Documente Academic

Documente Profesional

Documente Cultură

Gayan Glass Cracks

Încărcat de

Gayan PriyankaraDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Gayan Glass Cracks

Încărcat de

Gayan PriyankaraDrepturi de autor:

Formate disponibile

Exp No: L4/S1/ MT4051/01

DEPENDENCE OF STRENGTH ON FLAWS

INSTRUCTED BY: Mr. WANASINGHA D. D. PARTNERS: 1. SANDARUWAN A.P.A. 2. ANURADHA A.K. 3. BANDARA W.V. 4. CHANDIMAL N.D.S. 5. CHATHURANGA K.D.H.D.P. 6. DE ZOYSA K.P.S. 7. DISSANAYAKA D.M.N.N. 8. HEWA WEDAGE N.A. 9. JAYASINGHE W.G.P. NAME COURSE GROUP INDEX NO : DE SILVA R. G. P. : B. SC. ENGINEERING :A : 080071M

DATE OF PER: 05/03/2012 DATE OF SUB : 15/03/2012

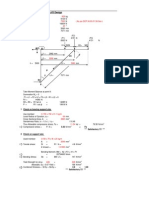

TITLE: DEPENDANCE ON STRENGTH ON FLOWS INTRODUCTION The classical brittle fracture mechanisms fail to account for the mechanical properties of glasses, but the widespread evidence of plastic flow in all glass fracture phenomena even at room temperature suggests that this flow might provide a consistent glass strength theory. Brittle materials do not undergo plastic deformation before fracture. That is due to the naturally generated cracks on the surface which cause the final fracture. Those tiny cracks act as the crack initiators and highly affect the strength of the material. In this practical the effect of the flows on the strength of a brittle material is tested. THEORY 1.) Breaking strength of sample 2.) Modulus of Rupture = Breaking load Area = 8FL/d3

Where, F Fracture force; L Length of glass rod; d Diameter of a glass rod 3.) The probability of survival (PS) of each ranked position n in a total sample size of N is given by

By

taking

logarithms of both sides of equation

After changing the sign of both sides to avoid negative values, taking logarithms again

CALCULATIONS Braking Strength of the first unetched sample = = 216 N (5.116)2mm2 10.5034 MPa

Similarly breaking strengths for other glass rods can also be calculated as above, Breaking Stress for Sample No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Un-etched samples (MPa) 10.5034 6.1270 5.8352 3.0635 5.1058 9.0446 5.1058 4.8140 6.5646 5.2517 7.5858 9.0446 5.2517 8.1693 7.8775 5.1058 4.8140 7.1481 5.1058 9.1904 Table 1 = = Braking Stress for Etched samples (MPa) 5.8926 5.7453 9.5756 4.0757 8.2497 10.6559 7.6604 7.5131 8.6917 3.5356 2.1115 5.7453 5.7453 5.1561 8.5443 13.9459 10.9014 5.4998 7.8078 9.2809

Maximum breaking strength for unetched samples Minimum breaking strength for unetched samples

10.5034MPa 3.0635MPa

When entire range is divided in to five intervals, interval of range = (10.5034-3.0635)MPa 5 = 1.488MPa Since the total number of etched specimens is 20 then frequency of broken samples within the interval can be tabulated as shown in table 3,

Probability for fail within the first interval = Frequency of broken sample within the interval Total Number of samples = = plotted as shown in result. Mean breaking strength = 130.7084 MPa 20 = 6.5354MPa 1/20 0.05

Same calculation is done for other intervals (as in Table 2). Probability density function can be

Cumulative frequency was considered and cumulative probability for fail was calculated in same way (as in Table for un-etched sample). Since the cumulative probability for safe = 1- cumulative probability for fail The cumulative probability for safe was calculated in same way also. (as in Table 3) Cumulative distribution function can be plotted using those values. Standard deviation = ( fd2/N- (fd/N)2)0.5

The standard deviation can be calculated by using this formula. The graph ln(ln(1/Ps)) vs ln(Breaking Strength/Mean Breaking Strength) can be plotted and slope of the graph was calculated. According to the theory the slope of this graph is the Weibull Modulus. Modulus of rupture for first un-etched sample= 8xFxL Nmm-2 d3 = 8x216x40Nmm-2 x5.1163 = 164.2432Nmm-2 Similarly modulus of rupture for other samples can be calculated. Calculations procedure is similar for other etched and un-etched samples.

