Documente Academic

Documente Profesional

Documente Cultură

ECCE 1101 011 Method For Integrating EVM With Delay Analysis Technique

Încărcat de

Mostafa GamalDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ECCE 1101 011 Method For Integrating EVM With Delay Analysis Technique

Încărcat de

Mostafa GamalDrepturi de autor:

Formate disponibile

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No.

1, January 2011

Method for Integrating EVM with Delay Analysis Technique

Khalid S. Al-Gahtani Civil Engineering Department, College of Engineering, King Saud University, P. O. Box 800, Riyadh 11421, Saudi Arabia

Email: kgahtani@ksu.edu.sa

Abstract: Earned Value Management (EVM) method is known method for tracking the project cost and time. Recently Total Float (TF) management technique has been introduced in the field of Delay analysis claim. This technique depends on day-by-day analysis to evaluate the impact of delay and the total float. The technique follows a systematic approach that can be implemented in computer programming. One of the shortages of this technique that the evaluation of the delay resulting from the lost productivity is not defined. This drawback can be overcome by utilizing the advantage of EVM while calculating the exact delay on a construction activity during progress time. This paper presents a method for integrating the EVM with TF Management Technique by calculating the daily delay on impacted activity and incorporates that on delay analysis technique. In addition, this paper introduces equation to quantify the delay that is derived from EVM method. Keywords: EVM, delay analysis, total float, loss of productivity. 1. INTRODUCTION Currently In the field of Construction Delay Claim, the loss of productivity is one of the challenging issues because of difficulties to calculate it and define their causation. On the other hand, many new techniques (Such as Windows and TF Management techniques) have been introduced to be more accurate in their analysis results. However, it lacks in determining the loss of productivity time and responsibilities. Earned Value Management (EVM) method is known in the field of project management as a tool for controlling construction project. EVM method is used to quantify the loss of the productivity (Ciccarelli and Bennink, 2010). However, it lacks to calculate the project delay because the method does not consider the activity critically (Fleming & Koppelment, 2005). Thus, this paper attempts to integrate the EVM within the process of the TF Management Technique to solve the issue of determining the loss of productivity time and to be credited while analyzing delay claim. This integration enables the current scheduling software to calculate the delay in project along with cost and time. 2. LOSS OF PRODUCTIVITY In general, productivity is used to measure performed work operation rate, and this rate can be expressed as work output divided by resource input. The situation of loss of productivity occurs when it takes longer to complete the project than it was estimated before. Loss of productivity can be calculated by comparing the contractor actual amount of labor or equipment hours against the hours planned in its bid. Another way of quantifying the loss of productivity is comparing the contractor accomplishes against the planned, using the same amount of labor or equipment resources within the same planned time frame. In either case, the contractor should prove that he/she is expending more labor or equipment resources per unit for work actually accomplished. Actually the three terms lost productivity, disruption, and inefficiency are often gives same meaning. The contractors who are usually paid a set amount for work installed, any excess resources they expend to accomplish this work will come out of the contractors project fee or profit, unless they can recover these amounts from the owner or others. However, in order for the contractor to get compensate in lost productivity, 3 conditions have to be proven: 1. Establish causation by demonstrating a causal link between specific factors (such as crowding of labor, stacking of multiple trades, or extended work hours or days) and its lost productivity. Assure that these conditions or impacts were out of its control and that they were not foreseeable as original project requirements. The contractor must establish it had a reasonable and achievable baseline productivity level for the work, and it must employ a sound method of calculating the lost productivity.

2.

3.

