Documente Academic

Documente Profesional

Documente Cultură

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

Încărcat de

CTMaungDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

Încărcat de

CTMaungDrepturi de autor:

Formate disponibile

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

[Home] Theme:

Search:

Issue : July-September 2003

Ductwork Leakage & Leak Testing

(Part 1 of 2) How much does ducting leak? Where does ducting leak? How much should it leak? What are the applicable standards? How to use them? How to set up a leakage target and, stay within it? What is a Leak Testing Rig and how does it help test and measure the leaks? These are some of the questions addressed in this two-part article.

By R. V. Simha Air Conditioning Consultant Airtron, Bangalore. R. V. Simha is a graduate engineer in both mechanical and electrical engineering, with over 40 years of experience in HVAC. He has been a practising consultant for the last 26 years. He is an active member of ISHRAE and ASHRAE South India chapter. Testing ductwork for leakage in HVAC systems is not a new concept. Visual inspection with particular attention to flanges and longitudinal joints, for example, is supposed to be regular and routine work for site engineers and supervisors. Visual inspection of escaping smoke from leaky ductwork propelled by the fan of the system has been in vogue for quite some time. However, all these "tests" are qualitative and subjective and are often carried out in a perfunctory manner. They do not conform to any specific standard; nor do they lend themselves to quantification of the leakage. The question as to why duct leakage should be quantified or for the matter, why

1 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

ductwork should be even tested at all, could be raised and therefore needs to be answered. Leaky ductwork has many consequences: Stipulated airflow rates will not be achieved Design conditions (DB & RH) may not be achieved Room air movement suffers Diffusers & terminals - particularly those at the tail end of long ducts - won't get adequate air Pressurization may not be achieved Air lost represents energy lost Room cleanliness may not be achieved Leakage air could be noisy Duct insulation could get blown Besides, the designer needs to know whether the system performance complies with the design goals. It is important for him to know whether the conditioned space is getting the air it was supposed to and whether it is being exhausted at the rate, it was supposed to be. Tests help in diagnosis and rectification of deficient performance.

How much does ductwork leak ?

It is not that engineers are totally unaware that ducting does leak and that allowance is to be made for such leakages in design calculations. It has been customary to allow a leakage of 10% in day-to-day design calculations in conventional comfort applications (as all such applications usually employ low pressure ducting). In practice however, leakage varies a great deal depending on amongst other things workmanship. The range of leakage variation encountered is as large as 5 to 15%; infact, ASHRAE observes that it could be as high as even 30%, as can be seen from the extract below from ASHRAE Fundamentals Hand Book - 2001 (pages 29.29 & 29.30) Poorly designed or installed duct systems can have leakage rates of 10 to 30%. Leakage from low-pressure lighting troffer connections lacking proper taping and sealing can be 35% or more of the terminal air supply. Improperly sealed high-pressure systems can leak as much as 10% or more from the high pressure side alone. Such extremes destroy the validity of any load calculation. Although leaks do not always affect overall system loads enough to cause problems, they will always adversely impact required supply air quantities.

2 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

Data in the following standards may be regarded as authentic:

DW/143 - A practical guide to Ductwork Leakage Testing HVAC Air Duct Leakage Test Manual - 1985 Heating and Ventilating Contractors Association(HVCA), UK Sheet Metal and Air Conditioning Contractors National Association,Inc (SMACNA) USA.

Given below are the leakage rates from the above standards:

Low Pressure Ducting (This is according to SMACNA, while DW indicates only 6%) Medium Pressure Ducting High Pressure Ducting - 3% - 2 to 0.5% - 515%

It will be noticed that while leakage can be upto 15% (in Low Pressure Ducting), it can be as low as 0.5% for High Pressure Ducting. Is it possible then to achieve lower leakage rates and perhaps, even aim at zero leakage ? It turns out that, achieving even lower leakage rates and for that matter, even zero leakage, is indeed possible, but from a practical standpoint, it is not necessary to aim for zero leakage. The reasons are simple enough it is not necessary in the first place and then it is too expensive.