Breaking strength of samples max load(Mpa) min load(Mpa) mean strength(Mpa) interval range

Un-eched 10.5034 3.0635 6.5354 1.488

Etched 13.9459 2.1115 7.3167 2.367

Table 2

Calculated data values for the un-etched samples,

Interval (MPa) Mean value (MPa) (x) Frequency of broken samples (f) Probability for fail (Pf) Probability for safe (Ps) Cumulative Frequency for broken samples (cf) Cumulative probability for fail (cPf) Cumulative probability for safe (cPs) d = (x-a) fd fd2 ln(Breaking Stress/ Mean Breaking Stress) ln[ln(1/Ps)]

3.0635 -4.5515 3.8075 1 0.05 0.95 1 0.05 0.95 -1.488 -1.488 2.2141 -0.5403 -2.9702

4.5515 -6.0395 5.2955 9 0.45 0.55 10 0.5 0.5 0 0 0 -0.2104 -0.3665 Table 3

6.0395 -7.5275 6.7835 3 0.15 0.85 13 0.65 0.35 1.488 4.464 6.6424 0.0373 0.0486

7.5275 -9.0155 8.2715 3 0.15 0.85 16 0.8 0.2 2.976 8.928 26.5697 0.2356 0.4759

9.0155 -10.5035 9.7595 4 0.2 0.8 20 1 0 4.464 17.856 79.7092 0.4010 -

fd2 = 115.1355 fd = 29.76 Standard deviation = ( fd2/N- (fd/N)2)0.5 =[115.1355/20- (29.76/20)2 ]1/2 =1.8822 Calculated data values for the etched samples, Interval (MPa) Mean value (MPa) (x) Frequency of broken samples (f) Probability for fail (Pf) Probability for safe (Ps) Cumulative Frequency for broken samples (cf) Cumulative probability for fail (cPf) Cumulative probability for safe (cPs) d = (x-a) fd fd2 ln(Breaking Stress/ Mean Breaking Stress) ln[ln(1/Ps)] 2.1115 -4.4785 3.295 3 0.15 0.85 3 0.15 0.85 -2.367 -7.101 16.8081 -0.7978 -1.817 4.4785 -6.8455 5.662 6 0.3 0.7 9 0.45 0.55 0 0 0 -0.2564 -0.5144 Table 4 6.8455 -9.2125 8.029 6 0.3 0.7 15 0.75 0.25 2.367 14.202 33.6161 0.0929 0.3266 9.2125 -11.5795 10.396 4 0.2 0.8 19 0.95 0.05 4.734 18.936 89.6430 0.3513 1.0972 11.5795 -13.9459 12.763 1 0.05 0.95 20 1 0 7.101 7.101 50.4242 0.5564 -

fd2 =190.4914 fd = 33.138 Standard deviation = ( fd2/N- (fd/N)2)0.5 = 2.6037

Modulus of rupture values for both etched and un-etched samples.

Sample No. Un - eched M.O.R Etched M.O.R

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

216 126 120 63 105 186 105 99 135 108 156 186 108 168 162 105 99 147 105 189

164.2432 95.8086 91.2462 47.9043 79.84046 141.4317 79.8405 75.2782 102.652 82.1216 118.6201 141.4317 82.1216 127.7447 123.1824 79.8405 75.27815 111.7766 79.8405 143.7128 Table 5

120 117 195 83 168 217 156 153 177 72 43 117 117 105 174 284 222 112 159 189

92.59708 90.28215 150.4703 64.04631 129.6359 167.4464 120.3762 118.0613 136.5807 55.5583 33.1806 90.2822 90.2822 81.0225 134.2658 219.1464 171.3046 86.4239 122.6911 145.8404

RESULTS : Mean breaking strength for un-etched samples Mean breaking strength for etched samples Standard deviation of un-etched samples Standard deviation of etched samples Mean Value of MOR for un-etched samples Mean Value of MOR for etched samples Weibull Modulus for un-etched samples Weibull Modulus for etched samples = 6.5354MPa = 7.3167MPa = 1.8822 = 2.6037 = 102.1958MPa = 114.9747MPa = 4.344 = 2.507

S-ar putea să vă placă și

- Suspension BridgeDocument56 paginiSuspension Bridgeritesh chauhanÎncă nu există evaluări

- Crane Stability and Ground PressureDocument17 paginiCrane Stability and Ground PressureAvinash Lal100% (3)

- Spot Welding Strength CalculationDocument14 paginiSpot Welding Strength CalculationVenkateswaran venkateswaranÎncă nu există evaluări

- Plate GirderDocument6 paginiPlate GirderOkayÎncă nu există evaluări

- An Introduction to Stochastic Modeling, Student Solutions Manual (e-only)De la EverandAn Introduction to Stochastic Modeling, Student Solutions Manual (e-only)Încă nu există evaluări