80

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

EVM is one of the methods that have been used for calculating loss of productivity (Ciccarelli and Bennink, 2010). 3. Earned Value Management (EVM) method EVM is a project management method for measuring project progress in an objective manner. EVM has the ability to combine measurements of scope, schedule, and cost in a single integrated system. EVM has number of advantages. One of them is the ability to quantify activity delay. Fleming & Koppelment believe that "earned value data by itself is not adequate to manage the project's time dimension" page 163 (2005). As a result, the method lacks to determine the delay precisely. Many of the current scheduling software include the EVM as one of their tools for measuring project progress. There are four steps which can be used for EVM. Step 1: define the work such as a WBS. This step helps to define a unit of measure for each activity. Step 2: assign a value called planned value (PV) to each activity. Most of the projects assign weighted point value which might not be a budget number. Step 3: define earning rules for each activity. This step shows how the money payment and when. Step 4: execute the project according to the plan and measure progress. This is typically done at regular intervals. In general, the shorter period performed, the more accurate results will get. The earned value requires creation of a project performance measurement plan called the planned value, which is typically specified by the project scheduling system. Then the earned value must be measured against the planned value, also with the use of project scheduling system. The physical earned valued performed is then related to the actual costs spent to accomplish the physical work, providing a measure of the project true cost performance (Fleming & Koppelment, 2005). In the following three major parameters that have been used in EVM method: 1. 2. Budgeted Cost of Work Scheduled (BCWS) is the budgeted amount of cost of the work scheduled to be accomplished in a given time period (including support and allocated overhead). Budgeted Cost of Work Performed (BCWP) is the budgeted amount of cost for the work completed in a given time period, including support effort and allocated overhead. (This is sometimes referred to as earned value of work accomplished.) Actual Cost of Work Performed (ACWP) is the amount reported as actually expended in completing the particular work accomplished within a given time period.

3.

4. DELAY TYPES Before going ahead, we need to define some terms that will be used in this paper: Excusable Compensable (EC) Delays are caused by the owner and require time extension and costs to be paid by owner. EC delays can occur due to number of different reasons. For example, every contractor face a situation that owner delay the project. This may be because of any change of the design or budget decision in the middle of the project. Non Excusable (NE) Delays are caused by the contractor, for which he is liable to pay liquated damages to the owner. NE Delays may arise due to lack of performance of the contractor. For example, if the contractor was unable to supply an adequate number of workers or machinery for the project at right time due to any reason, this may affect the progress of project and comes under No Excusable delay, incorrect work that needs to be corrected may also come under this type of delays. Excusable Non compensable (EN) Delays are those for which neither the owner nor the contractor are responsible. Earthquakes and heavy rains are examples of such delays. Usually the contractor is awarded time extension for EN delays. Concurrent Delays that occur in parallel path activities at the same time period are classified as concurrent delays, additionally if two delayed events are caused by two different parties on the same activity in the same time frame, such delays are also included as concurrent delays. The concurrent delays may be all on critical paths, all on noncritical paths or distributed between critical paths and noncritical paths. There are two rules to define the concurrent delay responsibilities in US courts which called Easy Rule and Fair Rule (Kraiem and Diekmann 1987). The Fair-Rule apportions the responsibility of concurrent delay between both contract parties, while Easy-Rule is not. However, in both rules, any delay concurrent with Excusable Noncompensable delay (EN) there is only time extension without compensable cost (Kraiem and Diekmann 1987). The paper example will use the "Fair-Rule" in dealing with concurrent delay.

