Documente Academic

Documente Profesional

Documente Cultură

MT Savage Insulating Castables

Încărcat de

BenqbboilerDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MT Savage Insulating Castables

Încărcat de

BenqbboilerDrepturi de autor:

Formate disponibile

INSULATING CASTABLES

DELTA t CRETE BLOCK MIX DELTA t CRETE 18 DELTA t CRETE 20-35 DELTA t CRETE 20-LI DELTA t CRETE 20 DELTA t CRETE 20-M DELTA t CRETE 22 DELTA t CRETE 22-LI DELTA t CRETE 23-M DELTA t CRETE 23-M-LI DELTA t CRETE 25 DELTA t CRETE 26-LI DELTA t CRETE 26-M DELTA t CRETE 28 DELTA t CRETE 30 DELTA t CRETE 33 FIBERCAST 72

PRODUCT

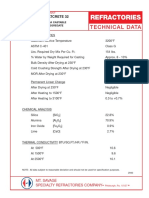

DELTA t CRETE BLOCK MIX

EXTREMELY LIGHTWEIGHT CASTABLE BLOCK INSULATION

REFRACTORIES

TECHNICAL DATA

1600F None 23 lbs. 150% 25 lbs./cu.ft. 70 - 100 psi 30 - 55 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 43.3% 7.8% 2.0% 39.4% Negligible -0.5 to -1.4%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F 0.51 0.73

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 6802

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 18

LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1700F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 42.3% 30.4% 6.9% 15.4% Negligible 0.0 to -0.3% -0.2 to -1.0% 1800F Class N 45 lbs. Approx. 70% 52 lbs./cu.ft. 400 - 650 psi 100 - 160 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.3 1.4 1.6

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 20-35

LIGHTWEIGHT CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1800F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 41.5% 33.6% 7.2% 14.2% Negligible 0.0 to -0.4% 0.1 to -0.8% 2000F Class O 30 lbs. Approx. 100% 35 lbs./cu.ft. 150 - 250 psi 49 - 90 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.0 1.2 1.4

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 20-LI

LOW IRON, LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

2000F Class O 33 lbs. Approx. 95% 38 lbs./cu.ft. 250 - 350 psi 60 - 110 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1900F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 43.1% 41.1% 0.3% 12.6% Negligible 0.0 to -0.2% -0.4 to -1.4%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.0 1.2 1.4

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 20

LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1900F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 40.4% 32.8% 6.6% 15.9% Negligible 0.0 to -0.2% -0.2 to -1.3% 2000F Class O 50 lbs. Approx. 62% 56 lbs./cu.ft. 450 - 750 psi 110 - 180 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.4 1.5 1.7

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 20-M

HIGH STRENGTH, INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1900F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 35.0% 39.1% 7.4% 17.0% Negligible 0.0 to -0.5% -0.3 to -0.9% 2100F Class P 62 lbs. Approx. 35% 67 lbs./cu.ft. 600 - 1050 psi 200 - 280 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 2.1 2.3 2.7

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 8810

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 22

LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2100F Negligible 0.0 to -0.6% -0.2 to -1.0% 2200F Class P 56 lbs. Approx. 45% 60 lbs./cu.ft. 500 - 800 psi 120 - 200 psi

CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 37.5% 36.9% 4.9% 16.1%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.4 1.7 1.9

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 22-LI

LOW IRON, LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

2200F Class P 45 lbs. Approx. 70% 51 lbs./cu.ft. 450 - 700 psi 130 - 210 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2100F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 47.2% 39.4% 0.5% 10.7% Negligible 0.0 to 0.1% -0.5 to -1.4%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 1.3 1.7 2.0

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 23-M

HIGH STRENGTH, INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2300F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 41.7% 34.9% 3.9% 15.5% Negligible 0.0 to -0.5% -0.6 to -1.1% 2300F Class Q 75 lbs. Approx. 30% 80 lbs./cu.ft. 900 - 1600 psi 250 - 360 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 2.3 2.5 2.8

