Documente Academic

Documente Profesional

Documente Cultură

Trex 01194

Încărcat de

OSDocs2012Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Trex 01194

Încărcat de

OSDocs2012Drepturi de autor:

Formate disponibile

CONFIDENTIAL

Message

subsea

From: Tootpusher {tootpusher@dwh.rig.deepwater.comj

Sont: Friday, June 17, 2005 g:52 !WJ

To: Horizon subsea (Deepwater Horizon Subsea)

Subject: FW: BOP Shear Rams

B1'lly this is the sheani1g c9psb1'lity

'T"1m WiJTrams + +

'too(puslicrtDct:p'lvatcrJ(ori.zort

too(pusfrer.tlwfz.riJ.tiilcp1Vatcr.com

(713-232-8262), 'FIV({713-232-8263}

- ---Qrlginlll Message-

From: Bowles, Tom T [mallto:Thomas.Bowles@bp.com)

Sent: Fr1day, June 17, 2005 6:10AM

Page I of2

To: Deepwater Horizon, Formen; Halvorson, Kathleen; Louviere, Robert

Cc: Coltrin, George; Skelton, Jake; Toolpusher@dwh.rlg.deepwater.com; OIM@dwh.rlg.deepwater.com

SUbject: FW: BOP Shear Rams

Bob Lowiere, -Thanks for sharing this Information from Steve ..... Copy distribution to all Involved ....

Referenced shear ram capabilities for high strength drill pipe landing strings on future BP wells, Bonsai and

Kasi<Jda .....

Tom .....

From: Louviere, Robert

sent: Thursday, June 16, 2005 6:43 PM

To: Colbin, George; Halvorson, Kathleen; Bowles, Tom T

Cc: Skelton, Jake

SUbject: FW: BOP Shear Rams

FYI .

From: Donohue, Steve [maUto:SDonohue@houston.deepwater.com]

sent: Thursday, June 16, 2005 3:45 PM

To: Louviere, Robert; Holst. Katy

Cc: Keetnn, John

Subject: RE: BOP Shear Rams

Bob,

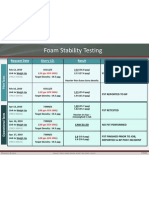

can't cut It with the SBR shear rams, but can c u t ~ with the casing shears. See attached chart. Although 50.4

S135, 6 5/8" pipe Is not tisted, 40.91s, and this Is already out of the pressure range for the SBR's. Note, the

Horizon has 4,000 psi available to both the casing shears and SBR's If required.

Regards

7/112005

EXHIBIT#

Ltcrtj

WIT: _____ _

TRN- MDL-00304884

TRN-M DL -00304884

CONFIDENTIAL

Message

Steve

-Original Message-

From: Louviere, Robert

Sent: Thursday, June 16, 2005 3:40PM

To: Holst, Katy

Cc: jkeeton@houston.decpwater.com;

SUbject: BOP Shear Rams

Katy,

Page 2 of2

Basic question has come up regarding BOP shear rams: willle rams shoat &518" 50.41 0.813 wr S-

1351andlng string if required tor any unforeseen reason? Asked a few folks here at BP. but no one was

definite In their response.

Pleasedarify.

Thanks,

Bob Louvlore

Sr. Drlnlng Englneoring Consul/ani

BP GOM Docpwolcr Exploration

Pl lono: (281) 366-3980

Cell: (337) 2585114

7/ 112005

TRN-MDL-00304885

TRN-MDL-00304885

()

0

z

11

5

m

z

-I

);

r

-I

;;o

z

~

0

r;-

0

0

(..)

0

...

())

())

Ol

.....

,....,

<.0

co

c:o

v

0

(V)

0

9

-'

0

~

z

a::

I-

CONFIDENTIAL TRN-MDL-00304887

TRN-MDL -00304887

Diverter valves

Quote and replace

BOPframe

Refurbish coating and anodes.

Pods

No maintenance required during the out of service period.

Tensioner air oil bottles

Thickness checks and borescope, diaphragms ok?

APV bottles

Thickness checks and borescope.

The plan forward is to remove the PODs from the BOP and store on the rig.

Separate the BOP, set on a barge and sent to Cameron or oil states for

disassembly and refurbishment of coatings on the BOP frame, replace anodes.

Recoat BOP components and assemble. Ray Pi chard and the Park 10 paint

supervisor to monitor .

. BOP SUPPORT EQUIPMENT

Under hull guidance system

Refurbish hydraulic cylinders, thickness checks on 2 ea. 15 gallon accumulators

thickness checks.

BOP gripper Arms

Purchase one each hydraulic motor and gearbox and replace, refurbish and rotate

remaining hydraulic motor and gearbox, refurbish cylinders if required, replace

hoses

LMRP gripper Arms

Purchase one each hydraulic motor and gearbox and replace, refurbish and rotate

remaining hydraulic motor and gearbox, refurbish cylinders if required, replace

hoses

BOP crane

CONFIDENTIAL TRN-MDL-00467329

c

CONFIDENTIAL

Refurbish main and aux gearboxes and hydraulic motor. We have a new motor,

gearbox winch assembly in Amelia 20 ton. We need to send to rig for condition

evaluation. Load Test.

BOP ttansporter

Purchase one each hydraulic motor and gearbox and replace, refurbish and rotate

remaining hydraulic motor and gearbox, refurbish cylinders if required, replace

hoses. Check rollers and bearings.

Recoil system

Verify throttling valves on air oil bottles operative. NOV due on the rig to

evaluate entire recoil system. Billy Stringfellow coordinating NOV. Mke Fy

traveling to Philadelphia Ohio to check on 6 tensioners on the ground that were

built for the new drill ships. It is believed these tensions have the infra red stroke

monitors already built in. If this is the case and the tensioners will fit the horizon

we should consider installing 1 or 2 of theses tensioners.

Cameron control system upgrade .

February 2009 quote 2, 1 OOK Mike Fry to send updated quote.

Riser Bolts

NDT and hardness checks due on approximately 40%

TRN-MDL-00467330

CONFIDENTIAL

250.445

anti ci pated surface pressures. antici-

pated methods of well control. t he sur-

r oundi ng environmenl. and Lhe corro-

siveness. volume. and abrasiveness of

drill ing tl utds and well fluids t hat you

n1ay encounter.

(b) Choke manifold components must

have a rated working pr essure at least

as gr eat as t he rated workmg pressure

of t he ram BOPs. If your choke mani-

fold has buffe1 tanks downstream of

choke assembl i es. you musL l nsLal l Iso-

lat ion valves on anv bleed lines.

(c) Val ves. pi pes.- flcx1ble steel hoses.

and :Jt hcr f!ttmgs upst r eam of the

choke manlfol d must have a rated

w01k ing prC'"-'<llrC' ;,t l<'a.<tt as gr<'<'lt as

t he r ated wor king pressure of the ram

BOPs.

[68 FR 8423. Feb. 20. 20031

250.445 What are the requirements

for kelly valves, inside nOPs, and

drill-string safety valves?

You must use or provide the fol-

lowi ng BOP eqUipment during dr il ling

operations:

(a) A k elly valve Installed below the

swivel (upper kelly val ve) :

(b) A kel lv valve Installed at the bot-

tom of the' l' elly (l ower kelly V<Jl vel.

You must be able to stnp the l ower

kelly valve th1ough the BOP stack.

(c) If vou drill with a mud motor and

use dri i l pipe Instead of a kelly. you

must Inst all one k elly valve above. and

one stnppable kelly valve below. the

joint of drill pipe used In pl ace of a

kell v

(d) "on a top-drive system equipped

w1th a remote-controll ed valve. you

must Install a s trlppabl e kel ly-type

valve below the remote-cont1oll ed

valve:

(e) An 1ns1de BOP m the open posi-

tion located on the rig floor . You must

be abl e t o i nstall an i nside BOP for

each size connecti on in the dri ll sttlng:

(f) /\ dnll-st rmg safety val ve 1n the

open position located on t he rig fl oor.

You must have a drtll -strmg safet y

val ve avai lable for each size connect ion

in the dri 11 string:

(g) When running casI ng. you must

have a safety valve in t he open positi on

avallable on t he r ig iloor to fit t he cas-

ing s tnng being run m t he hole:

(hJ All required manual and remote-

controlled k elly valves. drill-string

30 CFR Ch. II (7-l-Q4 Edition)

safety val ves. a:1d comparabl e-t ype

valves (i.e. kelly-type valve m a top-

dr i ve system) must be essentially ful l -

npPni ng: ;,nd

(l ) The dnll mg crew must have ready

<Jccess to a wrench to flt each m<Jnual

val ve.

[66 FR Feb 2C. 2003]

250.446 What arc the BOP mainte-

nance and inspection require-

ments?

(a) You must maint<Un your BOP sys-

tem to enst:re t hat the equipment func-

tions properly. BOP mai ntenance must

meet or exceed t he provisions of Sec

tions 17. 10 and 1&.10. Inspections: Sec-

Lions 17. 11 and 18 11. MalnLenance: a nd

SPct lons 17. 12 ami 13. 12. Q11allty M;,n-

agement, descr ibed in API RP 53. Rec-

ommended for Bl owout Pre-

venti on Equipment Systems for Drill-

mg Wells (tncol;:Joratec by n;rc,encc as

specified i n 250. 198) .

