Documente Academic

Documente Profesional

Documente Cultură

Advantages of Prestressed Concrete in 40 Characters

Încărcat de

atharvasaxena93Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Advantages of Prestressed Concrete in 40 Characters

Încărcat de

atharvasaxena93Drepturi de autor:

Formate disponibile

Advantages of Prestressed Concrete

he use of prestressed concrete offers distinct advantages over ordinary reinforced concrete. These advantages can be briefly listed as follows: 1. Prestressing minimises the effect of cracks in concrete elements by holding the concrete in compression. 2. Prestressing allows reduced beam depths to be achieved for equivalent design strengths. 3. Prestressed concrete is resilient and will recover from the effects of a greater degree of overload than any other structural material. 4. If the member is subject to overload, cracks, which may develop, will close up on removal of the overload. 5. Prestressing enables both entire structural elements and structures to be formed from a number of precast units, e.g. Segmented and Modular Construction. 6. Lighter elements permit the use of longer spanning members with a high strength to weight characteristic. 7. The ability to control deflections in prestressed beams and slabs permits longer spans to be achieved. 8. Prestressing permits a more efficient usage of steel and enables the economic use of high tensile steels and high strength concrete.

The prestressing of concrete has several advantages as compared to traditional reinforced concrete (RC) without prestressing. A fully prestressed concrete member is usually subjected to compression during service life. This rectifies several deficiencies of concrete. The following text broadly mentions the advantages of a pre-stressed concrete member with an equivalent RC member. For each effect, the benefits are listed. A) Section remains un-cracked under service loads 1. Reduction of steel corrosion o Increase in durability. 2. Full section is utilized o Higher moment of inertia (higher stiffness) 3. Less deformations (improved serviceability). 4. Increase in shear capacity 5. Suitable for use in pressure vessels, liquid retaining structures. o Improved performance (resilience) under dynamic and fatigue loading. B) High span-to-depth ratios 1. Larger spans possible with prestressing (bridges, buildings with large column-free spaces) 2. Typical values of span-to-depth ratios in slabs are given below. For the same span, less depth compared to RC member.

Reduction in self weight More esthetic appeal due to slender sections More economical sections. C) Suitable for precast construction The advantages of precast construction are as follows. Rapid construction Better quality control

Reduced maintenance Suitable for repetitive construction Multiple use of formwork 1. Reduction of formwork Availability of standard shapes. The following figure shows the common types of precast sections.

Limitations of Prestressing

Although prestressing has advantages, some aspects need to be carefully addressed.

Prestressing needs skilled technology. Hence, it is not as common as reinforced concrete. The use of high strength materials is costly. There is additional cost in auxiliary equipments. There is need for quality control and inspection.

Limitations of Prestressing The limitations of prestressed concrete are few and really depend only upon the imagination of the designer and the terms of his brief. The only real limitation where prestressing is a possible solution may be the cost of providing moulds for runs of limited quantity of small numbers of non-standard units.

S-ar putea să vă placă și

- Advantages and Limitations of Prestressed ConcreteDocument4 paginiAdvantages and Limitations of Prestressed ConcreteKanadeTachibanaÎncă nu există evaluări

- Advantages and Disadvantages of PrestressDocument2 paginiAdvantages and Disadvantages of Prestressjhun capangyarihan100% (2)

- Prestressed Concrete AdvantagesDocument18 paginiPrestressed Concrete AdvantagesLarete PaoloÎncă nu există evaluări

- Post Tensioning in Building StructuresDocument21 paginiPost Tensioning in Building StructuresLuan Truong VanÎncă nu există evaluări

- Advantages and Disadvantages of Prestressed ConcreteDocument1 paginăAdvantages and Disadvantages of Prestressed ConcreteMarlou Salazar SabanganÎncă nu există evaluări

- 22) Composite Beams - IIDocument47 pagini22) Composite Beams - IIPrabhumk07100% (2)

- Activity 1 in Pre-StressedDocument3 paginiActivity 1 in Pre-StressedFrancis Prince ArtiagaÎncă nu există evaluări

- Advanced Construction Methods in R.C.C: Prestessed ConcreteDocument12 paginiAdvanced Construction Methods in R.C.C: Prestessed Concretepoosa annupriyaÎncă nu există evaluări