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2940

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 23-M-LI

LOW IRON, LIGHTWEIGHT HIGH STRENGTH CASTABLE

REFRACTORIES

TECHNICAL DATA

2300F Class Q 70 lbs. Approx. 32% 76 lbs./cu.ft. 750 - 1500 psi 175 - 300 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2300F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 42.8% 43.5% 1.4% 11.8% Negligible 0.0 to -0.5% -0.6 to 1.1%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F At 1500F 2.1 2.4 2.7

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 8940

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 25

LOW IRON, LIGHTWEIGHT, INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

2500F Class R 50 lbs. Approx. 55% 54 lbs./cu.ft. 270 - 500 psi 90 - 150 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2300F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 37.2% 48.4% 0.9% 12.4% Negligible 0.0 to -0.3% 0.4 to 2.1%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2000F 1.4 1.9 2.3

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 26-LI

LOW IRON, LIGHTWEIGHT, INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

2600F Class R 50 lbs. Approx. 55% 54 lbs./cu.ft. 270 - 500 psi 90 - 150 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2500F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 37.2% 53.1% 0.6% 7.1% Negligible 0.0 to -0.3% 0.4 to 2.4%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2000F 1.4 1.9 2.3

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 26-M

LIGHTWEIGHT, HIGH STRENGTH FIRECLAY CASTABLE

REFRACTORIES

TECHNICAL DATA

2600F Class R 78 lbs. Approx. 30% 81 lbs./cu.ft. 780 - 1110 psi 260 - 370 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2500F Negligible 0.0 to -0.5% 0.0 to -0.9%

CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 43.3% 44.1% 1.6% 7.9%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2000F 2.4 2.6 3.0

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 8810

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 28

LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2700F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 41.1% 50.8% 0.9% 5.0% Negligible 0.0 to -0.3% 0.5 to 0.9% 2800F Class S 85 lbs. Approx. 28% 89 lbs./cu.ft. 800 - 1250 psi 200 - 350 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2500F 3.1 3.6 4.8

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2806

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 30

LIGHTWEIGHT INSULATING CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 2900F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 34.5% 58.8% 0.8% 4.0% Negligible 0.0 to -0.2% 0.2 to 1.6% 3000F Class U 87 lbs. Approx. 29% 91 lbs./cu.ft. 780 - 1050 psi 260 - 350 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2500F 3.0 3.6 5.8

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 8810

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

DELTA t CRETE 33

HIGH PURITY BUBBLE ALUMINA CASTABLE

REFRACTORIES

TECHNICAL DATA

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 3200F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 0.36% 92.7% 0.02% 6.8% Negligible Negligible 0.0 to -0.5% 3300F Class V 93 lbs. Approx. 25% 98 lbs./cu.ft. 1500 - 2500 psi 500 - 550 psi

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1500F At 2500F 6.1 5.0 5.2

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 2940

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

PRODUCT

FIBERCAST 72

FIBER REINFORCED LIGHTWEIGHT CASTABLE (CONTAINS NO ASBESTOS)

REFRACTORIES

TECHNICAL DATA

2400F Not Classified 80 lbs. Approx. 30% 87 lbs./cu.ft. 700 - 1100 psi 350 - 475 psi

PHYSICAL PROPERTIES Maximum Service Temperature ASTM C-401 Lbs. Required Dry Mix Per Cu. Ft. % Water by Weight Required for Casting Bulk Density After Drying at 230F Cold Crushing Strength After Drying at 230F MOR After Drying at 230F Permanent Linear Change After Drying at 230F After Heating to 1500F After Heating to 1600F CHEMICAL ANALYSIS Silica Alumina Iron Oxide Lime [SiO2] [Al203] [Fe2O3] [CaO] 32.7% 50.5% 1.2% 13.6% Negligible 0.0 to 0.2% 0.1 to 0.4%

THERMAL CONDUCTIVITY BTU/SQ.FT./HR./F/IN. At 500F At 1000F 2.6 2.9

NOTE: All data subject to reasonable deviation and should not be used for specification purposes. 8810

MT. SAVAGE SPECIALTY REFRACTORIES COMPANY

Pittsburgh, Pa. 15127

S-ar putea să vă placă și

- Super Heatcrete 32Document1 paginăSuper Heatcrete 32scax25Încă nu există evaluări

