Documente Academic

Documente Profesional

Documente Cultură

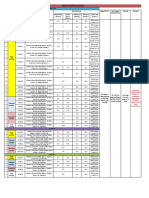

Ponderosa Farms 3-12

Încărcat de

Rockview FarmsDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ponderosa Farms 3-12

Încărcat de

Rockview FarmsDrepturi de autor:

Formate disponibile

ROCKVIEW FARMS -- BUILDING A PATH TO PROGRESS Some people might think the hot, arid region of the Amargosa

Valley in Nevada is an unlikely place for a dairy farm. But according to Amanda Arata, Dairy Manager for Rockview Farms Ponderosa Dairy, The area has ideal conditions for our organic and conventional dairy farming operations. The cows do well in this environment just look at how content they are! The 60 temperature on a clear winter day certainly seems ideal, but what about the hot summer months? Cows dont mind the heat so much as humidity thats what really drives up the heat index factor and makes them uncomfortable, according to Amanda. We get only about 3.8 inches of rain yearly and the humidity averages less than 14% in this region. That makes for ideal dairy farming conditions. Located off Highway 127, ninety miles north of Baker, Ponderosa Dairy is not likely a place youd pass on your way to somewhere else unless youre going to Death Valley, that is. Once there, however, you cant help but be impressed by the size, efficiency, and cleanliness of the operation. It Starts with the Cows For a cow to give milk, she has to have a calf. After spending a few months here in Nevada, the calves are transported to our ranches near Bakersfield, California where they graze on free-range grass until theyre bred and ready to have their first calf. Then, the springer heifers (what cows are called when theyre going to have their first calf) are brought back to Nevada to give birth and to enter the milking herd. Nearly 9,000 cows are milked twice a day at Ponderosa Farms in three state-of-the-art barns. Constructed of concrete, block, tile and stainless steel, these facilities are designed for the safety and protection of the animals and to ensure the efficient production of high quality milk. Animal welfare is a high priority and audits are conducted each year to ensure compliance. The barns are well lit and airy. Specially designed vents in the roof and huge fans overhead keep the cows cool and comfortable year round. Twice each day the cows eagerly walk into the barn and contentedly wait for the milking machines to be attached. The three barns are configured as follows: Barn #1, where the organic cows are milked, is a double 25 and was constructed in 1994. In this configuration, 50 cows can be milked at a time, 25 animals per side. Barn #2, a double 30, was constructed in 1996. Barn #3, a double 40, is the newest and largest of the three. Completed in February 2003, this barn replaces an outdated facility in Moapa (about 40 miles east of Las Vegas). In all three barns, milkers tend to the animals from a raceway about 3 below and between the two lines of milking stalls. The cows udders are thoroughly washed and dried before they enter

Page 1

the lanes where the milkers inspect the animals to make sure they are in good health and attach the milking machines. After milking, the cows teats are treated with emollients and an iodine solution that prevents bacteria from entering the milk ducts. Then the cows walk leisurely back out to their large openair pens and are treated to a nutritious diet of hay and mixed green feed. Quality milk starts with healthy animals and that is always first and foremost at Ponderosa farms. According to Amanda, Each cow consumes an average of 50 pounds of feed daily including 25 pounds of green feed. She drinks about 50 gallons of water and will give, on average, 70 pounds of milk daily (about 8 gallons). Thats not a high average because we dont inject our cows with rBST (artificial growth hormones) but it ensures the health of the cow and quality of the milk. After leaving the cow, the milk travels through stainless steel pipes to cooling plates and is chilled to 35. Its then briefly stored in stainless steel silos until an insulated tanker truck transports the milk to Rockview Farms (or other destinations) for processing and packaging. On average, one tanker truck leaves Ponderosa Farms every two hours around the clock. Protecting and Improving the Environment Ponderosas dairy farming operation is environmentally friendly. The entire site is elevated above grade so that storm water does not flow through the dairy. Two water retention ponds were constructed, each capable of holding 30 million gallons. 700,000 yards of dirt were moved to elevate the site thereby moving excess water off the corals and away from the animals. It is the first dairy in Nevada to have obtained an NPDES Permit, which declares it is in compliance with all Federal, State and local laws pertaining to storm water collection, retention and run off. By recycling organic dairy nutrients and improving the production level of existing fields the dairy has become an ongoing renewable resource in the community. Currently Ponderosa has 1,500 acres planted for feed. Roughly half of all the farming is organic including pastureland for grazing. Manure, composted by adding naturally occurring minerals, is used to supply valuable nutrients to the soil and turn the arid, desert floor into fertile fields. Dramatic increases in the cost of energy have lead to discussions for Ponderosa to begin converting methane gas into electricity. Its been estimated that they could produce enough methane to provide power to 6,000 homes. In addition to the three milking barns and farmland, the site houses a 14,400 square foot shop, four hay barns, and numerous other buildings. Ponderosa Dairy is able to produce half a million pounds of milk per day more than enough to supply Rockview Farms and all its valued customers with quality rBST-free conventional and organic milk.