- 1.2.2 Advantages of Prestressing: 1) Section Remains Uncracked Under Service LoadsDocument8 pagini1.2.2 Advantages of Prestressing: 1) Section Remains Uncracked Under Service LoadsVaibhav GaikarÎncă nu există evaluări

- NAME: Omar Bokhare Hassan Group: B Title: Home Work (Ch.6)Document3 paginiNAME: Omar Bokhare Hassan Group: B Title: Home Work (Ch.6)Omar BokhareÎncă nu există evaluări

- Prestressed Concrete STRUCTURES 1) Advantages of Prestressed ConcreteDocument2 paginiPrestressed Concrete STRUCTURES 1) Advantages of Prestressed ConcreteKannan CrÎncă nu există evaluări

- Theory of prestressed concreteDocument21 paginiTheory of prestressed concreteManasAroraÎncă nu există evaluări

- Pre-stressed Concrete Structures: Advantages, Limitations, and Need for High Strength MaterialsDocument11 paginiPre-stressed Concrete Structures: Advantages, Limitations, and Need for High Strength MaterialsAlbinPSunnyÎncă nu există evaluări

- Prestressed ConcreteDocument4 paginiPrestressed ConcreteNithun KumarÎncă nu există evaluări

- Pre-Tensioning and Post-Tensioning in Prestressed Concrete DesignDocument5 paginiPre-Tensioning and Post-Tensioning in Prestressed Concrete DesignLIZA MARIE QUINDAOÎncă nu există evaluări

- Permanent Formwork for Composite Bridge DecksDocument2 paginiPermanent Formwork for Composite Bridge DecksjimmydomingojrÎncă nu există evaluări

- Chapter Five Composite Structures (Concrete and Steel)Document15 paginiChapter Five Composite Structures (Concrete and Steel)Assefa Nigussie100% (1)

- Concrete Basics LectureDocument12 paginiConcrete Basics LectureMildred Ivy Bangoy Pangilinan0% (1)

- Research I Reinforcement Concrete II Prestressed Reinforced ConcreteDocument6 paginiResearch I Reinforcement Concrete II Prestressed Reinforced ConcreteHamez HabibiÎncă nu există evaluări

- Design of Composite BridgeDocument10 paginiDesign of Composite BridgeHarold Jackson MtyanaÎncă nu există evaluări

- Saturnino, Sebastiene P. Engr. Jao Advantages of Reinforced ConcreteDocument1 paginăSaturnino, Sebastiene P. Engr. Jao Advantages of Reinforced ConcreteSebastiene SaturninoÎncă nu există evaluări

- Pre StressingDocument5 paginiPre StressingAakriti VermaÎncă nu există evaluări

- Definition of PrestressDocument21 paginiDefinition of PrestressShashank PatoleÎncă nu există evaluări

- Unit 10Document4 paginiUnit 10Sajal SarkarÎncă nu există evaluări

- Prestresed ConcreteDocument6 paginiPrestresed ConcreteSantoshÎncă nu există evaluări

- Prestressed Concrete COMPOSITE CONT. METHODDocument5 paginiPrestressed Concrete COMPOSITE CONT. METHODReggie DuranÎncă nu există evaluări

- Ce1302 Design of RC ElementsDocument22 paginiCe1302 Design of RC Elementsjs kalyana rama100% (1)

- Advantages of PrestressedDocument3 paginiAdvantages of PrestressedLarete PaoloÎncă nu există evaluări

- DPSC Mod 1 IntroductionDocument12 paginiDPSC Mod 1 IntroductionKajalÎncă nu există evaluări

- Two Mark QuestionsDocument9 paginiTwo Mark QuestionsNitin SureshÎncă nu există evaluări

- Tos Vii Unit 01 & 02dfhtgfijkDocument20 paginiTos Vii Unit 01 & 02dfhtgfijkKanak YadavÎncă nu există evaluări

- Flat Slab (Efficient Construction)Document4 paginiFlat Slab (Efficient Construction)tanhh5678Încă nu există evaluări

- Reinforced Concrete Design GuideDocument19 paginiReinforced Concrete Design GuideRom Reyes Dela CruzÎncă nu există evaluări