(b) You mt:st visu ally inspect your

sur face BOP syst em on a datly ba.s1s.

You must visually .Inspect your subsea

BOP svstem and rnanne nser a t least

once every 3 days if weather and sea

condilions permit. You Tllay use tele-

vision c3meras to Inspect subse3 equip-

ment.

[Sb FR Feb 20. 003)

250.447 When must I pressure test

the BOP system?

You must pressure test your BOP

system (this mcludes the choke mani-

fol d. kelly valves. inside BOP, and

dri ll -sning valve) :

(d) When mstal l ed:

(b) Before 14 days have elapsed si nce

your last BOP r;ressure test You muse

begi n to test your BOP system before

rnldnlglit on t he 14th d<Jy following t he

conclusion of the prev10us test. How-

ever . the District Supervisor may rc-

ql. lre more frequent testing If condl-

tlons or BOP performance warrant : and

(c) Befort- drlllh,g out A<'!Ch string of

casi ng or a !mer T:-tc District Super-

visor may allow you to omit thls test If

you d1dn"t remove the BOP stack to

run the casing str ing or liner and the

rPCJUil"Pd BOP test prpssures for thE'

next secti on of t he hole are not

t ha n t he test pressures for the previous

BOP test. You must Indicate In your

318

TRN-MDL-00495966

CONFIDENTIAL

Minerals Monogement Service, Interior

APD which st ri ngs <md llncrs

meet these crtte1ta.

[GS FR 8423. Feb. 20. 20031

2110.448 What are the BOP prel<sure

tests requirernents?

When you pressur e t est the BOP sys-

t em, y ou must conduct a low-pressure

and a htgh-pl-essUJe test for each BOP

component. You must conduct the low-

pressure test before the high-pressute

lesl. Each indivHiu;,l pressure lest

musr hol d lcnR enouRh to

demonstrate that the tested compo-

nent (s) holds the required pressure. Re-

quired test p1essures a1e as foil ows:

(a) Low-pressure test All l ow-pressure

tests must be between 200 and 300 psi.

Any p1cssule 300 psi must

be bled back to a pressure between 200

and 300 psi before starting the test. If

the initial pressure exceeds 500 pst, y ou

must bleed back to zero and re!mttate

the test.

(b) resr for rd17l-rype

BOPs. the choke manifold. and other

BOP components. The htgh-pn:ssure test

must equal the rated working

of the equipment or be 500 psi greater

than your calculated maximum anti ci -

pated surface pressure {MASP) for the

applicable section of hole. Befor e you

may test BOP equipment to the MASP

plus 500 psi, the District Supervisor

must have approved those test pres-

s u1es tn your APD.

(c) Htgh pressure test for annular-type

BOPs. The htgh pressure t est must

equal 70 percent of the rated wo1king

pressure of the equipment or to a pres-

sure i-!pproved m your APD.

(d) D11ratlon of prPSSIIre rest. Each test

mus t hold the required pressure for 5

mi nutes. However, for sur face BOP sys-

tems and surface equipment of a s ubsea

BOP system, <1 :>-minute test

ts a cceptable If you reco1d your test

pressur es on t he outermost half of a 1-

hour chart. on a J-hour chart. or on a

dtgltal recorder . If the equipment does

not hold t he required pressure durtng a

lest. you must correct the problem and

retest the affected component (s).

[68 FR 8423. F eb. 20. 2003]

250.450

250.449 What addit i onal BOP test i ng

requi rements must I meet?

You must meet the following a ddi -

tional BOP testing requ11ements:

(a) Cse water to test a surface BOP

system;

(b) St11mp tP.st r. s11bsea BOP systPm

before Installat ion. You must use

water to condu::t t h1s test. You may

use drilling flui ds t o conduct subse-

que!.t tests of a subsea BOP system:

(c) Alternate tests between control

stat10ns and pods:

(d) Pressure test the bltnd or bltnd-

sher. rr.m BOP dur tne st11mp test s and

at a II cast ng pot :.ts;

(e) The interval between any blind or

bltnd-shear ram BOP pressure tests

may not exrPed 30 days.

(f) Pressure test vanable bore-pipe

ram BOPs ;ogaJnst the lar gest and

smallest sizes oi pipe In use. excluding

drill collars and bottom-hole tools,

(gl Pressure test affect ed BOP com-

ponents followmg the disconnection or

repair of any well -pressure contaJn-

ment seal 1n the wellhead or BOP stack

assembly:

(h) Functwn test annular and ram

BOPs every 7 days between pressure

tests: nnd

(!) Act..!ate safety valves assembl ed

wtth proper cas1 ng connections befo1e

running casing.

[SS F R 842S, F eb 2C, 20031

250.450 What are the recordkeeping

f or BOP t ests?

You must r ecmd the time. date, and

results of all pressure tests. actuatJOns.

and tnspec;:tons of the BOP system.

system components, a"'ld manne nser

1n t he dri ller 's report. In addtuon, you

rnust :

(a) Recor d BOP test pressu1es on

pressure charts:

(b) Requi re your ensile representa-

tive to sign and date BOP test charts

and 1epots as correct :

(c) Document the sec;uenttal order of

BOP and aux1ltary equipment testing

and t he pressure and duration of each

test. For subsea BOP systems, you

must a lso record the closi ng C1Jnes for

annular and ram BOPs. You may ref-

erence a BOP test pl a n i f It is available

at the facility:

(d) I dentlfy the cont r ol station and

pod used dunng the test;

319

TRN-MDL-00495967

CONFIDENTIAL

250.451

(c) Identify any probl ems or irreg-

ul arities observed during BOP system

testlng and record acnons taken to

l'f>medy the problems or i iTE'gul aritie.c;;

and

(f) Retain nil records. including pres-

sure charts, dnller's report. and ref-

erenced documents pertai ning to BOP

tests. actuations. and inspect ions at

the faclllty for the duration of dril l ing.

[68 FR 8423, 20. 20031

250.451 What must I do in certain sit-

uations involving BOP equipment

or systems?

The tDbl e in this section describes ac

tions that lessees must take when cer-

Lain slluallons occur wtlh BOP sys-

tems durl ng drill ing rtct. ivlti es .

It you encounter the tollow1ng

situation:

(il) BOP oquipmont d ooto not

hold the required pressure

during a tcGt.

(b) Need Io repair or repl ace

a or s ubs:oa BOP

system.

(c) Io postpone o BOP

test due t o well-control

prot:lems SIJCh as lost

cu1stlon, fonnatlon fluid In-

flux, or stuck dr111 pl po.

(d) BOP control slalion or pod

that does n ot f unction pr op-

erly.

(o) \1/onl to dnll Yoith a t.:l-

pered

(0 Install casing rams In a

BOP stack.

(g) Wont to use An annul ar

BOP with a rated working

prouure loss than tho an-

tJclpa.ted surface pressure.

{h) Use a sut!:ea BOP sys-

t em In ice-10cour ar ea.

Thon you muct ...

Correct t he problem and

ret est the affocled equip-

mont.

F1rst place the well In a

controlled condtlon (o.g.,

before drilling out a casing

shoe or aller a ce-

ment plug, bridgo or

a packer).

Rocord tho for po::t-

poning lhe test in the

drillers report and conduct

tho roqulrcd BOP tom on

the 11rs1 t rip out of tho hole.

Suspend further drilling oper-

ations th.,.t station or

pod Is operable.

ln:.to1ll two or mora of

conventional or variable

b ore pipe rams in tho BOP

stack t o provide for 1he 1ol

lowing: two sets of rams

mut! bo o1 GoJ.Ilng

around t ho iorgor-sl2o drill

string and ono sot of pipe

rams must be of

seaJing around the srnal er ..

si ze drill &tring.

Test lhe ram bonnots before

running casino.

Demonstrate that your wei

control procedures or the

anticipated well

Wlll not place oemands

abcve it!: rit Ad working

ptca5Urc ond obtain np-

provol trom the District Su-

pervisor.

lnztaD t he BOP t:tacK In a

gl ory hole. The glory hol e

mu::.t bo docp enough to

ensure that the top of the

stack is bolow tho doopost

probable Ice-scour depth.

[68 F R 8423. Feb. 20. 2003]

30 CFR Ch. II (7-1-Q4 Edition)

DRl LLINI; fLl:JD

250-455 What arc the gen eral r equir e-

ments f or a drilling fluid program?

You trrust design and lmf.Jierrrent your

dnlllng fluid program to prevent the

loss of well This program must

address drilling flurd safe practlces.

testing and monitormg equipment.

drilling !luid qrirtnt.iri e.<: . rtnd dr illing

flutd-handltng areas.

[68 FR 84?::. F eb 20. 20031

250-456 What safe practices must the

drillinr.:- fluid proJ:ram follow?

Your dnlltng fluid program muse In-

clude the follow: ng safe practices:

(a) Before slarting oul of Lhe hole

with d r!L pipe. you must properly con-

di t ion the drilling fluid. You must ci r -

culat e a vol ume of dnllmg fluid equal

to the annul ar vol ume with the dri ll

pipe j ust off-bottom. You may omit

this practice if documentation in the

dril ler's report shows:

(I) No mdtcatlon of formatlon flUid

1nf1ux before starting :o pull the dnll

pipe fr-om the hcle;

(2) The weight of returning dri l ling

fluid IS within 0.2 pounds per gall on (1.5

pounds per cubic foot ) of the dri lling

flutd the ho:e; and

(3) Other fluid properties are

withi n thf:: limi ts e:cst<:tblished by the

program approved in the APD.

