Documente Academic

Documente Profesional

Documente Cultură

Aplus Compactor

Încărcat de

Alex ChewDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aplus Compactor

Încărcat de

Alex ChewDrepturi de autor:

Formate disponibile

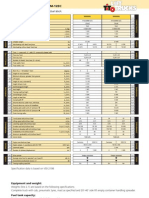

TECHNICAL SPECIFICATIONS

*Picture for illustration purpose only

REFUSE GARBAGE COMPACTOR

16+1,5 m

A-PLUS MANUFACTURING SDN BHD Lot 7755, Jln Mangga, Bukit Cherakah 40150 Shah Alam, Selangor, MALAYSIA Tel: 03-78469397 Fax: 03-78423646 9404 Mobile: 019-2364236 Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

SPECIFICATIONS

Dimensions Dimensi

Technical Information Teknikal

Body Width (Outer) : 2310 x 2010 mm Saiz Badan (Chamber) 2310 x 2010mm

Body Inside Dimensions

Body Length can change depending on the vehicle.

Width 2140mm

Height 1850mm

Saiz Badan

Body Size

16+1,5 m

Jenis Bahan Ketebalan

Body Iron-Plate Thickness

Keluli Tegangan Tinggi Spec ST57/ High Tensile Steel Spec ST57 Lantai 4 mm Tepi 3mm Atas 3mm Floor 4 mm Sides 3 mm Ceiling 3mm

Hydraulic Cylinder 9 Units

Hidraulik Silinder

Kapasiti Hopper

Hopper Capacity

1,5 m

BERAT

WEIGHT

Badan dan Chassis

Body and Chassis

It changes depending on the vehicle.

Berat Badan Body Weight

5800 Kg

Berat Chassis

Chassis Weight

It changes depending on the vehicle

Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

NO PARAMETER 1

SPECIFICATION

General Design The design construction and mounting of the body is to meet the Health and Safety.

Quality Manufacturer Ayalka is Certificate & currently registered Capability with relevant registration standards for construction & welding, and is to be able to proof production and sales in case its necessary according International DIN EN 1501 standards.

2 3

Install The superstructures assembly shall be realized According to the trucks superstructure installation directives. The superstructure shall be mounted with rigid connection at rear, and flexible connection in front to provide the required elasticity. AAK 16 Ayalka brand rear loading garbage compactor. Compactor Body Dimensions Dimensions can only be (mm) - interior given according to truck chassis dimensions. Capacity (m) 16 m excluding hopper

Total Weight(kg) = 5800 kg Roof (ceiling) High TensileST-57 / 3.0 mm Body Floor High Tensile ST-57 / 4.0 mm Body Sides High Tensile ST-57 3.0 mm The sidewalls shall be formed to trapezoid shape to increase the strength.

Side Traverses (Braces)

All reinforcements of body, shall be in the form U shaped braces and full-seam welded on the body sheets, of thickness ST-57/4.0 mm.

Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

Sub Frame

U shape full length 3 or 4 mm ST-57

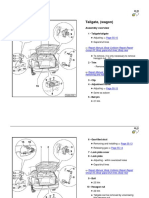

Tailgate

Collecting The loose garbage inside the & hopper is taken into to the Compacting body via a sweeper shovel being actuated by two double-acting hydraulic cylinders, and than after being pushed into the body by two double-acting sledge cylinders. The sledge cylinders have min. 24 tones pushing force.

Compaction The compaction ratio (volumetric) varies between 3:1 to 6:1 according to the characteristic Ratio of the garbage.

Lifting The tailgate raise is achieved by two double acting hydraulic cylinders, which must be equipped with safety devices to prevent the tailgate from falling abruptly in the event of hydraulic failure or hose burst.

Hopper The loose garbage capacity Capacity (m) of loading hopper is around 1,5 m with the self cleaning ability during discharge.

Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

Steel Thickness High Abrasive Resistant 6 (mm) mm steel material, which of hardness 450 HB for enduring sweeper and shovel considered necessary other parts of hopper.

Hopper (tailgate) Floor HB 450 / 6 mm

Hopper Sides under the rail HB 450 / 4 mm,

Hopper Sides above the rail HB 450 / 4 mm,

Sliding Rails

There used 50x50mm and 50x30mm steel profiles to guide compacting system. The compacting panel slides up and down over these rails thanks to a set of Kestamide wear blocks in four points.