3 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

[top]

Elements of leakage from ductwork

We shall now take a look at the different ways that ductwork can leak. 1. Pressure/leakage relationship. The fundamental relation is that leakage in ducting is proportional to the static pressure (in the duct) raised to the power of 0.65. This is the basis adopted in both DW & SMACNA Standards. This is in fact but a re-statement of the oft-quoted power law equation : Where Q = air flow rate c = flow co-efficient p = pressure difference n = pressure exponent, dimensionless- In our case, the value of n = 0.65. Please see 2001 ASHRAE Fundamentals Handbook, Chapter 26, Ventilation and Infiltration, page 26.12. 2. Leakage related to duct area. Leakage can also be taken as proportional to the surface area of the ductwork, even though there may be considerable variation in different sections of a complete system because of the changing pressures and sizes of the ducts and the number and variety of the fittings. The surface area is easily calculable as part of the design procedure. 3. The weak points" in duct work. Air leakage in installed ductwork occurs almost entirely at the longitudinal seams and the cross joints, particularly at the corners, and at the intersection of the seams and crossjoints (See Figure 1). The specifications adopted for the joints, methods of fabrication adopted, material and thickness stipulated - all have a bearing on the leakage rate. The last but not the least, the workmanship of ductwork - especially, in our country - is also obviously a key factor, which influences the leakage.

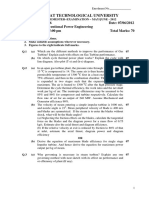

Ductwork classes & leakage limits

It has already been noted that leakage is proportional to the pressure raised to the power of 0.65, duct area and that the weak points is a major player where leakage matters are concerned. This is reflected in the categorization of ductwork classes, leakage limits, etc. in the paragraphs and tables that follow :

4 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

DW Standards

Ductwork classes, permissible leakage limits, applicable pressure limits and leakage flow rates at the same pressure (250 Pa) are furnished the Table 1.

Table 1 : Air Leakage Limits (DW/144) Ductwork Classes Leakage limit l/s per m2 of duct surface 0.027 x p0.65 0.009 x p0.65 Static Pressure limit - Pa Positive Low Pressure - Class A Medium Pressure Class B High Pressure Class C 500 1000 Negative 500 750 Leakage flow rate at a static pressure of 250 Pa 0.977 0.326

C 0.003 x p0.65

2000

750

0.109

It may be noted that even though the static pressure limit is above 250 Pa for all the classes, leakage shown is for this value. This is with a view to provide a level playing ground for all the ductwork classes for a comparative assessment of their leak tightness. Earlier DW142 had included a Class D also (with a leakage flow rate limit of 0.036 l/s per sqm), but DW144 has subsequently omitted this high pressure class, the reason adduced being - "in order to conform to European practice".

SMACNA Standards

The permissible leakage limits according to SMACNA are shown in Table 2 for duct types and for sealed and unsealed ductwork. Table 2 below corresponds to Table 1, (which contains DW values), even though the two tables are not strictly identical. Thus, Table 2 also deals with duct type and the corresponding predicted leakage rates for several kinds of ductwork. In this table also, the pressure considered is 250 Pa. It will be appreciated, that this permits a direct comparison of DW and SMACNA Standards. In this case also, the pressure considered is 250 Pa. A cursory glance shows that the permissible leakage rate for almost all ducting is higher than in DW standards, in other words, DW ducts are tighter. Tables 3A & 3B show the sealing requirements for various ductwork locations.

5 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

Table 2 : Recommended Ductwork Leakage Class by Duct Type (SMACNA) Duct Type Leakage Class Leakage Rate, l/s per m2 at 250 Pa 0.14 0.14 0.29 0.29 4 8 0.14 0.29

Metal Round Flat Oval Rectangular Flexible Fibrous glass Round Rectangular 8 4 4 8

This Table does not contain any values for unsealed ducting - evidently because the predicted leakage rates are far too high.

Table 3A : Recommended Duct Seal Levelsa (SMACNA) Duct Type Supply Duct Location Outdoors Unconditioned spaces Conditioned spaces (concealed ductwork) Conditioned spaces (exposed ductwork) 500 Pa A B C A >500 Pa A A B A Exhaust A B B B Return A B C B

Table 3B : Duct Seal Levels (SMACNA) Seal Level A B Sealing Requirementsa All transverse joints, longitudinal seams and duct wall penetrations All transverse joints and longitudinal seams

6 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

Transverse joints only

Transverse joints are connections of two ducts or fitting elements oriented

perpendicular to flow. Longitudinal seams are joints oriented in the direction of airflow. Duct wall penetrations are openings made by screws, non-self-sealing fasteners, pipe, tubing, rods, and wire. Round and flat oval spiral lock seams need not be sealed prior to assembly but may be coated after assembly to reduce leakage. All other connections are considered transverse joints, including but not limited to spin-ins, taps and other branch connections, access doorframes, and duct connection to equipment.