(b) Record each t ime you circulate

dnll l ng fluid 1n the hole m the dnllcr's

report;

(c) When coming out of the hole with

dri ll pipe. ymJ m11st fill the a nnul us

>>ith drilling fl uid before the hydro-

static pressure decreases by 75 psi. or

every flve stands of drill plpe. which-

ever gives a l ower decrease in hydm-

static pressure. Ycu must calculate the

number of stands of dr-: 11 pipe and dri ll

collars that you mc.y pull before you

must fi ll the hole. You must also cal-

culat e Lhe equivalent drill ing flu1d vol-

ume needed to fill the hole. Both sets

of numbers must be posted near the

dnl l er s statlon. You must use a me-

char:!cal. volumetric. or electronic de-

vi et: to measurf:: the drllllng fluid 1'!::-

qui r ed to fi ll the hole;

(d) You must run and pull drill pipe

and downhol e tools at controlled rates

so you de not swal:: or sJrge the well ;

320

TRN- MDL-00495968

CONFIDENTIAL

Minerals Management Service, Interior

(c) When thctc Is an indication of

swabbing or influx of formanon fluids,

you must take appr opr i ate measures to

control t he well. You must c1rcul:ote

and condition the well. on or near-bot -

tom. unless well or dr!lling-t1uid condi-

tions pre-vent runnlng the drill pipe

back to the bottom:

(i) You must calculat e and post near

the dri ll ers console the maximum

pressures that you may safely contain

under a shut-in BOP for each casing

string. The pr essures posted must con-

Sider the surface pressure at which the

formation at the shoe would break

down. tlc rated workt ng 1.wcssurc or

The BOP stack. 70 percPnt of casing

burst (or casing test as approved by the

Distrtct Supervisor). /\s a minimum,

you must post the follov.>i ng two pres-

sures:

(1) The surface pressur e at whtch the

shoe would bteak down This calcula-

tion must consider the current dtilling

fluid weight In the hole: vnd

(2) The lesser of the BOP"s rated

working pressur e or 70 percent of cas-

ing-burst ptessure (or castng test oth-

approved uy the District Super-

visor):

(g) You must install em oper able

dri lling fluid-gas separator and

de-gasser be-fote you begin dtlll1ng opet-

atlons. You must maintain this equip-

ment throughout the dr!lllng of the

well ;

(h) Before pulling dr ill -stem test

tools from rhp ha l!'. you must ctrculatP

or reverse-ci r cul ate the test fluids i n

the hole. If circulating out t est fluids

1s not fcas1blc. you may bullhead test

fluids out oi t he drill -stem test stl-tng

and Lools w!Lh an appr opriate kill

weight flUJd:

(i) When circulating. you must test

the drilling flUid at least once each

tour. or more frequently if conditions

wan-ant. Your tests must conform to

industry-accepted practtces and in-

clude, viscosi ty . <md gel

strength: hydrogcnlon conccnt l ation:

fi ltration : and any ot her tests the Dis-

trict Supcrvtso1 rcqutres for mont-

taring and mclintaining drilling fluid

prevc-nr l nn of downhole- eqtit p-

ment problems c:md for kick detection.

You must record the r esults of these

tests In the drtlllng fluid report: and

250 . .458

0l In Cl r CClS where permafrost and/or

hydrate zones are J=resent or may be

present , you must control drilling fluid

tpmpPri'ltllrPS to drill safely thtough

those zones.

FR Fc:u 20. 2003. dR FR 14271. Mar. 24.

2003]

250.457 What equipment is required

to monitor drilling fluids?

Once you establish fluid re-

turns, you mus: mstall and maintain

t he follov.:mg dnllmg flUJd-system

m::mltortng equlpmenr Th1oughour .sub-

sequent drill i ng operations. This eqmp-

men: must have the following lndtc3-

tors on t he rig floor:

(a) Pll level tndicalor La deLermlne

dri 11 1 ng f1 til cl -p! r vol 11 me ns ;mel

losses. This Indicator must include

both 3 visual and a n audible watmng

device:

(b) Volume measutl ng devt ce Lo accu-

cJrtPrminP GrtlJing fluid VOlumes

requi red to fil l the hole on t r ips:

(c) inCicat or dc,;ces that in

dicate t he relationship between dnll-

lllg fluid-return flow rate and pump

discharge rate. This indicator must ln-

clJde both a visual and an audible

warni ng device; and

(d) Gas-detecti ng eqt:ipment to mon-

Itor the dnlling fluid returns. The lnd!-

catot may be located tn the drtlllng

fluid-loggmg compartment or on the

rig rloor. I f the Indicators <lr c only in

the logging compartment. you must

continually man Lhe equipment and

have a means of Immediate commu-

with the rig floor. If the indi-

catots are or: the rig floor only. you

must Install an audible alarm.

FR R123. Feb 2C. 2003]

250-458 What quantities of drilling

fluids arc required?

(<l) You must usc. m<llntaln. <lnd rc-

plemsh quantities of dnlltng fl uid and

drilling fluid :natertals at the drill site

?.S t o ensure we-11 control.

You must determine those quantities

based on known or anticipated drilling

conditions, ng storage capacity.

weather conditions. and eSti mated

time for delivery.

(b) You must r ecord the daily mven-

tortes of dnllmg fluid and drtlling flUid

matenals, inclt:dlng we1ght materi als

321

TRN- MDL-00495969

CONFIDENTIAL

2SO.AS9

<J.nd <J.ddit lvcs in the drilling fluid re-

port.

(c) If you do nol have sufficient qu:om-

titles of drilling fluid and drilling fluid

material to maintain wel l control, you

must suspend dri lling operations.

[68 FR 8423, F cb. 20, 2003]

250.459 What are the safety require-

ments for drilling flui d-handling

areas?

You must classify dr1lli ng fluid-han-

dhng areas according to API RP 500,

Recommended Practice for Cl assifica-

tion of Locations for Elecnical Instal -

lations at Petrol eum Faclllttes. Classi -

fied as Class 1. Di vision l and Divtslon

2 (i ncorpotat ed by reference as speci-

fied in 250.198): or API RP 505. Rec-

ommended Ptactice for Classification

ot Locati ons for Electrical Installa-

tions at P etroleum Facilities, Classi-

fied as Class 1. Zone 0. Zone 1. and Zone

2 (i ncorpmated by refe1ence as speci -

fied 1n 250.198) . In areas where dan-

gerous concentrations of combustible

gas may accumulate. you must instal l

and maintai n a venti l ation system and

gas monitors. Drillmg fl uid-handhng

areas must have t he follo'.vmg safety

equipment:

(a) A ventilation system capable of

replacing Lhe air once every 5 minules

or 1.0 cub1c feet of air-volume flow per

minute. per square foot of area, which-

ever 1s greater. I n addition:

(1) If natural means pr ovide adequate

ventilati on. ventila-

tion system is not necessary:

(2) Tf a mechanical system does not

run conti:mously, chen it must acti-

vate when gas detectors i ndicate t he

presence of I percent or lTlore of con1-

bust1ble gas by volume: and

(3) If discharges fr om a mecharucal

ventilation system may be haza,dous,

then you must maintain the drilling

fluid-hattd11ng area at a negative ptes-

sure. You must protect the negative

pressure area by using at least one of

Lhe following: a pressure-sensi Live

a larm. open-door alarms on each access

to the area. automatic door-closing de-

vi ces. atr l ocks. or other deVices ap-

proved by t he Distnct Supervisor:

{b) Gas clet ecton; and al;onms except

in open areas where adequate ventila-

tion is provaled by natural means. You

must t est and r ecal!brate gas detectors

30 CFR Ch. II (7-1-QA Edition)

qcartcrly . No more than DO days may

elapse between tests:

(c) Explosion-proof or pressurized

electrical equipment to prevent t he ig-

nitton of expl osive gases. Where you

use au for pressunng equipment, you

must locate the air intake outside of

and as far as pract1cable fr om haz-

ardous area-;: and

(d) Al arms that activate when the

mC'chanl cal venti 1 at1 on system fn11s.

[G6 FR F cb 20. 2003]

OTHER DRILLING

* 250.460 What are the requirements

for conducting a well test?

(a) 17 you intend to conduct a well

test, you must include your projected

pl 1ms fat the test with yoUt APD (fatm

M:v!S-123) or m an Appl icat1on for Per-

mit to l\l.od1fv (APM) (form MMS-124).

Your plans n1ust include ar I east the

followinE! info1mation:

(!) Estimated flowing and shut-in

t ubing pressures:

{2) Est.mated r1ow rates and cumu-

lative volumes.

(3) Time duration of :Jaw, buil dup.

and drawdown periods:

(4) Description and rating of surfuce

and subsurface test equipment:

(5) Schematic drawing. showing the

I ayout oft est equi ;Jment:

(6) Description of safety equipment.

includmg gas detectors and fire-fight-

ing equipmC'nt:

(7) methods to handl e or

ttansport produced tlut :Is: and

(8) Description of the test procedures.

(b) You must the Dist rict Super-

visor at least 24-hours noti ce befo1e

starnng a well test.