Locking Hydraulic locking by means of reverse action of two hydraulic tailgate lifting cylinders, which also prevents the leakage of the wastewater when the truck bounces due to road conditions. Container 500 kg lifting capacity Lifting Devices to lift 1100 L. (1.1 m) metal containers and 2 bins 240 lt.

Loading Height The loading height is 1100-1200 mm around, and the design lets the manual loading from (mm) hand-held containers. Safety Props The tailgate is provided with safety props between the body and tailgate for safety purposes during maintenance or cleaning. Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

Ejector Panel Ejector Panel There shall be a totally automatic hydraulic system to allow the panel to advance forward as garbage is packed against it.

Material St-57 / 6mm thickness.

Rail The ejector panel shall glide on a Standard NPU 120mm profile, centered by means of friction resist polyamide bases. The ejector panel shall slide forward and rear over these rails thanks to a set of Polyamide wear plates in four points. 6 7

In case of there is enough and suitable space on truck chassis, Sewage tank 120 lt. under the body is made by means of body floor plate. Operation & Control Operation The operation is fully automatic PLC system. The operation is capable of continuous cycle, semi-automatic single cycle and manually operated. The system is controlled from the PLC control box, which enables, start, stop, 1cycle, continuous cycles, and rescue activities. Sewage Tank

Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

Control Panel

Tailgate and ejector controls are in front of the body. All devices for loading control are mounted on tailgate right side, and all are manual control for safety purposes. Compaction is controlled electrically via push buttons, and manually in case. There is an emergency stop button each of side the truck on the control panel. To warn or contact to the driver.

Comm. Buzzer 8

Hydraulic System P.T.O. Controlled inside the cab, original P.T.O of the truck, or the P.T.O can be arranged by our company.

Working Pressure (bar) Oil Tank Hydraulic Valves

170 bar

125 lt. oil tank equipped with breather and gauge Front Distributor Operates the ejector panel and tailgate, mounted on front wall and on left side. Container Valve Operates the container lifting device manually Sequence Valve This is arranging the order of the sweeping and sledge cylinders. When the sweeping cylinder reaches to maximum pressure, then the sledge cylinders shall start to compact the garbage inside the chamber. 9 units of hydraulic cylinders; and telescopic cylinder with 2 extensions. Hydraulic All the hydraulic cylinders Cylinders are double-acting cylinders. The pipes on hydraulic cylinders are Italy origin. Pipes to be made of honed drawn steel pipe, and cylinder miles are grinded and chrome coated against corrosion.The dimensions of cylinders are designed to accomplish the stipulated cycle times and compaction ratio. To comply International DIN 2391 C Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

Hydraulic Pump PTO driven hydraulic gear pump 30 80 cm / rev max.1500 rpm. All high pressure hydraulic oil hoses have a burst rating 4 times more than the specific Hydraulic Hoses system working pressure (SAE 100R2) The hoses in motion and has risk of friction or contact, are covered and protected by steel wire. All steel parts surfaces free of rust and oil residue will be applied with two primers, and one 9 Painting final paint coating in color of demand. Minimum dry film thickness of the paint is 60 microns. Two steel mudguards with rubber flaps at rear ends. 10 General 1 rotating beacons light at the tailgate. Two foldable type rear foot boards for crew to stand One elliptical handle at each side pipe handle for the crews to grasp The necessary traffic lights, reflectors, and warning devices shall be mounted at rear which complies to PUSPAKOM/JPJ regulations. Electrical system is separated from the circuit of the truck Specifications and dimensions are not binding. Manufacturers tolerance may apply. Ayalka International has the spare parts and after sale service Supplying of spare parts for super structure is guaranteed for ten years by Ayalka International

The manufacturer is ISO certified and meets International DIN EN 1501 standards.

