Documente Academic

Documente Profesional

Documente Cultură

An Update On In-Pit Crushing-Conveying-Stacking Systems in Surface Metal Mines

Încărcat de

Robert KnightDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

An Update On In-Pit Crushing-Conveying-Stacking Systems in Surface Metal Mines

Încărcat de

Robert KnightDrepturi de autor:

Formate disponibile

~ l \ ' ~

SOCIETY FOR

MINING, METALLURGY,

AND EXPLORATION, lNC.

P.O. BOX 625002 LITTLETON. COLORADO 80162-5002

PREPRINT

97-14

AN UPDATE ON IN-PIT CRUSHING-CONVEYING-STACKING

SYSTEMS IN SURFACE METAL MINES

S. A. Jeric

Phelps Dodge Morenci, Inc.

Morenci, AZ

M. J. Hrebar

Colorado School of Mines

Golden, CO

For presentation at the SME Annual Meeting

Denver, Colorado - February 24-27, 1997

Permission is hereby given to publish with appropriate acknowledgments, excerpts or

summaries not to exceed one-fourth of the entire text of the paper. Permission to print in more

extended form subsequent to publication by the Society for Mining, Metallurgy, and Exploration

(SME), Inc. must be obtained from the Executive Director of the Society.

If and when this paper is published by the SME, it may embody certain changes made by

agreement between the Technical Publications Committee and the author so that the form in

which it appears is not necessarily that in which it may be published later.

Current year preprints are available for sale from the SME, Preprints, P.O. Box 625002,

Littleton, CO 80162-5002 (303-973-9550). Prior year preprints may be obtained from the Linda

Hall Library, 5109 Cherry Street, Kansas City, M064110-2498 (800)662-1545.

PREPRINT AVAILABILITY LIST IS PUBLISHED PERIODICALLY IN

MINING ENGINEERING

ABSTRACT

In-pit crushing and conveying of waste

has been utilized in the mining industry for over

30 years. In recent years, innovations in

crushing, conveying, and particularly waste and

leach stacking technology have sparked a

renewed interest in continuous haulage systems

for large-scale open pit applications. A review

afthe advantages/disadvantages and operating

techniques of crushers, feeders, conveyors, and

stacking systems currently available is made.

The paper examines some operations that are

currently using large scale continuous haulage

systems. Finally, a case study is presented that

evaluates the application of a continuous waste

haulage system in a large open pit mine in the

Western United States, The case study includes

a economic comparison with the existing truck

haulage system.

Introduction

The transport of ore and/or waste

material in hard-rock mines generally falls into

two separate categories: conventional truck

haulage and continuous conveyor haulage.

These haulage methods are interchangeable to

various degrees in order to attain the most cost

effective and flexible system for the

requirements of a particular mine.

In nearly all large-scale hard rock

applications of in-pit conveying, where more

than one face is being mined and fully mobile

crushers are not applicable, some degree of

intermediate conventional truck haulage is

required. The resulting haulage configuration is

dependent on the mobility of the in-pit crusher,

the frequency of crusher moves relative to the

advancing shovel face(s), and, consequently, the

transport distance from the shovel face( s) to the

crusher location in the pit. For waste and leach

material haulage, stacking systems consisting of

a transfer station, a shiftable or mobile

conveyor, and a tripper and boom spreader have

enabled mines to use in-pit crushing and

conveying systems.

In general, conveying for surface mines

is considered suitable for either new mines with

substantial tonnages of ore and waste and

medium-distance hauls of over 2 miles, or well

established mines possessing aging truck fleets

and large vertical climbs out of the pit (Cabrera,

1983). Longer life mines generally favor

1

conveyors over trucks due to their longer

economic life.

Conveyors

High capacity conveyors for open pit

mines are now capable of transporting material

at rates of over 11,000 tph at speeds up to 1,200

ft/min. Steel cable reinforced belts are available

in standard widths of 72 inches with tension

ratings in excess of 6000 lb/inch width. With

the development of high capacity belts, single

vertical lifts of over 2000 feet are achievable.

Conveyors generally can run efficiently up to

17 (30%) slope angles.

The main components for high tonnage

conveyors include steel reinforced belting,

idlers, drives, pulleys, tables, tension take-up

mechanisms, and a braking system. The

selection of conveyor components is generally a

function of vertical lift, capacity, material type,

system availability, and capital and maintenance .

costs.

The principal economic and operating

advantages of belt conveyors over truck haulage

include:

o Grades of up to 30 percent maybe attained

by belt conveyors without any lost efficiency

compared to the recommended 8 percent

for trucks.

o Due to conveyors ability to climb steeper

grades, haul distances are much shorter,

and, in some instances, the required

stripping can be reduced.

o Preventive maintenance for conveyors can

result in high overall availability of up to

98%, low overall maintenance costs,

minimal spare part inventories, and an

overall reduction of the maintenance

operation (Cabrera, 1983).

o Conveyors require a smaller workforce than

for equivalent production with truck

haulage.

o Conveyors have a longer economic life than

trucks with up to 25 years of operation

reported (Cabrera, 1983).

o Conveyors have low per ton operating costs

and power requirements, with 80% of the

energy consumption expended solely for

payload transportation.

The limitations and disadvantages for conveyor

haulage in an open pit mine include:

o The feed size for conveyors is generally

limited to material less than 1/3 operating

belt width, thus requiring in-pit crushing in

most mining situations. This results in an

additional cost for haulage that would not

be allocated with conventional truck

haulage.

o Generally higher initial investment costs are

associated with in-pit conveying systems.

o Conveyors require more sophisticated mine

planning to limit required moves and

maximize proper utilization of system.

o Conveyors are less flexible to changing

mine plans and changing production rates.

o If not properly planned, conveyors can

cause potential sterilization of reserves and

an interruption of the natural progression of

mining the next best ore.

o Grade control and material separation is

very restricted and complicated, requiring

sophisticated planning and costly transfer

stations and stockpiles.

o Conveyors require a permanent, stable wall

or underground tunnel in order to avoid

numerous and costly conveyor relocations.