- Design Calculation, Analysis & DesignDocument49 paginiDesign Calculation, Analysis & Designarif_rubin100% (2)

- 4 Unconfined CompressionDocument12 pagini4 Unconfined CompressionShoaib Alam100% (1)

- Esr 2583Document19 paginiEsr 2583VaniaCuevaSotoÎncă nu există evaluări

- Strength of MaterialsDocument103 paginiStrength of MaterialsHundera DiribaÎncă nu există evaluări

- Handling and Erection of Steel Joists and Joist Girders: Technical Digest 9Document19 paginiHandling and Erection of Steel Joists and Joist Girders: Technical Digest 9samuel tejeda0% (1)

- Seismic Response Coefficient: I R T S I R S C I SDocument45 paginiSeismic Response Coefficient: I R T S I R S C I SMariano Jesús Santa María CarlosÎncă nu există evaluări

- Numerical Method For Engineers-Chapter 17Document30 paginiNumerical Method For Engineers-Chapter 17Mrbudakbaek90% (10)

- A Review of Basic Statistical Concepts: Answers To Odd Numbered Problems 1Document32 paginiA Review of Basic Statistical Concepts: Answers To Odd Numbered Problems 1Abbas RazaÎncă nu există evaluări

- Comparative Study of Is, Euro, Australian and American CodeDocument78 paginiComparative Study of Is, Euro, Australian and American CodeTirthGanatraÎncă nu există evaluări

- Platform - Bracing SupportDocument12 paginiPlatform - Bracing Supportpandiangv100% (1)

- Stress Corrosion Cracking PDFDocument48 paginiStress Corrosion Cracking PDFPako RosasÎncă nu există evaluări

- Strain and Deflection of A Circular Plate - Lab ReportDocument4 paginiStrain and Deflection of A Circular Plate - Lab ReportRoshane NanayakkaraÎncă nu există evaluări

- Lecture33-Problems in LiquefactionDocument31 paginiLecture33-Problems in LiquefactionArun Goyal100% (2)

- Lab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataDocument7 paginiLab1 MEE30004 - Lab1 - 2021 Sem2 - Raw DataAbidul IslamÎncă nu există evaluări

- Strut BucklingDocument9 paginiStrut BucklingEvonYong100% (1)

- Seminarski Rad: Teorija Eksperimentalnih IstraživanjaDocument20 paginiSeminarski Rad: Teorija Eksperimentalnih IstraživanjakenanÎncă nu există evaluări

- Hand Calculation 2 - Simple Homogeneous Wet SlopeDocument10 paginiHand Calculation 2 - Simple Homogeneous Wet SlopeWashington BobadillaÎncă nu există evaluări

- Assignment No: 01: Quarterly Data-Quarter Quantity PriceDocument5 paginiAssignment No: 01: Quarterly Data-Quarter Quantity PriceSANIUL ISLAMÎncă nu există evaluări

- HW2Document7 paginiHW2ITzFredWaZyÎncă nu există evaluări

- Mathcad - Example 8Document20 paginiMathcad - Example 8cutefrenzyÎncă nu există evaluări

- Ho There Is No Significant Difference Among The Means. Ha There Is A Significant Difference Among The MeansDocument3 paginiHo There Is No Significant Difference Among The Means. Ha There Is A Significant Difference Among The MeansClarissa TeodoroÎncă nu există evaluări

- Exercises 2011Document6 paginiExercises 2011Narasimha Moorthy ThoramÎncă nu există evaluări

- Lab Data: Major Principal Stress (Mpa)Document12 paginiLab Data: Major Principal Stress (Mpa)RidwanIrhasyuarnaÎncă nu există evaluări

- Dise OfinalDocument7 paginiDise OfinalVanesa DelgadoÎncă nu există evaluări

- Milikan's Photoelectric Effect Experiment - A Modern AnalysisDocument4 paginiMilikan's Photoelectric Effect Experiment - A Modern AnalysisLolwutLolwutÎncă nu există evaluări

- 1M110ZS5 Diodo ZenerDocument10 pagini1M110ZS5 Diodo Zenerconti51Încă nu există evaluări

- (Fatigue Test) : Strength Lab Report Experiment #Document12 pagini(Fatigue Test) : Strength Lab Report Experiment #john rozz bbÎncă nu există evaluări

- Compression Exp ReportDocument5 paginiCompression Exp Reportabo MakbasÎncă nu există evaluări

