Documente Academic

Documente Profesional

Documente Cultură

En Mikroe Article C Pic 01 09

Încărcat de

Elhaitar AchrafDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

En Mikroe Article C Pic 01 09

Încărcat de

Elhaitar AchrafDrepturi de autor:

Formate disponibile

ADVERTISEMENT

OK. TOUCHSCREEN

Do you want your new device to have a simple and intuitive interface? If the answer is YES, then a graphic LCD display with touch panel is the best choice because together they create a Touchscreen (Glcd + Touch Panel = Touchscreen). In that way, with a small number of electronic components you will be able to create an attractive and easy to use device.

What is a touch panel? A touch panel is a thin, self-adhesive transparent panel placed over the screen of a graphic LCD. It is very sensitive to pressure so that even a soft touch causes some changes on output signal. There are a few types of touch panel. The simplest one is the resistive touch panel which will be discussed here. ue of the divider is read on the bottom contact of the Y surface. Voltage can be in the range of 0V to the power supply and depends on the X coordinate. If the point is closer to the left contact of the X surface, the voltage will be closer to 0V. In order to determine the Y coordinate, it is necessary to connect the bottom contact on the Y surface to ground, and the upper contact to power supply. By Dusan Mihajlovic Mikroelektronika Hardware Department

Now you need a...

In this case, the voltage is read on the left contact of the X surface.

Connecting to microcontroller

In order to connect a touch panel to the microcontroller it is necessary to create a circuit for touch panel control. By means of this circuit, the microcontroller connects appropriate contacts of the touch panel to ground and the power supply (as described above) in order to determine the X

Principle of operation

A resistive touch panel consists of two transparent rigid foils, forming a sandwich structure, that have resistive layers on their inner sides. The resistance of these layers usually does not exceed 1Kohm. The opposite sides of the foils have contacts available for use through a flat cable. The process of determining coordinates of the point in which the touch panel is pressed can be broken up into two steps. The first one is the determination of the X coordinate and the second one is the determination of the Y coordinate of the point. In order to determine the X coordinate, it is necessary to connect the left contact on the X surface to ground and the right contact to the power supply. This enables a voltage divider to be obtained by pressing the touch panel. The val-

Flat cable detail

Determination of Y coordinate

Figure 1. Touch panel internal structure

Advertisement article of MikroElektronika www.mikroe.com mikroC and EasyPIC5 are registered trademarks of MikroElektronika. All rights reserved.

... making it simple

SOFTWARE AND HARDWARE SOLUTIONS FOR EMBEDDED WORLD

www.mikroe.com

Schematic 1. Connecting Touchscreen Example 1: Program to demonstrate touchscreen operation

and Y coordinates (Refer to Schematic 1). The bottom contact of the Y surface and left contact of the X surface are connected to the microcontrollers A/D converter. The X and Y coordinates are determined by measuring voltage on these contacts, respectively. The software consists of writing a menu on graphic LCD, turning the circuit for touch panel control on/off (driving touch panel) and reading the values of A/D converter which actually represent the X and Y coordinates of the point. Once the coordinates are determined, it is possible to decide what we want the microcontroller to do. For the purpose of illustration, let us examine Example 1. It explains how to turn on/off two digital microcontroller pins, connected to LED diodes A and B, using a display and a touch panel.

const char msg1[] = TOUCHPANEL EXAMPLE; const char msg2[] = MIKROELEKTRONIKA; const char msg3[] = BUTTON1; const char msg4[] = BUTTON2; const char msg5[] = RC6 OFF; const char msg6[] = RC7 OFF; const char msg7[] = RC6 ON ; const char msg8[] = RC7 ON ; long x_coord, y_coord, x_coord128, y_coord64; char msg[16]; char * CopyConst2Ram(char * dest, const char * src){ for(;*dest++ = *src++;) ; return dest; } unsigned int GetX() { PORTC.F0 = 1; PORTC.F1 = 0; Delay_ms(5); return ADC_read(0); //reading X // DRIVEA = 1 (LEFT drive on, RIGHT drive on, TOP drive off ) // DRIVEB = 0 (BOTTOM drive off ) // reading X value from RA0 (BOTTOM) // scaled x-y position

unsigned int GetY() { PORTC.F0 = 0; PORTC.F1 = 1; Delay_ms(5); return ADC_read(1);

//reading Y // DRIVEA = 0 (LEFT drive off, RIGHT drive off, TOP drive on) // DRIVEB = 1 (BOTTOM drive on) // reading Y value from RA1 (from LEFT)

Flat cable on-board connector before...