[oS FR Feb 2C. 20031

250.461 What are the requirements

for directional and inclination sur-

veys?

For this subpmt, 1\AMS classif1es a

Wf'll as verti ca l if the calculated aver-

age of inclination readings does not ex-

ceed 3 degrees from the vertical.

{a) Survey rcqulrcmmtS for a vertica l

well. (l) You must conduct inclination

surveys on each vertical wel l anrl

record t.'1e results. Survey intervals

may not exceed 1.000 feet durt ng the

normal course of dnlllng:

322

TRN-MDL-00495970

CONFIDENTIAL

Minerals Management Service, Interior

(2) You must conduct d1rec-

tlonal survey that provides both lncll-

naUon and a:t.imuth. and d1g1Lally

tecord the results in electronic format:

(I) Within 500 feet of setting surfucc

or 1ntermed1ate casing:

(11) WiLhin 500 fe.,-t of selt mg any

liner: and

(Ill) When you reach total depth.

(b) Survey requirements for directional

well. You must conduct directional sur-

veys on each directional well and

digitally record the r esults. Surveys

must gtve both incllnation and azl-

ntuth at intervals not to exceed 500 fet:t

during the notmal coutse of drilling

Intervals dunng anglc-changmg pO!-

ttons of the hol e may not exceed 100

feet .

(c) :v!easurement whlle dnlling. You

may usc mcasUtcmcnt-whtlc-drllltng

technology tf It meet s the requt r e-

ments of this section.

(d) Composite survey requirements. (I )

Your composite directional survey

must show the 1 nterval from the bot-

tom of the conductor to total

depth. I n the absence oi conductor cas-

in:;?;. the survey must show the interval

from t he bottom of the drive or struc-

tural casing to total depth. and

(2) You must correct all surveys to

Universal-Transverse-Mercator-Grid-

north or Lambett -Grid-north after

n'IBkmp; the map;netic-to-true-nort h

conectt on. Sutveys must s how the

lllogne::Llc and grid used aJtd

include a listing of the directionally

computed incltnations and a:>Jmuths.

(e) Tf you drtll within 500 feet of an

adjacent lease. t he Regional Supervisor

mAy require you to flllnlsh " ropy of

the well's directional survey to the af-

fected l easeholder. Thts coul d occur

when the adj omi ng leaseholder re-

quests a copy of the su tvey for the pro-

tect JOn of cor rel ative nghts.

!GR FR R423. F Pb. 20. 20031

250.462 What arc the requirement.<

for well-control drills?

You must conduct a weekly well-con-

t rol drill with each drilling crew. Your

dr\11 must famtltartze the crew wtth Its

r ol es and functtons so that all crew

members can perform t heir duties

promptly and efficiently.

(a) Wel l-control dnll plan. You must

prepare a well comrol drill plan for

250.465

each well. You r plan must outline the

assignments fm ead: crew member and

esLabllsh limes Lo complete each por-

tion of the drill You must post a copy

of the well control drill plan on the rtg

tloo1 or bul:etin board.

(b) Timing o: drllls. You must conduct

each drill during a period of acttv!ty

that mlmm1zcs risk to drtlltng op-

erattons. The t lntng of your drills

must cover a range of differet1l oper-

ations. Includi ng d1tll ing with a di -

vertrr. on-bottom drll ling. and t np-

p!ng.

(c) Recordkeeping requil'ements. For

each cr1ll. you must record the fol -

lowhg in the dtiller's repor t :

( I) The tlme to be ready to close the

diverter or BOP system: and

(2) The tota: t ime to compl ete the en-

tire drill.

(d) lviMS ordered dnJJ. An !1.1MS au-

thonzed repres entattve may reqUlre

you to concuct a wel l control dri II dur-

mg an MMS inspectior .. The MMS rep-

resentative wi ll consult with your on-

site tepresemat1ve before tequirt ng the

dril l.

ISS FR 842:i. Fe-b 20. 2003]

250.463 Who establishes field drilling

rules?

(a) The Distri ct Supervisor may es-

tabl ish fie:d drilling rules different

frorr; the requir ements of this subpar t

when geolog1cal and engineering infor-

mation shows that specific operating

requir.,tttents ate approJ.>tiate. You

must comply with field dri ll ing rules

and nonconf.ict!ng requirements of

this subpart. The District Supervisor

may e mend or cancel fteld dril ltng

nJie.s at any ttme.

(b) You may request the District Su-

pervisor to establlsh. amend. or cancel

fiel d dnlllng rules.

!So FR. 842::, F<>b 2C. 20031

APPLYING f:OR A P ERl\tiT TO MODIFY AND

WELL RECORDS

250.465 When must I submit :m Ap-

plication for Permit to Modify

(APM) or an End of Operations Re-

port to MMS?

(11) You submit An APM (fmm

M:'v!S-124) or an End of Operat10ns Re-

port (for:-n MMS-i 25) and or her mate-

ri als to rhe Regional Supervisor as

323

TRN-MDL-00495971

CONFIDENTIAL

250.466

shown In the followi ng tabl e . You must

also submit a publ ic information copy

of each form.

30 CFR Ch. II (7-1-{)4 Edition)

When you Then you muot And

(1 ) tnlond to relllse your drDIIng

plan, change major drilling

equipment, or plugback..

SUbmn torm Z4 <X re- Recet\'e wrtnon cr otal approval toem lho Olstrlct SupoiVlsor

quest oral 3pproval. before you begin the intendod opor.otion. U you get an ap-

pro-val, you must submit fonn MM5-124 no later than the

end of tho 3rd buslne"" day following the oral approV'JI. In

nil eo.ooG, or you muot moot tho "ddltlonol roqulromontc In

p.1rogroph (b) ell t h s sOCII on.

(2) Determine a well's tlnnl sur-

face loc.a.tion, Wdter depth,

and the rotary kelly buohonq

NfiVittlon.

Immediately Submit .a form Sobmil a plot ccrlifiod by o re()iGtcrcd land sutvcyor lt'l ot

MM5-124. meeb the of 250.412.

(3) Move a drllng umt from a

wcllbore bolore complotlng a

well.

SUbmn forms SUbmit MilAs- S<A>mlt approprlale copies or the well rocods.

124 and MM5-125 Within 30

dayc; after the :.uscp:oion of

wenDore operallon!>.

(b) If you lt 1tend t o perform a.Joy of

the actions specified In pa,.agraph (a) (I)

of t his section. you must meet the fol

lowing add1ttonal r equt r <>ments:

(!) Your form MMS-124 must contain

a detai l ed statement of the proposed

work that vvi ll materially ch an ge from

the approved APD:

(2) YoUJ- form 1\ IMS- 124 must Incl ude

the present st atus of t he well . depth of

a ll casing strings set t o date. well

depth. present production zones and

productive c<.<p<:< bl ltty. and a ll other In-

formation spec( fl ed: and

(3) Withi n 30 days after completi ng

t hls wor k. vou must subm1t form

MMS-124

about the work to the Distri ct Super -

visor, unless y ou have already provided

suffi cient information In a Well Act iv-

ity Report , forrn MMS-133 (2SOA68(b) ).

[68 FR 8423. F.-b. 20. 2003]

250.466 What records must I keep?

You must keep compl ete, l egible. and

accurate records for each well. You

must keep drilling rPc.ords onslt P whil e

250.467 How long must I keep records?

drilling ocrlv1tl es Lurrtlloue. Aft er corrr-

pl etton of dnllt ng actlvtttes. you must

keeJ: all drilling ond othet v.:ell record::;

for the t 1me pettods s hown In 250. 469.

You k::cp thcsc rccords <:JL "' loCl:l-

tion of your choi ce. The r ecords must

contain cor.rpl cte information on a ll of

the followmg:

(a) Wel: ope:-ations:

(b) Descnpt!Ot1S of formations pene-

t r ated:

(c) Content and character of orl. p,as,

water, and other mineral depos1ts ln

each formation:

(d) Kind, wet g:-tt . s ize. grade. and set-

ting depth of casing:

(e) All well l ogs and su:-veys run In

t he wel l hare:

(f) Any stgnlftcant malfunction ot

probl em: a r .d

(g) All other Informati on tcqutred by

the Di.sttt ct Supervisor in the tnr erf>.sts

of resource evaluation. waste preven-

tion. conservation of natural r esources.

and t he protection of correlative

r ights . "'-nd Pnvironment .

I6R FR Ft>b ?C.

You must kPep for t he time periods ,<;hown In the fol l owing tablt>.

You must koop rocords: rolatins t::) Unttl

(a) Dnllrng .................................................................................... Nonety days aner you complete dnllrng operaloons.

(b) C;,clng :.nd llnor prcc,uro toch;, divcr1or tost,, ;,nd BOP Two yo.1r& ;,11of the co"nplotlon of drll'ng opcr.JtionG.

tests.

(c) Completion o1 a wei or of any workover aclMty that materi-- You permanently plug and abandon the well or until you for-

ally atter'S the completion configuration or affoctG a hydro- ward the records with o loa$e

c.arllon-bearing ZCM'le.

(68 F R 8423. F eb. 20. 20031

324

TRN-MDL-00495972

CONFIDENTIAL

Minerals Mcnogement Service, Interior

250.468 What well records am I re-

quired to submit?

