Documente Academic

Documente Profesional

Documente Cultură

Trex 05351

Încărcat de

OSDocs2012Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Trex 05351

Încărcat de

OSDocs2012Drepturi de autor:

Formate disponibile

Minerals Management Service, Interior

you will follow in drilling the well. This prognosis includes but is not limited to the following: (a) Projected plans for coring at specified depths; (b) Projected plans for logging; (c) Planned safe drilling margin between proposed drilling fluid weights and estimated pore pressures. This safe drilling margin may be shown on the plot required by 250.413(g); (d) Estimated depths to the top of significant marker formations; (e) Estimated depths to significant porous and permeable zones containing fresh water, oil, gas, or abnormally pressured formation fluids; (f) Estimated depths to major faults; (g) Estimated depths of permafrost, if applicable; (h) A list and description of all requests for using alternative procedures or departures from the requirements of this subpart in one place in the APD. You must explain how the alternative procedures afford an equal or greater degree of protection, safety, or performance, or why you need the departures; and (i) Projected plans for well testing (refer to 250.460 for safety requirements).

[68 FR 8423, Feb. 20, 2003]

250.417

65, Recommended Practice for Cementing Shallow Water Flow Zones in Deep Water Wells (incorporated by reference as specified in 250.198), if you drill a well in water depths greater than 500 feet and are in either of the following two areas: (1) An area with an unknown shallow water flow potential is a zone or geologic formation where neither the presence nor absence of potential for a shallow water flow has been confirmed. (2) An area known to contain a shallow water flow hazard is a zone or geologic formation for which drilling has confirmed the presence of shallow water flow.

[68 FR 8423, Feb. 20, 2003, as amended at 72 FR 8903, Feb. 28, 2007]

erowe on DSK5CLS3C1PROD with CFR

250.415 What must my casing and cementing programs include? Your casing and cementing programs must include: (a) Hole sizes and casing sizes, including: weights; grades; collapse, and burst values; types of connection; and setting depths (measured and true vertical depth (TVD)); (b) Casing design safety factors for tension, collapse, and burst with the assumptions made to arrive at these values; (c) Type and amount of cement (in cubic feet) planned for each casing string; and (d) In areas containing permafrost, setting depths for conductor and surface casing based on the anticipated depth of the permafrost. Your program must provide protection from thaw subsidence and freezeback effect, proper anchorage, and well control. (e) A statement of how you evaluated the best practices included in API RP

250.416 What must I include in the diverter and BOP descriptions? You must include in the diverter and BOP descriptions: (a) A description of the diverter system and its operating procedures; (b) A schematic drawing of the diverter system (plan and elevation views) that shows: (1) The size of the annular BOP installed in the diverter housing; (2) Spool outlet internal diameter(s); (3) Diverter-line lengths and diameters; burst strengths and radius of curvature at each turn; and (4) Valve type, size, working pressure rating, and location; (c) A description of the BOP system and system components, including pressure ratings of BOP equipment and proposed BOP test pressures; (d) A schematic drawing of the BOP system that shows the inside diameter of the BOP stack, number and type of preventers, location of choke and kill lines, and associated valves; and (e) Information that shows the blindshear rams installed in the BOP stack (both surface and subsea stacks) are capable of shearing the drill pipe in the hole under maximum anticipated surface pressures.

[68 FR 8423, Feb. 20, 2003]

250.417 What must I provide if I plan to use a mobile offshore drilling unit (MODU)? If you plan to use a MODU, you must provide:

349

VerDate Nov<24>2008

10:16 Aug 12, 2009

Jkt 217119

PO 00000

Frm 00359

Fmt 8010 Sfmt 8010 TREX-05351 Y:\SGML\217119.XXX EXHIBIT

217119

S-ar putea să vă placă și

- Design Criteria StructuralDocument56 paginiDesign Criteria Structuralvenkiee100% (1)

- Reducing Tee PDFDocument4 paginiReducing Tee PDFpankrasius herbudiÎncă nu există evaluări

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Well PlanningDocument43 paginiWell PlanningAbrar Ahmed Khan100% (1)

- Design and Construction Standards For Public Water SuppliesDocument64 paginiDesign and Construction Standards For Public Water SuppliesLLÎncă nu există evaluări