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Super Heatcrete 33Document1 paginăSuper Heatcrete 33scax25Încă nu există evaluări

- 4140 HTDocument2 pagini4140 HTwillys8Încă nu există evaluări

- Ultra-Green 45: Product DataDocument1 paginăUltra-Green 45: Product DataWatashi Wa Abilene RockanLoverÎncă nu există evaluări

- Valbruna Grade Steel TypeDocument3 paginiValbruna Grade Steel TypeLebasÎncă nu există evaluări

- PP-R Pipe GradeDocument6 paginiPP-R Pipe GradeRAJESHÎncă nu există evaluări

- Valbruna Grade Steel TypeDocument3 paginiValbruna Grade Steel TypeLebasÎncă nu există evaluări

- Supercritical PMIDocument76 paginiSupercritical PMIVinod Mahajan100% (1)

- Aisi A2: Cold Work Tool SteelDocument21 paginiAisi A2: Cold Work Tool SteelRahul NambiarÎncă nu există evaluări

- Remanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La CarteDocument36 paginiRemanit: Stainless, Acid and Heat-Resistant Special Steel Grades À La Cartepipedown456Încă nu există evaluări

- Extintor Portatil CO2Document2 paginiExtintor Portatil CO2CentralarmÎncă nu există evaluări

- KAOCAST®Document3 paginiKAOCAST®1repsaperuÎncă nu există evaluări

- CPM Magnacut - Technical Data: Your in Specialty MetalsDocument2 paginiCPM Magnacut - Technical Data: Your in Specialty MetalscpÎncă nu există evaluări

- Datasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Document7 paginiDatasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Rubén Leal RuizÎncă nu există evaluări

- Alloy 330 Spec SheetDocument2 paginiAlloy 330 Spec SheetArman MominÎncă nu există evaluări

- Spec 4140 & 4130Document7 paginiSpec 4140 & 4130Nisa_nisheÎncă nu există evaluări

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocument2 paginiAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonÎncă nu există evaluări

- Aux Boiler Final DWG Kangrim PA0501P32Document507 paginiAux Boiler Final DWG Kangrim PA0501P32Dario LušaÎncă nu există evaluări

- Commercial Gas Water Heaters: Models BTN 120-400 (A)Document4 paginiCommercial Gas Water Heaters: Models BTN 120-400 (A)xukaiauÎncă nu există evaluări

- Super Heatcrete 28Document1 paginăSuper Heatcrete 28scax25Încă nu există evaluări

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Document6 paginiDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderÎncă nu există evaluări

- High Temperature Hot Water BoilersDocument4 paginiHigh Temperature Hot Water BoilersRibhi HamdanÎncă nu există evaluări

- At Ice Machine Brochure EMAILDocument12 paginiAt Ice Machine Brochure EMAILRicardo Morán SilvaÎncă nu există evaluări

- Apmln 2019 07 15 - 13 23 57Document3 paginiApmln 2019 07 15 - 13 23 57yannÎncă nu există evaluări

- Aisi D2: Cold Work Tool SteelDocument7 paginiAisi D2: Cold Work Tool SteelEdilson Sarmiento AlonsoÎncă nu există evaluări

- Valbruna Grade Steel TypeDocument3 paginiValbruna Grade Steel TypeLebasÎncă nu există evaluări

- 468 PDFDocument4 pagini468 PDFJoshua WalkerÎncă nu există evaluări

- Materials Selection 3 PDFDocument2 paginiMaterials Selection 3 PDFnovell2003Încă nu există evaluări

- Steam Turbine Materials and Corrosion: Gordon R. HolcombDocument47 paginiSteam Turbine Materials and Corrosion: Gordon R. HolcombypoptoÎncă nu există evaluări

- Thermal Ceramics Kaolite 2500 LI Insulation CastablesDocument3 paginiThermal Ceramics Kaolite 2500 LI Insulation Castablesjoel cisnerosÎncă nu există evaluări

- MaterialData 6877Document2 paginiMaterialData 6877Maxi PianelliÎncă nu există evaluări

- Valbruna Grade Steel TypeDocument3 paginiValbruna Grade Steel TypeLebasÎncă nu există evaluări

