Documente Academic

Documente Profesional

Documente Cultură

Cash Flow Analysis

Încărcat de

Aditya PhatakDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cash Flow Analysis

Încărcat de

Aditya PhatakDrepturi de autor:

Formate disponibile

Analysis of Cash Flow Statement

Presented By:

Aditya Phatak Bhagyesh Pitale Dhanashri Pitale Garima Prakash Zeeshan Quershi Kundan Ramteke Gharendra Raut Prachi Raut Swapnil Raut Aniket Reddy 121 122 123 124 125 126 127 128 129 130

Topics Covered :

1. Analysis of profit per unit 2. Price Projections 3. Adequacy of Working capital Projections 4. Ratio Analysis 5. Justification of CapEx 6. Justification of Repayment of Debt 7. Justification of Dividend policy 8. Analysis of Macroeconomic data

ANALYSIS OF PROFIT PER UNIT

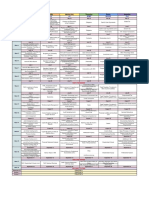

Year-> COGS Transportation Total Cost Total Increase % Price Price Increase % Margins Cost

2005 458 120 578

2006 523.5 128 651.5

2007 625.2 135 760.2

2008E 687.72 140 827.72

2009E

2010E

756.49 832.14 145 150

901.49 982.14

12.72% 16.68% 8.88% 728 734 0.82% 150 82.5 784 6.81% 23.8 846.77 8.01% 19.05

8.91%

8.95%

919.76 1000.8 8.62% 18.27 8.81% 18.66 2.13%

Margins %

45.00% 71.15% 19.96% 4.09%

The cost per unit is increasing YOY. However, if we continue to increase the price per unit with the cost per unit the profit per unit will be increased. Since selling price less than most of the competitors it will not have much effect on market shares.

PRICE PROJECTIONS

The projections regarding the total costs and selling price:-

As you can see we have taken a very conservative growth rate in years for which the forecasting is being done. We expect a minimum of 40% growth in sales in 2008, this has been considered due to sufficient advertising expenditure and past growth performance. We took a conservative forecast due to expected price hike. Further the growth rate of 20% and 10% in next two years is assumed to constant price hikes, even at the low margins and low growth rate the firm should be able to comfortably achieve its projections. Further the above price model is more sustainable as the estimation is very conservative in terms of margins and growth. According to our analysis we feel that the firm must have had a very underpriced product, because of which it could achieve such phenomenal growth numbers. And hence, we believe a constant price hike of 8% would not affect the market position considerably. Further even if the cost of each mattress goes up at a rate greater than our estimate the firm could easily afford to hike the price at 10-12% per annum. As the margin & growth predictions are as it is very conservative, it would not be very difficult to achieve the above figures.

ADEQUACY OF WORKING CAPITAL PROJECTIONS

Working capital is a measure of both a company's efficiency and its short-term financial health.

Here as we have calculated the working capital ratio, we can see that it increases from 20005(1.22) to 2007(1.64), it decreases in the year 2008(1.48). A declining working capital ratio over a longer time period could be a red flag for the company. But the projected working capital ratio increases in 2009(1.65) which is a good sign for company. The net cash for operating activities has been fluctuating, but net cash used in investing activities and financing activities have increased considerably. The projected working capital is reasonablely increasing and hence good for the companys survival.

RATIO ANALYSIS

Cash Flow Adequacy Ratio It indicates a company's capability of covering capital expense, debt repayment and dividends from cash flow generated from operating activities. It is calculated as Cash Flow Adequacy Ratio = (Cash Flow from Operations) / (Long-term debt paid + Fixed assets purchased + Cash dividends distributed) Significance: Cash flow adequacy is the primary measure of cash sufficiency. This performance ratio should have a value of 1 or higher. A ratio of 1 or more indicates that the company's operations produce sufficient cash to meet necessary business obligations. A ratio of less than one indicates potential liquidity problems. Year Cash Flow Adequacy Ratio 2005 0.97 2006 0.61 2007 0.79 2008 0.94 2009 0.80 2010 1.44