- ASME B31.3: Code For Process PipingDocument53 paginiASME B31.3: Code For Process Pipingdipesh6030100% (2)

- Volume 7 Section 9 - P&ADocument11 paginiVolume 7 Section 9 - P&AM Zaki AHÎncă nu există evaluări

- PSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013Document72 paginiPSC Post-Trial Brief (Phase One) (Doc 10458) 6-21-2013OSDocs2012100% (1)

- Soil Investigation and Foundation DesignDe la EverandSoil Investigation and Foundation DesignEvaluare: 4.5 din 5 stele4.5/5 (9)

- CM Dashboard Arunachal PradeshDocument8 paginiCM Dashboard Arunachal PradeshDebashish Goswami100% (1)

- Predicting Drilling Mud Loss Occurrence While Using Directional Drilling To Install Pipelines Across RiversDocument20 paginiPredicting Drilling Mud Loss Occurrence While Using Directional Drilling To Install Pipelines Across RiversObumse Chukwuebuka MichaelÎncă nu există evaluări

- Well PlanningDocument55 paginiWell Planningmts1234100% (1)

- Design Practice For Piping Arangement (Pipe Rack)Document53 paginiDesign Practice For Piping Arangement (Pipe Rack)Chairul Anwar100% (2)

- Disposal Water WellsDocument4 paginiDisposal Water WellsRichi SBÎncă nu există evaluări

- Drilling Engineering (Pag403-424ing3)Document22 paginiDrilling Engineering (Pag403-424ing3)Aldo Aprian PratamaÎncă nu există evaluări

- WWW - Bca.gov - SG StructuralPlan Others Piling RequirementsDocument80 paginiWWW - Bca.gov - SG StructuralPlan Others Piling RequirementsLiu JianqiÎncă nu există evaluări

- Accomplishment Report in ESPDocument7 paginiAccomplishment Report in ESPAldrin Perez85% (39)

- Oil Tender Part 3Document40 paginiOil Tender Part 3Dhrubajyoti SonowalÎncă nu există evaluări

- Abrasive Water Jet Perforation and Multi-Stage FracturingDe la EverandAbrasive Water Jet Perforation and Multi-Stage FracturingÎncă nu există evaluări

- 33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 201912201346448977Document11 pagini33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 201912201346448977Ayman ElMawardyÎncă nu există evaluări

- Thrust and Anchor Blocks Design PDFDocument26 paginiThrust and Anchor Blocks Design PDFKS LeeÎncă nu există evaluări

- Drinking Water Well ConstDocument7 paginiDrinking Water Well ConstBhuiyan RazonÎncă nu există evaluări

- Final Informatics Practices Class XiDocument348 paginiFinal Informatics Practices Class XisanyaÎncă nu există evaluări

- Part417 Continuous Flight Auger PilesDocument5 paginiPart417 Continuous Flight Auger PilesNaga RjkÎncă nu există evaluări

- Method Statement For PaintDocument5 paginiMethod Statement For Paintxxx100% (2)

- DeWatering and Ground Water Control US Army Corp PDFDocument158 paginiDeWatering and Ground Water Control US Army Corp PDFhossinmaaÎncă nu există evaluări

- Relief Well Planning ChecklistDocument9 paginiRelief Well Planning Checklistbyed100% (2)

- NBIC Part 2 PDFDocument12 paginiNBIC Part 2 PDFjhonjimenez87Încă nu există evaluări

- Piling RequirementsDocument80 paginiPiling Requirementsapsapsaps1988100% (1)

- FHWA Shotcrete Guide SpecificationDocument7 paginiFHWA Shotcrete Guide SpecificationHector GalvezÎncă nu există evaluări

- (This Part Is PTSOM's Code of Practice, Volume 2 - Train System (CP2) "Drainage" CP-TS-958)Document16 pagini(This Part Is PTSOM's Code of Practice, Volume 2 - Train System (CP2) "Drainage" CP-TS-958)AlbanÎncă nu există evaluări

- Thought Leadership Is The New Sales PitchDocument8 paginiThought Leadership Is The New Sales PitchChad NelsonÎncă nu există evaluări

- Ballastless TracksDocument20 paginiBallastless TracksYacoub Cheikh67% (3)

- Approval of Deepwater Operations PlanDocument9 paginiApproval of Deepwater Operations PlankarthikeyanbemechÎncă nu există evaluări