[top]

DW & SMACNA compared

We are now in a position to juxtapose and compare DW & SMACNA Standards as shown in Table 4. This comparison is shown graphically in Figure 2. It will be readily seen that DW's Class A & Class C ductwork are tighter than the corresponding SMACNA classes CL34 & CL4

Table 4 : Comparision of DW & SMACNA Class DW Equivalent. SMACNA Pressure Leakage @ 250 Pa Classification Equivalent. Pa SMACNA DW Remarks

7 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

A B C

CL34 CL8 CL4

250 1000 2000

1.3 0.72 0.55

0.95 0.8 0.41

DW Class A is more stringent SMACNA CL8 is more stringent DW Class C is more stringent

Table 5 : Leakage as Percentage of Airflowa,b (SMACNA) Leakage Class 68 System leakage l/s per m2 Duct Surfacec 10 12.7 15 20 25 34 10 12.7 15 20 25 17 10 12.7 15 20 25 8 10 12.7 15 20 25 4 10 12.7 15 20 25 1.0 0.8 0.6 0.5 0.4 1.9 1.5 1.3 1.0 0.8 1.5 1.2 1.0 0.8 0.6 3.8 3.1 2.6 1.9 1.5 3 2.4 2.0 1.5 1.2 2.4 1.9 1.6 1.3 0.9 7.7 6.1 5.1 3.8 3.1 6 4.8 4.0 3.0 2.4 4.7 3.8 3.1 2.4 1.9 3.1 2.4 2.0 1.6 1.2 Static Pressure, Pa 125 15 12 10 7.7 6.1 12 9.6 8.0 6.0 4.8 9.4 7.5 6.3 4.7 3.8 6.1 4.9 4.1 3.1 2.4 7.4 5.9 4.9 3.7 3.0 250 24 19 16 12 9.6 19 15 13 9.4 7.5 12 9.8 8.2 6.1 4.9 7.4 5.9 4.9 3.7 3.0 4.8 3.8 3.2 2.6 1.9 500 38 30 25 19 15 25 20 16 12 9.8 15 12 9.8 7.4 5.9 9.6 7.7 6.4 4.8 3.8 750 49 39 33 25 20 30 24 20 15 12 19 15 13 9.6 7.7 1000 1500 59 47 39 30 24 38 31 26 19 15 77 62 51 38 31

1. From HVAC Air Duct Leakage Test Manual (SMACNA 1985, Appendix A). 2. Percentage applies to the airflow entering a section of duct operating at an assumed pressure equal to the average of the upstream and downstream

8 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

pressures. 3. The ratios in this column are typical of fan volumetric flow rate divided by total system surface. Portions of the systems may vary from these averages.

Leakage as percent of airflow

The designer understandably finds it convenient to think of leakage values as percent of system flow also. This is presented in Table 5. In this table, percent leakage is related to leakage class, system flow rate in terms of l/s per sqm of ducting and the static pressure. The table and the underlying concepts are best understood by looking at an example. Consider a 60 TR Plant for which the following typical values can be assumed : Supply air flow rate 13640 l/s Supply air ducting area 555 sqm System - l/s / sqm 13640 555 = 24.58 l/s/ sqm. From Table 5 read, leakage as 4.8% of air flow at the intersection of system l/s / sqm of 25 at a static pressure of 250 pa. Now consider the effect of ducting the return air also. Return Air duct area 665 sqm Total duct area 1220 sqm System - l/s / sqm 13640 1220 = 11.18 l/s / sqm. This is the same thing as saying that for the same flow rate, the leakage increases as the area of ducting. The larger the area of ducting (for the same flow rate), the tighter it needs to be to stay within a stipulated maximum permissible leakage rate whether in terms of l/s per sqm or per cent of air flow. Next Issue : Part 2 leakage budget & AHU leakagev [top]

9 of 10

10/3/2012 2:03 PM

Ductwork Leakage & Leak Testing (Part 1 of 2) - Issue Jul-Sep 2003

http://www.ishrae.in/journals/2003july/article03.html

10 of 10

10/3/2012 2:03 PM

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Ca Va de SoiDocument15 paginiCa Va de SoiManideep SrirangamÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Ashrae Cooling and Heating Load Calculation ManualDocument2 paginiAshrae Cooling and Heating Load Calculation ManualTorus Engenharia0% (1)

