Documente Academic

Documente Profesional

Documente Cultură

GlaxoSmithKline Supply Chain Challenges

Încărcat de

Suraj SomashekharDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

GlaxoSmithKline Supply Chain Challenges

Încărcat de

Suraj SomashekharDrepturi de autor:

Formate disponibile

GlaxoSmithKline Supply Chain Challenges Part 1

Supply chains have improved drastically in the past ten to fifteen years. The revolution can be attributed to companies shift in focus on efficiency, total quality control and management. This is the case both to the supply and manufacturing operations. We are analysing the supply chain management initiatives undertaken by GlaxoSmithKline. It has made concerted efforts in betterment of its production processes, packaging and enhanced supply to meet demand better. GlaxoSmithKline The Company GlaxoSmithKline (GSK) is the worlds second largest pharmaceutical and healthcare company. Its revenues figured around the GBP 20 billion mark, yielding an after tax profit of GBP 6 billion approximately. It provides employment to 100,000 people worldwide, with over 40,000 focused in sales and marketing. Primarily headquartered in London, it has 2 headquarters in the US, Philadelphia and Research Triangle Park respectively. GSKs priority is and always has been activities include creation, discovery, development, manufacture, and marketing pharmaceutical and consumer health-related products the world over. GSK operates primarliy in two segments, Pharmaceuticals and Consumer Healthcare. GSK has more than 36,000 SKUs manufactured across over 80 manufacturing plants worldwide. GSK has a market share of 7% in the pharmaceutical business.

Year

1989 1995 2000 2001

Merger/Acquisition

Beecham merged with SmithKline Beckman Glaxo acquires Burroughs Wellcome & Co. Glaxo Wellcome merged with SmithKline Beecham GlaxoSmithKline acquires consumer health care company Block Drug Co.

New Company Name

SmithKline Beecham Glaxo Wellcome GlaxoSmithKline GlaxoSmithKline

Exhibit 1: Merger and Acquisition activity at GSK The Challenges Post merger Integration Issues With the spate of mergers and acquisitions, GSK faces three major integration challenges: * Integration of 2 separate identities * Integration of different strategies and missions

* Integration of the manufacturing and packaging operations of Glaxo, Burroughs Wellcome, Beecham, SmithKline Beckman and Block Drug Co. Complex product portfolio Market dynamics has been moving towards the implementation of customized drugs and therapy for each human being. The short life expectancy of patients has tilted the demand in favour of specialised and targeted drugs. GSK, like its competitors has to combat the need for specialised drugs continuously and reaping quick rewards. Such driving forces alongside a changing industry make creative marketing and innovative products crucial. Multi-faceted US Markets The US market mainly comprises of a chain pharmacy stores, more traditional mom and pop stores and high-end deliveries. Such diverse markets have diverse supply chain needs. Catering to this varied bunch of customers brings along with it its own set of challenge, namely managing small volumes of niche packages. Regulatory and operational challenges The frequent M&A activities implies a complex and laborious paper trail which requires reregistration and labelling and compliance with regulatory frameworks of different countries. With over 250 legal entities across the world and no centralized legal framework, printing and other associated challenges emerge, each with different names that must appear on different products sold in different countries. The complexity multiplies with the mergers owing to labelling changes. Moreover, different markets have different schedules on when GSK must incorporate the labelling changes. Different departments could always make different packaging design changes, but the communication of these changes, namely packaging specifications, graphics and artwork changes across the length and breadth of the organization covering varied functions and divisions is a herculean task in the least. Outsourcing/supplier challenges One of GSKs products Aquafresh FlossNCap (AFNC) is a prime example of the typical outsourcing challenges. AFNC has a flip top containing dental floss and toothpaste in the tube. AFNC had three custom designed sub-assemblies which had been outsourced to three different suppliers. The suppliers worked in sequence on the custom designed cap. Once the package reaches GSK, only filling of the tube with toothpaste remained. Coordination with these three cross Atlantic suppliers, especially outside GSKs manufacturing facilities was a challenging task. This also included sharing proper specifications that met with all the design parameters of all suppliers involved. Finding alternate/multiple suppliers GSK had an ugly experience early on, supply disruptions were rampant due to there a single source supplier. Almost a decade ago, one of its sole resin suppliers plants exploded. Due to the absence of alternate suppliers, GSK consequently had to lose market share not to mention