- Sample Chapter - Oil and Gas Well Drilling Technology PDFDocument19 paginiSample Chapter - Oil and Gas Well Drilling Technology PDFDavid John100% (1)

- Foundation Investigation and Reports Foundation InvestigationDocument6 paginiFoundation Investigation and Reports Foundation InvestigationHundeejireenyaÎncă nu există evaluări

- Ministry of Energy and Energy Industries: November 30, 1996Document33 paginiMinistry of Energy and Energy Industries: November 30, 1996SAKÎncă nu există evaluări

- 15A NCAC 05H .1502 Well Site Construction StandardsDocument2 pagini15A NCAC 05H .1502 Well Site Construction Standardssigit praÎncă nu există evaluări

- 3 Requirements Regarding Submission of PlansDocument10 pagini3 Requirements Regarding Submission of PlansRavi ShankarÎncă nu există evaluări

- What Is A Well PrognosisDocument2 paginiWhat Is A Well PrognosisjennisAC100% (1)

- Ddokpukpuokopedhiwuluunuobodo Project EkpeyeDocument7 paginiDdokpukpuokopedhiwuluunuobodo Project EkpeyeAllswell ElleÎncă nu există evaluări

- Lifeboat ChecklistDocument12 paginiLifeboat ChecklistmfazioliÎncă nu există evaluări

- New Mexico Office of The State Engineer Dam Safety BureauDocument12 paginiNew Mexico Office of The State Engineer Dam Safety BureauYudhi Febrian100% (2)

- TheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Document60 paginiTheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Omar George Cayllahua SaicoÎncă nu există evaluări

- Oil Well DesigningDocument15 paginiOil Well DesigningShashank SacamuriÎncă nu există evaluări

- LifeboatChecklist Partie1Document2 paginiLifeboatChecklist Partie1baaziz2015Încă nu există evaluări

- 20210331Document2 pagini20210331aniketÎncă nu există evaluări

- Chapter 3Document18 paginiChapter 3VanhKhuyen ChimÎncă nu există evaluări

- Culvert DesignDocument21 paginiCulvert DesignIbrahim Ahmed Liban (Eng ibra)Încă nu există evaluări

- Petrobras N-2409-A2Document88 paginiPetrobras N-2409-A2traveller_16812847100% (4)

- PVD & PHDDocument9 paginiPVD & PHDMahbub AlamÎncă nu există evaluări

- Special Note 11c For Drilled ShaftsDocument9 paginiSpecial Note 11c For Drilled ShaftsM. SanjeevÎncă nu există evaluări

- Measurement of PilingDocument7 paginiMeasurement of Pilingwanyusoff62Încă nu există evaluări

- MSC Circ 406Document20 paginiMSC Circ 406Saurabh KulkarniÎncă nu există evaluări

- Outlet Structures: 2.3.1 Symbols and DefinitionsDocument20 paginiOutlet Structures: 2.3.1 Symbols and DefinitionsMihai MihailescuÎncă nu există evaluări

- PRG.E1-27.2020.07.10.Automatic Sprinkler SystemsDocument10 paginiPRG.E1-27.2020.07.10.Automatic Sprinkler Systemshassanqr89Încă nu există evaluări

- Sample Spec Jet Grouting PDFDocument11 paginiSample Spec Jet Grouting PDFJonathanÎncă nu există evaluări

- Vertical Alignment (Profiles) .: A. Cover Over PipelineDocument5 paginiVertical Alignment (Profiles) .: A. Cover Over Pipelinerathod.sanju8Încă nu există evaluări

- 33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 202201141044176218Document11 pagini33 05 07.13 Utility Horizontal Directional Drilling (HDD) - 202201141044176218Anonymous iTzCnMÎncă nu există evaluări

- Mechanical Integrity 2018 - Brian GravesDocument106 paginiMechanical Integrity 2018 - Brian GravesHosamMohamedÎncă nu există evaluări

- Completion Engineering - Best ChapterDocument26 paginiCompletion Engineering - Best ChapterihtxamÎncă nu există evaluări

- Pipeline GuidelinesDocument20 paginiPipeline Guidelinessidrana7Încă nu există evaluări

- Thrust Block DesignDocument26 paginiThrust Block DesignAmit KumarÎncă nu există evaluări