As we can see, the cash flow adequacy ratio is improving YoY basis from 2005 to 2007, which is a good sign for the company. In projections, it falls (conservative) in 2008 and then increases steadily in 2009 and 2010. In 2009, though they pay a large chunk of their debts, still cash flow adequacy ratio remaind in control, as they generate enough cash from operations.($1027m)

Dividend Payout Ratio:

The dividend payout ratio is the amount of dividends paid to stockholders relative to the amount of total net income of a company. The amount that is not paid out in dividends to stockholders is held by the company for growth. The amount that is kept by the company is called retained earnings. Net income shown in the formula can be found on the company's income statement. This formula is used by some when considering whether to invest in a profitable company that pays out dividends versus a profitable company that has high growth potential. In other words, this formula takes into consideration steady income versus reinvestment for possible future earnings, assuming the company has a net income.

2005 Year 0.14 Dividend Payout Ratio

2006 0.15

2007 0.15

2008 0.13

2009 0.11

2010 0.10

The dividend payout ratio is almost consistent at 0.15 in the years 2005, 2006 and 2007. In the projections, it is estimated to decrease, as dividend paid out is constant (1049m) despite of the net income projected to increase from 716.6m in 2007 to 1038.6m in 2010.

Long Term Debt Repayment: It is defined as the ratio of long term debt paid by a company to the quantity of cash flow derived from the operations for the period under consideration. In short,

Long term repayment ratio = __Long term debt paid__ Cash flow from Operations

b) Long Term Debt Repayment

2005 0.00

2006 0.43

2007 0.25

2008 0.03

2009 0.31

2010 0.02

As seen above, Long term repayment ratio has been very low (0.0011) in the year 2005. It has been descent in the years 2006 and 2007 (0.13 and 0.25 respectively). Then as per the projections, it will again decreases drastically in 2008 to 0.03. In 2009, as it is expected that company will pay of a major chunk of its long term debt (323.4m) the Long term repayment ratio will shoot to 0.31 which again reduces to 0.02 in 2010 As the company is in growth stage, it is expected that the company need a lot of cash for its expansion and operations. So it will be better if company keeps profits for expansions and pay off les amount of long term debt. In short, a low and constant Long term repayment ratio is expected. It is evident that in 2008, the company keeps cash for its expansion plans

Reinvestment Ratio: It is defined as the ratio of fixed assets purchased by the company to the cash flow from operations for the particular period. In short, it gives the amount the company reinvests in the business in terms of buying Fixed assets considering the cash flowing in due to operations. Hence the name Reinvestment Ratio. Reinvestment Ratio = __Fixed asset purchased__ Cash Flow from Operations

Year Reinvestment Ratio

2005 0.89

2006 1.05

2007 0.92

2008 0.92

2009 0.83

2010 0.76

As seen above, the company maintains it Reinvestment Ratio well above 0.9 from 2005 to 2007. In 2008 it is projected that it will maintain this ratio at 0.92 which is quite feasible. Also, on a conservative basis, the 2009 and 2010 figures are projected to 0.83 and 0.76 respectively.

Dividend payment ratio: Depreciation Impact ratio = (Depreciation + ammortalization expenses) Cash Flow from operations Recapitalization Ratio = Reinvestment Ratio Depreciation Impact Ratio

Summary Of Ratios : 1) Cash Flow Adequacy Ratio 2) Decomposed Ratios: a) Reinvestment Ratio b) Long Term Debt Repayment c) Dividend Payout Ratio 3)Depreciation Impact Ratio 4) Recapatalization ratio 0.97 0.89 0.00 0.13 0.32 2.78 0.61 1.05 0.43 0.15 0.39 2.69 0.79 0.92 0.25 0.09 0.21 4.38 0.94 0.92 0.03 0.11 0.29 3.17 0.80 0.83 0.31 0.10 0.26 3.19 1.44 0.76 0.02 0.09 0.23 3.3