customer goodwill, due to which customers had to do without critical drugs and life saving devices. GSK wanted to mitigate and try and eliminate such situations. The challenge was 2 fold : find alternate suppliers and they should be ones who complied with the FDA regulations and supplied according to schedule. On the major machinery and equipment side, GSKs goals were different. Its objective was to limit the number of machinery suppliers which would consequently lead to better familiarisation with the manufacturers equipment and establish partnerships with machine suppliers who offered total packages when compared with independent system integrators. Operational/production challenges The foremost challenge in production processes was synchronising with a varied number of manufacturing locations and multiple suppliers. Different packaging and assembly lines, implementing automation and advanced technology or process improvement programmes presented huge challenges. Some other considerations were quick machine setup, better equipment availability, minimum production stoppages, and flexibility besides handling innumerable design changes. Technological Challenges Technologies, for example RFID in anti-counterfeiting are largely untested or simply not the best. GSK has RFID supply chain projects planned but faces a tough test with respect to being the first mover in investing huge sums into the technology or adopt a wait and watch policy. GSK may lose out in both cases owing to failure of the relatively new technology or lose out to competitors who can gain significantly by adopting the technology faster.

GlaxoSmithKline Supply Chain Challenges Part 2

Glaxo Smithkline (GSK) spends about GBP 800 million to in R&D expenses on a drug. Its efforts and money will go waste unless its customers get the product in time without any defects and have no difficulty in package hadling. In other words, every facet of GSKs supply chain should be up to the mark. Countering Market Dynamics Late pack customisation To counter the challenges of supplying to a multifaceted US market and low volume niche segments, GSK implemented the late pack customisation programme. Typical production runs were up to 30,000 numbers for cost effectiveness but GSK would produce as low as 100 or 500 packs to increase efficiency at a time with this programme. For example, basic boxes were volume filled with blisters at the packaging warehouse and shifted to the two distribution centres in Europe. At these centres, labels were clearly printed online with

country related information and automatically applied. Even country specific leaflets were automatically attached. Quality was ensured with three two-dimensional bar codes, one preprinted on the top of the box, the other pre-printed on the leaflet and another printed online on the label. Online inspection on the codes could be performed at one go owing to their inline position. Countering Packaging Complexities Global Pack Management With more than 36,000 SKUs and a six-month life cycle of its products, handling package specifications, associated graphics was an enormous task. Standardization of the packaging changes was another major issue. GSK developed the Global Pack Management (GPM)to counter packaging complexity. The GPM programme focussed on four major issues: 1.Change Standardisation- Packaging changes are standardised using global training and implementation programmes. 2. Developing a pack catalogue- All employees have access to packaging information which is centralized and streamlined. This helps improve idea sharing while achieving packaging optimisation simultaneously. 3. Central artwork development: Accordingly, four centres (strategically chosen at US, UK, Italy and India) were designated to service the packaging graphic needs of all products. Earlier, 250 centres performed the same activity. 4. Uniform and centralised information technology- This has helped streamline workflow. Since all the employees use the same applications which ensures uniformity. There are no serious encryption and security issues, if packaging artwork is transferred between similar standard systems. Paperless labelling/electronic leaflets According to FDA regulations, all drug companies in the US must print and attach labels to every product they sell in the market. So, any label or leaflet change requires up to a year to reflect with pharmacy stores, since existing inventory must be emptied. Working along with the Pharmaceutical Research and Manufacturers of America (PhRMA), GSK has been striving hard to introduce its paperless labelling initiative. The aim of paperless labels and electronic leaflets is to make the whole process automated and easy to analyse data. This will help instant updating as any change in the leaflet/label is reflected automatically. Patient safety is of paramount importance of GSK. Online Printing GSK is working on developing online printing which would help synchronize the speed of the packaging line and prints at the prescribed quality level. The objective is to keep costs of online printing down.