- Seismic Retrofitting Techniques of RCC BuiidingsDocument29 paginiSeismic Retrofitting Techniques of RCC BuiidingschbaskerÎncă nu există evaluări

- Advantage Pre Stresssed ConcreteDocument2 paginiAdvantage Pre Stresssed Concreteyesuf abdulhakimÎncă nu există evaluări

- Reinforced Concrete Buildings: Behavior and DesignDe la EverandReinforced Concrete Buildings: Behavior and DesignEvaluare: 5 din 5 stele5/5 (1)

- High Performance Concrete and Fundamentals: International Journal of Advanced Science and ResearchDocument3 paginiHigh Performance Concrete and Fundamentals: International Journal of Advanced Science and Researchruya mÎncă nu există evaluări

- Prestressed ConcreteDocument14 paginiPrestressed ConcreteMilenaÎncă nu există evaluări

- RCC and SteelDocument12 paginiRCC and SteelSHAHID THAKURÎncă nu există evaluări

- Various Types of Jacketing in Construction. - CivilwalaDocument15 paginiVarious Types of Jacketing in Construction. - CivilwalaJhon shonÎncă nu există evaluări

- StructuresDocument453 paginiStructuresMamphey Emml100% (2)

- Types of Formwork (Shuttering) For ConcreteDocument29 paginiTypes of Formwork (Shuttering) For Concretesaima BatoolÎncă nu există evaluări

- Report Composite AnkurDocument19 paginiReport Composite AnkurAnkur DubeyÎncă nu există evaluări

- Introduction To: Prestressed ConcreteDocument26 paginiIntroduction To: Prestressed ConcreteTerityÎncă nu există evaluări

- 3 1-StructuralSteelConstruction PDFDocument15 pagini3 1-StructuralSteelConstruction PDFShahrol Faizal AbdullahÎncă nu există evaluări

- Advantages of Prestressing Comparative To RCCDocument1 paginăAdvantages of Prestressing Comparative To RCCMandeep GusainÎncă nu există evaluări

- Hoi - Thao T11-03 LuuDocument22 paginiHoi - Thao T11-03 LuuvuhachauÎncă nu există evaluări

- RoofDocument31 paginiRoofsamÎncă nu există evaluări

- PRINCIPLES RC MODULE Unit 1Document16 paginiPRINCIPLES RC MODULE Unit 1Stephen Bulay-ogÎncă nu există evaluări

- Composite Structure (31-38)Document48 paginiComposite Structure (31-38)Badri DadiÎncă nu există evaluări

- Innovation in Composite ConstructionDocument6 paginiInnovation in Composite ConstructionnicholasÎncă nu există evaluări

- Composite ConstructionDocument27 paginiComposite Constructionharsha333100% (1)

- PGCM 44Document11 paginiPGCM 44AMAN RAYÎncă nu există evaluări

- تلخيص الكود الامريكىDocument41 paginiتلخيص الكود الامريكىENG HASSAN HADIÎncă nu există evaluări

- Introduction to Design of Building StructuresDe la EverandIntroduction to Design of Building StructuresEvaluare: 4 din 5 stele4/5 (22)

- Elastic, Plastic and Yield Design of Reinforced StructuresDe la EverandElastic, Plastic and Yield Design of Reinforced StructuresÎncă nu există evaluări

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDe la EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesEvaluare: 4.5 din 5 stele4.5/5 (16)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)De la EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Evaluare: 4 din 5 stele4/5 (10)

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Patrickgeddestheory 131111210053 Phpapp02Document24 paginiPatrickgeddestheory 131111210053 Phpapp02atharvasaxena93Încă nu există evaluări

- Calc NotesDocument49 paginiCalc NotesAnubhav SwaroopÎncă nu există evaluări

- TERI Bangalore Case StudyDocument56 paginiTERI Bangalore Case Studyatharvasaxena9357% (7)

- Thesis Topic PDFDocument10 paginiThesis Topic PDFVivek Puni75% (8)

- InstallDocument4 paginiInstallatharvasaxena93Încă nu există evaluări

- 2014.07.15 FAQs Transparence 14Document3 pagini2014.07.15 FAQs Transparence 14atharvasaxena93Încă nu există evaluări

