillScribd Government DocsÎncă nu există evaluări

- Successful Installation of The First Dual Concentric Completion System On 9 5 8inch Casing ESP ESP Type in ColombiaDocument18 paginiSuccessful Installation of The First Dual Concentric Completion System On 9 5 8inch Casing ESP ESP Type in ColombiaAbe RmÎncă nu există evaluări

- 13.375 CASING Tally KH #C Wspace OutDocument14 pagini13.375 CASING Tally KH #C Wspace OutnabiÎncă nu există evaluări

- GEOREPORT Mudlogging ExampleDocument2 paginiGEOREPORT Mudlogging ExampleCarmen Ibeth Olivos PradaÎncă nu există evaluări

- Vibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter MeasureDocument1 paginăVibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter Measuresaeed65Încă nu există evaluări

- AHMSW 8 Fiche de PhaseDocument12 paginiAHMSW 8 Fiche de PhaseBOUBAKER LOGBIÎncă nu există evaluări

- 2.2 Replacing Casing Oil Seal AssemblyDocument3 pagini2.2 Replacing Casing Oil Seal AssemblynabiÎncă nu există evaluări

- Application of Drilling Performance Data To Overpressure DetectionDocument8 paginiApplication of Drilling Performance Data To Overpressure DetectionDidik HartadiÎncă nu există evaluări

- Migrasi TrapDocument66 paginiMigrasi TrapmalamlamaÎncă nu există evaluări

- WebtocDocument10 paginiWebtocriobmÎncă nu există evaluări

- Mud Engineer Work ScopeDocument5 paginiMud Engineer Work ScopeMohamed AbozeimaÎncă nu există evaluări

- Tdi FCR Data 9 625 47ppf n80 BTC Rev 6Document1 paginăTdi FCR Data 9 625 47ppf n80 BTC Rev 6Villalba XavichoÎncă nu există evaluări

- Students Industrial Work Experience Scheme (Siwes)Document46 paginiStudents Industrial Work Experience Scheme (Siwes)Vanessa Ada ElokaÎncă nu există evaluări

- Optimization Drilling Parameters Performance During Drilling in Gas WellsDocument8 paginiOptimization Drilling Parameters Performance During Drilling in Gas WellsOmotayo Akinpelumi100% (1)

- Spe 135704 MS PDFDocument9 paginiSpe 135704 MS PDFKd FaÎncă nu există evaluări

- Herunefer W 13Document3 paginiHerunefer W 13Islam AtifÎncă nu există evaluări

- Asamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22aDocument13 paginiAsamera (South Sumatra) LTD Mechanical Status Production Engineering Department RB-22afauzan kartiyasaÎncă nu există evaluări

- Product Data: PF 'Lignosperse'Document2 paginiProduct Data: PF 'Lignosperse'gplese0Încă nu există evaluări

- Bits & Core HeadsDocument74 paginiBits & Core HeadsdaveÎncă nu există evaluări

- Daily Drilling Report: The Gold DiggersDocument3 paginiDaily Drilling Report: The Gold DiggerscodigocarnetÎncă nu există evaluări

- Section 11 - Drilling Mud ManualDocument4 paginiSection 11 - Drilling Mud ManualMohamed AbozeimaÎncă nu există evaluări

- Amal-18 Sta DDR#18 29-02-2020Document30 paginiAmal-18 Sta DDR#18 29-02-2020eng7mohamed7hashimÎncă nu există evaluări

- GTO SampleDocument24 paginiGTO Samplego25101992Încă nu există evaluări

- NeoFlo 1-58 Datasheet PDFDocument4 paginiNeoFlo 1-58 Datasheet PDFSteven MarinoffÎncă nu există evaluări

- Scope of Work Location Prepration For Wafa Drilling Well A61Document7 paginiScope of Work Location Prepration For Wafa Drilling Well A61ابرار عمرÎncă nu există evaluări

- 9.625 Inter-Prod 53.5 PPFDocument17 pagini9.625 Inter-Prod 53.5 PPFAnonymous XbmoAFtIÎncă nu există evaluări

- Pipe Reinforcing at SupportDocument12 paginiPipe Reinforcing at SupportSeungmin Paek100% (3)

- DOJ Pre-Trial Statement On QuantificationDocument14 paginiDOJ Pre-Trial Statement On QuantificationwhitremerÎncă nu există evaluări

- To's Proposed FOF and COLDocument326 paginiTo's Proposed FOF and COLOSDocs2012Încă nu există evaluări

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Document41 pagini2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012Încă nu există evaluări

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Document13 pagini2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012Încă nu există evaluări

- To's Post-Trial BriefDocument57 paginiTo's Post-Trial BriefOSDocs2012Încă nu există evaluări

- BP's Proposed Findings - Combined FileDocument1.303 paginiBP's Proposed Findings - Combined FileOSDocs2012Încă nu există evaluări

- BP Pre-Trial Statement On QuantificationDocument13 paginiBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlDocument13 pagini2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012Încă nu există evaluări

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Document121 paginiUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012Încă nu există evaluări

- HESI's Proposed FOF and COLDocument335 paginiHESI's Proposed FOF and COLOSDocs2012Încă nu există evaluări

- HESI's Post-Trial BriefDocument52 paginiHESI's Post-Trial BriefOSDocs2012Încă nu există evaluări