...and after connecting touch panel.

void main() { PORTA = 0x00; TRISA = 0x03; ANSEL = 0x03; ANSELH = 0; PORTC = 0 ; TRISC = 0 ;

// RA0 i RA1 are analog inputs // Configure other AN pins as digital I/O // PORTC is output // Glcd_Init_EP5 // Choose font // Copy TOUCHPANEL EXAMPLE string to RAM // Copy MIKROELEKTRONIKA string to RAM //Display Buttons on GLCD:

Considering that the touch panel surface is slightly larger than the surface of the graphic LCD, in case you want greater accuracy when determining the coordinates, it is necessary to perform the software calibration of the touch panel.

Glcd_Init(&PORTB, 0, 1, 2, 3, 5, 4, &PORTD); Glcd_Set_Font(FontSystem5x8, 5, 8, 32); Glcd_Fill(0); // Clear GLCD CopyConst2Ram(msg,msg1); Glcd_Write_Text(msg,10,0,1); CopyConst2Ram(msg,msg2); Glcd_Write_Text(msg,17,7,1); Glcd_Rectangle(8,16,60,48,1); Glcd_Rectangle(68,16,120,48,1); Glcd_Box(10,18,58,46,1); Glcd_Box(70,18,118,46,1); CopyConst2Ram(msg,msg3); Glcd_Write_Text(msg,14,3,0); CopyConst2Ram(msg,msg5); Glcd_Write_Text(msg,14,4,0); CopyConst2Ram(msg,msg4); Glcd_Write_Text(msg,74,3,0); CopyConst2Ram(msg,msg6); Glcd_Write_Text(msg,74,4,0); while (1) { x_coord = GetX(); y_coord = GetY(); x_coord128 = (x_coord * 128) / 1024; y_coord64 = 64 -((y_coord *64) / 1024);

Functions used in the program

ADC_Read() Read analog value Delay_ms() Delay Glcd_box() Draw lled box* Glcd_circle() Draw circle Glcd_Dot() Draw dot Glcd_Fill() Delete/ll display* Glcd_H_Line() Draw horizontal line Glcd_Image() Import image Glcd_Init() LCD display initialization* Glcd_Line() Draw line Glcd_Read_Data() Read data from LCD Glcd_Rectangle() Draw rectangle* Glcd_Set_Font() Select font* Glcd_Set_Page() Select page Glcd_Set_Side() Select side of display Glcd_Set_X() Determine X coordinate Glcd_V_line() Draw vertical line Glcd_Write_Char() Write character Glcd_Write_Data() Write data Glcd_Write_Text() Write text* * Glcd library functions used in the program

// Copy BUTTON1 string to RAM // Copy RC6 OFF string to RAM // Copy BUTTON2 string to RAM // Copy RC7 OFF string to RAM

// read X-Y and convert it to 128x64 space

mikroC for PIC library editor with ready to use libraries such as: Ethernet, CAN, SD/MMC etc.

NOTE:

Code for this example written for PIC microcontrollers in C, Basic and Pascal as well as the programs written for AVR and dsPIC microcontrollers can be found on our web site www.mikroe.com/en/article/

//if BUTTON1 is selected if ((x_coord128 >= 10) && (x_coord128 <= 58) && (y_coord64 >= 18) && (y_coord64 <= 46)) { if(PORTC.F6 == 0) { PORTC.F6 = 1; CopyConst2Ram(msg,msg7); // Copy RC6 ON string to RAM Glcd_Write_Text(msg,14,4,0); } else { PORTC.F6 = 0; CopyConst2Ram(msg,msg5); // Copy RC6 OFF string to RAM Glcd_Write_Text(msg,14,4,0); } } //if BUTTON2 is selected if ((x_coord128 >= 70) && (x_coord128 <= 118) && (y_coord64 >= 18) && (y_coord64 <= 46)) { if(PORTC.F7 == 0) { PORTC.F7 = 1; CopyConst2Ram(msg,msg8); // Copy RC7 ON string to RAM r pile Glcd_Write_Text(msg,74,4,0); com } n in else { tte Wri PORTC.F7 = 0; CopyConst2Ram(msg,msg6); // Copy RC7 OFF string to RAM Glcd_Write_Text(msg,74,4,0); } } Delay_ms(100);

roC mik IC for P

Microchip, logo and combinations thereof, PIC and others are registered trademarks or trademarks of Microchip Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- High Voltage High Current OpampDocument19 paginiHigh Voltage High Current Opampjanjan22Încă nu există evaluări

- 70fieldbus Ex600Document59 pagini70fieldbus Ex600paulomarques22Încă nu există evaluări