- OvenDocument54 paginiOvenIsmail Hasan SaputraÎncă nu există evaluări

- Bohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelDocument2 paginiBohler-Uddeholm SUPERIOR® H13 Hot Work Tool SteelAgustine SetiawanÎncă nu există evaluări

- Quality 1.2329 Chemical Composition: Lucefin GroupDocument0 paginiQuality 1.2329 Chemical Composition: Lucefin Groupramelow1982Încă nu există evaluări

- Lecture-1, Maraging SteelsDocument30 paginiLecture-1, Maraging Steelssatish chinthamÎncă nu există evaluări

- Alluminium SheetsDocument7 paginiAlluminium SheetsVaibhav ShuklaÎncă nu există evaluări

- Alloy 330 Spec SheetDocument2 paginiAlloy 330 Spec SheetAA.KarandishÎncă nu există evaluări

- Saudi Pak TowerDocument8 paginiSaudi Pak TowerHamza EllahiÎncă nu există evaluări

- Ginplate Ni - 426: Technical Data SheetDocument7 paginiGinplate Ni - 426: Technical Data SheetLuuThiThuyDuongÎncă nu există evaluări

- Beryllium Nickel Strip: High Strength at Elevated TemperatureDocument4 paginiBeryllium Nickel Strip: High Strength at Elevated TemperatureImags GamiÎncă nu există evaluări

- Contact Material Beryllium Nickel Be NiStrip360 PDFDocument4 paginiContact Material Beryllium Nickel Be NiStrip360 PDFImags GamiÎncă nu există evaluări

- Datasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Document7 paginiDatasheet-Sanicro-69-En-V2022-10-26 14 - 22 Version 1Agustin CesanÎncă nu există evaluări

- Chemical CompositionDocument6 paginiChemical CompositionAkbar DarmawansyahÎncă nu există evaluări

- AISI 440 Martensit PDFDocument4 paginiAISI 440 Martensit PDFJimmyVargasÎncă nu există evaluări

- Cast Steel Is EquivalentDocument15 paginiCast Steel Is EquivalentParmasamy SubramaniÎncă nu există evaluări

- Actchem 85 85 RST 8-15Document1 paginăActchem 85 85 RST 8-15rivrsideÎncă nu există evaluări

- 100Cr6 PropertiesDocument1 pagină100Cr6 PropertiesRudrendu ShekharÎncă nu există evaluări

- ChassisDocument30 paginiChassisRavi KiranÎncă nu există evaluări

- m43 Aux. BoilerDocument657 paginim43 Aux. BoilerPavel PaskarÎncă nu există evaluări

- Annealing FundamentalsDocument41 paginiAnnealing FundamentalsSuvro ChakrabortyÎncă nu există evaluări

- Component List Efficent InsulationDocument5 paginiComponent List Efficent Insulationnikesh moreÎncă nu există evaluări

- Sandvik 254 Smo Tube and Pipe, Seamless: DatasheetDocument9 paginiSandvik 254 Smo Tube and Pipe, Seamless: DatasheetReadersmoÎncă nu există evaluări

- Green PipeDocument62 paginiGreen Pipecrebdt2017Încă nu există evaluări

- Variable Flow: Process Heating Solutions WorldwideDocument2 paginiVariable Flow: Process Heating Solutions WorldwidenitantharaniÎncă nu există evaluări

- Altret Industries Private LimitedDocument5 paginiAltret Industries Private LimitedJinalÎncă nu există evaluări

- ASSAB PM 30 SuperClean Brochure EnglishDocument12 paginiASSAB PM 30 SuperClean Brochure EnglishnithiÎncă nu există evaluări

- ISO 27001 Gap Analysis ChecklistDocument6 paginiISO 27001 Gap Analysis Checklistlijo jacob70% (10)

- Purposive Communication NotesDocument33 paginiPurposive Communication NotesAlexis DapitoÎncă nu există evaluări

- Vr31a OmDocument5 paginiVr31a OmrudydanielleÎncă nu există evaluări

- Technical Data Sheet: BS-510 All Pressure Solvent CementDocument1 paginăTechnical Data Sheet: BS-510 All Pressure Solvent CementBuwanah SelvaarajÎncă nu există evaluări