High Angle Conveyors

High angle conveyors (HAC) were first

successfully developed in the 1980's in order to

provide mine operators with a more flexible and

sometimes more economic alternative to both

trucking and conventional in-pit conveying.

The most promising HAC design was developed

by Continental Conveyor, which uses the

sandwich belt principle where ordinary rubber

belts and idlers sandwich the conveyed material

and transport it directly up the mine face, as

illustrated in Figure 1. The system is reported to

have capacities up to 15,000 tph and can lift

material up 90 slopes.

The highest tonnages achieved in a

working mine with a high angle conveyor is at

the Majdapek Copper mine in the former

Yugoslavia in which 4000 tph is being conveyed

up a 35.5 high-wall a total of 300 vertical feet

(lA. dos Santos, 1988). Annual savings in

operating cost for the High Angle Conveyor

system over truck haulage are estimated at $1.9

M (Reisler and Stanisic, 191H).

2

The application of HAC's for a

particular mining scenario is dependent on the

material feed size and characteristics, required

lift, slope stability along conveyor route,

throughput, estimated availability, and capital

and operational costs of the system. Also .

maintenance access to the conveyor can be a

critical factor for some mines.

One of the primary benefits of the high

angle system is the ability to transport mined

material with very minimal (if any) excavation,

as would normally occur in constructing truck or

conveyor ramps. Furthermore, the system

allows more flexibility to mine design due to the

reduction of tied up pit walls with ex-pit ramps.

High capital costs, lack of proven operating

experience, and limited lift and capacity for high

tonnages of coarse, in-pit material are reported

as the main deterrents for their widespread

adoption in hard rock open pit mining

(Atkinson, 1992).

- -"--.

Fig. I-Modular High Angle Conveying System

Source: Mining Technology, April 1991.

Waste Dump Conveying and Stacking

Under certain conditions, continuous

waste and leach stacking systems can provide

mines with significant cost savings due to large

reductions in haul truck fleets used on long ex-

pit (external to pit) hauls. The most beneficial

scenario for continuous haulage is for large

tonnage mines possessing high strip ratios or

high tonnages of leach material, large vertical

ascents outofthe pit, and long overland

transport distances both to and on the dump

itself. Also a large, level dump configuration

that permits long lateral cycles with minimal

movement of the stacking conveyor and transfer

station is required for effective continuous

stacking.

There are predominantly two basic

methods for stacking. The first method, which

was developed in the open pit coal industry in

Germany, uses shiftable conveyors that consist

of portable sleeper-mounted conveyor

framework modules mounted on a jointed rail.

The conveyors are shifted sideways by

"snakelike" bending of the rail using a crane

suspended shifter head mounted on a dozer that

pulls the entire conveyor to the side, as

illustrated in Figure 2. While the conveyor is

being shifted, the operation of the system is

temporarily discontinued. The head and tail

stations are skid mounted and are relocated with

either a tractor or crawler transporter depending

on the size. Modules can be added or eliminated

to the conveyor to lengthen or shorten the flights

as needed to fit the configuration of the dump

(Krupp Industries, 1994).

Fig. 2-Shiftable Conveyor Being Shifted

Laterally With Bulldozer.

Source: Kennedy,1990.

A crawler mounted boom stacker

(illustrated in Figure 3) is fed with either a

crawler or rail mounted tripper car with a

slewing discharge boom that travels along the

shiftable conveyor. The stacker is composed of

either two or three conveyors which can be

raised or lowered independently to adjust the

stacking discharge height. This allows the

stacker to operate in both an advance mode,

where waste is discharged onto the slope just

below the advancing top edge of the dump, or in

retreat mode in which waste is lifted up to the

next highest lift. This permits the system to

stack at a higher overall lift than in a normal

advance along the dump face, thus minimizing

3

the effective movement of the shiftable

conveyor. Waste stacking systems with shiftable

conveyors have been used for over 30 years and

are considered well proven in operations

worldwide (yu, 1990).

Fig. 3-Crawler Mounted Boom Stacker Using

Advance Stacking Method.

Source: Krupp Industries, 1994.

A second stacking method first

developed in the United States utilizes a rail

mounted mobile tripper on a crawler mounted

mobile bridge conveyor (illustrated in Figure 4).

The system, which has been used in industry for

19 years, was first applied predominantly in

gold heap leach applications due to the system's

minimal amount of compaction ofleaching

material. However, high tonnage leach and

waste mobile stacking conveyor (MSC) systems

are presently being applied in South American

copper operations (Mining Engineering, April

1996). Present systems are now capable of

10,000 tons per hour stacking capacity. The

system can be operated in either an advance or

retreat stacking mode (RAHco International,

1996). Maximum single lift dump heights of

over 600 :ft are achievable with the system,

depending on the geotechnical properties of the

dump (Baker, by correspondence, 1996).

The mobile stacking conveyor consists

of a self-propelled conveyor with a traveling

tripper. Material is transferred onto the MSC

from a fixed conveyor or a mobile tripper. The

material is carried along the mobile conveyor

and is then transferred onto the traveling tripper

which discharges the material. Material can

bypass the traveling tripper and be sent out to

the end ofthe conveyor. The mobile conveyor

consists of multiple frame sections that may be

added or subtracted to fit changes on the dump.

The tripper travels upon crane rails along the

length of the MSC system. The operation is

able to continue production during conveyor

moves. The system also possesses a leveling

system which permits the system to travel up

and down grades while keeping the conveyor

and stacker level. This allows the system to

continue operation while climbing or

descending on dump lifts. Overall length of the

MSC is presently limited to approximately 2400

feet (Baker, by correspondence, 1996).