- Chapter 9 - Prestressing: WJ Martin 9.1 ScopeDocument21 paginiChapter 9 - Prestressing: WJ Martin 9.1 ScopeDr. MOHAMED ALZAINÎncă nu există evaluări

- New Dam Plan Review Checklist: General Design InformationDocument2 paginiNew Dam Plan Review Checklist: General Design InformationFikir YoÎncă nu există evaluări

- IS2911 (Part1sec2) 2005draft PDFDocument35 paginiIS2911 (Part1sec2) 2005draft PDFkanagarajodishaÎncă nu există evaluări

- DOJ Pre-Trial Statement On QuantificationDocument14 paginiDOJ Pre-Trial Statement On QuantificationwhitremerÎncă nu există evaluări

- To's Proposed FOF and COLDocument326 paginiTo's Proposed FOF and COLOSDocs2012Încă nu există evaluări

- 2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411Document41 pagini2013-9-18 Aligned Parties Pre-Trial Statement Doc 11411OSDocs2012Încă nu există evaluări

- 2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349Document13 pagini2013-9-11 BPs Phase II PreTrial Reply Memo For Source Control Doc 11349OSDocs2012Încă nu există evaluări

- To's Post-Trial BriefDocument57 paginiTo's Post-Trial BriefOSDocs2012Încă nu există evaluări

- BP's Proposed Findings - Combined FileDocument1.303 paginiBP's Proposed Findings - Combined FileOSDocs2012Încă nu există evaluări

- BP Pre-Trial Statement On QuantificationDocument13 paginiBP Pre-Trial Statement On Quantificationwhitremer100% (1)

- 2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlDocument13 pagini2013-09-05 BP Phase 2 Pre-Trial Memo - Source ControlOSDocs2012Încă nu există evaluări

- USAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)Document121 paginiUSAs Proposed Findings Phase I (Doc. 10460 - 6.21.2013)OSDocs2012Încă nu există evaluări

- HESI's Proposed FOF and COLDocument335 paginiHESI's Proposed FOF and COLOSDocs2012Încă nu există evaluări

- HESI's Post-Trial BriefDocument52 paginiHESI's Post-Trial BriefOSDocs2012Încă nu există evaluări

- BP's Post-Trial BriefDocument72 paginiBP's Post-Trial BriefOSDocs2012Încă nu există evaluări

- USAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)Document49 paginiUSAs Post Trial Brief Phase I (Doc. 10461 - 6.21.2013)OSDocs2012Încă nu există evaluări

- State of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)Document23 paginiState of LAs Post Trial Brief Phase I (Doc. 10462 - 6.21.2013)OSDocs2012Încă nu există evaluări

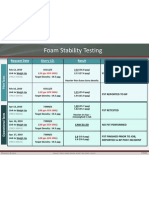

- Foam Stability Testing: Request Date Slurry I.D. Result CommentsDocument1 paginăFoam Stability Testing: Request Date Slurry I.D. Result CommentsOSDocs2012Încă nu există evaluări

- Exterior: Circa 2003Document1 paginăExterior: Circa 2003OSDocs2012Încă nu există evaluări

- Plaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013Document199 paginiPlaintiffs Proposed Findings and Conclusions (Phase One) (Doc 10459) 6-21-2013OSDocs2012Încă nu există evaluări

- State of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)Document22 paginiState of ALs Post Trial Brief Phase I (Doc. 10451 - 6.21.2013)OSDocs2012Încă nu există evaluări

- Macondo Bod (Basis of Design)Document23 paginiMacondo Bod (Basis of Design)OSDocs2012Încă nu există evaluări

- Arnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"Document5 paginiArnaud Bobillier Email: June 17, 2010: "I See Some Similarities With What Happened On The Horizon"OSDocs2012Încă nu există evaluări

- Driller HITEC Display CCTV Camera System: Source: TREX 4248 8153Document1 paginăDriller HITEC Display CCTV Camera System: Source: TREX 4248 8153OSDocs2012Încă nu există evaluări

- Circa 2003Document1 paginăCirca 2003OSDocs2012Încă nu există evaluări

- DR Gene: CloggedDocument1 paginăDR Gene: CloggedOSDocs2012Încă nu există evaluări