(a) 'You must submit copies of logs or

charts of el ectrical. radioa ctive. sonic,

and other well-logging operations: di -

rectional and vertical-well surveys: ve-

locity p roflies and surveys: and anal-

ysiS of cores to MMS. Each Region will

provide specific lnsLruclioJ IS for sub-

mitting well logs <mel suJveys.

(b) For drilling operations in the

GOM OCS Region. you must submit

form Ml'v!S-133, Well Activity Report.

to the Dlstnct Supervisor on a weekly

(c) Fm dl'ill ing operati ons in the Pa-

Cific ot Alaska OCS Regions. you must

submit form MMS- 13:;, Well Activity

Report. to t he Distri ct Supervisor on a

dally baSIS.

FR Feb.

250.469 What other well records

could I be required to submit?

The Regional or Dtstrlct Supervisor

may require you to submit copies of

any or all of the followmg well records.

(a) Well records as specified In

250.466;

(b) Prlk ontolnglcnl lntrrpretatlnns or

reports 1dentlfy1ng microscopic fossi l s

by depth and/or w<Jshed s<Jmplcs of drill

cuttings that you normally maintain

for paleontological determinations.

The Regional Supervisor may Issue a

Notice t o Lessees t hat prescribes the

manner. t 1meframe. and format for

submitting t his information:

(c) Se1v!ce company reports on ce-

menting. perforating, acl diztng, test-

t ug. or other sllllllar services. o:

(d) Orher and records of oper-

a t ions.

[68 F R S423. 20.

HYDROGEN SL.'L!'JDE

250.490 Hydrogeo sulfide.

(a) What precautions must I take when

operating Jn an H:S a rea? You must :

(I) Take all necessary and feasibl e

precauti ons and measures to protect

persu11r ud from the:: toxir e:: ffe::cts of H:S

and to mitigate damage to property

and the environment caused by H:S.

You must follow the requi r ements of

th!s secuon when conducting dnllmg.

250 . .490

wcll-completi on!well-wor k over. and

pr oducti on operations in zones with

H:S present and when condu cting oper-

ations m zones where the presence of

H:S Is unknown. You do not need to

follow t hese r equirements when oper-

ating In zones where the absence of H,S

has been confi rmed: and

(2) Follow you r approved contingency

pl an.

(b) Defln!ttons. Terms used 1n this

section the followi ng meanings

Facl11ry means a vessel. a structure.

or an artificial island used for drilling.

well-compl eti on. well -workover. and/o1

pr oduction operations.

H,S absent means:

(I) Drilling. loggmg, coring, test mg.

or producing operati ons have con-

firmed the absence of H: S In concentra-

tions that coul d potent ially result in

atmospher l r concenl rallons of 20 ppm

or more of H:S: or

(2) Drllltng In t he surrou:1dtng areas

and correlallon of geological and s ei s-

mic data with equivalent stratigraphic

uni ts bove:: conflrrne::c! em aus e1 oce of H2S

throughout the a rea to be dnlled.

H2S present means that dr ill i ng. l og-

ging. coring, testing. or producing op-

erat i ons have conflrm::-d the presence

of H, S In concentratlcns and volumes

that could po:entially result in atmos-

phenc concentrations of 20 ppm or

mor e ofH1S.

ll

2

S un known means the deslgnatl on

of a zone or geologi c formation where

neither the presence no1 absence of H7S

h<Js been confirmed.

Well-control fluid :neans dnlhng mud

and completion or wor kover fluid as

appropriate t o the particul ar operation

bci ng conduct ed.

(c) Classifying an area for the presence

of H,S. You must:

{l) Request and obtain an approved

classification for the area from the Re-

g i onal Supervisor before you begin op-

erations. Cl assifications are '' H: S ab-

sent ." H,S present." or "H!S unknown":

(Z) Su bmit your request with your

application for permit to drill:

(3) Suppol't your re quest with DVDil-

ablc informati on such us ;.md

325

TRN-MDL-00495973

CONFIDENTIAL

250.490

geophysical und corrclutlons. well

l ogs. format i on t ests, cores and a nal-

ysts of formation fluids; and

(4) Submit request fot

tlon of a zone when addnional data In-

dicat e a different classification is need-

ed.

(d) What do I do if condi tions change?

If you encounter H: S that could poten-

t ially result In atmospheri c concentra-

t ions of 20 ppm or more in ar eas not

previously classified as having HoS

present, you must Immediately notify

MMS and begin to follow tequllements

for ar eas with HoS present.

(e) What are the requirements for con-

ducting simultaneous operations? When

rondur tlng any combination of drill-

ing. well-compl etion. well-workover.

and production operations simulta-

neously. you must follow the teqUire-

mem s in the secti on applicable to each

indJ vi dual operClti on.

(f) Requirements for submJWng an HoS

Contingency Plan. Before you begi n op-

erations. you must submtt an H0S Con-

tingency P l all to t h e Dtstl'i ct Super-

visor for approval. Do not begin oper-

ations before the Dlstnct Supervisor

ap[Jrove.o. y our pla11. You mu>.t keep a

copy of the approved pl an in the ftcld.

Htld you 11111St rull oW t h e plHll ;.t [ all

times. You1 pl an must Include:

(1) Safety procedures <md rules that

you wtll follow concerning eqUipment.

dnlls, and smoktng;

(2) Trnining you pmvi de fm employ-

ees. contractors. and visitors;

(3) Job posi t ion and t itle of the per-

son responsi ble for t he overall safety of

personnel;

{4) Other key positions. how these po-

sitions fit i nto your organi7.atl on. and

what the functions. duties. wd respon-

sibi lities of those job positions are;

(5) Actions that you will Lak e when

the concentration of l i:S In t he atmos-

phere reaches 20 ppm. who wil l be re-

spor.slble for those actions. and a de-

scription of the audible and visual

<t l>t rrns to be ><Ctlvat<d:

(6) Br!C'f!ng areas where personnel

wil l assemble during an H:S al ert. You

must have at l east t wo brteftng a reas

on each facility and use the briefing

t haT is upvvind of the H,S smtrr.e

at .:my ven time:

(7) Cntena you wtl l use to dectde

when to evacuate t he facillty a nd pro-

30 CFR Ch. II (7-1-().4 Edition)

ccdures you wil l usc to

a ll personnel from the facility by ves-

sel. capsule. or lifebcat. If you use hel i-

cnpt ers citJri ng H,S de_-;cti he t he

types of HoS emergencies dur ing which

you consider t he risk of hclicopt e1 ac-

tivity to be a cceptable and the pre-

cautions you will t ake duri ng the

flights

(8) Ptacedurcs you wtll usc to safel y

position a ll vessels attendant to the fa-

ctlity. Jndtcate where you will l ocate

the vessels with respect to direc-

tion. Include the distance from the fa-

ct:tty and what procedures you will use

to safely r elo::-ate the vessels i n an

emergency;

{!l) How you will provtde proterrlve-

breathmg equip:nent for all personnel.

including contrzctors and visitors;

(10) The agen:::es and factltt1es you

will noll!'y in case of a release of H:S

(that constitut es an emergency). how

you will not ify them. and their tele-

phone numbers. Include all fac!li t tes

that mtght be exposed to a tmosphenc

concentrations of 20 ppm or mor e of

H:S:

(II) The medi cal pers::mnel and

lle:; you "ill ' u:;e If needed. the! J ad-

dresses. a nd telephone numbers:

(12) H,S det,..ctor loc<-!rtons in prochl<:-

t ion fa::: l lit ies producing gas containing

20 ppm or more of H:S. Include an "H:S

Detector Locatton Drawmg" showmg.

(i) All vessels. fl are outlets,

WPll hea rls. othPt' eqlli pment h.<m-

dling product ion cont aining H

0

S;

(I I) /\pproxlr.tat e max1mum con-

centration of H:S i n the gas stream:

and

(tit) Location of all 1-I:S sensors i n-

cl uded i n your contingency plan;

(13) Operational condi tions when you

expect to f.are gas contai ni ng in-

c: l Jtli ng the estimated rnaximun t gas

now rate. H:S concentration. and dura-

tion at fl ar ing:

( 11) Your assessment of the nsks to

petsonnel during flar ing and what pre-

c>tutiot"'ry es you will t;;k e.

(15) P nmary a nd alternate methods

to ignite the fl ure <lll d procedures for

sustaining tgnltion and monltott ng the

status of t he fl are (I.e .. Ignit ed or ex-

t i ngllt."hPcl) ;

{16) Procedures t o shut off the to

the n a:-e tn t he event the flare ts ext m-

326

TRN-MDL-00495974

CONFIDENTIAL

Minerals Management Service, Interior

(li) Portable or fixed s ulphur dioxide

(SO::)-detection system(s) you will use

to determine SO: concentration and ex-

po!;ure whpn H,S is btnned:

(18) Increased monitoring and warn-

ing procedures you will take when the

SO: concentration In the atmosphere

reaches 2 ppm:

(19) Personnel protection measures or

evacuation procedures you w111 Initiate

when the SO: concentrotion in the at-

mosphere reaches 5 ppm:

(20) cont:-ols to protect

personnel from 50

1

: and

(2J) Any special equi pment. proce-

dures. or precautiOns you wtll use If

you conduct any combmation of drill-

ing, well -completion. well-workover.

and production operations simulta-

neously.