Either system can provide extremely

low operating costs in the range of 1 to 2 cents

per ton with high productivity and availability

under proper conditions. Availability for both

systems is estimated at 98% (Brenker and

Baker, personal correspondence, 1996).

However, utilization for shiftable conveyors is

generally lower since the conveyor cannot

operate while being laterally shifted. In

addition, a separate cost must be considered for

dozers to shift sections of the conveyor (Baker,

personal correspondence, 1996). The

disadvantages for both continuous waste

stacking systems include high initial capital

investment, limited flexibility for material

segregation, and the requirements for some

dump preparation prior to installation to provide

large even surface areas for efficient operation.

Fig. 4-Typical Mobile Stacking Conveyor

System Performing Advance Stacking

Source: RAHco International, 1995.

There are two primary arrangements

used for shiftable and mobile conveying on

dumps. First, a radial stacking configuration

where the shiftable conveyor rotates in a semi-

4

circular ard anchored from a pivoting drive

station illustrated in Figure 5. The radial

configuration can also be used to construct

circular sweeps to advance the dump in

approximately a rectangular configuration, as

illustrated in Figure 6. A lateral design is

illustrated in Figure 7 in which the shiftable

conveyor runs perpendicular to a crossing

conveyor at the dump base. A combination of

both lateral and radial stacking can be utilized

to closely match a wide variety of dump

configurations, as illustrated in Figure 8.

MSC T.lppcr

Fig.5- Stacker Contructing Radial Dump.

Source: RAHco International, 1995.

Fig.6-Stacker Constructing Rectangular Dump

With Radial Stacking

Source: RAHco International, 1995.

jMoboleT_

-

M_--,

---+

Fig. 7- Stacker Constructing Rectangular Dump

With Lateral Stacking.

Source: RAHco International, 1995.

Fig.8-Combined Lateral and Radial Stacking on

Dump.

Source: RAHco International, 1995.

In-Pit Crushing Systems

In-pit crushers are classified by the

mobility of the crusher. This ranges from fully

mobile crushers that continuously follow the

advancing working face, to permanent crushers,

which require increasing truck travel distances

with expansion of the mine over time. Mobile

crusher is a generic term for any crusher that

may be moved. The crushing plant is mounted

on a frame base that is either a complete stand-

alone unit or that can be disassembled into

modules for transport. The in-pit crushing

systems can be moved either on skids, with a

crawler, or with a wheeled or walking

transporter. The mobile crushing plant

generally includes a hopper, feeder, crusher, and

discharge conveyor, along with built-in

electrical, mechanical, and auxiliary systems

(Frizzel and Martin, 1992).

The crusher size for in-pit conveying is

dependent on the type of material being crushed,

feed size, output size, and selected capacity for

the entire system. As a general rule, maximum

particle size for conveyed material should not

exceed 30% of belt width (Frizzel and Martin,

1992). Fourteen inch feed is usually considered

maximum size for 72 inch steep inclined

.5

conveyors in hard rock (Bailey, by

correspondence, 1996).

For large in-pit applications in hard

rock mines with throughputs in excess of 3000

tph, gyratory crushers are the most preferable

due to their high throughput, ability to handle a

large range of feed size, and relatively high

reliability. As of 1989, 11 of the 16 in-pit

crushing installations with capacities in excess

of 4,000 tph were gyratory crushers in the 54175,

60/89, and 60/109 inch size class. The largest

throughput being attained with a single crusher

is 9 600 mtlh at the Chuquicamata mine in

Chile using a 60/109 gyratory crusher with four

dump pockets and two indirect feeders

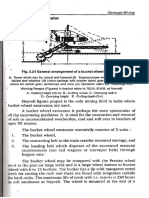

illustrated in Figure 9.

Figure 9: Chuquicamata 9000 tph Movable

Waste Crushing Plan with 4 Side Dumping

Source: Kropp Industries, 1995.

Crusher Feeder Systems

The two primary methods for feeding

in-pit crushing plants are direct feed and

indirect feed. The proper selection in feeder

configuration for a particular mining situation is

determined with consideration of the crusher

feed size, system availability, crusher

throughput, crusher and truck utilization,

material characteristics, bench height, frequency

of crusher re-Iocations, and capital costs.

The direct feeder system involves haul

trucks dumping into a crusher feed hopper,

which usually has a two truck capacity

(commonly 400 tons). The bin is either located

by excavating a notch in the bench with concrete

and earth reinforcement or using a dump-bridge

for trucks to access the crusher, as illustrated in

Figure 10. Dual dumping of trucks is possible

with the direct feed method. Advantages for

using direct crusher feeding include lower

capital costs, simplified operation, and higher

availability due to the elimination of a moving

feed mechanism.

Figure 10: Direct Feed Mobile Crusher with

Dump Bridge

Source: Utley and Laidlaw, 1984.

However, there are some drawbacks to

direct feeding. Utilization of crushers generally

are lower due to lack of crusher feed control,

limited capacity in the feed bin and limited

dump points. Problems also occur if two trucks

simultaneously dump fine material that passes

right through the crusher. The large surge in

fine material can overload the bottom discharge

conveyor causing a backup and packing of the

crusher. Direct feed also requires a 15 to 30 foot

higher crusher installation to provide room for

bottom surge, which might conflict with the

bench heights of many mines (typically around

20 ft for gold, 50 ft in copper mines).

Constructing a notch in a bench for a crusher

bin is also not advised ifbench slope stability is

an issue (Johnson, 1982).