- Book1 XlsxuuuDocument9 paginiBook1 XlsxuuuKenn SenadosÎncă nu există evaluări

- Pure Bending Exp ReportDocument5 paginiPure Bending Exp Reportabo MakbasÎncă nu există evaluări

- Special Edition College Station, Texas 77845 USADocument5 paginiSpecial Edition College Station, Texas 77845 USADomis2466Încă nu există evaluări

- QT - Assignment AnswerDocument20 paginiQT - Assignment AnswerIsuru WijewardeneÎncă nu există evaluări

- Statistical Methods I: Stor 455Document35 paginiStatistical Methods I: Stor 455EL Hafa AbdellahÎncă nu există evaluări

- Tubeline Circular Hollow Sections GRADE C250L0 (AS 1163) : Dimensions and Properties ® ® ® ® ®Document6 paginiTubeline Circular Hollow Sections GRADE C250L0 (AS 1163) : Dimensions and Properties ® ® ® ® ®Adrian CallusÎncă nu există evaluări

- The Simplified Elasto-Plastic Analysis Model of Reinforced Concrete Framed Shear WallsDocument8 paginiThe Simplified Elasto-Plastic Analysis Model of Reinforced Concrete Framed Shear WallsProfNDAcharyaÎncă nu există evaluări

- MATT115B MockTest Final K58Document2 paginiMATT115B MockTest Final K58Vịt HoàngÎncă nu există evaluări

- 3.2 BMC - Detail S39,41,41B - R0a - 20160317Document1 pagină3.2 BMC - Detail S39,41,41B - R0a - 20160317Naba Raj ShresthaÎncă nu există evaluări

- 20nov PDFDocument20 pagini20nov PDFgianni moiÎncă nu există evaluări

- EC3EXT200102 Steel Reference in EC3Document6 paginiEC3EXT200102 Steel Reference in EC3mileÎncă nu există evaluări

- Business Statistics, 5 Ed.: by Ken BlackDocument34 paginiBusiness Statistics, 5 Ed.: by Ken BlackRushabh VoraÎncă nu există evaluări

- Mott Appendix PDFDocument65 paginiMott Appendix PDFbrian_fanÎncă nu există evaluări

- For Angle of Attack 0 Deg SL - No X (MM) X/C PI (Pa) CP CP (X/C)Document12 paginiFor Angle of Attack 0 Deg SL - No X (MM) X/C PI (Pa) CP CP (X/C)prodn123Încă nu există evaluări

- Randomization Test For Multiple RegressionDocument18 paginiRandomization Test For Multiple RegressionJohniel ⎝⎲⎲⎠⎝⓿⏝⓿⎠ BabieraÎncă nu există evaluări

- Tabla De Distribución Del Estadístico De Cochran Α = 0.01 O 99%Document150 paginiTabla De Distribución Del Estadístico De Cochran Α = 0.01 O 99%Alexander Junior Sandoval FloresÎncă nu există evaluări

- Steel EmilieDocument3 paginiSteel EmilieEmilie JuneÎncă nu există evaluări

- CH 04Document9 paginiCH 04Gandhi HammoudÎncă nu există evaluări

- Bowles-Foundation Analysis and DesignDocument6 paginiBowles-Foundation Analysis and DesignBUILDING PERMITÎncă nu există evaluări

- Flaws S NDocument23 paginiFlaws S Nadiraju07Încă nu există evaluări

- Assignment No. 2: (Blasting Technology)Document3 paginiAssignment No. 2: (Blasting Technology)Ayush Anshuman SupakarÎncă nu există evaluări

- MS Jan 2006 Paper - 5 & 6Document21 paginiMS Jan 2006 Paper - 5 & 6Parbon AcharjeeÎncă nu există evaluări

- Examination Paper Subject: Examiner:: Certificate in Strata Control (Coal) D. NealDocument5 paginiExamination Paper Subject: Examiner:: Certificate in Strata Control (Coal) D. NealAscento- Consultoria Jurídica100% (1)

- Matrix Analysis - Alternative Formulation of The Stiffness Method - Summary and ExamplesDocument7 paginiMatrix Analysis - Alternative Formulation of The Stiffness Method - Summary and ExamplesRobin D. Ramirez MolinaÎncă nu există evaluări

- Use of Statistical Tecniques For Testing of Hypothesis: - Mansi Mrunmayee ShrutiDocument12 paginiUse of Statistical Tecniques For Testing of Hypothesis: - Mansi Mrunmayee ShrutiMansi RamtekeÎncă nu există evaluări

- Nozzle EfficiencyDocument8 paginiNozzle EfficiencySunil Choudhary50% (2)