(g) Trammg program.

(I) When and how often do employees

need to be trained? All oper ators and

contract personnel must compl ete an

H:S training program to meet the re-

quirements of this section:

(i) Before begtrming work at the fa-

ctlity: and

(11) Each year. wlthln I year af'tet

C.:OITI!Jielion of Lhe pr evlous cla.ss.

(2) 'vVhat training documentation do T

n,.-d? F or each Individual working on

the platform. elthet:

(I) You must have documentat ion of

thts training at the faclllty where the

individual is empl oyed: or

(11) The employPe mu!;t catry

i ng completion card.

(3) What o-a1ntng do I need to gtve to

VJSJtors and employees preViously trained

on another facJJHy?

(1) Trained employees or contractors

transferred from another fadlity must

attend a supplemental briefing on your

H2S equipment and procedures before

beginning duty al your facility:

(!i) Visitors who w1ll remain on your

facility more than 24 hours must re-

ceive the tralrung requi r ed for employ-

ees by paragtaph (g)(4) of this section:

;.md

(iii) Visitors who will depart before

spending 24 hours on the facility arc

exempt from the train! ng r equired for

employees. but they must, upon ar-

complE't e a btleflng that In-

cludes:

(A) Information on the locanon and

use of an ass1gned resplrotor: practice

250.490

in donning and acjusting the assigned

respirator: information on the safe

bneflng areas, alarm system, and haz-

ard<: of H!S and SO,: -'lnci

(B) Instructions on t het r responslb!l-

ities in the event of an H,S rel ease.

(4) What training must I provide to all

othN employees? You must train all in-

dividuals on your fadllty on the:

(I) Hazards of H,S and of so, and the

provisions for personnel safety con-

tained In tr.e H,S Contingency Plan:

(ii) Projjer use of safety equipment

which :he employee may be tequlred to

use:

(Ill) Locat 1 on of protect 1 ve breath! ng

equl;:m1cnt . detectors and alarms.

ventil at ion equipme:ot. briefing

warrung systems. evacuation proce-

dt.:res. and the di rection of prevailing

winds:

(iv) Restrictions and correclive

measures concetmng beards. spec-

t acles. and cont act lenses ln conform-

ance wtth ANSI Z88.2. American Na-

tional Standarc for Respiratory Pro-

tection (incorpo1ated by reference as

specified in 250. 19R):

(v) Baste first-aid procedures applica-

bl e Lo victims of H1S exjjo.sure. Duri ng

all dril l s and training s essions. you

rnust rtcldrt<SS procedures for r escue Hnd

first aid fot H,S victims:

(Vl) of:

(A) The first -aid kit on the facil it y.

(B; Resuscitators: dl1d

(Cl L1 t ter nr other devt ce on t he fa-

ciilty.

(v11) Meaning of all warning s ignals.

(5) Do I need to post safety informabon?

You musL prom.lnenLiy posl safeLy 1n-

format10n on the fac1 lity and on ves-

sels serving the facl.tty (Le.. basic

frrst-md. escape routes. Instructions

for use of life boats, etc.).

(h) Drill!;. (!) When and how often do I

nee-d to conduct drJJls on 1 I:S safetv dis-

cussions on the facility? You must '

(IJ Conduct a dnll fo; each person at

the facility during normal duty hours

at 1 east 0 1 tee evPry 7-::Jay period T he

crills must consist of a dry-run per-

formance of personnel activit ies re-

l ated to assigned Jobs.

(II) At a safety meeting or other

meetings of all personnPl. discuss drill

performance. new H:S considerations

at the fac1hty. and other updated H,S

tnformat:on at least monthly.

327

TRN-MDL-00495975

CONFIDENTIAL

250.490

(2) What documenwtJon do I need( You

must keep r ecor ds of attendance fat:

(i) Drillml'(. wel.1-complellon. ami

well-work over operations at the facil -

Ity until opcrm1ons arc completed; and

(ii) Production operations at the fa-

cility ot at tltt' ttear est ftelt! office for

l year.

(1) VIsual and audtb)e wamlng sys-

tems-(1) How must T Install wind dlrcc-

Uon equipment? You rnust inst all wind-

direction equipment in a locati on visi -

ble at all t imes to indjvJduals on or m

the Immediate VlCJmty of the factl1ty.

(2) When do T nc::cd to dl.,;p)ay op.:r-

atlonal danger signs. display flags. or ac-

tfv<Jt<' visual or audible nlarms?

(1) You mus: dis play warnJng signs at

all limes on faci l!Lie:s with wells capa-

ble of producing II,S and on factltties

that pr ocess gas containing H,S In con-

centrations of 20 ppm at more.

(ii) In add! lion Lo the signs. you must

activate audibl e alarms a nd display

fl ags or activate flashing red lights

when atmospheric concentration of HzS

' eaches 20 pprn.

(3) What are che requirements for

Each sign must be a hi gh-vi si bility yel-

low col or with hl ack letteri ng as fol-

lows:

Lotter hlght Wording

12 ........ ...........

Poisonous Gas.

Hydrogen Sulfide.

7 inchet:> - Do not approoch H red fbg Iii

nytng.

(U"e appropriate wording at Do not approach red lights

right). arc flaMing.

(4) May I use exJsdng signs? You may

use existing s i gns containing the words

"Danget'-Hydrogett pro-

vided t he words 'Poisonous Gas. Do

Not J\pproach If Red Flag Is Flying" or

''Red Lights are Flashing" in l ettering

of a ntinimum of 7 inches in height are

displayed on a sign i mmediately adJa-

cent to the existing sign.

(5) What are the requirements f or flash-

ing lights or flags? You must aclivate a

sufficient number of lights or holst a

sufficient number of flags to be visible

to vessels and aircraft. Each !Jght must

be of s uffi cient Intensity to be seen by

approaching ve.ssels or aJtcrafl a ny

time 1t is activated (day or night ).

Each flag must be red. r ectangular. a

rrummum Width of 3 feet. and a mm-

i mum height of 2 feet.

30 CFR Ch. II (7-1-{)4 Edition)

(6) Wh<Jt is an <JudioJe wammg system?

An audible warning system is a public

address sys:em or siren. horn. or other

w;,rning clevice with n unique

sound used only for H,S.

(7) A:e there any other requi rements for

visual or audible wa."'l1ing devices? Yes.

you must:

(1) Illuminate all signs and flags at

night ;,nd 11nder condit ions of poor visi-

bil ity: and

(11} Use warning devices that are suit-

able for the electrical of

the a r ea.

(8) What actions must I take when the

il rP WhPn rhe ng

devices are activat ed. the designated

responsible persons must inform per-

sonnel of t he level of danger and 1ssue

lnstructtons on the initiation of appro-

;xot Prtlve me>tsures.

OJ H,s-derection and H,s monitoring

equipmen!-(1) What are che requirements

for a n dctcctio:1 system? An H,S de-

tection syst em must :

(i) Be capabl e of sensing a minimum

of 10 ppm of H,S i n the atmosphere:

and

(II) Activate audi bl e and VJsual

al arms when the concentration of

In the atmosphere reaches 20 ppm.

(2) Where must I have sensors for dl'iJJ-

Jt tg. we/1-<owpJerJor ' a1 td welJ-workover

operations? You must locate sensors at

the:

(i) Bell nippl e:

(11) ldud-return l ine receiver tank

(possum belly):

(Ill) Pi pe-trip tank :

(lv) Shale shaker:

(v) Wel>connol nu1u pit area.

(v1) Drill er 's stallon.

(vi i) L1vh8 quar.ers. a nd

(vll!) All other areas where H,S m3y

accumul ate.

(3) Co I :1eed mJd sensors? The Dis-

tri ct Supervisor may require mud sen-

sors In the possum bell y In cases

the <:unblcrtt <>ir scnsors In t he mud-re-

turn system do not consistently detect

the pcsence of H

2

S.

(4) How oft en must r observe the sen-

sors? Durtng dr i lling. well-completion

and well-workover operations, you

musr conrlnuously ohs<"I''VE' rhe H,S lt"v-

els indicated by the monitors in the

work areas dunng the followtng oper-

aoons:

328

TRN-MDL-00495976

CONFIDENTIAL

Minerals Management Service, Interior

(1) When you pull CJ wet s tring of drill

pipe or work over scri ng:

(i i) When circulating bott oms-up

after a dr!lllng break:

(11 1) During cemenllng operall ons:

(lv) During logging operations : and

(v) \.vhen c11 culatl11g to concllnon

mud or other well -control fluid.

(5) Whc-rc must 1 have sensors for pro-

duction opcmtions? On <J platform where

gas containing H2S of 20 ppm or geat!'r

is produced. processed. or otherwise

handled:

(I) Yo11 must have a sens o1 In rooms.

bu!ldings. deck areas. or low-laymg

deck 3re;;s not oche1w1se covered by

paragr aph 0) (2) of t his sect10n. where

otJ nosphtrlc conc..:ntrotloJ IS of H,S

could r each 20 ppm or more. You must

have at least one sensor per 400 square

feec of deck area m fractiOnal part of

400 square feet :

(11) You must have a sensor In build-

ings where peisonnel have their l iving

quarters:

(ill) You must have a sensor within 10

feet of each vessel. compressor. well-

head, manifold, or pump. which coul d

release enough H,S to resul t In atmos-

pheric concentrctl ons of 20 ppm at a

distance of tO feet from t he component :

(lv) You may use one sensor to detect

H:S around multiple pieces of equip-

ment. provided t he s ensor ts located no

mor e t hon 10 feet from eetch ptece. ex-

cept t hat you need to use at least t wo

sensors to moni tor compressors exceed-

ing 50 hosepower:

(v) You do not need t o have sensors

near wells that are shut ln at the mas-

ter valve and sea led closed.