Indirect feeding of crushers can be

performed using either overlapping flight apron

feeders, vibrating feeders, or belt feeders, to

provide regulated feed to the crusher. Indirect

feeding of crushers provides higher throughputs

than direct feeding, and usually has lower

installation costs due to the elimination of a

bench slot for the crusher bin. Systems have

been developed with dual feeders that can

permit up to four trucks to dump

simultaneously. This is important for achieving

throughputs approaching 10,000 tph from a

single crushing plant (Utley, by correspondence,

1996).

Capacity, crusher and truck utilization,

and crusher bench configurations are the main

consideration for selecting indirect feeding

6

systems. Generally, operating and maintenance

costs are higher than for a direct feed system due

to the additional mechanical component of a

feeder. However, indirect systems have a lower

profile and feeders may be inclined from a lower

bench level, making the system more compatible

to a mine's bench configuration.

Figure 11: Indirect Feed Mobile Crusher with

Inclined Apron Feeder.

Source: Utley and Laidlaw, 1984.

The apron feeder is the most commonly

used feeding mechanism for in-pit crushing

applications due to its rugged construction and

its ability to start up with a heavy load. The

apron feeder is similar to a crawler tread with

fabricated steel or heavy cast plates, which carry

feed directly from the hopper into the gyratory

crusher. It is preferable to keep a layer of rock

on top of the feeder to cushion the impact from

truck dumping cycles.

Vibrating feeders have a flat vibrating

pan that can handle up to 6000 tph. Belt feeders

have increased in usage in recent years due to

advances in materials used .. Belts are two to

three inches thick constructed with fabric or

steel cable reinforcement. Belt feeders are

considerably cheaper to purchase and maintain

than apron feeders and require less cleanup

(Frizzel and Martin 1992).

Scalpers and Grizzlies

The use of scalpers and grizzlies can

have application in certain situations in which

there is a large percentage of conveyab1e

material in the run-of-mine feed. Grizzlies have

been used to increase throughputs for crushers

by allowing large proportions of undersized feed

to pass directly on the belt with remaining

oversized material being directed through the

crusher.

In-pit scalpers are also applicable for

materials that contain only a small portion of

oversized feed. A high capacity scalper as

illustrated in Figure 14, requires apron feeders

to provide regulated feed in order to be effective.

Separate handling of coarse oversize is generally

done with front-end loaders. This operation is

reported as difficult and expensive due to hard

digability in blocky oversized waste-piles

(Kutschera, 1992).

As of 1992, capital costs for 4,400 tph

scalping plants are estimated at $4.8 million

with operating costs of 7-14 cents per ton.

Operating and maintenance costs are estimated

to be slightly less than gyratory crushers of

equal capacity, while similar labor costs and

power consumption between a gyratory

crusher's apron feeder and a scalper can be

expected. However, increased re-handling of

oversized material can quickly escalate the total

operating costs for a scalping system

(Kutschera, 1992).

Large Scale Continuous Haulage Systems

The Sierrita property is located 30 mi.

south of Tucson and is a low-grade copper-

molybdenum orebody. In 1981, Sierrita

operated three movable 60-89 gyratory crushers

with apron feeders, five 12-inch ore belts with a

total distance of 16,000 ft, and four separate

sections of waste belting totaling 8000 ft. Total

production using crushing and conveying at the

time was 250,000 tpd, with ore accounting for

92,000 tpd. The waste belting includes a

movable stacker belt located on the waste

dumps, which is moved by bulldozers

approximately 65 meters every 60 to 90 days.

Sierrita was the first large open-pit

mine in the United States to utilize movable

crusher technology. In 1983, Duval (the

original mine operators) transformed its existing

haulage system, which used stationary in-pit ore

crushing and conveying, into mobile in-pit

crushing with extendIble conveyors for hauling

ore and waste. The average relocation time for

the crusheris 48 hours at a cost oUI million.

Total capital investment in the system as of

1984 was estimated at $32 million. The

portable crusher system was reported to have

saved $.29/ton hauled out of the pit, lowered per

shift truck requirements from 24 to 14 trucks,

7

and reduced the overall operating costs over the

first 10 years of operation by over $120 million.

In addition, truck purchases were to decrease

37%, saving an added $23 million in capital

costs (Sassos, 1984).

Kennecott Bingham Canyon

Kennecott's Bingham Can):on copper

mine is located approximately 25 miles

southwest of Salt Lake City, Utah. Between

1986 and 1988, as part of a $400 million

modernization program to lower operational

costs, Kennecott installed a semi-mobile in-pit

crushing and conveying system for ore to

replace much of its outdated rail system. The

60-109 gyratory crusher has a 10,000 tph

throughput and is situated on a concrete

foundation notched inside a 30 meter high

double bench and supported by earth reinforced

walls. The bench is located on the same

elevation as the tunnel portal.

Actual realized capacity is around 6000

tph due to its direct feed configuration which

has a capacity of 780 yd'3. The ore bin has two

dump slots for the 170-ton trucks which dump

independently. The system uses a 3.7 mile

tunnel previously used for rail haulage to route

the 12-in conveyor from the pit to the

concentrator stockpile. A total of six conveyors

with a total length of 5.3 miles are used with a

total installed drive power of 17,500 Hp (Kaerst,

1987).

Phelps Dodge Morenci

Phelps Dodge's Morenci Mine, located

200 miles east of Phoenix, Arizona installed a

120,000 tpd in-pit ore crushing and conveying

system in 1989 at an estimated cost of $43

million. The system uses two 60-89 in. semi-

portable in-pit crushing stations, each having

8000 tph capacity, along with three inclined and

two downhill regenerative conveyors. An

intermediate surge pile with a 9000 tph capacity

is used to increase overall system utilization. As

of 1993, the system was designed to be

permanent for ten years (Dowall and Linde,

1993).