JUSTIFICATION OF CAPEX Definition: Capital Expenditures (CAPEX) are those expenses incurred on property (excluding intellectual property), plant or equipment to: Augment the capacity of the network to meet demand growth; Replace ageing and obsolete assets; Extend the useful lives of network assets to beyond the standard regulatory lives; Improve the quality and reliability of supply; Make capital improvements that are necessary for meeting the established service quality targets and/or technical and safety obligations imposed by regulatory or statutory agencies; and Purchase or construct Non-network Assets required for the normal efficient operation of the Regulated Distribution System. Soft mattresses manufacturing company ABC Ltd. invested consequently from the year 2005 to 2007 in Capital Expenditures (CapeX). In the year 2005 it was 695.3 which is increased by 2.59% to 713.6 and later increased by 55.40% to 1108.8. It indicates that company had been more intended to invest in property, plant and equipment which gone help to increase the sale but in the estimated years 2008 to 2010 it shows constant invest in capeX. As it is sufficed to invest in assets so in the coming years company is focusing to invest in advertising as it plays major role in shot up the revenue. So in these estimated years companys investment in advertisement is growing up exponentially keeping PP&E expenditure at constant level.

JUSTIFICATION OF REPAYMENT OF DEBT

Following is the details of the long-term and short-term debt:-

As you can see from the above figures the company raised a long-term debt of 295.6 and 296.9 respectively in years 2006 and 2007. Further the company paid considerable short-term debts in these two years. In 2008 and 2009 the company aims to pay most of its long-term as well as short-term debt and the company does not a plan to raise any new debt post 2007. The reason for this may be that the company was previously in growth stage and had low sales. To have rapid expansion they had to raise considerable debt. But now that the company is in a favorable position it may be trying to pay-off its expensive long-term and short-term debt. This might be in view to reduce interest expense, which could hamper the already dwindling margins on sales. Further the company might feel that its retained earnings which are close to 85% of its net profit might be sufficient to fuel its future expansions.

JUSTIFICATION OF DIVIDEND POLICY

The company has paid a dividend of 104.8 million in 2005 and 105.2 million in 2006 which 0.38% more than the previous year. In the year 2007 the dividend paid by the company was 0.28% less than 2006 despite its earnings being increased by 0.47%. In estimated Cash Flow statement for 2008, 2009 and 2010 the dividend paid remains constant at 104.9 million despite its estimated growth increasing by 40% in 2008, 20% in 2009 and approximately 10% in 2010. Since the company is growing at a steady rate it can increase its dividend in order to satisfy shareholders expectations.

ANALYSIS OF MACRO ECONOMIC DATA Indian Polyurethane Industry is expected to grow at 15% in 2007-2012. India will consume 1 kg of polyurethane (PU) per capita by 2020 at 1200,000 tpa, as per a conservative estimate by the Chairman of the Indian Polyurethane Association (IPUA). Current per capita PU consumption in India is about 200 grams. The 1 kg per capita target will be possible, depending mainly on easing bureaucracy by the government that will speed up some of the processes and make it easy to set up factories and help to build infrastructure, as well as initiatives by the industry. At annual consumption levels of 180,000 tons of Polyurethane (PU) in 2007, India has just about 1.5% share of the global PU consumption of 11.25 mln tons. In the last few years PU has grown at over 15% pa, and is expected to continue to be robust at an average rate of 15%. PU consumption in 2012 could reach more than 350,000 tons and could possibly touch 400,000tons. Recent government reforms of the banking sector in India allow an environment where people feel more confident about investing. There is a classic trend in India's rising wealth and it's distribution, where availability of wealth is not only because of foreign investment, but mainly because of domestic entrepreneurs and businesses that are creating their own wealth within the economy. Increased consumer spending power of Indias evolving middle class is fuelling the demand growth for foam products. India has a population of over one billion people, of which it is estimated less than 10% sleeps on a foam-based mattress. Hence there exists a good growth potential growth for PU foam in India. However, the dominance of natural bedding products, at times subsidised or protected by import duties on substitute materials, has also hindered the market penetration of PU foams at times. The Indian bedding market is substantial and dominated by low cost coir (coconut fibre), latex and cotton mattresses, but people are increasingly looking to upgrade to higher quality products made from or incorporating PU foam. As their wealth increases, the comfort of PU foam mattresses is also becoming increasingly important along with rising standards of living in India. Foam production in India is still fragmented and localized, with many small players, while transport infrastructure and distances involved make it difficult for regional producers to expand. The market still requires a lot of development in terms of appropriate products, logistics and technical and marketing expertise. Standards in foam production vary widely among the smaller players, and need to be regulated. PU foam mattresses in India are generally restricted to low and medium density foams that contain lots of fillers. Indian PU market is very price sensitive in relation to alternative, value added products, hence better understanding of the technical issues around efficient, consistent production of good quality foams is also required. The rising demands of the cold chain and the retail boom will drive demand for commercial vehicles and change the face of the commercial vehicle business. When