Page 2

S-ar putea să vă placă și

- Sustainable Sheep ProductionDocument12 paginiSustainable Sheep ProductionOpirex100% (1)

- Ann Wigmore Chart For Raw Foods & Living Foods PDFDocument3 paginiAnn Wigmore Chart For Raw Foods & Living Foods PDFJYOTHI DÎncă nu există evaluări

- Beekeeping in WestDocument184 paginiBeekeeping in WestAle BioleÎncă nu există evaluări

- SausagesDocument205 paginiSausagescarlos sandovalÎncă nu există evaluări

- Keeping one cow: Being the experience of a number of practical writers, in a clear and condensed form, upon the management of a single milch cowDe la EverandKeeping one cow: Being the experience of a number of practical writers, in a clear and condensed form, upon the management of a single milch cowÎncă nu există evaluări

- Goat Farming Project ReportDocument43 paginiGoat Farming Project ReportRajpal BhargavaÎncă nu există evaluări

- Hydroponics Fodder Factory RsaDocument40 paginiHydroponics Fodder Factory RsaJose Castanedo100% (1)

- Salted Caramel Brownie Cookies - Baked by An IntrovertDocument3 paginiSalted Caramel Brownie Cookies - Baked by An IntrovertNASIMÎncă nu există evaluări

- Dirt To Soil - Chapter Four: Rethinking Our Livestock FocusDocument17 paginiDirt To Soil - Chapter Four: Rethinking Our Livestock FocusChelsea Green PublishingÎncă nu există evaluări

- Breeds of CattleDocument18 paginiBreeds of CattleStephen PradeepÎncă nu există evaluări

- Australian goat manual for Malaysian farmersDocument53 paginiAustralian goat manual for Malaysian farmersGeorge Feitosa Feitosa100% (2)

- The FarmMade Essential Skills Book: Handmade Projects from America's FarmersDe la EverandThe FarmMade Essential Skills Book: Handmade Projects from America's FarmersÎncă nu există evaluări

- Hydroponic FourrageDocument12 paginiHydroponic FourrageSalman LabiadhÎncă nu există evaluări

- PROJECT FOR ESTABLISHMENT OF BREED MULTIPLICATION FARM - Project AmritDocument23 paginiPROJECT FOR ESTABLISHMENT OF BREED MULTIPLICATION FARM - Project Amritsunlight architect100% (2)

- Product Catalog: Spring-Summer 2018Document40 paginiProduct Catalog: Spring-Summer 2018Andrea Ko50% (2)

- The Illustrated Guide to Cows: How To Choose Them - How To Keep ThemDe la EverandThe Illustrated Guide to Cows: How To Choose Them - How To Keep ThemEvaluare: 4.5 din 5 stele4.5/5 (6)

- KMF Project Report on OperationsDocument52 paginiKMF Project Report on OperationsRajeshShindhe70% (10)