- BP's Post-Trial BriefDocument72 paginiBP's Post-Trial BriefOSDocs2012Încă nu există evaluări

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Document49 paginiUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012Încă nu există evaluări

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Document23 paginiState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012Încă nu există evaluări

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDocument1 paginăFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012Încă nu există evaluări

- Exterior: Circa 2003Document1 paginăExterior: Circa 2003OSDocs2012Încă nu există evaluări

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 paginiPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Încă nu există evaluări

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Document22 paginiState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012Încă nu există evaluări

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Document72 paginiPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- Macondo Bod (Basis of Design)Document23 paginiMacondo Bod (Basis of Design)OSDocs2012Încă nu există evaluări

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 paginiArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012Încă nu există evaluări

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Document1 paginăDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012Încă nu există evaluări

- Circa 2003Document1 paginăCirca 2003OSDocs2012Încă nu există evaluări

- DR Gene: CloggedDocument1 paginăDR Gene: CloggedOSDocs2012Încă nu există evaluări

- Laboratory Results Cement Program Material Transfer TicketDocument13 paginiLaboratory Results Cement Program Material Transfer TicketOSDocs2012Încă nu există evaluări

- Circa 2003Document1 paginăCirca 2003OSDocs2012Încă nu există evaluări

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDocument1 paginăProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012Încă nu există evaluări

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDocument22 paginiApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012Încă nu există evaluări

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDocument1 paginăEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012Încă nu există evaluări

- Webster:: Trial Transcript at 3975:2-4Document1 paginăWebster:: Trial Transcript at 3975:2-4OSDocs2012Încă nu există evaluări

- Using Ms-Dos 6.22Document1.053 paginiUsing Ms-Dos 6.22lorimer78100% (3)

- Nodal Analysis Collection 2Document21 paginiNodal Analysis Collection 2Manoj ManmathanÎncă nu există evaluări

- Unit 7 - Evolution and Classification: Regents BiologyDocument24 paginiUnit 7 - Evolution and Classification: Regents BiologyTalijah JamesÎncă nu există evaluări

- LNWH Alcohol GUIDELINE SUMMARY 2018Document1 paginăLNWH Alcohol GUIDELINE SUMMARY 2018Ai Hwa LimÎncă nu există evaluări

- Malaybalay CityDocument28 paginiMalaybalay CityCalvin Wong, Jr.Încă nu există evaluări

- Unit 2 Module 2 Combined-1Document14 paginiUnit 2 Module 2 Combined-1api-2930012170% (2)

- SchedulingDocument47 paginiSchedulingKonark PatelÎncă nu există evaluări

- 02 Laboratory Exercise 1Document2 pagini02 Laboratory Exercise 1Mico Bryan BurgosÎncă nu există evaluări

- Piston Master PumpsDocument14 paginiPiston Master PumpsMauricio Ariel H. OrellanaÎncă nu există evaluări

- Trading Rules To Successful ProfitsDocument89 paginiTrading Rules To Successful ProfitsOuattaraÎncă nu există evaluări

- Feature Glance - How To Differentiate HoVPN and H-VPNDocument1 paginăFeature Glance - How To Differentiate HoVPN and H-VPNKroco gameÎncă nu există evaluări

- CBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Document6 paginiCBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Aryan BhardwajÎncă nu există evaluări

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document4 paginiStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderÎncă nu există evaluări

- Facts About The TudorsDocument3 paginiFacts About The TudorsRaluca MuresanÎncă nu există evaluări

- Group 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasDocument12 paginiGroup 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasSeyell DumpÎncă nu există evaluări

- Form PersonalizationDocument5 paginiForm PersonalizationSuneelTejÎncă nu există evaluări

- Demand, Supply, and Market EquilibriumDocument15 paginiDemand, Supply, and Market EquilibriumAnonymous HBQ86kÎncă nu există evaluări

- Agile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)Document67 paginiAgile in ISO 9001 - How To Integrate Agile Processes Into Your Quality Management System-Springer (2023)j.paulo.mcÎncă nu există evaluări

- Risk Management: Questions and AnswersDocument5 paginiRisk Management: Questions and AnswersCentauri Business Group Inc.Încă nu există evaluări

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserDocument13 paginiGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutÎncă nu există evaluări

- Cultural AnthropologyDocument12 paginiCultural AnthropologyTRISH BOCAÎncă nu există evaluări

- Matter Around Me: SC1 - Teaching Science in ElementaryDocument27 paginiMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)

- Color Coding Chart - AHGDocument3 paginiColor Coding Chart - AHGahmedÎncă nu există evaluări

- Award Presentation Speech PDFDocument3 paginiAward Presentation Speech PDFNehal RaiÎncă nu există evaluări

- Integrated Management System 2016Document16 paginiIntegrated Management System 2016Mohamed HamedÎncă nu există evaluări

- Jail Versus Substance Abuse TreatmentDocument5 paginiJail Versus Substance Abuse Treatmentapi-240257564Încă nu există evaluări

- Sample Paper Book StandardDocument24 paginiSample Paper Book StandardArpana GuptaÎncă nu există evaluări

- (LaSalle Initiative) 0Document4 pagini(LaSalle Initiative) 0Ann DwyerÎncă nu există evaluări

- Technical Data - Tad1342veDocument9 paginiTechnical Data - Tad1342veRachid SmailiÎncă nu există evaluări

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysDocument6 paginiGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়Încă nu există evaluări