81

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

Pacing delay is the deceleration of the project work, by one of the parties to the contract, due to the delay to the end date of the project caused by the other party, so as to maintain steady process with the revised project schedule. 5. TF MANAGEMENT TECHNIQUE The methodology for the TF management technique follows a day-by-day analysis technique, rather than using a Window periods analysis technique (Al-Gahtani and Mohan, 2007). In each delayed day, three major analyses are performed. First is defining the critical path delays. Second is addressing the concurrent delays responsibilities. Since the daily method is used, the accuracy of defining the concurrent delay period is high. The third analyses concerns of defining the delay responsibility on non critical paths and total float (TF). This issue can solve the pacing delay that has been recently introduced. One concern of using the day-by-day analysis is the availability of time and data for the delay events. TF Management follows systematic approach that has been computerized. It is designed to work during the project progress by integrating the calculation of the analysis with the updated schedules. For example, by the end of month, the owner and contractor know about the delay times and responsibilities. Also, they know the TF and TFs entitlement for each party. Another concern is about affecting the approved change order and planned acceleration on the daily analysis. For this reason, the analysis requires an updating of the schedule as soon as the change order and owner-directed-acceleration is approved. The previous concerns, as well as other concerns such defining the delay of productivity and multiple calendars in the schedule, can be solved by including the delay/acceleration responsibilities in the scheduling software and using EVM as demonstrated in this paper. 6. INTEGRATING EVM AND TF MANAGEMENT TECHNIQUE EVM is one of the methods that can be used to quantify the loss of productivity (Ciccarelli and Bennink, 2010). However, this method has a shortage to calculate the project delay in accurate method as discussed before. In determining the project delay, EVM can be produced an accurate result if it is used in a small scale within one activity. On large scale it needs to be integrated with other Delay Technique to show the impact of productivity delay on overall project time, as well as, the responsibility of this loss of productivity. Before start using EVM, it needs to define the baseline of planned productivity for the project. It is a critical point because it can be used against the contractor for accounting the responsibility to delay the project. For simplification and fair usage, we will use the linear productivity as baseline planned productivity. After quantifying the loss of productivity time, TF Management technique can be used to indicate the criticality of this delay on the project. John and Michael used the EVM for calculating the loss of productivity (2010). They used the working hour as a unit for measuring the productivity. The following basic steps for applying the integrated methods: Step 1: Record the daily earned value units based on WBS of the activity. Step 2: Compare the earned value unit progress with planned value unit for each activity. Step 3: Define the delay or acceleration of that activity. Step 4: Assign the responsibility of this delay or acceleration. Step 5: Record this delay on the Updating schedule to analyze the delay impact. Step 6: Do the TF Management daily analysis on that delayed record to quantify the delay impact. Step 7: Repeat the process for next day or time of analysis. These steps are illustrated on Figure 1 that shows the flowchart of this process. 6. DERIVATIVE EQUATION FOR USING EVM IN CALCULATING ACTIVITY DELAY EVM uses S-curve to present the project as a result of overlapping the activity sequences on the project. Also EVM use S-curve for an activity by assuming the production rate will be increased in the early stage of the activity then it will decrease in the late stage of the activity. As a result the cumulative work load becomes S-curve. This assumption is accurate when the activity time becomes long. For small activity, the assumption of fix rate production will be more accurate. The cumulative of this fix rate becomes a linear as shown in Figure 2. We start the derivative by assuming BCWS S-curve as line between point D & E as shown in Figure 2. This assumption can be reasonable because the activity time usually small value. Also, because the difficulties to agree on the degree of work load, the linear assumption becomes a good baseline for parties, the owner and the contractor, to agree on it in the case of delay claim. In addition, assuming the BCWS S-curve to be linear makes the calculation of activity delay easier. Because of Assuming BCWS to be linear we can reach to two equations:

82

(1)

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

By using the % as indicator , BAC will be 100% and Equation (1) becomes =

%

(2)

The two triangles of A-B-C and D-E-F in Figure 2 have same slope. From that we can conclude these equations.

= =

Since we are using %, equation 4 becomes: =

(%) % (%)

(3)

(4)

(5)

Now, substitute equation 2 in 5, the following equation is derived: =

% (%)

(6)

Equation 6 can be used only when 0 <tto date <OD. If tto date > OD, the equation 6 needs to verify. Now, we need to define the new extended point of BCWS that exceeds the BAC(100%) value. BCWSextended represents the new extended value as shown in Figure 2 (point G). To get the value of BCWSextended, we need to consider the slope similarity of the two triangles D-E-F and D-G-H. The following equation, will reach: =

%

(7)

Equation 7 is similar to equation 2 which means equation 6 will be valid for all value of t. To calculate the delay between the two periods (this period), we will apply equation 6 twice and substitute the two values. As a result, the following equation is concluded: =

% (%)

(8)

Because this analysis accepts only the integer number of delay, this equation will be used as following: = ( ) (9)

Finally we can get the Recorded Delay by using the integer number of Delay this period as it is in the following equation: = 7. LIMITATION Method of integrating EVM with TF Management technique in analyzing delay claim is a time consuming with increasing the project scope. For this reason, the method needs to be programmed. The method follows a systematic approach that can be computerized. Since most of the current scheduling software is using EVM within their application, this computerized method is best to be included in this software. By doing so, analyzing delay claim becomes easier and more accurate. Another limitation of this method is defining the productivity rate baseline. In a conflict situation, the owner and contractor can raise problem to agree upon the productivity rate of the BCWS. However, it needs to agree which rate of learning curve is acceptable as baseline. It might need to define a linear curve for each group of activity that has same nature of work. Developing an equation to quantify delay for variable rate of productivity is needed to overcome this lack of this proposed integrated method. It needs more study in this area to develop a set of acceptable curve with corresponding delay equations that can be accept it in the construction industry. In addition, a set of corresponding delay equation similar to one that is developed in this paper, but it is going to be complicated. ( ) (10)