(vi) When you deternune where t o

place sensors. you must consider:

(A) The location of system fittings.

fl anges. valves. and other devices sub-

ject t o leaks to t he atmosphere: and

(B) Design factors. such as t he type

of decktng " nd t he of fire

walls: and

(vi!) The Dist ri ct Supervisor may re-

qUire add1t10nal senso1s or other mom-

tonng capabllt ttes. If warranted by Site

specific conditions.

(6) How rrn tsr T funrrio,,;; //y resr rhe

Detectors?

(1) P ersonnel t r aJ :->ed to calibrate the

pa1t1cular H,S detectm eqUi pment

betng used must test detectors by ex-

250.490

posing t hem to CJ known concentr<Jtion

in t he range of 10 to 30 ppm of HzS.

(ii j If t he results of any functional

test are not within 2 ppm or iO percent,

whi chever is gceatei. of the appli ed

concentrati on . recahbrate the lnstru-

men: .

(7) How often must I test my detectors?

(\l When conduct ing dt\1 1\ng. drill

stem testing. well-completion. or well-

Wolkover operati ons i n areas classified

as H:S present or unknown. test all

detectors <J C least once ever y 24 hours.

When dnlling, bep,tn functional testinp,

before the bit Is 1,500 feet (venlcallyl

nhove t hP potent in! H,S zone.

(It) WhE'n conduct ing pr oduction op-

erat ions. test all detectors at least

ever y 14 days be: ween tests.

(lll) If equipment r eqUJres cahbr at1on

as a 1esult of two consecutive func-

Li onal Lests. Lhe Disll"icl Supervisot

may require that 1 hS-detectt on and

H.S-monitoring equi pment be function-

a lly test ed anc calibrated more fre-

quer.tl y.

(8) What documentation must 1 keep?

(1) You must ma in:a!n records of

testing and calibr ations (in t he drilling

or produccton operations report. as ap-

pli cable) ut the facili t y to show the

presE-nt status and history of each de-

vl :e. Includi ng dat es and deta1ls con-

cetnl ng

(A) Installation.

(B) Removal :

(Cl Inspection:

(D) Rep;nrs:

<E; and

(F} Remstall ation.

(ii) Records must be available fot i n-

spec: ton by MMS personnel.

(9) Whc.t ar e the requirements for near-

by vessels? If vessels a r e slatloned over-

ni ght al ongside facil ities in a reas of

H: S present or H:S unknown, you must

equi;J vessels With a n H:S-dctectton

system t :,at activates audi bl e and vis-

ual olonns whc:'1 t he conccnln:Jllotl of

H:S In the atmospheie reaches 20 ppm.

This rcqui cmcnt docs not apply to

vessels positi oned UJ:Wlnd and at a safe

distance from t he facility In accord-

nllce wirh r;,e posiricning prucenure de-

scrlbed ln t he a ppoved Conti n-

gency P l an

(IOl What are the requ:rements for near-

by fac11Wes7 The District Supervtsor

329

TRN-MDL-00495977

CONFIDENTIAL

250.490

require you to equip facUl-

ties w1t h portable or fi xed detec-

tor(s) and to test and calibrate those

dPtPctor:;. To invoke t his rPquirc>ment.

the District Supervisor Will consider

dispersion modeling results from a pos-

sible release to dete1m1ne If 20 ppm

concentration levels could be exceeded

at near by facti! ties.

(1 1) What I111..1St I do to protect against

50

2

1f I bum _gas contaJnJn_!! You

must :

(1) Momtor the concent r ation m

the ai r with portabl e or strategical ly

pl at:ed fixed devices capable of delecl-

1ng a m!n!mum of 2 ppm of so,:

(!l) Take readings at least hourly and

at <my time personnel detect odor

or nasal irntatlon;

(1 11) lmplemen"t the personnel protec-

tive measures specified tn the H,S Con-

tingency Pl<m If the SO, concentration

in the work area reaches 2 ppm; and

(iv) Calibrate devices every 3 months

if you use fixed or portable electronic

sensing devices t o detect SO,.

(12) :!>. lay I use altemaove mteasures?

You may follow alternative measur es

Instead of t hose !n paragraph (IJ (l l ) of

t hi s secti on i f you propose a nd t he Re-

gional approves the alter-

native measur es.

(13) What are the requirements for pro-

tectJve--bn:athlng L"'<JUipment? In an

cl ass1 f1 ed as I hS present or I hS un-

known. you must:

(i) Prov1de all personnel. mcludmg

contractors and visitors on a factlity,

with immediate access to self-con-

tai ned pre.s.sure-delnand-ty1Je 1 e.s-

pirators with baseline capability and

breathi ng time of at least IS minutes.

(II) Design. sel ect. use. and maintain

respirators in conformance wi t h ANSI

Z88. 2 (Incorporated by refenmce as

s peci fi Pd in 250. I 98}.

(til) }_fakt:: dVdllabl t:: at l t::dSt two

voi ce-transmission devices. which ca:1

be used while a rcspir;:J. t or. for

use by designated personnel.

(lv) Mak e spectacle kits avallable as

needed.

(v) Store protective-breathing equtp-

mr-nt In" lccrtrlon thi'lt is qlllrkly anrl

eastly accessible to all personnel.

(vi) Label aJJ breatbmg-aJr bottl es as

contammg breathmg-quahty atr for

human use.

30 CFR Ch. II (7-I -Q4 Edition)

(vii) Ensure thOJt vessels attendant to

fa::ilities carry appropriate protective-

breathmg equl pment for each crew

membe1 The District Supervisor

requtre additional protectlve-breachmg

equipment on certain vessels attendant

to the facility.

(vi ti) During H

2

S alerts. li mit heli-

copter flights to anc from faci liti es to

the conditions s pccl f:ed In t he l-1,S Con-

tingency Plan Duri ng authorized

fltghts, t he fl tght crew and passengers

must use pr essure-demand-type res-

ptJ-ators. 'l"ou must trai n all members

of flight crews !n t he use of the par-

ticular t vpe(s) of resp1 :ator equipment

made availabl e.

(lx) A<. appropriate to the par t i cular

operation(s). (producti on. dnlling.

well-completion or well-workover oper-

ations. or any combmat1on of them) .

provide a sysl em of breathing-air

manifolds. noses. and masks at the fa-

c!l!ty and the bnefmg areas. You must

provide a cascade atr-bottle system for

t he breaching-air manifolds to reftll tn-

divitlual proteclive-brealhing appa-

rat us bottl es The c ascade air-bot tle

system may be recharged by a hi gh-

pressure compr ess01 sui table for pio-

vldtng b1eathlng-qualtty a1t. provided

t he cotnpressm SI JCtt oi i Is located 111 an

uncontaminat ed atmosphere.

(k) Personnel S<Jf ety cqulpmcn t-(1)

What additional personnel-safety equip-

ment do I need? You must ensure t hat

your ir.riltty has;

(i) Portabl e detectors capabl e of

detecting a 10 ppm concentrati on of

H:S In t he air available for use by all

personnel ;

(il ) Retrieval ropes with safety har -

nesses to ret rieve Incapaci t ated per-

sonnel frorr. contamlna;: ed areas;

(111) Chalkboar ds a:1dlor note pads for

cor11rnunicalion puqJoses localeu 011

the ng fl oor. shale-sh;:1ker area. the ce-

ment-pump rooms. well-bay areas. pr o-

d"ccnon processing equipment area. gas

compressor area. and p1pel ine-pump

(tv) Bull horns and flashing ltghts:

and

(v) .<\t least three rcsusc1tato1s on

manned facilities. and a number equal

to t he pPtsonnel on not to f'X-

ceed three. on normallv unn1anned fa-

ct : tttes. compl ete With -face masks. ox-

ygen bottles. and spare oxygen bottl es.

330

TRN-MDL-00495978

CONFIDENTIAL

Minerals Management Service, Interior

(2) What arc d1e requirements for ven-

tilation equipment? You must :

(1) Use only explos1on-proof venttla-

t io:1 devices:

(11) Inst all ventil ation devices In

areas wher e H,S or SO, may accumu-

late: and

(ili) Provide movable venttlation de-

vices in work ar eas. The movable ven-

tilation devi ces must be mult!direc-

lioncJ and capable of dispersing H:S or

SO: vapors away from working per-

sonnel.

(3) What other personnel safety equip-

ment do I need? You must have the fol-

lowing equipment readily available on

each fac1l1ty:

(1) A first-aid ki t of appropriate size

and content for the number of pel-

sonnel on t he fac1hty: and

(11) At least one litter or

lent devi ce.

(1) Do I need to notify 1\IMS in the

event of an H,S release? You must notlfy

MMS Without del ay ln the event of a

gas release which results In a I S-

minute ti me weighted aver age atmos-

pheric concenttCltlon of H,S of 20 ppm

or 1110n:: anywhere on the fae1llty.