Web: www.aplusgroup.com.my Email: alex@aplusgroup.com.my

S-ar putea să vă placă și

- Remote Car Key and Smart Remote Programmer BrochureDocument6 paginiRemote Car Key and Smart Remote Programmer Brochurejunior jrÎncă nu există evaluări

- Guide To Complete Repair Planning: Operations Reference HandbookDocument24 paginiGuide To Complete Repair Planning: Operations Reference HandbookRohit Rajput100% (1)

- 3-Spec Lowboy TrailerDocument9 pagini3-Spec Lowboy TrailerHugo RodriguezÎncă nu există evaluări

- Restoration ChecklistDocument4 paginiRestoration ChecklisteduardowilkÎncă nu există evaluări

- OptistructDocument85 paginiOptistructSahithyananda ShashidharÎncă nu există evaluări

- 11 Lifting Blocking Clamping PDFDocument48 pagini11 Lifting Blocking Clamping PDFEbied Yousif AlyÎncă nu există evaluări

- QY35k5英文 PDFDocument7 paginiQY35k5英文 PDFErika Justiniano VargasÎncă nu există evaluări

- 1412TP 204 204Document8 pagini1412TP 204 204Muhammad UmairÎncă nu există evaluări

- BIW Unit 1 NotesDocument50 paginiBIW Unit 1 NotesJhon bendÎncă nu există evaluări

- Can OpenDocument130 paginiCan Openninja dragonÎncă nu există evaluări

- BROCHURE PEGSON 4242SR - TerexPegson+SpecsDocument9 paginiBROCHURE PEGSON 4242SR - TerexPegson+SpecsGoran Erakovic100% (1)

- 9103796-105CN - Techn Descr SC 45Document139 pagini9103796-105CN - Techn Descr SC 45happyÎncă nu există evaluări

- S CS Mega Configurator GBDocument14 paginiS CS Mega Configurator GBtonychavez3Încă nu există evaluări

- Artison Plus HFD HFGDocument12 paginiArtison Plus HFD HFGcrisstina1979Încă nu există evaluări

- Pump TruckDocument11 paginiPump TruckJozsef MagyariÎncă nu există evaluări

- Mobile Crusher 900x600Document7 paginiMobile Crusher 900x600macross086100% (7)

- 1000 MaxtrackDocument6 pagini1000 MaxtrackJaimeAguilar0% (1)

- ALIMAK SC45-30 - Technical Description - Construction HoistDocument60 paginiALIMAK SC45-30 - Technical Description - Construction HoistErick Adrian Quintero Jaramillo67% (3)

- 02-Crown Intstacker MDocument4 pagini02-Crown Intstacker MJacob GrechÎncă nu există evaluări

- Rig Sa 04: Delfico-General Trading - LLCDocument31 paginiRig Sa 04: Delfico-General Trading - LLCAdhie Waelacxh100% (1)

- SSP483 - Audi A7 Sportback - Convenience Electronics and Audi Active Lane AssistDocument36 paginiSSP483 - Audi A7 Sportback - Convenience Electronics and Audi Active Lane AssistSaepudin JuhriÎncă nu există evaluări

- Technical SpecificationDocument12 paginiTechnical SpecificationAnkit Somani100% (1)

- Storm BrakesDocument63 paginiStorm Brakesrochim_putech_126885Încă nu există evaluări

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 paginiRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezÎncă nu există evaluări

- Citroen Xsara Picaso KatalogDocument8 paginiCitroen Xsara Picaso KatalogRobert S.Încă nu există evaluări

- HM10 Intro Hyper Mesh (Altair)Document124 paginiHM10 Intro Hyper Mesh (Altair)Miro GrulovicÎncă nu există evaluări

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDDocument58 pagini6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARIÎncă nu există evaluări

- PA-18 Information Manual PDFDocument58 paginiPA-18 Information Manual PDFrecaluwe100% (1)

- P H Omega T 250 25 TonDocument9 paginiP H Omega T 250 25 TonUday Pratap0% (1)

- Armtrac 400 BrochuresDocument4 paginiArmtrac 400 Brochurespolkmijn100% (2)

- 2 ZJ20主车 650 英Document5 pagini2 ZJ20主车 650 英Haitham DrillingÎncă nu există evaluări

- EX 2500 Especificaciones TecnicasDocument16 paginiEX 2500 Especificaciones TecnicasElvis Eberth Huanca Machaca100% (2)

- Technical SpecificationDocument9 paginiTechnical SpecificationRaisa AviannyÎncă nu există evaluări