- Going Green Cookery CourseDocument1 paginăGoing Green Cookery CourseMaria SolÎncă nu există evaluări

- AgricultureDocument13 paginiAgricultureSrikanth SÎncă nu există evaluări

- Dairy Cattle And Milk Production - Prepared For The Use Of Agricultural College Students And Dairy FarmersDe la EverandDairy Cattle And Milk Production - Prepared For The Use Of Agricultural College Students And Dairy FarmersÎncă nu există evaluări

- History of Jersey Farm Dairy, San Bruno, CaliforniaDocument36 paginiHistory of Jersey Farm Dairy, San Bruno, CaliforniapeninsulastoryÎncă nu există evaluări

- Statement of The ProblemDocument86 paginiStatement of The ProblemMedini Chippali100% (2)

- The Nexus: Horse Manure, From Waste To ResourceDocument8 paginiThe Nexus: Horse Manure, From Waste To ResourcesnohomishcdÎncă nu există evaluări

- Tour Report On Visit To "BAMUL - Bangalore Dairy"Document16 paginiTour Report On Visit To "BAMUL - Bangalore Dairy"Rohit100% (2)

- WIYLS visits £500,000 beef finishing shedDocument7 paginiWIYLS visits £500,000 beef finishing shedGalani MothobiÎncă nu există evaluări

- Livestock Fact Cards v1 WebDocument28 paginiLivestock Fact Cards v1 Webgw23shewardgeorginaÎncă nu există evaluări

- Shannon Brook Farm Newsletter 3-23-2013Document3 paginiShannon Brook Farm Newsletter 3-23-2013shannon_ratcliff_1Încă nu există evaluări

- Raising Commercial Ducks As A 4-H or FFA Project: The Origin of DucksDocument9 paginiRaising Commercial Ducks As A 4-H or FFA Project: The Origin of DucksMark Jovin RomÎncă nu există evaluări

- Research PaperDocument3 paginiResearch Paperapi-340376311Încă nu există evaluări

- Dairy Project ReportDocument8 paginiDairy Project ReportPramod52289% (9)

- Brooks Farms Environmental ManagementDocument9 paginiBrooks Farms Environmental ManagementZoey BrooksÎncă nu există evaluări

- Shannon Brook Farm Newsletter 4-27-2013Document2 paginiShannon Brook Farm Newsletter 4-27-2013shannon_ratcliff_1Încă nu există evaluări

- March15 BontempoDocument4 paginiMarch15 Bontempoapi-285432373Încă nu există evaluări

- High Welfare Milk Production IndiaDocument4 paginiHigh Welfare Milk Production Indiaarpit85Încă nu există evaluări

- 02 Jacob Springs Farm King Hodgson BidDocument7 pagini02 Jacob Springs Farm King Hodgson BidAndre HoussneyÎncă nu există evaluări

- PlanetLife - Feb12 - 2014Document7 paginiPlanetLife - Feb12 - 2014danfacebookÎncă nu există evaluări

- Housing For Dairy CattleDocument12 paginiHousing For Dairy CattleManasi KarankalÎncă nu există evaluări

- Statement of The ProblemDocument35 paginiStatement of The Problempradeepkallur100% (3)

- From Farms To Fridge: 2.bad Living Conditions in The FarmsDocument2 paginiFrom Farms To Fridge: 2.bad Living Conditions in The FarmsAndrei SbârneaÎncă nu există evaluări

- Dairy Farming - Wikipedia, The Free EncyclopediaDocument15 paginiDairy Farming - Wikipedia, The Free Encyclopediapuru0410% (1)

- Feedlot Fattening of Sheep & Goats PDFDocument50 paginiFeedlot Fattening of Sheep & Goats PDFYaserAbbasiÎncă nu există evaluări

- Stanton Farms New State-of-the-Art Dairy FacilityDocument23 paginiStanton Farms New State-of-the-Art Dairy FacilityswordprakashÎncă nu există evaluări