- GATE2014 Qual MarksDocument1 paginăGATE2014 Qual Marksatharvasaxena93Încă nu există evaluări

- SBI PO Prev Paper 2013 Gr8AmbitionZDocument31 paginiSBI PO Prev Paper 2013 Gr8AmbitionZatharvasaxena93Încă nu există evaluări

- Thesis Topic PDFDocument19 paginiThesis Topic PDFz3cyberÎncă nu există evaluări

- Notification Regarding Date For Filling The Exam Form of BCA IIIrd Sem. Exam Dec. 2013 (For SOS and Colleges) 1057Document1 paginăNotification Regarding Date For Filling The Exam Form of BCA IIIrd Sem. Exam Dec. 2013 (For SOS and Colleges) 1057atharvasaxena93Încă nu există evaluări

- 2014.07.15 FAQs Transparence 14Document3 pagini2014.07.15 FAQs Transparence 14atharvasaxena93Încă nu există evaluări

- Surface Preparation WoodDocument4 paginiSurface Preparation Woodatharvasaxena93Încă nu există evaluări

- CAT GATE SSC CDS NICMAR EXAM GuideDocument1 paginăCAT GATE SSC CDS NICMAR EXAM Guideatharvasaxena93Încă nu există evaluări

- PUBLIC GARDEN Landscape Project II 2014Document4 paginiPUBLIC GARDEN Landscape Project II 2014atharvasaxena93Încă nu există evaluări

- Answer BooksDocument1 paginăAnswer Booksatharvasaxena93Încă nu există evaluări

- 8 SN, UUID, PN&SLP Tools IntroductionDocument16 pagini8 SN, UUID, PN&SLP Tools Introductionatharvasaxena93Încă nu există evaluări

- 3 BHK FileDocument1 pagină3 BHK Fileatharvasaxena93Încă nu există evaluări

- Suruhanjaya Tenaga - Guidelines For Wiring ResidentialDocument55 paginiSuruhanjaya Tenaga - Guidelines For Wiring Residentialkingcloud7100% (24)

- Passive Climate Design Heritage BuildingsDocument20 paginiPassive Climate Design Heritage Buildingsatharvasaxena93Încă nu există evaluări

- Details ArchDocument1 paginăDetails Archatharvasaxena93Încă nu există evaluări

- Timber SurfacesDocument2 paginiTimber Surfacesatharvasaxena93Încă nu există evaluări

- Building Enclosures Exterior Building Materials: Madhav Institute of Technology and Science GwaliorDocument18 paginiBuilding Enclosures Exterior Building Materials: Madhav Institute of Technology and Science Gwalioratharvasaxena93Încă nu există evaluări

- Avgremover MsilogDocument6 paginiAvgremover Msilogatharvasaxena93Încă nu există evaluări

- Site Analysis TighraDocument23 paginiSite Analysis Tighraatharvasaxena93Încă nu există evaluări

- Scientific Revolution 1500-1800 A.D.Document14 paginiScientific Revolution 1500-1800 A.D.atharvasaxena93Încă nu există evaluări

- About Design TheoryDocument14 paginiAbout Design Theoryatharvasaxena93Încă nu există evaluări

- IesengghDocument7 paginiIesengghNaveen Kumar ReddyÎncă nu există evaluări

- Management Accounting: Product & Service CostingDocument49 paginiManagement Accounting: Product & Service CostingSyed Wahedul AzadÎncă nu există evaluări

- Entrep MODULE 2Document8 paginiEntrep MODULE 2al-zhamill sahialÎncă nu există evaluări

- Chapter 4 Supplement Process Costing Using The FIFO Method: True/FalseDocument38 paginiChapter 4 Supplement Process Costing Using The FIFO Method: True/FalseRashedul Islam PaponÎncă nu există evaluări

- Dividend and Retained Earnings Formula - Google SearchDocument1 paginăDividend and Retained Earnings Formula - Google SearchMaaz HussainÎncă nu există evaluări

- Sec. 24. Election of Directors or Trustees.Document7 paginiSec. 24. Election of Directors or Trustees.Lean Rain SandiÎncă nu există evaluări