- Linear Motion vs. Rotational MotionDocument24 paginiLinear Motion vs. Rotational MotionSai DeepakÎncă nu există evaluări

- Ball Screw DocumentationDocument13 paginiBall Screw DocumentationZeynep Emirhan ŞenyüzÎncă nu există evaluări

- 1095 Truck Technical Specification For Procurement of TruckDocument2 pagini1095 Truck Technical Specification For Procurement of TruckPradeep AcharyaÎncă nu există evaluări

- CANopen Manual 920-0025LDocument101 paginiCANopen Manual 920-0025LVictor ManuelÎncă nu există evaluări

- Workshop Lubrication Truck Mercedes 2Document23 paginiWorkshop Lubrication Truck Mercedes 2Aprizal AzisÎncă nu există evaluări

- HITACHI - Clamshell Telescopic Arm KA-En072Document4 paginiHITACHI - Clamshell Telescopic Arm KA-En072fvmattosÎncă nu există evaluări

- BELAZ 7555 - enDocument7 paginiBELAZ 7555 - endno256Încă nu există evaluări

- Catalogo Polipastos Neumaticos ATLAS COPCO - English - 2010Document8 paginiCatalogo Polipastos Neumaticos ATLAS COPCO - English - 2010Toni RenedoÎncă nu există evaluări

- ForkliftDocument5 paginiForkliftpramodtry100% (1)

- MOW Equipment Manufacturing: Kershaw 12-12 Tie CraneDocument3 paginiMOW Equipment Manufacturing: Kershaw 12-12 Tie Cranecamelia_pirjan5776Încă nu există evaluări

- 65-95 GBDocument2 pagini65-95 GBLorena HesterÎncă nu există evaluări

- QY50K Truck Crane Technical SpecificationDocument9 paginiQY50K Truck Crane Technical Specificationkim alfonsoÎncă nu există evaluări

- Prezentare Platforme LiftanteDocument8 paginiPrezentare Platforme LiftanteRaluca ZahariaÎncă nu există evaluări

- Ancilary EquipmentssDocument56 paginiAncilary EquipmentssRezhaÎncă nu există evaluări

- Model Bl53 Industrial Gate Operator: DescriptionDocument2 paginiModel Bl53 Industrial Gate Operator: Descriptionosto72Încă nu există evaluări

- Model: 1. General DescriptionDocument4 paginiModel: 1. General DescriptionAlly KhooÎncă nu există evaluări

- 48kl Tank Semi TrailerDocument7 pagini48kl Tank Semi Trailerali hassanÎncă nu există evaluări

- 95-130 GBDocument2 pagini95-130 GBLorena HesterÎncă nu există evaluări

- Mantis 20010Document16 paginiMantis 20010thauwui86Încă nu există evaluări

- Eco Fit RomDocument3 paginiEco Fit RomRobin AttallaÎncă nu există evaluări

- Mustang 4-F4 6991 1324 01Document4 paginiMustang 4-F4 6991 1324 01Girish Kasturi0% (1)

- Specification of GHR 1520 - 3BDDocument3 paginiSpecification of GHR 1520 - 3BDDoãn VănÎncă nu există evaluări

- Octo 1465Document4 paginiOcto 1465aaÎncă nu există evaluări

- H16 00-18 00xm-12ecDocument6 paginiH16 00-18 00xm-12ecIan WoodsÎncă nu există evaluări

- Avon EB450 Parking Barrier Version 2 7 14 PDFDocument2 paginiAvon EB450 Parking Barrier Version 2 7 14 PDFFeritFazliuÎncă nu există evaluări

- The Loader Specialist: System 180Document8 paginiThe Loader Specialist: System 180dm1680Încă nu există evaluări

- Trailers For Flammable Liquids 0411Document7 paginiTrailers For Flammable Liquids 0411Davaajargal BinderyaÎncă nu există evaluări

- Kershaw 12-12BridgeCraneDocument3 paginiKershaw 12-12BridgeCranecamelia_pirjan5776Încă nu există evaluări

- Vio38U: Call For Yanmar SolutionsDocument8 paginiVio38U: Call For Yanmar SolutionsTomy Abad AbadÎncă nu există evaluări