- Feedlot Finishing Fact Sheet FINAL - 4 26 06Document1 paginăFeedlot Finishing Fact Sheet FINAL - 4 26 06Jose CastanedoÎncă nu există evaluări

- KFCDocument4 paginiKFCOwais KhanÎncă nu există evaluări

- First Crop Coffee Rwanda Ruli MountainDocument2 paginiFirst Crop Coffee Rwanda Ruli MountainDaniel Dorje ByronÎncă nu există evaluări

- Evaluation of The Welfare of Cattle Housed in Outdoor Feedlot Pens1Document6 paginiEvaluation of The Welfare of Cattle Housed in Outdoor Feedlot Pens1Eric ChienÎncă nu există evaluări

- Raising Sheep Farm ManagementDocument5 paginiRaising Sheep Farm ManagementMoises CalastravoÎncă nu există evaluări

- Dairy Farming - Use of Hormones and AntibioticsDocument32 paginiDairy Farming - Use of Hormones and AntibioticsRaja TomerÎncă nu există evaluări

- School ReportDocument18 paginiSchool ReportAbhinayaa BalajiÎncă nu există evaluări

- Paso1 - Zuleima Papamija - P.RumiantesDocument11 paginiPaso1 - Zuleima Papamija - P.RumiantesZuleima PapamijaÎncă nu există evaluări

- Housing For Dairy CattleDocument8 paginiHousing For Dairy CattleMuhammad Saif KhanÎncă nu există evaluări

- Mini Tropics: Integrated Farming Don't Panic It's OrganicDocument15 paginiMini Tropics: Integrated Farming Don't Panic It's OrganicVijaya Raju VugginaÎncă nu există evaluări

- Story of The Chicken-The ProducerDocument10 paginiStory of The Chicken-The ProducerGeorge OparÎncă nu există evaluări

- 1861 O'Neill Ridge Farm PPDocument14 pagini1861 O'Neill Ridge Farm PPDermit8190Încă nu există evaluări

- Mangrove Crab Broodstock ManagementDocument22 paginiMangrove Crab Broodstock ManagementKristian Karl Bautista Kiw-is100% (1)

- Tree Nursery in CalgaryDocument2 paginiTree Nursery in CalgaryStraindichÎncă nu există evaluări

- Online Research (Farm Animals)Document7 paginiOnline Research (Farm Animals)chynaÎncă nu există evaluări

- Advantages of Hydroponics FodderDocument5 paginiAdvantages of Hydroponics FodderJohnÎncă nu există evaluări

- Cold Water HatcheryDocument71 paginiCold Water Hatcheryjoshigauta100% (1)

- CC F4P Newletter April 2018Document7 paginiCC F4P Newletter April 2018Laura LakeÎncă nu există evaluări

- 2016 - November Wildlife NoteDocument3 pagini2016 - November Wildlife NoteNicholas Ryan KolbeÎncă nu există evaluări

- Management of Dairy Cattle MenureDocument12 paginiManagement of Dairy Cattle MenureLathifahÎncă nu există evaluări

- Bryn Coed Duey Milking Parlor Stuff West Vincent TownshipDocument16 paginiBryn Coed Duey Milking Parlor Stuff West Vincent TownshipthereadingshelfÎncă nu există evaluări

- Channel Catfish: (Chapter 17)Document15 paginiChannel Catfish: (Chapter 17)Kezni SavitriÎncă nu există evaluări

- Project Proposal For Dairy Development Name& Address Sri Siddhivinayaka Ganesh Bhat, Bangaramakki, Gerasoppa, Honnavar TQ. U.Kannada, KarnatakaDocument8 paginiProject Proposal For Dairy Development Name& Address Sri Siddhivinayaka Ganesh Bhat, Bangaramakki, Gerasoppa, Honnavar TQ. U.Kannada, KarnatakaNarayana HegdeÎncă nu există evaluări

- SR - KG AUGUST MONTH WORKSHEETDocument12 paginiSR - KG AUGUST MONTH WORKSHEETeduMETA The i-SCHOOLÎncă nu există evaluări