Countering Supplier/Outsourcing issues GSK realises the importance of finding and qualifying multiple suppliers to avoid any supply disruptions. For instance, for its popular Advair Diskus device, GSK has three suppliers, two in Europe and one in the US. The goal is to have enough capacity globally with all suppliers producing identical components with identical tooling on identical machines. Meeting strict regulations is of prime importance. Communication can play a vital role in establishing coordination among multiple suppliers. GSK uses an electronic CAD package. The CAD package has drawings indicating minor details and any subsequent or ongoing review to every component to overcome communication gaps if any. Countering Operational/production challenges GSK has limited the number of equipment suppliers to reduce downtime. For instance, on one packaging line it has one supplier Schuberts four robotic systems. Robots do the cartooning and case packing as well. In response, Schubert gives GSK the advantage of assigning a dedicated and focused team that works for GSK alone. The team also has an office in GSKs plant itself. Healthy supplier relationships have helped GSK reduce downtime substantially. Moreover, all equipment from a single supplier facilitates a better understanding of the equipment functioning, than having disparate machines for same tasks. Thus training costs are also less. Furthermore, GSK uses a central TIPS production management system which minimises downtime. The system tracks downtime data allowing for ongoing production improvements. GSK has been able to maintain product quality with cameras and online inspection using bar code scanners. Instead of using packaging only lines, GSK uses lines, which are integrated to do final assembly and packaging also. GSKs concerted efforts have been successful. Organisations can follow its Supply Chain Management strategies which increase the value of plants, product, packages, and people.

S-ar putea să vă placă și

- Supply Chain ManagementDocument17 paginiSupply Chain ManagementAjakumbi Ajax Baba100% (1)

- GSK SwotDocument13 paginiGSK SwotYasir Alvi0% (1)

- ON Supply Chain Management ofDocument23 paginiON Supply Chain Management ofmaria younusÎncă nu există evaluări

- GSK Pakistan Supply ChainDocument12 paginiGSK Pakistan Supply ChainMuzammil Abdul QadirÎncă nu există evaluări

- Inventory Management GSKDocument20 paginiInventory Management GSKNasir Hussain0% (1)

- PfizerDocument4 paginiPfizerscsew8332100% (1)

- GSK Quality in Supply Chain & After SalesDocument15 paginiGSK Quality in Supply Chain & After SalesReal Will SelfÎncă nu există evaluări

- Ryder Reverse Logistics Strategy Saves Time and Money With Co-Located ServicesDocument5 paginiRyder Reverse Logistics Strategy Saves Time and Money With Co-Located ServicesRuchika PanjwaniÎncă nu există evaluări

- GSK Operations ManagementDocument20 paginiGSK Operations ManagementMaira Hassan80% (5)

- Supply Chain Management of Pharmaceuticals: "Working Together For Healthier World"Document19 paginiSupply Chain Management of Pharmaceuticals: "Working Together For Healthier World"Shahrukh Ghulam NabiÎncă nu există evaluări

- 3pl and 4plDocument86 pagini3pl and 4plongbak21Încă nu există evaluări

- Hilton Pharma Report on Pharmaceutical IndustryDocument8 paginiHilton Pharma Report on Pharmaceutical IndustryFakhrunnisa khanÎncă nu există evaluări

- Term Report On AbbottDocument16 paginiTerm Report On Abbottmominansari80% (5)