83

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

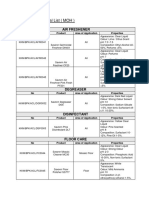

7. ILLUSTRATED EXAMPLE To show the overall procedure of the proposed method a simple example using seven activities is depicted in Figure 3.The planned work rate in this example assumed to be fixed. These rates are represented inside each of the activity bar in Figure 3, now the schedule will be updated. In addition the TF of this example will be owned by the contractor (as shown in the Figure 3). Day 3 & 4 Analysis The final result of day 3&4 analysis is that the project is delayed by 2 day (1 cause by the owner and 1 by contractor) as shown in Figure 4. Table 1: Analyzing result of day 3 &4

EVM Analysis Activity A B C D E F G BCWP

(To Date)

Delay

(To date)

Delay

(This period)

Recorded Delay 2EC 2EC 0 day 0 day

TF 0 day 0 day 0 day 0 day 0 day 4 day

(before this period)

TF Management Analysis TF Delay on entitlement

(After this period)

Critical 1O 1C 0 day 0 day

TF 0 0 day 0 day (1O+5C)

50% 0% 0% 61% 0% 100% 8%

2 day 2.2 day 0 day 0 day

2-0 = 2day 2.2-0 = 2.2 = 2day 0 day 0 day

0 day 0 day 0 day 0 day 0 day 6 day

Legend: C= Contractor, O = Owner, EC = Excusable and Compensable Delay, NE=Non excusable Delay, EN =Excusable and Non compensable. Day 3 and 4 activities A and D impacted from delay. The BCWP for each activities are shown in Table 1.The daily breakdown of BCWP for each activity shown in Figure 4 up to day 4.The delay to date and recorded delay are calculated for each activity according to equation 7,8,9.By applying TF Management method the TF before and after the delay event are calculated. According to the criticality of the activity and the consideration of the concurrent delay, the project delay will be calculated. The impact of delay on TF will be resulted in the last column on table 1. Day 5&6 Analysis Table 2: Analyzing results for day 5&6

EVM Analysis Activity BCWP Delay (To Date) (To date) 100% 0% 0% 65% 0% 100% 8% 2 day 4.1 day 0 day 2 day Delay (This period) 2-2 = 0 day 4.1-2 = 2.1 = 2 day 0 day 2-0 = 2 day Delay Record 0 day 2EC 0 day 2EC TF (before this period) 0 day 0 day 0 day 0 day 0 day 6 day

TF Management Analysis TF Delay on entitlemen (After this Critical t TF period) 0 day 0 day 0 day 0 day 0 day 4 day 1O 1C+2C = 3C 0 day 0 day 0 day 0 day 0 day (-1O+5C)

A B C D E F G

Legend: C= Contractor, O = Owner, EC = Excusable and Compensable Delay, NE=Non excusable Delay, EN =Excusable and Non compensable. In day 5 & 6 analyzing the procedure will be repeated as shown in Figure 5 and Table 2.The final result will be delaying the project by 2 more days caused by the contractors. Besides, the owner consumed 1 disentitlement float for the project.

84

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

8. CONCLUSION The paper introduced a method for integrating EVM method and a delay analysis method, as well as, an equation has been developed for quantifying loss of productivity and it has been derived in this paper. The integrated method overcomes the shortages of the two basic methods. First, it solves the deficiency of calculating the delay of the EVM method. Second, it responds to the drawback of quantifying the delay location in using TF Management technique that is used a daily methodology in their analysis. Third, the derived equation from EVM method can be used for quantifying the loss of productivity. In general, number of recommendations has been introduced in this paper. The integrated method needs to be incorporated in the current scheduling software because of the time consuming in the calculation. Also, there should be some point on which the contractor and the owner agree upon the planned productivity rate. Moreover, the derived equation needs to be developed to include the nonlinear productivity rate.