- EC20B BrochureDocument10 paginiEC20B Brochuredalibor_bogdan100% (1)

- GB ViO50U 0113Document8 paginiGB ViO50U 0113Tomy Abad AbadÎncă nu există evaluări

- 6 Cube Barrel Blast "S": "Blasting Solutions"Document2 pagini6 Cube Barrel Blast "S": "Blasting Solutions"elias0311Încă nu există evaluări

- BoschLiftsBrochure ElevatorDocument20 paginiBoschLiftsBrochure ElevatorSimona Ioana RujoiuÎncă nu există evaluări

- Bucket Elevators: Installation and Operation ManualDocument20 paginiBucket Elevators: Installation and Operation Manualboyka yuriÎncă nu există evaluări

- Tailgate, (Wagon) : Assembly OverviewDocument14 paginiTailgate, (Wagon) : Assembly OverviewDenis RaudseppÎncă nu există evaluări

- 000096716Q 9671 6Q 0 96716QDocument8 pagini000096716Q 9671 6Q 0 96716QKandy KnÎncă nu există evaluări

- Comparison Between Features and Variants of Scorpio'S Model: TechnologyDocument11 paginiComparison Between Features and Variants of Scorpio'S Model: TechnologyAtul KumarÎncă nu există evaluări

- AOC Catalog Insignia Sports Tourer Central Market English PDFDocument15 paginiAOC Catalog Insignia Sports Tourer Central Market English PDFGreen_Beret_8Încă nu există evaluări

- Citroen c4 Picasso PDFDocument266 paginiCitroen c4 Picasso PDFAroma OrganicaÎncă nu există evaluări

- NEW Bravo User ManualDocument262 paginiNEW Bravo User ManualSergio RdÎncă nu există evaluări

- Volvo s40 v40 2004 Wiring DiagramDocument10 paginiVolvo s40 v40 2004 Wiring DiagramWillie100% (51)

- MINI F60 Owners ManualDocument328 paginiMINI F60 Owners ManualinfoinyourfingertipsÎncă nu există evaluări

- Grande Punto Actual - enDocument216 paginiGrande Punto Actual - enikhediraÎncă nu există evaluări

- Citroen Xcarra PicassoDocument8 paginiCitroen Xcarra Picassodragoslavg1Încă nu există evaluări

- Lancia K Coupe' 97: Specific Vehicle Alarm Fitting Instructions Rev. 00Document1 paginăLancia K Coupe' 97: Specific Vehicle Alarm Fitting Instructions Rev. 00Лешик ЯÎncă nu există evaluări

- Scenic: Vehicle User ManualDocument372 paginiScenic: Vehicle User ManualJhonJamesÎncă nu există evaluări

- Vito SpecificationsDocument2 paginiVito SpecificationsSorin Barlatzean100% (1)

- Kia Sportage Prislusenstvi 2015Document12 paginiKia Sportage Prislusenstvi 2015Anonymous GKqp4Hn0% (1)

- 3er (E90) 2007 DEIDocument7 pagini3er (E90) 2007 DEIMikeÎncă nu există evaluări

- GEELY 2008 Fc-VisionDocument211 paginiGEELY 2008 Fc-VisionКостя ДолинськийÎncă nu există evaluări

- Montaža Dautel RampiDocument61 paginiMontaža Dautel RampiLikÎncă nu există evaluări

- Accesorii Astra KDocument16 paginiAccesorii Astra KfofutzÎncă nu există evaluări

- Tiguan Leaflet East MyDocument2 paginiTiguan Leaflet East Mypbc3199Încă nu există evaluări

- Model S Owners Manual North America en Us PDFDocument233 paginiModel S Owners Manual North America en Us PDFJason LiÎncă nu există evaluări

- Suzuki SX4 2009 Owner's Handbook ManualDocument50 paginiSuzuki SX4 2009 Owner's Handbook ManualPrisacariu Nicu - IonelÎncă nu există evaluări

- Ssp379 The Eos 2006 Part 1Document19 paginiSsp379 The Eos 2006 Part 1psychoreality100% (1)

- Suzuki - Brochure Wagonr 05-10-2018Document4 paginiSuzuki - Brochure Wagonr 05-10-2018Aijaz RajarÎncă nu există evaluări