Highland Valley Copper

Highland Valley Copper is located 140

miles northeast of Vancouver in British

Columbia. The present ore conveying system

has a capacity of 143,000 tpd using in-pit

crushing from two 60-89 semi-mobile gyratory

crushing plants. The duplicate crushing and

conveying systems are arranged in parallel. The

conveyors are designed as modules, simplifying

lengthening and shortening of conveyors. Total

capital costs for the system in 1987 was C$46.4

million. For the first ten years of operation,

savings in operating costs were estimated at 25

cents/ton, which is expected to increase to 37

cents/ton. Also a truck fleet reduction of 18

190-ton trucks is expected with savings of

C$18.2 The un-discounted pay-back is reported

at 7.2 years with a return on investment of

10.3%. The second 10 year period estimates a

C$160 million saving with expenditures of C$15

million (MacPhail and Richards, 1994).

Chuquicamata

Codelco's Chuquicamata mine in

Chile, wIllch is presently the world's largest

copper mine, commissioned a waste in-pit

crushing and conveying system in 1991. The

semi-mobile crusher is presently the largest for

waste handling in the world, with an average

handling rate of 9000 mtph. Six 60-in width

conveyors carry waste material 1.5 km up an

incline, 2.3 km overland, 1.1 km downhill and

1.24 km along the shiftable conveyor on the

dump (Januschenck and Papajewski, 1992).

The crushing plant is comprised of four

modules: two apron feeders, one crushing

module, and one discharge conveyor. This

configuration allows haul trucks to discharge

waste rock into two separate feed bins, each with

a 540 ton (1080 m

3

) capacity. The system

allows both a higher truck utilization rate due to

reduced queue times, and higher crusher

utilization due to consistently controlled feed to

the crusher. Also the configuration has the

ability to sustain partial production during

individual feeder maintenance shutdowns.

Capital cost for the crushing plant was $21

million in 1990.

8

Palabora Copper Mine

The Palabora copper mine of South

Africa, faced with an escalation in fuel prices of

320% between 1980 and 1985, and increasing

mining rates due to a pit expansion, has used

both trolley assist and in-pit crushing/conveying

to offset haulage costs. A trolley assist truck

haulage system was implemented in 1981 with

an internal rate of return estimated at 102% and

net present value cash flow of R152 million

(1980 terms) (Gliddon and Wade, 1988).

In addition, a 91,800 tpd in-pit

crushing and conveying system for ore through

an underground incline was commissioned in

1988 (partially due to plans to develop high

grade underground reserves). Waste will

continue to be hauled primarily using

conventional trolley assisted trucks. A series of

underground inclines that will be constructed in

three phases as the pit advances in depth. Initial.

estimates for pay-back are at four years with an

internal rate of return of almost 20%. Economic

savings include a reduct;ion of 14 trucks and

reduced diesel and trolley assisted electric

consumption (Gliddon and Wade, 1988). As of

1995 it is estimated that a further 46% energy

savn:g will be made by conveying ore from the

in-pit crusher compared with trucking under

trolley assist (Mining Magazine, 1995).

Majdanpek Copper Mine

The Majdanpek Copper mine, located

in the former Yugoslavia, is known for being the

first mine to use high angle conveyor (HAC)

technology in an open pit hard rock mine. The

high angle conveyor elevates 4000 tph of

material out of the pit over a vertical height of

295 ft at 35.5.

In addition, the mine uses two semi-

mobile 60-89 in-pit crushers with 3000 mtlhr

capacities that load 6000 tph capacity belts

exiting the pit to an 8000 tph continuous waste

haulage system This system consists of a 1.3

km long slewing shiftable conveyor with a

tripper that transfers waste onto the crawler-

mounted spreader on the primary dump. A

transfer system is centrally located to route ore

to the mill and waste to the dump, thus

eliminating duplication of systems for separate

material routing. Total accumulated savings

due to the in-pit crushing and conveying system

in comparison to truck only haulage is estimated

at US$142 million by year 2002 (Dos Santos,

1991).

Case Study

A pre-feasibility study was made on the

application of continuous waste haulage in a

large surface metal mine. The mine, located in

the Western U.S., produces 400,000 tpd. Of ore

and waste. The time frame for the study is 1998

to projected end of mining in 2010. Currently a

fleet of76 190 ton trucks are operated in the

mine with peak projected fleet size occurring in

2001 at 88 190 ton trucks. Conditions favorable

for installing an in-pit crushing system with

interconnecting conveyors to a continuous

mobile stacking system on the waste dump

include:

D High waste strip ratios of approximately 18

to 1 through life of mine.

D Haul times approaching 50 minutes for

most adverse hauls to dump during life of

mine with present haulage system.

D High vertical ascent from pit to dump

locations ranging from 410 to 2070 feet.

D A net reduction of approximately 11,750 ft

of adverse grade ramp is provided by

proposed conveyor system.

D Availability of permanent wall for location

of long standing crusher and conveyor

route.

D Large surface area on dump for effective

deployment of continuous or shiftable

stacking system.

D Large truck fleet replacement and

expansion scheduled with current haulage

system in 1998 and 1999.

Difficulties for installing a continuous waste

haulage system include:

D Slope stability constraints due to susceptibly

active pit walls limit potential surface and

underground conveyor routes.

D Limited locations for crusher and

subsequent crusher re-Iocations.

D Large one time capital expenditure.

D Reduced pit design flexibility over life of

mine.

9

The methodology used in the study

follows: 1) Determination of potential crusher

and conveyor locations. 2) Evaluation of mine

waste types and tonnages suitable for continuous

haulage. 3) Selection of optimal capacity for the

crushing-conveying-stacking system. 4) Truck

simulation to determine yearly effects of waste

crushing and conveying on truck fleet size and

operating costs. 5) Economic cost analysis of

truck haulage versus conveyor haulage.