- Sample Calculatio For Design of Structures and Foundations For Vibrating MachinesDocument6 paginiSample Calculatio For Design of Structures and Foundations For Vibrating MachinesRay LeeÎncă nu există evaluări

- Trip TicketDocument2 paginiTrip TicketKynth Ochoa100% (2)

- 13 Standpipes Sprinklers FdnyDocument20 pagini13 Standpipes Sprinklers FdnyHualy DelgadoÎncă nu există evaluări

- Introduction To CPHQDocument24 paginiIntroduction To CPHQmonir61Încă nu există evaluări

- DMCR Protection Relay For Oil TransformerDocument9 paginiDMCR Protection Relay For Oil TransformerDawn HernandezÎncă nu există evaluări

- Dyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.Document10 paginiDyefix-CF - Dye Fixing Agent With Excellent Fastness To Chlorine.L.N.CHEMICAL INDUSTRYÎncă nu există evaluări

- Sony MP3 NWZ B143F ManualDocument82 paginiSony MP3 NWZ B143F ManualdummihaiÎncă nu există evaluări

- Netsh Wlan Start HostednetworkDocument3 paginiNetsh Wlan Start HostednetworkM Nanda KumarÎncă nu există evaluări

- Chapter 8-Stringing and Miscellaneous WorksDocument3 paginiChapter 8-Stringing and Miscellaneous Workschintan pandyaÎncă nu există evaluări

- BW17V1D24Document5 paginiBW17V1D24Lye YpÎncă nu există evaluări

- R07 Set No. 2Document8 paginiR07 Set No. 2dileepÎncă nu există evaluări

- Samsung ML-1710 Recarga PDFDocument6 paginiSamsung ML-1710 Recarga PDFarkittoÎncă nu există evaluări

- Building An Online Shopping Cart Using C Sharp Part 2Document17 paginiBuilding An Online Shopping Cart Using C Sharp Part 2TrungChanhNguyenÎncă nu există evaluări

- Vxlan White Paper c11 729383Document10 paginiVxlan White Paper c11 729383steve stevensonÎncă nu există evaluări

- Dune Supreme/ Dune Vector: WWW - Armstrong-Ceilings - Co.Uk WWW - Armstrong-Ceilings - IeDocument2 paginiDune Supreme/ Dune Vector: WWW - Armstrong-Ceilings - Co.Uk WWW - Armstrong-Ceilings - IeMuneer KonajeÎncă nu există evaluări

- Tips For Internship ReportDocument1 paginăTips For Internship ReporthummayounnasirÎncă nu există evaluări

- Broadcast Servers for all WorkflowsDocument2 paginiBroadcast Servers for all WorkflowsJosé FélixÎncă nu există evaluări

- GTU BE- Vth SEMESTER Power Engineering ExamDocument2 paginiGTU BE- Vth SEMESTER Power Engineering ExamBHARAT parmarÎncă nu există evaluări

- Atheros Valkyrie BT Soc BriefDocument2 paginiAtheros Valkyrie BT Soc BriefZimmy ZizakeÎncă nu există evaluări

- EE331 Lab 1 v2Document13 paginiEE331 Lab 1 v2Áo ĐenÎncă nu există evaluări

- D85 D275Document8 paginiD85 D275ssinokrotÎncă nu există evaluări

- Piston SkirtDocument2 paginiPiston SkirtAmmar OmranÎncă nu există evaluări

- Hydraulic Cylinder Joints: Understanding Loads and DesignDocument16 paginiHydraulic Cylinder Joints: Understanding Loads and DesignVinaySeebaÎncă nu există evaluări

- Libro Desarrollo Organizacional Xady Nieto - AntiCopy - CompressedDocument190 paginiLibro Desarrollo Organizacional Xady Nieto - AntiCopy - Compressedleandro cazarÎncă nu există evaluări

- Owner's Manual Safety Instructions Operating InstructionsDocument16 paginiOwner's Manual Safety Instructions Operating InstructionsKevin CharlesÎncă nu există evaluări

- ME116P Weeks 1-4Document243 paginiME116P Weeks 1-4Ska dooshÎncă nu există evaluări

- Problems - SPCDocument11 paginiProblems - SPCAshish viswanath prakashÎncă nu există evaluări

- Gas Pressure Regulator Installation InstructionsDocument10 paginiGas Pressure Regulator Installation Instructionssayem biswasÎncă nu există evaluări