- Strategic Analysis of Pharmaceutical Firms in BangladeshDocument13 paginiStrategic Analysis of Pharmaceutical Firms in BangladeshTarequl IslamÎncă nu există evaluări

- DHL Express Usa Overview - enDocument14 paginiDHL Express Usa Overview - enSyed Danish AliÎncă nu există evaluări

- Assignment of Strategic ManagementDocument22 paginiAssignment of Strategic ManagementJishan M Hasan100% (1)

- Inventory ManagementDocument48 paginiInventory ManagementNarendra ChhetriÎncă nu există evaluări

- HR Practices at Hilton PharmaceuticalsDocument15 paginiHR Practices at Hilton PharmaceuticalsSaiyed Fauzan Ali88% (8)

- Sanofi Strategic Management ReportDocument37 paginiSanofi Strategic Management ReportEmmara MoidÎncă nu există evaluări

- Supply Chain Management Abbot Pharmaceutical PDFDocument23 paginiSupply Chain Management Abbot Pharmaceutical PDFasees_abidÎncă nu există evaluări

- Profile of GlaxoSmithKlineDocument22 paginiProfile of GlaxoSmithKlineNilufar Sharmin JessyÎncă nu există evaluări

- Total Quality Management in Pharmaceuticals PDFDocument11 paginiTotal Quality Management in Pharmaceuticals PDFNarongchai PongpanÎncă nu există evaluări

- Supply Chain Management of Getz PharmaDocument11 paginiSupply Chain Management of Getz PharmaBilalYounus50% (2)

- Scm. LupinDocument8 paginiScm. LupinSanjib Biswas100% (1)

- Beximco Pharmaceuticals LTDDocument4 paginiBeximco Pharmaceuticals LTDNaheed ImranÎncă nu există evaluări

- Working Together For Healthier WorldDocument25 paginiWorking Together For Healthier WorldKathy RomanÎncă nu există evaluări

- Consumer BehaviourDocument30 paginiConsumer BehaviourSami Jamal0% (1)

- A Study On SWOT Analysis of Pharmaceutical Industry: The Bangladesh ContextDocument10 paginiA Study On SWOT Analysis of Pharmaceutical Industry: The Bangladesh ContextKamran AlamÎncă nu există evaluări

- Presentation Marketing and Distribution ChannelsDocument15 paginiPresentation Marketing and Distribution Channelsavtarsingsadaf_28176Încă nu există evaluări

- Merger of Glaxo Wellcome and SmithKline BeechamDocument4 paginiMerger of Glaxo Wellcome and SmithKline BeechamTawfiq FayedÎncă nu există evaluări

- Supply Chain in Pharmaceutical Industry PDFDocument46 paginiSupply Chain in Pharmaceutical Industry PDFSaima Nazir KhanÎncă nu există evaluări

- Supply Chain in Pharmaceutical IndustryDocument46 paginiSupply Chain in Pharmaceutical IndustryKamesh MoonÎncă nu există evaluări

- Cold Chain in PharmaDocument4 paginiCold Chain in PharmaChandan Ahire100% (1)

- Analysis of The Pharmaceutical IndustryDocument69 paginiAnalysis of The Pharmaceutical Industrymohammed_jibran67% (3)

- Strategic Management ProjectDocument84 paginiStrategic Management ProjectTalha Abdul Rauf57% (7)

- SanofiDocument15 paginiSanofiNaureen AhmedÎncă nu există evaluări

- Supply Chain Management at Engro FoodsDocument31 paginiSupply Chain Management at Engro Foodsarsalankhan22Încă nu există evaluări

- Pfizer Case StudyDocument4 paginiPfizer Case StudyxcygonÎncă nu există evaluări

- Outsourcing Logistic Activities in Karachi (Pakistan)Document0 paginiOutsourcing Logistic Activities in Karachi (Pakistan)muhammad_meraj7Încă nu există evaluări