Conclusions

It was determined in this preliminary

assessment that the application of in-pit

conveyor haulage of waste was technically

feasible from 1998 to 2009 with a 60 million

tons per year average capacity. In addition, the

deployment of a continuous haulage system

could achieve significant cost savings in waste

haulage costs of approximately $0.32/ton due to

an estimated average reduction of 27 trucks per

year. Estimated truck reductions from reduced

cycle times to an in-pit <ifllsher location was

calculated using truck haulage simulation

methodology currently employed by mine

engineering . The large initial capital

expenditure for the conveying system was

determined to be offset by the reduction in

haulage operating costs for waste material

transported from the lowest/portion in the mine.

Net capital outlay for the conveyor system is

lessened by the subsequent reduction in required

truck replacements which is currently scheduled

for a major portion of the aging truck fleet in

1998 and 1999.

Component escalation was found to

have no observable effect on influencing the

economic comparison of continuous and truck

haulage systems. A contingency sensitivity

assessment of costs for the continuous haulage

system determined that the relative comparative

overall economics of the system was not

dramatically affected with a 100% increase in

either capital or operating costs.

Table 1: Total Average Operating Cost per ton

for Conventional Truck and Conveyor Haulage.

0.9

0.8

0.1

56

SO.5

0.2

0.1

Conventionol

Truck Haulage

Continuous III<i

InteunediaIe

HouIa8e

Table 2: Estimated After Tax Net Present Value

of Total Operating and Capital Costs for .

Haulage Systems at 12% Cost of Capital.

i!l400

...

S300

200

100

o

1. Atkinson, Thomas. 1992. Future

Conceptsin Surface Mining. Mining

Engineering Handbook: 1352-1356.

2. Bailey, Richard. 1996. Personal

Correspondence. Continental Conveyor and

Equipment Co.

3. Baker, Derrick. 1996. Personal

Correspondence. RAHco. International.

4. Breuker, Chris. 1996. Personal

Correspondence. Krupp Robbins, Inc.

5. Cabrera, Victor. 1983. Conveyor Belts

Make Sense for Long Distance Haulage.

Conveyors in Mining: 3-12.

6. Dos Santos, 1. A, 1988. High Angle

Conveyors for Surface Mining - 1988.

Mine Planning and Equipment Selection.

Singhal (ed.), Rotterdam: 221-227.

7. Dowall, W. M. and T. B. Linde. 1993.

Morenci's In-pit Crushing and Conveying

System. Mining Engineering: 257-262.

8. Frizzel, E. M. and T. W. Martin. 1992.

In-Pit Crushing and Conveying. Mining

Engineering Handbook: 1343-1350.

10

9. Gliddon, 1. P. and G. C. Wade. August

1988. Palabora - Changing to Meet the

Challenge of the 80's. Mining

Engineering: 808-814.

10. Januscheck, W. and D. Papajewski.

February 1992. Crushing to Scale. How

the World's Largest Copper Mine Uses the

World's Largest Semi-Mobile Crusher for

Waste Handling. World Mining

Equipment: 28-29.

11. Kaerst, D. November 1987. Bingham

Bounces Back - With Mobile Conveyors.

World Mining Equipment: 37-41.

12. Kutschera, Sepp A. 1992. Continuous

Mining and Transport Methods for Large

Open Cast Mines. Randol Gold Forum,

Vancouver, Canada: 31-36.

13. MacPhail, A. D. andD.M. Richards.

October 1994. hi-Pit Crushing and

Conveying at Highland Valley Copper.

Mining Engineering: 1186-1190.

14. Reisler, N. and Z. Stanisic. October 1981. .

Converting to Conveyors. Engineering and

Mining Journal: 106-108.

15. Sassos, Michael R April 1984. In-Pit

Crushing and Conveying Systems.

Engineering and Mining Journal: 46-59.

16. Utley, R W. and R 1. Laidlaw. 1985.

Movable In-Pit Crushers Design

Parameters. Fuller Co.: 1-28.

S-ar putea să vă placă și

- 4 In-Pit Crushing & ConveyingDocument29 pagini4 In-Pit Crushing & ConveyingChandan KumarÎncă nu există evaluări

- High Angle Conveyor Offers Mine Haulage SavingsDocument27 paginiHigh Angle Conveyor Offers Mine Haulage SavingsJDÎncă nu există evaluări

- Application of Conveyors For UG HaulageDocument11 paginiApplication of Conveyors For UG Haulageminerito2211Încă nu există evaluări

- High Angle Conveyor Offers Mine Haulage SavingsDocument20 paginiHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- Modelling of In-Pit Crusher Conveyor AlternativesDocument8 paginiModelling of In-Pit Crusher Conveyor AlternativesJosue GonzalezÎncă nu există evaluări

- Selecting Shaft or DeclineDocument8 paginiSelecting Shaft or DeclineluisparedesÎncă nu există evaluări

- Large Surface MinersDocument6 paginiLarge Surface MinersNaveen Tiwari100% (1)

- Belt ConveyorsDocument39 paginiBelt ConveyorsAhmed BakurÎncă nu există evaluări

- BWEDocument16 paginiBWEMas YoanÎncă nu există evaluări

- In Pit Crushing & ConveyingDocument19 paginiIn Pit Crushing & ConveyingBadar Hayat100% (1)

- 10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryDocument10 pagini10.bulk Materials Handling by Belt Conveyors at New Denmark CollieryjsaulÎncă nu există evaluări

- IPCC ConceptDocument24 paginiIPCC ConceptTapadev DasÎncă nu există evaluări

- Shaft or DeclineDocument10 paginiShaft or DeclineElias ArayaÎncă nu există evaluări

- Wagons Modern Bulk Material HandlingDocument4 paginiWagons Modern Bulk Material Handlingparuchurivenkat5272Încă nu există evaluări

- Moore 2012 PDocument7 paginiMoore 2012 PSACHIDHANANDHAM AÎncă nu există evaluări