- DN2145 PDFDocument90 paginiDN2145 PDFaislandesouza23Încă nu există evaluări

- Error Code Zx330-3Document14 paginiError Code Zx330-3Huấn ĐặngÎncă nu există evaluări

- Pioneer Avic f900btDocument187 paginiPioneer Avic f900btrapsz100% (1)

- H.264 DVR User's ManualV - 2.1 PDFDocument72 paginiH.264 DVR User's ManualV - 2.1 PDFshadyghanemÎncă nu există evaluări

- Prelab (To Be Completed INDIVIDUALLY) : Lab 2 - Transformer CharacteristicsDocument4 paginiPrelab (To Be Completed INDIVIDUALLY) : Lab 2 - Transformer CharacteristicshotboangaÎncă nu există evaluări

- SAMSUNG LIB Battery System For UPS Product Specification 136S 128SDocument40 paginiSAMSUNG LIB Battery System For UPS Product Specification 136S 128Ssergiob63Încă nu există evaluări

- Ima 600Document14 paginiIma 600Euler GiovaniniÎncă nu există evaluări

- Badger M1000 ManualDocument36 paginiBadger M1000 ManualMahbub HemalÎncă nu există evaluări

- TDC-GPX An000512 1-00Document9 paginiTDC-GPX An000512 1-00अमरेश झाÎncă nu există evaluări

- US Patent: US7641611Document30 paginiUS Patent: US7641611Jason JerseyÎncă nu există evaluări

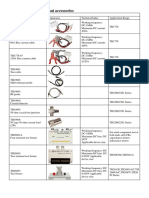

- Selection Guide of Tonghui Accessories 20181227Document17 paginiSelection Guide of Tonghui Accessories 20181227prasadÎncă nu există evaluări

- User Manual of WIT-301 Syringe PumpDocument44 paginiUser Manual of WIT-301 Syringe PumpGalih NugrohoÎncă nu există evaluări

- E Series Service Manual: 9650-1450-01 Rev. D January 2014Document280 paginiE Series Service Manual: 9650-1450-01 Rev. D January 2014Francisco PanteraÎncă nu există evaluări

- Data Sheet 6EP1436-3BA00: InputDocument3 paginiData Sheet 6EP1436-3BA00: InputAjdin BuljubasicÎncă nu există evaluări

- Warning: Downloaded From Manuals Search EngineDocument320 paginiWarning: Downloaded From Manuals Search EngineJorge MarcilloÎncă nu există evaluări

- 204.4331.03 - DM4270 - Installation GuideDocument44 pagini204.4331.03 - DM4270 - Installation GuideVagner ZanoniÎncă nu există evaluări

- Ear 864Document1 paginăEar 864api-3833673Încă nu există evaluări

- Datasheet PLC ABB Analog Input Module AI523Document14 paginiDatasheet PLC ABB Analog Input Module AI523EnlynÎncă nu există evaluări

- Tangent Delta TesterDocument27 paginiTangent Delta TesterNguyen Linh TuanÎncă nu există evaluări

- NHD 0420D3Z NSW BBW: Serial Liquid Crystal Display ModuleDocument15 paginiNHD 0420D3Z NSW BBW: Serial Liquid Crystal Display ModuleAMIR GHASEMIÎncă nu există evaluări

- Doble M4120 Ext Ref Application GuideDocument5 paginiDoble M4120 Ext Ref Application GuideDeepen SharmaÎncă nu există evaluări

- MASS 6000 - ManualDocument16 paginiMASS 6000 - ManualAlberto GonzalezÎncă nu există evaluări

- Bordomacchina Accessori Di CablaggioDocument207 paginiBordomacchina Accessori Di CablaggioAshutosh PendkarÎncă nu există evaluări

- TV LG 55EC9300+OLED+SMPS+TestingDocument6 paginiTV LG 55EC9300+OLED+SMPS+Testingwanderson wendellÎncă nu există evaluări

- DIY Mini UPS For WiFi Router V50Document77 paginiDIY Mini UPS For WiFi Router V50navin_netÎncă nu există evaluări

- H0FL-S01100SN User's Manual V1.4Document45 paginiH0FL-S01100SN User's Manual V1.4AdeyemiÎncă nu există evaluări

- BE Descriptive Notes PDFDocument199 paginiBE Descriptive Notes PDFBOOMERaNG boomÎncă nu există evaluări

- DS-3E05 Series Gigabit Ethernet Switch: Installation ManualDocument16 paginiDS-3E05 Series Gigabit Ethernet Switch: Installation ManualSebastian BadilaÎncă nu există evaluări