- Riveted Joints: SymbolsDocument23 paginiRiveted Joints: SymbolsbobcrystoÎncă nu există evaluări

- Course: Soil Mechanics II Code: CVNG 2009 Lab: Consolidation Name: Adrian Rampersad I.D:809001425Document16 paginiCourse: Soil Mechanics II Code: CVNG 2009 Lab: Consolidation Name: Adrian Rampersad I.D:809001425Adrian Mufc RampersadÎncă nu există evaluări

- TheisMatchFt ComDocument21 paginiTheisMatchFt ComBarbu IonelÎncă nu există evaluări

- Ch06 Deflection CalculatorDocument4 paginiCh06 Deflection CalculatorMicron MacronÎncă nu există evaluări

- Econometrics Final Exam 2010Document2 paginiEconometrics Final Exam 2010Chau Minh NguyenÎncă nu există evaluări

- Dougherty5e IM 2015 10 30 ch07Document13 paginiDougherty5e IM 2015 10 30 ch07Chathula NayanalochanaÎncă nu există evaluări

- Reliability of Engineering Systems and Technological RiskDe la EverandReliability of Engineering Systems and Technological RiskÎncă nu există evaluări

- Method of Lines PDE Analysis in Biomedical Science and EngineeringDe la EverandMethod of Lines PDE Analysis in Biomedical Science and EngineeringÎncă nu există evaluări

- Quick Masonry Users GuideDocument81 paginiQuick Masonry Users GuideGeorge BryanÎncă nu există evaluări

- 13.theories of Failure PDFDocument12 pagini13.theories of Failure PDFharshdeepÎncă nu există evaluări

- 01 Scaling LawsDocument60 pagini01 Scaling LawsFatih KarpatÎncă nu există evaluări

- 120131-Perforated Sheet Metal - IPRF - CD PDFDocument239 pagini120131-Perforated Sheet Metal - IPRF - CD PDFMisagh100% (1)

- Erosion Abrasion and Cavitation of ConcreteDocument8 paginiErosion Abrasion and Cavitation of ConcreteS Praveenkumar100% (4)

- Surface Vehicle Recommended PracticeDocument6 paginiSurface Vehicle Recommended PracticeRanjit RajendranÎncă nu există evaluări

- 24-04 - 1200-1330 - Ejercicio Geotextile Reinforced Embankment With Consolidation (PLAXIS)Document16 pagini24-04 - 1200-1330 - Ejercicio Geotextile Reinforced Embankment With Consolidation (PLAXIS)Andres Flores BaezÎncă nu există evaluări

- F.Rauscher - Design by Analysis - Direct Route For Cases With Pressure and Thermal ActionDocument9 paginiF.Rauscher - Design by Analysis - Direct Route For Cases With Pressure and Thermal ActionwircexdjÎncă nu există evaluări

- Astm G39-99-2021Document8 paginiAstm G39-99-2021hashem Al-NasserÎncă nu există evaluări

- نسخة من 224.2R-92 Cracking of Concrete Members in Direct TensionDocument12 paginiنسخة من 224.2R-92 Cracking of Concrete Members in Direct TensionwalidkcÎncă nu există evaluări

- Cellulose Nanopaper Structures of High Toughness PDFDocument7 paginiCellulose Nanopaper Structures of High Toughness PDFPablo Gonzalez CortesÎncă nu există evaluări

- CI2400 BS2400 Product DataDocument6 paginiCI2400 BS2400 Product DataDaniel BrownÎncă nu există evaluări

- Standard Specification For: Designation: B167 11Document9 paginiStandard Specification For: Designation: B167 11Allan DiasÎncă nu există evaluări

- Chapter 2 Outline: NSCP Strength and Serviceability RequirementsDocument7 paginiChapter 2 Outline: NSCP Strength and Serviceability RequirementsYo FangirlsÎncă nu există evaluări

- Design ConsiderationsDocument5 paginiDesign Considerationssaurabhjerps231221Încă nu există evaluări

- Carbon Fiber - BrochureDocument16 paginiCarbon Fiber - BrochureEdgar TorresÎncă nu există evaluări

- Mechanics of Materials: Sample Problem 3.4Document7 paginiMechanics of Materials: Sample Problem 3.4BoucharebKarimÎncă nu există evaluări

- Welded Connections - ASCE - 2003Document12 paginiWelded Connections - ASCE - 2003el.salumbidesÎncă nu există evaluări

- Causes of Failures of Earth DamsDocument6 paginiCauses of Failures of Earth DamsAlwaysdedy BettaÎncă nu există evaluări