- A Comparison Study of Process Scheduling in Freebsd, Linux and Win2KDocument12 paginiA Comparison Study of Process Scheduling in Freebsd, Linux and Win2Kbenito agusÎncă nu există evaluări

- METR3210 Clausius ClapeyronDocument28 paginiMETR3210 Clausius Clapeyronshubhang2392Încă nu există evaluări

- 3rd QuarterDocument14 pagini3rd QuarterZula DapugoÎncă nu există evaluări

- Eco-Friendly Fire Works CompositionDocument4 paginiEco-Friendly Fire Works CompositionYog EshÎncă nu există evaluări

- Drone Survival GuideDocument2 paginiDrone Survival GuidevthiseasÎncă nu există evaluări

- Bc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreDocument60 paginiBc63kb8a Dy152 - 153 Vendor Drawing n001 Air Compressors SperreSimonaMauna33% (3)

- Open National Abacus Competition 2021 - Maats PVT LTDDocument8 paginiOpen National Abacus Competition 2021 - Maats PVT LTDRanjana GalphadeÎncă nu există evaluări

- BITS Pilani: Scale Up and Post Approval ChangesDocument56 paginiBITS Pilani: Scale Up and Post Approval ChangesshrikantmsdÎncă nu există evaluări

- BS9266 2013 Adaptable HousingDocument46 paginiBS9266 2013 Adaptable HousingGrant MastersonÎncă nu există evaluări

- Directional: 12 1/4in Sdi519 PDCDocument1 paginăDirectional: 12 1/4in Sdi519 PDCKhairatul Nada BurhanuddinÎncă nu există evaluări

- Engineers House Fire Fighting Course FP 01Document54 paginiEngineers House Fire Fighting Course FP 01Muhammad ElbarbaryÎncă nu există evaluări

- Siasun Company IntroDocument34 paginiSiasun Company IntromoneeshveeraÎncă nu există evaluări

- EE 720 - HW Set 3 - 1Document2 paginiEE 720 - HW Set 3 - 1Abdullah AL-RazemÎncă nu există evaluări

- 1 Ha Cabbages - May 2018 PDFDocument1 pagină1 Ha Cabbages - May 2018 PDFMwai EstherÎncă nu există evaluări

- h2s Naoh Equilibrium CurveDocument22 paginih2s Naoh Equilibrium Curvesmartleo_waloÎncă nu există evaluări

- TRG TRC001 en PsychrometryDocument89 paginiTRG TRC001 en PsychrometryhonismeÎncă nu există evaluări

- Sherman Notes PDFDocument213 paginiSherman Notes PDFAbdul Hamid Bhatti100% (1)

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument8 paginiHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILÎncă nu există evaluări

- APCO CSAA ANS2 101 1webfinalDocument38 paginiAPCO CSAA ANS2 101 1webfinalJUAN CAMILO VALENCIA VALENCIAÎncă nu există evaluări

- Development of Mmlps in India: Western DFC Eastern DFCDocument2 paginiDevelopment of Mmlps in India: Western DFC Eastern DFCsdfg100% (2)

- Roman Helmet From SivacDocument33 paginiRoman Helmet From SivacArachne DreamweaverÎncă nu există evaluări

- Brushless MotorsDocument20 paginiBrushless Motorsbwatkins6Încă nu există evaluări

- MYP Unit Planner - MathDocument5 paginiMYP Unit Planner - MathMarija CvetkovicÎncă nu există evaluări

- Chapter Vii. Damascius and Hyperignorance: Epublications@BondDocument10 paginiChapter Vii. Damascius and Hyperignorance: Epublications@BondRami TouqanÎncă nu există evaluări

- SAP EHSM - Risk Assessment - User Guide - Help FilesDocument15 paginiSAP EHSM - Risk Assessment - User Guide - Help FilesKishor Kolhe50% (2)

- Methley Railway Station: A Proposal To The Department For Transport.Document38 paginiMethley Railway Station: A Proposal To The Department For Transport.Rt Hon. Alec Shelbrooke, M.P.0% (1)