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseDocument29 paginiServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechÎncă nu există evaluări

- Incline Haulage TrucksDocument2 paginiIncline Haulage Trucksgarves007Încă nu există evaluări

- Spiral Classifier English VersioinDocument5 paginiSpiral Classifier English VersioinRogelio Israel LedesmaÎncă nu există evaluări

- 8531Document3 pagini8531Srinivas VenkateshÎncă nu există evaluări

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 paginiKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasÎncă nu există evaluări

- Bucket Wheel ExcavatorDocument26 paginiBucket Wheel ExcavatorAnshul yadav100% (1)

- Chapter 7Document44 paginiChapter 7Nebiyou KorraÎncă nu există evaluări

- Belt Conveyor IsmDocument16 paginiBelt Conveyor IsmPrasenjit ChoudhuryÎncă nu există evaluări

- Obata - Grab Bucket Type Ship UnloaderDocument20 paginiObata - Grab Bucket Type Ship Unloadertrungnq_ktd97Încă nu există evaluări

- Trommel Drum Scrubber Jiangxi IndustryDocument11 paginiTrommel Drum Scrubber Jiangxi IndustryCarlos Daniel Cuba JaraÎncă nu există evaluări

- Equipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyDocument14 paginiEquipment Selection For HPGR-Based Comminution Circuits Part 1 - Chris - MorleyWilson VicencioÎncă nu există evaluări

- Mechanical Grain ConveyingDocument64 paginiMechanical Grain ConveyingDaniel CookÎncă nu există evaluări

- Bulk Materials Handling: in MiningDocument10 paginiBulk Materials Handling: in MiningHimesh Desai100% (1)

- Jaw Crusher Kinematics Simulation and AnalysisDocument5 paginiJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceÎncă nu există evaluări

- CBG Mining 1Document28 paginiCBG Mining 1Ahsan AliÎncă nu există evaluări

- Mobile Coal Handling Systems Feb12Document4 paginiMobile Coal Handling Systems Feb12Kroya Hun100% (1)

- Conveyor Belts 1Document30 paginiConveyor Belts 1EGS_1977Încă nu există evaluări

- Flying BeltDocument2 paginiFlying Beltshazz_28Încă nu există evaluări

- 9.1 Lecture Material - Pneumatic Transport and Slurry TransportDocument51 pagini9.1 Lecture Material - Pneumatic Transport and Slurry TransportDondon Irig100% (1)

- I Feeder Application Design CalculationsDocument2 paginiI Feeder Application Design Calculationsarsaniose100% (1)

- ThyssenKrupp - Open Pit Mining Systems and EquipmentDocument28 paginiThyssenKrupp - Open Pit Mining Systems and EquipmentBoy Alfredo100% (1)

- Bucket Wheel ExcavatorDocument4 paginiBucket Wheel ExcavatorNisha raoÎncă nu există evaluări

- Applications & Advantages of Pipe ConveyorsDocument4 paginiApplications & Advantages of Pipe Conveyorsayaskant751001Încă nu există evaluări

- 0737 Open Pit Mining Sys EquipDocument28 pagini0737 Open Pit Mining Sys EquipSivaraman SelvapandianÎncă nu există evaluări

- Pipe Conveyor Belts: With Steel Cord and Fabric ReinforcementDocument5 paginiPipe Conveyor Belts: With Steel Cord and Fabric ReinforcementEugenepaccelli Kolandai SamyÎncă nu există evaluări

- Type of Failure in Conveyor SystemDocument13 paginiType of Failure in Conveyor Systemzainonayra100% (2)

- BOF Plant Write UpDocument20 paginiBOF Plant Write UpKalyan HalderÎncă nu există evaluări

- Pipe Conveyor SystemDocument6 paginiPipe Conveyor Systemsurajit81100% (2)

- Belt SwayDocument29 paginiBelt SwayNishantKumarGauravÎncă nu există evaluări

- AnilDocument49 paginiAnilAnil BhairatÎncă nu există evaluări

- Polysiushpgr (HPGR)Document20 paginiPolysiushpgr (HPGR)Alexis GodoyÎncă nu există evaluări

- Japan Pipe Belt Conveyor Sy...Document7 paginiJapan Pipe Belt Conveyor Sy...salkan_rahmanovic810Încă nu există evaluări

- Materi Training Coal HandlingDocument108 paginiMateri Training Coal HandlingtakasyaÎncă nu există evaluări

- Telescopic ChuteDocument2 paginiTelescopic Chutebiswajit sabuiÎncă nu există evaluări

- Electrical Documentation For Radar Level TransmitterDocument6 paginiElectrical Documentation For Radar Level TransmittersatfasÎncă nu există evaluări

- Design and Development of Automated Conveyor System For Material HandlingDocument5 paginiDesign and Development of Automated Conveyor System For Material HandlingNurKholisÎncă nu există evaluări

- Surface Mining MethodsDocument34 paginiSurface Mining MethodsGeorge MudzimuÎncă nu există evaluări

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDocument5 paginiHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiÎncă nu există evaluări

- Spiral Classifier Brochure - Triveni EnggDocument4 paginiSpiral Classifier Brochure - Triveni Enggrajeevup2004Încă nu există evaluări

- Grinding-Fundamentals and Theory: Dr. Chandranath Banerjee Sr. Engineer and Lead Minerals and Separation TechnologyDocument32 paginiGrinding-Fundamentals and Theory: Dr. Chandranath Banerjee Sr. Engineer and Lead Minerals and Separation TechnologyVarun InamdarÎncă nu există evaluări

- Excavator SelectionDocument10 paginiExcavator SelectionMario HezkeeaÎncă nu există evaluări