- PepsiCo's Supply Chain Management StrategiesDocument7 paginiPepsiCo's Supply Chain Management Strategiesajay sharmaÎncă nu există evaluări

- Novartis International AGDocument2 paginiNovartis International AGAshish NirmalÎncă nu există evaluări

- Market Penetration of SanofiDocument12 paginiMarket Penetration of SanofiShishir Tazverul AmeenÎncă nu există evaluări

- Global Pharma StrategyDocument15 paginiGlobal Pharma StrategyDr Amit RangnekarÎncă nu există evaluări

- Pharmaceutical Industry of PakistanDocument20 paginiPharmaceutical Industry of PakistanAli UsamaÎncă nu există evaluări

- Proposal of Green Supply Chain in Manufacturing IndustryDocument7 paginiProposal of Green Supply Chain in Manufacturing IndustryPraveena IvanaÎncă nu există evaluări

- Assignment - Beximco Pharmaceuticals Bangladesh LimitedDocument14 paginiAssignment - Beximco Pharmaceuticals Bangladesh LimitedAhmad O. ShakurÎncă nu există evaluări

- SOP Manual For Supply Chain Management - Print Ready PDFDocument39 paginiSOP Manual For Supply Chain Management - Print Ready PDFIsaac Okiring100% (2)

- Sanofi - MOD Term ReportDocument33 paginiSanofi - MOD Term Reportsadia100% (1)

- Pharmaceutical Industry Analysis of IndiaDocument13 paginiPharmaceutical Industry Analysis of IndiaKushal KapoorÎncă nu există evaluări

- Supply Chain Process of Sanofi Aventis Limited in PakistanDocument1 paginăSupply Chain Process of Sanofi Aventis Limited in PakistanJawwad HanifÎncă nu există evaluări

- SCLM ChecklistDocument38 paginiSCLM ChecklistMayur GaidhaneÎncă nu există evaluări

- Cepton Strategic Outsourcing Across The Pharmaceuticals Value ChainDocument9 paginiCepton Strategic Outsourcing Across The Pharmaceuticals Value ChainFrenzy FrenesisÎncă nu există evaluări

- Supply Chain Challenges Faced by Glaxosmithkline at The Time of PandemicDocument39 paginiSupply Chain Challenges Faced by Glaxosmithkline at The Time of Pandemicminahil chÎncă nu există evaluări

- SanofiDocument9 paginiSanofiddlj1989Încă nu există evaluări

- Alkermes High Potency Whitepaper 2014 PDFDocument11 paginiAlkermes High Potency Whitepaper 2014 PDFPrashansa ShresthaÎncă nu există evaluări

- GSK's Supply Chain Performance Case StudyDocument17 paginiGSK's Supply Chain Performance Case StudyAvinash KumarÎncă nu există evaluări

- GSK's Diversified Global Business StrategyDocument2 paginiGSK's Diversified Global Business StrategyMudaser ChÎncă nu există evaluări

- 4 Supply Chain PharmaDocument13 pagini4 Supply Chain PharmaMirena Boycheva100% (1)

- Chapter 3 PlanningDocument29 paginiChapter 3 PlanningDagm alemayehuÎncă nu există evaluări

- Financial Accounting CH 2Document12 paginiFinancial Accounting CH 2Karim KhaledÎncă nu există evaluări

- Business DirectoryDocument4 paginiBusiness DirectoryRegunathan PadmanathanÎncă nu există evaluări

- Breathes: Entrepreneurship and Innovation Strategy ProjectDocument26 paginiBreathes: Entrepreneurship and Innovation Strategy ProjectSaqib NaeemÎncă nu există evaluări

- 42-Electric Arc FurnacesDocument11 pagini42-Electric Arc Furnacessureshkumar908Încă nu există evaluări

- Income Statement 2014 2015: 3. Net Revenue 5. Gross ProfitDocument71 paginiIncome Statement 2014 2015: 3. Net Revenue 5. Gross ProfitThu ThuÎncă nu există evaluări