farmers have little access to cold storage for their products, they are totally dependent on a local market to sell produce. Food rapidly spoils and harvests are damaged without such facilities in Indias hot and humid climate. The cold chain needs a dramatic improvement and this is one reason that demand for PU insulation is rising fast in the country. Insulation for the cold chain is becoming more widely needed, because food prices are going up, and the government is also advocating to build houses which are greener. North and Western India are major consumers of PU in India, the South is now developing very well, while the East is the smallest segment. Demand from the South is picking up because investments from automotive companies are changing the demand for flexible systems. Seating is by far the largest PU use in the automotive market. India's huge and ever-expanding market for two-wheelers is a growth sector for PU for seat foam. Total new passenger car production in India is around 1.6 million, with twowheeler production much higher than car production. India is a very fast growing market for uses such as insulation for construction, elastomers, flexible foam for car seats and also in ISF (integral skin foam) uses in furniture, but specific growth rates vary widely across the different PU segments. PU systems are growing at around 10-12%. Flexible PU applications constitute almost 70% of total PU consumption in India, while rigid applications constitute 21% share. Footwear at 13.5% is the third largest application, as PU soles have been replacing PVC soles in the past decade, and majority of the formal higher priced leather shoes use PU for soles. Despite some challenges in terms of higher cost and consumer acceptance, a robust GDP growth has improved the standard of living for a large aspiring middle income bracket group, who in order to upgrade their living standards are willing to spend. They have more disposable income, but demand total value for money and will increasingly resort to the use of PU for bedding, insulation and shoe soles. The Indian PU majors will need to show their far-sightedness and step forward and invest in this growing economy. Though the average size of PU foam manufacturer is small in India, the market is growing fast. Consolidation is unlikely because of the growth and the size of the country as the geographical distances throw up opportunities for multiple flexible foamers in different locations, since it is not feasible to ship foam country-wide across India. The PU industry is facing complex environmental challenges and opportunities, which it needs to deal with effectively, or it risks restrictions which will hurt the sector, limiting growth and adding costs. By 2012, Asia will have 3.5 mln tons capacity for PU materials, or 38% of global capacity. Several upcoming regulatory requirements on occupational exposure issues, emission limits, global warming, as well as the REACH regulations in Europe will pose problems for the PU industry.

S-ar putea să vă placă și

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Exercise No.4 Bus. Co.Document56 paginiExercise No.4 Bus. Co.Jeane Mae BooÎncă nu există evaluări

- Beta Bloomberg OtomotifDocument52 paginiBeta Bloomberg OtomotifayuvwxyzÎncă nu există evaluări

- ECG BoilerDocument1 paginăECG BoilerImaya ElavarasanÎncă nu există evaluări

- Lecture 12 - Recap (Solutions)Document19 paginiLecture 12 - Recap (Solutions)Stefano BottariÎncă nu există evaluări

- David H Friedman I Bet You ThoughtDocument36 paginiDavid H Friedman I Bet You Thoughtncwazzy100% (3)