- FeederDocument23 paginiFeederShabrina NadhilaÎncă nu există evaluări

- Pit To Plant - Current TrendsDocument6 paginiPit To Plant - Current Trendsretrospect1000Încă nu există evaluări

- 1 s2.0 S0167903188907773 MainDocument11 pagini1 s2.0 S0167903188907773 Main88127050Încă nu există evaluări

- Inpit CrusherDocument34 paginiInpit Crusheredgardo olateÎncă nu există evaluări

- Analysis of The Effectiveness of Shovel-Truck Mining System PDFDocument6 paginiAnalysis of The Effectiveness of Shovel-Truck Mining System PDFRobert KnightÎncă nu există evaluări

- Four-Pass Loading - Must-Have or Myth PDFDocument9 paginiFour-Pass Loading - Must-Have or Myth PDFRobert KnightÎncă nu există evaluări

- Maintainability Analysis of Mechanical Systems of Electric Cable Shovels PDFDocument5 paginiMaintainability Analysis of Mechanical Systems of Electric Cable Shovels PDFRobert KnightÎncă nu există evaluări

- Eh1700 3Document8 paginiEh1700 3Robert KnightÎncă nu există evaluări

- An Expert System For Hydraulic Excavator and Truck Selection in Surface MiningDocument12 paginiAn Expert System For Hydraulic Excavator and Truck Selection in Surface MiningRobert KnightÎncă nu există evaluări

- At Chi SonDocument8 paginiAt Chi SonRobert KnightÎncă nu există evaluări

- Conveyor Dynamic Analysis Case StudyDocument16 paginiConveyor Dynamic Analysis Case StudyarcelitasÎncă nu există evaluări

- Exercícios Elementos de MáquinasDocument8 paginiExercícios Elementos de MáquinasThomas AlmeidaÎncă nu există evaluări

- AixamDocument156 paginiAixamdockerwatsonÎncă nu există evaluări

- Installation Handbook - Multiply Conveyor Belts - Rev.4Document36 paginiInstallation Handbook - Multiply Conveyor Belts - Rev.4Guru Raja Ragavendran NagarajanÎncă nu există evaluări

- Basic Concept of Mechanical EnggDocument8 paginiBasic Concept of Mechanical EnggAsad Bin Ala QatariÎncă nu există evaluări

- 3 V Belt DriveDocument29 pagini3 V Belt DriveMurugesan RameshÎncă nu există evaluări

- tm1 1550 1689 CLDocument196 paginitm1 1550 1689 CLJessica R LattimoreÎncă nu există evaluări

- T7X-03 Treadmill Service ManualDocument85 paginiT7X-03 Treadmill Service ManualChinmaya Kumar MohantyÎncă nu există evaluări

- 2010 - Telescopic ChuteDocument29 pagini2010 - Telescopic ChutesteelageÎncă nu există evaluări

- Electric Skateboard Motors The Complete GuideDocument15 paginiElectric Skateboard Motors The Complete GuideriverbendfcÎncă nu există evaluări

- German Industrial Standard Din 22112 12010Document5 paginiGerman Industrial Standard Din 22112 12010Zlatko PentekÎncă nu există evaluări

- Acrylic I3 Pro B 3D Printer Building Instruction PDFDocument94 paginiAcrylic I3 Pro B 3D Printer Building Instruction PDFFrederik HøjlundÎncă nu există evaluări

- Continental Belt Monitoring Systems - v04Document50 paginiContinental Belt Monitoring Systems - v04dabdillahÎncă nu există evaluări

- Chieftain 1700 Dry - RinserDocument17 paginiChieftain 1700 Dry - RinserbogdanmichaelÎncă nu există evaluări

- Fort Fitness - Feb 2023Document29 paginiFort Fitness - Feb 2023Prerogative GreenÎncă nu există evaluări

- Belt CleanersDocument9 paginiBelt Cleanerskevenalbert27Încă nu există evaluări

- Cowells Manuals PDFDocument16 paginiCowells Manuals PDFpedjaÎncă nu există evaluări

- 6342 - Greenacres 9560 2011Document6 pagini6342 - Greenacres 9560 2011Cva AvelarÎncă nu există evaluări

- Ce 12p Product ManualDocument36 paginiCe 12p Product ManualHrsDesingÎncă nu există evaluări

- Dunlop Conveyor Belt Design ManualDocument16 paginiDunlop Conveyor Belt Design ManualTabor TamiruÎncă nu există evaluări

- Terex Jaques Torrent ScreensDocument16 paginiTerex Jaques Torrent ScreensKarin AndersonÎncă nu există evaluări

- Price List A60HDocument6 paginiPrice List A60HMaintenance PlannerÎncă nu există evaluări

- Iso 9981 1990Document9 paginiIso 9981 1990turgutÎncă nu există evaluări

- Section 6 D3 BucketsDocument29 paginiSection 6 D3 Bucketsiman zareieÎncă nu există evaluări

- Different Types of Conveyor ComponentsDocument2 paginiDifferent Types of Conveyor ComponentsMatt Suarez TudgeÎncă nu există evaluări

- SANDVIK CJ408:01: Spare Parts CatalogDocument16 paginiSANDVIK CJ408:01: Spare Parts Catalogleonidas cespedes100% (1)

- E84AVSCx 8400 StateLine C v1-2 en Ma-2Document76 paginiE84AVSCx 8400 StateLine C v1-2 en Ma-2oscarÎncă nu există evaluări

- Stacker Cum Reclaimer - Operation & MaintenanceDocument7 paginiStacker Cum Reclaimer - Operation & MaintenanceDurjoy Chakraborty75% (4)

- Final of Small Plowing MachineDocument89 paginiFinal of Small Plowing Machinenigus gereziher67% (3)

- Sitrans: Speed SensorsDocument24 paginiSitrans: Speed SensorsJaime ViloriaÎncă nu există evaluări