- Laboratory Results Cement Program Material Transfer TicketDocument13 paginiLaboratory Results Cement Program Material Transfer TicketOSDocs2012Încă nu există evaluări

- Circa 2003Document1 paginăCirca 2003OSDocs2012Încă nu există evaluări

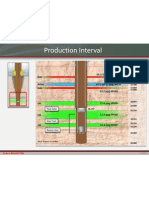

- Production Interval: 14.1-14.2 PPG M57B Gas Brine GasDocument1 paginăProduction Interval: 14.1-14.2 PPG M57B Gas Brine GasOSDocs2012Încă nu există evaluări

- April 20, BLOWOUT: BP Misreads Logs Does Not IdentifyDocument22 paginiApril 20, BLOWOUT: BP Misreads Logs Does Not IdentifyOSDocs2012Încă nu există evaluări

- End of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateDocument1 paginăEnd of Transmission: Transocean Drill Crew Turned The Pumps Off To InvestigateOSDocs2012Încă nu există evaluări

- Webster:: Trial Transcript at 3975:2-4Document1 paginăWebster:: Trial Transcript at 3975:2-4OSDocs2012Încă nu există evaluări

- MotRadar System PrinciplesDocument26 paginiMotRadar System PrinciplesReadmotÎncă nu există evaluări

- Kinematics of MachinesDocument2 paginiKinematics of MachinesBhavesh J MakwanaÎncă nu există evaluări

- Đề luyện tập 5Document5 paginiĐề luyện tập 5Nguyễn Duy TânÎncă nu există evaluări

- PDFDocument2 paginiPDFSalim AshorÎncă nu există evaluări

- Work Term Report GuidelinesDocument4 paginiWork Term Report GuidelinesWaleed WaleedÎncă nu există evaluări

- Performance of Trinidad Gas Reservoirs PDFDocument11 paginiPerformance of Trinidad Gas Reservoirs PDFMarcus ChanÎncă nu există evaluări

- Study of Deduru OyaDocument9 paginiStudy of Deduru OyaJGonÎncă nu există evaluări

- 4 Litre Closed SamplersDocument3 pagini4 Litre Closed Samplerslimhockkin3766Încă nu există evaluări

- Ba 206 LPC 03Document13 paginiBa 206 LPC 03rachna357Încă nu există evaluări

- Educational Design Research: Introduction and Illustrative CasesDocument24 paginiEducational Design Research: Introduction and Illustrative Casespatterson nji mbakwaÎncă nu există evaluări

- Population Forecast: The Population of Three DecadesDocument8 paginiPopulation Forecast: The Population of Three DecadesaejazÎncă nu există evaluări

- 2015 Lanzar Web Optimized PDFDocument58 pagini2015 Lanzar Web Optimized PDFrecursowebÎncă nu există evaluări

- Muse Score 3Document246 paginiMuse Score 3lejuan0Încă nu există evaluări

- 100-DBMS Multiple Choice QuestionsDocument17 pagini100-DBMS Multiple Choice Questionsbiswarupmca67% (3)

- Lecture 5Document33 paginiLecture 5nic_nishantÎncă nu există evaluări

- Burner, Series 6-26Document2 paginiBurner, Series 6-26Arshad SaifanÎncă nu există evaluări

- Fundamentals and History of Cybernetics 2Document46 paginiFundamentals and History of Cybernetics 2izzul_125z1419Încă nu există evaluări

- HDPE Pipe InstallationDocument7 paginiHDPE Pipe InstallationJeferson Binay-an100% (1)

- Kinematic Analysis of 5 Dof Lynx ArmDocument6 paginiKinematic Analysis of 5 Dof Lynx ArmsathyaÎncă nu există evaluări

- Ertalyte TXDataDocument5 paginiErtalyte TXDatavizcensoÎncă nu există evaluări

- PSS Report206Document90 paginiPSS Report206Abhishek TiwariÎncă nu există evaluări

- Installation, Operation, and Maintenance Manual: Ansi Process PumpDocument56 paginiInstallation, Operation, and Maintenance Manual: Ansi Process Pumpfaundes100% (1)

- Aiwa MC CSD-A120, A140 PDFDocument35 paginiAiwa MC CSD-A120, A140 PDFRodrigo NegrelliÎncă nu există evaluări