- Curret Ratio Acid Test RatioDocument7 paginiCurret Ratio Acid Test RatioNIKHIL MATHEWÎncă nu există evaluări

- Mini Case Study of JP Morgan and ChaseDocument2 paginiMini Case Study of JP Morgan and ChaseMarvin niloÎncă nu există evaluări

- CV Stefano PasquarelliDocument1 paginăCV Stefano PasquarelliDaniele RocchiÎncă nu există evaluări

- ReSA Batch 46 ScheduleDocument1 paginăReSA Batch 46 ScheduleMica TolentinoÎncă nu există evaluări

- 31-The Forex GambitDocument6 pagini31-The Forex Gambitlowtarhk100% (1)

- Acc Company Profile of Endurance TechnologiesDocument12 paginiAcc Company Profile of Endurance TechnologiesPriya piyankaÎncă nu există evaluări

- Business Diary: Paul Trible, Paul WatsonDocument7 paginiBusiness Diary: Paul Trible, Paul Watsondiso1236Încă nu există evaluări

- COmpetitive Analysis Bank of BarodaDocument84 paginiCOmpetitive Analysis Bank of BarodaShubham Chavan0% (1)

- Application For Allotment of Industrial Plot/Shed in The INDUSTRIAL ESTATE ATDocument9 paginiApplication For Allotment of Industrial Plot/Shed in The INDUSTRIAL ESTATE ATDivyansh Shekhar RaiÎncă nu există evaluări

- FM 2 - Final ExamDocument4 paginiFM 2 - Final ExamNANÎncă nu există evaluări

- Circular Flow of Income and Expenditure in Two Three & Four SectorDocument23 paginiCircular Flow of Income and Expenditure in Two Three & Four SectorUP 16 GhaziabadÎncă nu există evaluări

- Musharakah by Sheikh Muhammad Taqi UsmaniDocument9 paginiMusharakah by Sheikh Muhammad Taqi UsmaniMUSALMAN BHAIÎncă nu există evaluări

- First Light Asia HSBC 18 Marco 2011Document40 paginiFirst Light Asia HSBC 18 Marco 2011lonely_investorÎncă nu există evaluări

- Phoenix Light SF Limited Vs Morgan StanleyDocument311 paginiPhoenix Light SF Limited Vs Morgan StanleyRazmik BoghossianÎncă nu există evaluări

- GEM LOPEZ TransactionsDocument12 paginiGEM LOPEZ TransactionsRon83% (6)

- Kathmandu Financial Group Case Study AnalysisDocument7 paginiKathmandu Financial Group Case Study Analysisjayan_unnithan2265Încă nu există evaluări

- F3 Mock Exam 1Document12 paginiF3 Mock Exam 1Smith TiwariÎncă nu există evaluări

- Oil and Gas Roundtable Members 29-5-15Document30 paginiOil and Gas Roundtable Members 29-5-15Quang Huy TrầnÎncă nu există evaluări

- PM Term SheetDocument19 paginiPM Term SheetVidya AdsuleÎncă nu există evaluări

- ACCOUNTING AllPapersDocument128 paginiACCOUNTING AllPapersAbbas AliÎncă nu există evaluări

- ALFM Peso Bond Fund Inc. - 202205 1Document2 paginiALFM Peso Bond Fund Inc. - 202205 1C KÎncă nu există evaluări

- Final Test HP0 PDFDocument22 paginiFinal Test HP0 PDFMỹ DuyênÎncă nu există evaluări

- Section 112 - Tax On Long-Term Capital GainsDocument2 paginiSection 112 - Tax On Long-Term Capital GainsParth UpadhyayÎncă nu există evaluări

- Econ CH 14Document12 paginiEcon CH 14BradÎncă nu există evaluări

- Transcript / Minutes of Conference Call (Company Update)Document20 paginiTranscript / Minutes of Conference Call (Company Update)Shyam SunderÎncă nu există evaluări