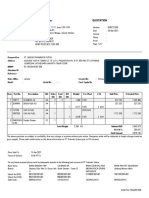

- PT Trakindo Utama Quotation for PT Basuki Rahmanta PutraDocument2 paginiPT Trakindo Utama Quotation for PT Basuki Rahmanta PutraDeden PramikaÎncă nu există evaluări

- ProblemDocument2 paginiProblemchandra K. SapkotaÎncă nu există evaluări

- TaxonomyDocument9 paginiTaxonomyMauricio KlasserÎncă nu există evaluări

- Chapter 6 Instructor - Managing A Global BusinessDocument22 paginiChapter 6 Instructor - Managing A Global BusinessYusuf ÇubukÎncă nu există evaluări

- Law510 Law429 PDFDocument5 paginiLaw510 Law429 PDFAinnabila Rosdi0% (1)

- Carbon Fijo E 870 - 82Document2 paginiCarbon Fijo E 870 - 82MIGUEL FITZ CASTILLOÎncă nu există evaluări

- Crec Masterlist Format v8Document83 paginiCrec Masterlist Format v8Jojie HugoÎncă nu există evaluări

- Instructions for Principal, Associates, and Checklists for DiscussionsDocument20 paginiInstructions for Principal, Associates, and Checklists for DiscussionsAnoushka GuptaÎncă nu există evaluări

- Modern Data Strategy 1664949335Document39 paginiModern Data Strategy 1664949335Dao NguyenÎncă nu există evaluări

- Printmedia 100813115605 Phpapp02Document24 paginiPrintmedia 100813115605 Phpapp02Sudesh BanareÎncă nu există evaluări

- Relevant CostingDocument5 paginiRelevant CostingBeatriz Basa DimainÎncă nu există evaluări

- Ejercicios ContabilidadDocument3 paginiEjercicios ContabilidadCarolina RvÎncă nu există evaluări

- Business Law Assignment Questions (Class E) - January 2024 IntakeDocument5 paginiBusiness Law Assignment Questions (Class E) - January 2024 Intakewtote404Încă nu există evaluări

- COPC Inc Overview PresentationDocument43 paginiCOPC Inc Overview Presentationpradip_sinha86% (7)

- Estimation Engineer Role, Duties & Career GrowthDocument19 paginiEstimation Engineer Role, Duties & Career GrowthBehram Ciodia100% (1)

- Portfolio Activity 7Document5 paginiPortfolio Activity 7Aidah Bunoro0% (1)

- Inside the Black Box: Role of CEO Compensation Peer GroupsDocument14 paginiInside the Black Box: Role of CEO Compensation Peer GroupsneckitoÎncă nu există evaluări

- Imagine Education: Student Assessment Cover SheetDocument35 paginiImagine Education: Student Assessment Cover SheetMarcy Megumi Sombilon100% (2)

- Entrepreneurial Mindset: The Evolution of EntrepreneurshipDocument26 paginiEntrepreneurial Mindset: The Evolution of EntrepreneurshipCzarina MichÎncă nu există evaluări

- Industrial Visit Report Visit Us at Management - Umakant.infoDocument13 paginiIndustrial Visit Report Visit Us at Management - Umakant.infowelcome2jungle0% (1)

- A Project Report On The Study of Consumer Satisfaction: Submitted ToDocument35 paginiA Project Report On The Study of Consumer Satisfaction: Submitted ToAshuÎncă nu există evaluări

- Islamic Banks and Investment FinancingDocument29 paginiIslamic Banks and Investment FinancingAhmad FananiÎncă nu există evaluări

- Percentage Completion Revenue RecognitionDocument31 paginiPercentage Completion Revenue RecognitionGigo Kafare BinoÎncă nu există evaluări

- Fintech and TechfinDocument13 paginiFintech and TechfinMaryam IraniÎncă nu există evaluări