- Prakas On Construction License - CambodiaDocument4 paginiPrakas On Construction License - CambodiaVP SadokaÎncă nu există evaluări

- Solved Draw A Scatter Diagram of The Price of Oil andDocument1 paginăSolved Draw A Scatter Diagram of The Price of Oil andM Bilal SaleemÎncă nu există evaluări

- Field Inspection Manual The Shell Petroleum Development Company of Nigeria LimitedDocument31 paginiField Inspection Manual The Shell Petroleum Development Company of Nigeria LimitedMathias Onosemuode100% (1)

- Prosthetid Hand Pugh MethodDocument91 paginiProsthetid Hand Pugh MethodFaddhila FadhilaÎncă nu există evaluări

- Topic 3 Long-Term Construction Contracts ModuleDocument20 paginiTopic 3 Long-Term Construction Contracts ModuleMaricel Ann BaccayÎncă nu există evaluări

- Bidding DocumentsDocument82 paginiBidding DocumentsPalwasha GulÎncă nu există evaluări

- Modern Data Strategy 1664949335Document39 paginiModern Data Strategy 1664949335Dao NguyenÎncă nu există evaluări

- Fintech and TechfinDocument13 paginiFintech and TechfinMaryam IraniÎncă nu există evaluări

- ECEN 5833 Low Power Embedded Design TechniquesDocument4 paginiECEN 5833 Low Power Embedded Design TechniquesMehul Patel100% (1)

- Ablockers Fitness 101Document10 paginiAblockers Fitness 101iqbal kamilÎncă nu există evaluări

- White and Blue Clean Lines Sales Executive ResumeDocument2 paginiWhite and Blue Clean Lines Sales Executive ResumeAbegail TutorÎncă nu există evaluări

- Dokumen - Pub Cost and Management Accounting I 9789387572423 9387572420Document748 paginiDokumen - Pub Cost and Management Accounting I 9789387572423 9387572420Sie Humas Septia Ardianti100% (1)

- 1-2 Math at Home Game TimeDocument1 pagină1-2 Math at Home Game TimeKarla Panganiban TanÎncă nu există evaluări

- DEY'S ECONOMICS-XII - Exam Handbook For 2024 ExamDocument62 paginiDEY'S ECONOMICS-XII - Exam Handbook For 2024 ExamYash Shrivastava100% (1)

- PGCIL approval request for structural steel manufacturerDocument3 paginiPGCIL approval request for structural steel manufacturervijaymandiÎncă nu există evaluări

- Economics Assignment IDocument2 paginiEconomics Assignment IDEVASISHÎncă nu există evaluări

- AS9100D Quality ManualDocument22 paginiAS9100D Quality ManualHoang TanÎncă nu există evaluări

- Wilson, Harry - Silverwork and JewelryDocument542 paginiWilson, Harry - Silverwork and JewelryTecnologiaFAUDUNMdPÎncă nu există evaluări

- 4 PumpsDocument219 pagini4 PumpsVũ QuangÎncă nu există evaluări

- Determination Fiar Market Value Unquoted Equity Shares Start Up 6 2 2018Document1 paginăDetermination Fiar Market Value Unquoted Equity Shares Start Up 6 2 2018Jhalak AgarwalÎncă nu există evaluări

- PJM5900 Final Exam: Key Concepts and FormulasDocument26 paginiPJM5900 Final Exam: Key Concepts and FormulaskirinÎncă nu există evaluări

- Work Breakdown Structure Template 22Document6 paginiWork Breakdown Structure Template 22luismlmÎncă nu există evaluări

- BiMedis - Your Own Online Store For Selling Medical EquipmentDocument14 paginiBiMedis - Your Own Online Store For Selling Medical Equipmentxbiomed.frÎncă nu există evaluări

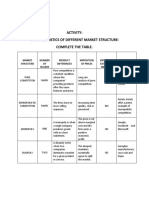

- Characteristics of Different Market Structures TableDocument2 paginiCharacteristics of Different Market Structures TableJustine PadohilaoÎncă nu există evaluări

- Decision TheoryDocument14 paginiDecision TheoryBless TettehÎncă nu există evaluări