- SegmentationDocument2 paginiSegmentationRajaÎncă nu există evaluări

- Deepak Memorialacademy School: Submitted To:-Submitted ByDocument24 paginiDeepak Memorialacademy School: Submitted To:-Submitted ByKhushi100% (3)

- Namagunga Primary Boarding School Primary Five Holiday Work - 2021 Social StudiesDocument10 paginiNamagunga Primary Boarding School Primary Five Holiday Work - 2021 Social StudiesMonydit santino100% (2)

- Tle 7 Farm Tools ActivityDocument6 paginiTle 7 Farm Tools Activityjessacles picklesÎncă nu există evaluări

- Fishmeal Ls PPT DefenseDocument40 paginiFishmeal Ls PPT DefenseManguera, Cy Thomas B.Încă nu există evaluări

- Agritech - Tnau.ac - in-ORGANIC FARMING Success StoriesDocument4 paginiAgritech - Tnau.ac - in-ORGANIC FARMING Success StoriesMoolam RaoÎncă nu există evaluări

- Suryakanta KhandaietalDocument10 paginiSuryakanta KhandaietalKuldeep DekaÎncă nu există evaluări

- The Complete List of Emulsifier CodesDocument8 paginiThe Complete List of Emulsifier CodesubaidÎncă nu există evaluări

- Deininger Et Al (1996) Mechanized Ensiled Beet PDFDocument7 paginiDeininger Et Al (1996) Mechanized Ensiled Beet PDFjjÎncă nu există evaluări

- Vertical Supports for Staple Food RiceDocument26 paginiVertical Supports for Staple Food RiceRaj RahulÎncă nu există evaluări

- Powerpoint Product DevelopmentDocument16 paginiPowerpoint Product Developmentapi-537851383Încă nu există evaluări

- Yam Ube-VarietiesDocument12 paginiYam Ube-VarietiesALL ABOUT PAGEANTARYÎncă nu există evaluări

- Ethiopian Livestock and Fisheries Sector Current Status and Future ProspectsDocument13 paginiEthiopian Livestock and Fisheries Sector Current Status and Future Prospectsfre mcÎncă nu există evaluări

- PBL Bio 2022Document17 paginiPBL Bio 2022DanishÎncă nu există evaluări

- Module 6 Tle Activity SheetDocument4 paginiModule 6 Tle Activity SheetMHAYLANI OTANESÎncă nu există evaluări

- McDonalds Food Supply Chain PDFDocument7 paginiMcDonalds Food Supply Chain PDFabishek reddyÎncă nu există evaluări

- Developing Processed Chocolate Agroindustry Based on Farmer Groups in Kapalo Koto VillageDocument8 paginiDeveloping Processed Chocolate Agroindustry Based on Farmer Groups in Kapalo Koto VillageGrace AngelinaÎncă nu există evaluări

- MUSCOVADO PRODUCTION AND MARKETING PROFILEDocument5 paginiMUSCOVADO PRODUCTION AND MARKETING PROFILEElle XcelsieÎncă nu există evaluări

- 2017 2 20 Feedlot Cattle Nutrition 2 PG PDFDocument27 pagini2017 2 20 Feedlot Cattle Nutrition 2 PG PDFMuhammadIbrahimÎncă nu există evaluări

- Species Scientific Name (Follow Proper Format) Main UsesDocument5 paginiSpecies Scientific Name (Follow Proper Format) Main UsesMARK LOUIE SUGANOBÎncă nu există evaluări

- Coffee BeansDocument1 paginăCoffee BeansTrần Thị Thanh NgânÎncă nu există evaluări

- Anp 306Document14 paginiAnp 306Oyewo SamuelÎncă nu există evaluări

- 30 CCT FATTENING PIGS Mixing Advice PDFDocument1 pagină30 CCT FATTENING PIGS Mixing Advice PDFHerman SsenkandwaÎncă nu există evaluări