(m) Do I need to use special dr111ing.

completion a nd workover flu ids or proce-

du res? When wo rking in e.n area classi -

fied as H:S present or H;,S unknown:

(1) You :11ay usc either water- or oi l-

base muds m accordance wi t h

250.300(b) (1).

(2) If y ou usc water-base well-control

fluids, a11d lf ambient ai r sensors detect

H,S, you must immediately conduct ei-

ther the Garrett-Gas-TraJn test or a

compa table test for soluble sul fides t o

conf irm t he presence of

(3) If the concenLralion deLecLed by

air sensors in over 20 ppm. personnel

conducti ng the tests must don protec-

tlve-breachmg equipment conformmg

to paragraph Ol (13) of thls s ection.

(4) You must maintain on the facility

:suffick ut <]UHlltlttes of adrlit iv .. s for

t he cont rol of I hS. well-control fluid

pH. and cor rosion equ i pment .

(1) Sc<Jvcngcrs. You must h<Jvc sc<Jv-

cngcrs for conttol of H,S avat la bl e on

the facility. When Hz$ Is detected. you

mu.-;t add s cavE>ngE>rs as nt-E>oed You

must suspend unt il the scav-

enger IS ctrculated throughout the sys-

tem.

250 . .490

(it) Control pH. You must addi-

tives for t he cont 1ol of pH to water-

base well-control fluids In sufficient

qc::mr it.iP-"' r o ntain pH of le?..-;t

10.0.

(iii) Corrosion inhibitors. You must

add addluves to the well-cont rol flui d

system as needed for t he control of cor-

rosion.

(5) You must degas well -control

fluids cont aining at the optimum

l ocat ion --or the particular facility. You

must collect the r emoved and

bctn them m a cl osed flare system con-

for-mmg to paragraph (q) (6) of t his sec-

tion.

(n) What must l do in rhe event of a

kick? In t he evenr of a kirk. you mu.-;t

use one of t he following alternatives to

dispose of t he well-Influx fluids giving

cons1derat10n to pe1sonnel safety. pos-

s i ble envl ronmenLal damage. and pos-

si bl e facility well -equipment damage:

( 1) Contain the well-fluid Influx by

shutting In the wel l a nd pumpmg the

fluids back !n:o the formation.

(2) Conl rol the kick by using appro-

pri ate well-cont rol techniques to pre-

vent formation frac:urlng 1n an open

hol e wllhln Lhe pre;:,::;ure llmlts of the

well equi pment (dl'l ll p1pc. work s t1tng.

c;-1.-;ing. wcllhe..,d. BOP ,;ystem . ..,rod n :-

lated equipment ). The disposal of l l,S

and ot her gases must be through pres-

surized or at:-nosJ:;her\c mud-separator

equipment dependmp, on volume. pres-

sure ;mel concemrarton of H,S. The

equi?mcnt :nust be ceslgned to recover

well-control flUl ds and burn the gases

sepa rated from the well-control flUid.

The well-control fluid musL be treated

to neut r alize H: S and restore and

matnta!n t he proper qual!ty.

(o) WeJj testJng 1n a zone known to con-

tain When testing a well In a zone

with H,S pnsent. you musL do all of

the followmg:

(I) Before starting a well test . con-

duct safety meet ings for a ll personnel

who wil l be on the facility duri ng the

test . At T l 1e meet 111gs, <-'mphasJ7.e the

usc of protective-breathing equipment.

first-aid procedures. and t he Cont1n-

g::ncy Pl a n Only competent personnel

who ar e trained and are knowledgeable

oft he ri'ffert s of H,S must be

in these t ests.

(Z) Perform wel l testmg w1 th the

mlmmum numl::er of personnel in the

331

TRN-MDL-00495979

CONFIDENTIAL

250.490

immediate vicinity of the rlg floor and

w1th the approp nate test equipment to

safely and adequately perform the t est.

Duri ng t he test. y ou must conti nuously

monitor H,S l evels.

(3) Not bum pmduced gases except

through a flare which meets t he re-

qunements of paragruph (q) (6) of this

section. Before flanng gas conta!mng

H

0

S, you must activat e SO: monitoring

equipment in accordance with para-

graph of thls section. If you de-

tect S0

0

In excess of 2 ppm. you must

t mpl ement the personnel protecttve

measures i n your H,S Contingency

Pl a n. r c<julrcd by r.n ... -agaph (f)(13)(1v)

o f rhls sec:-T1on. You must a lso foll ow

the r eqUJ rement:; of 250. 1105. You

must pipe gases from stored test fluids

into t he :1ar e outlet a:'ld burn t hem.

(4) Use down"'ole test tools and well-

head equipment SUitable for serv-

ice

(5) UsC' Lubul ars suitable for H,S serv-

iLe You must not 11se d1ill pipe for well

testing without the prior appr oval of

the D1str t ct Supervisor . W<:.ter cush-

ions must be thoi'Oughly inhibited In

order t o prevent H:S attack on metals.

You must flush the test stnng flu1d

t r eated for this purpose after comple-

tion of t he test.

(6) Use surface test units and rel ated

equ ipment t hot ts designed for H,S

service.

(p) Merallur,t:;Jcd.l properrtes of equJp-

ment. When operating in a zone v.1th

H

2

S present . you must use P.rJUi pmenr

that is constructed of material s wi th

metallurgical prope1ties t hat resist or

prevent s ulfide str ess crackmg (also

known as hydrogen embrlttlement.

s tr"'ss cor rosloll or H:S l:!m-

bri ttlcmcnt ). chloride-stress crack in g.

hydrogen-I nduced cracking, and other

fallurc modes. You must do all of the

following:

(I) Use tubul ars and other equi pment.

C'a"iing. tubing. dri ll pipe. C'oupli ngs.

fl anges. and rel at ed equipment that 1s

designed for H:S service.

(2) Use BOP system components.

wel l head. pt-cssure-conti'OI equl pment.

and related equipment exposed to HzS-

he;n-tng flmds In conforman re wlth

NACE S t andard MROJ75-99 (lncor-

POI'ated by r eference as specified In

250. 198).

30 CFR Ch. II (7-1-{)4 Edition)

(3) Usc t empor ary downhole well -se-

curity devices such as retri evable

packers and bridge plugs t hat are de-

s i gned for H:$ servicP.

(4) When producmg in beanng

H:S. usc equipment constructed of ma-

tenals caj:able of resisting or pre-

venting sul fide stress cracking.

(5) Keep the use of welding to a min-

Imum duri ng the Installation or modi -

fi cation of a production faol lty Weld-

i ng be done 111 a :-nanner that en-

sures res1Sta11ce t o sulfide stress crack-

Ing.

(q) Generdl requ1rements when oper-

atln;< In an H,S zone-(!) Corln;< oper-

ations. \\-'hen you conduct cor ing oper-

a tions In H:S-bearlng zones. all per-

sonnel 111 the workmg ar ea must wear

protective-breathlng equipment at

l east 10 stands 111 advance of retrievmp,

Lhe core barrel. Cores Lo be Lransp01-Led

must be sealed and marked for the

presence of H,S.

(2) Logging operations. You must treat

and condition well-control fluid i n use

for l ugging upm-alion.s t o minl nuze the

ef:ects of H,S on t he l oggl ng equlp-

(3) Stripping D)JeraUons. P er:,OI mel

must monitor displaced well -cont rol

ll\l lcl ret urns protectlve-

b-eat hmg equipment In the working

a r ea wh en t he atmospher ic concentra-

tion of H2S r eaches 20 ppm or tf t he

well is under press..1re.

(4) G-'\s-rut well-control fluid or wpJl

kick from H:S- bearmg zone If you decide

to c-Ircul ate out a klcl.;, personnel in

the worki r.g area during bottoms-up

and exLended-klll operaL!ons musl weal-

protective-breathing equipment.

(5) DrJIJ- and workover-srring design

and precautions. Drill- and workover-

strlngs must be designed consistent

with the anlic1pated t..lept h . condi t ions

of the hole. and reservoir environment

to be encountered You must minimize

exposure of the drt ll- or \.\orkover-

sti-ing to high stresses as much as prac-

ticnl and coll:Slstt-llt with well condi -

tions. Proper handli ng techniques must

be taken to mirnmize notching and

sr-css concentrati ons. Precautions

must be taken to mi nimize stresses

causerl by dogl Pgs. Improper st I ffne_<;:<

ratios. 1mproper torque. whi p. abrasive

wear on tool J0111ts. and Jomt Imba l-

ance.

332

TRN-MDL-00495980

CONFIDENTIAL

Minerals Management Service, Interior

(6) Flare sysrcm. The flure outlet must

be of a diamete1 that allows easy non-

restricted flow of gas. You must locate

fl'lre line outlet!> on thP downsicie of

the facility and as far from the facility

as is feasible. taking into account the

prevrul!ng wmd directions. the wake

effects caused by the facility and adja-

cent structure(s). and the height of all

such fac111t1cs and structures. You

must eqU!p the flare outlet wlth an

automatic 1gn1tlon system 1nclud1ng a

p;as source or <m equivalent

system. You must have alternate

methods for 1gmnng the flare. You

must pipe to the flare system used for

H,S all vents from production pr ocess

equipment, ranks. rPiiPf valve. bursr

plates. and simil ar devices