REFERENCES Al-Gahtani, Khalid S.; Mohan, Satish B., "Total Float Management for Delay Analysis", Cost Engineering, Vol. 49, No. 02, AACE International, Morgantown, WV, 2007 Ciccarelli, John, J. and Bennink, Michael, J. Revisiting Lost Productivity: A Primer and Update for the Industry, 2010 AACE International Transactions, CDR.05, AACE International, Morgantown, WV, 2010 Kraiem, Z. M., and Diekmann, J. E. (1987). "Concurrent Delays in Construction Projects." Journal of Construction Engineering & Management-ASCE, 113(4), 591-602. Mattos, Aldo D.; Delarue, Ricardo, "Monitoring Productivity with Earned Value Analysis A New Approach", 2010 AACE International Transactions, EVM.S01, AACE International, Morgantown, WV, 2010 Quentin W.Fleming and Joel M.Koppelman Earned Value-Project Management Third Edition, PMI, New town square, Pa, USA, 2005.

85

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

Determine Baseline Schedule.

Define delay/acceleration/ change order Events.

Assign original TF responsibility,. (Ownership of the TF) t = day 1

Sort the Events by time beginning from Project Start Date.

100%

(%)

Is the delay/acceleration > 1 day?

No

Yes

Define the delay/ acceleration type? NE/CA EN/SA EC/OA

Recorded Delay this period = Integer of (Delay this period)

Perform daily analysis for TF Management Technique.

t= t +1 day

END Figure 1: Flowchart to show the steps of integrating EVM with TF Management Technique to analyze construction delay

86

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

Productivity (%) G E BCWP BCWS Assume linear BCWS X B (BCWSBCWP) BAC=100 A C Delay H D OD tto date F Time (day)

Figure 2: S-Curve for an activity.

A 25% 25% 25% 25% B 25% 25% 25% 25% C 25% 25% 25% 25% D 33% 33% 33% E 20% 20% 20% 20% 20% F 33% 33% 33% C C G 20% 20% 20% 20% 20% 4 5 6 7 8 C C

Projec t Dela y As-Built projec t com pletion date

C 9

C 10

C 11

C 12 13 14 15 16

Legend: C= Contractor Entitlement Float.

Figure 3: Bar Chart of Example Baseline Schedule.

87

Canadian Journal on Environmental, Construction and Civil Engineering Vol. 2, No. 1, January 2011

A A EC 25% 25% 0%

EC 0%

A B B B B C C C C

D D NE NE 20% 19% 11% 11%

D E E E E E

F F F 30% 35% 35% G 8% 4 G 5 G 6 G 7 G 8 C 9 C 10 C 11 C 12 C 13 C 14 15 16 17

Legend: C= Contractor Entitlement Float

Figure 4: Bar Chart of TF Entitlement, Day 3 Analysis.

A A EC 25% 25% 0%

EC A A 0% 25% 25% B B B B C C C C C C

D D NE NE NE 20% 19% 11% 11% 0%

NE 4%

D E E E E E

F G 8% 4 EC 0% 5 EC 0% 6 G 7 G 8 G 9 G 10 C 11 C 12 C 13 C 14 C 15 C 16 17

Legend: C= Contractor Entitlement Float

Figure 5: Bar Chart of TF Entitlement, Day 5 Analysis.

88

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Equine PregnancyDocument36 paginiEquine Pregnancydrdhirenvet100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Radio Network Parameters: Wcdma Ran W19Document12 paginiRadio Network Parameters: Wcdma Ran W19Chu Quang TuanÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Percy Bysshe ShelleyDocument20 paginiPercy Bysshe Shelleynishat_haider_2100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Acts 1 Bible StudyDocument4 paginiActs 1 Bible StudyPastor Jeanne100% (1)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Maria MakilingDocument2 paginiMaria MakilingRommel Villaroman Esteves0% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Foxit PhantomPDF For HP - Quick GuideDocument32 paginiFoxit PhantomPDF For HP - Quick GuidekhilmiÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- GearsDocument14 paginiGearsZulhilmi Chik TakÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Basic Translation TerminologyDocument7 paginiBasic Translation TerminologyHeidy BarrientosÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Scatchell Jr. V Village of Melrose Park Et Al.Document48 paginiScatchell Jr. V Village of Melrose Park Et Al.Gianna ScatchellÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Design Thinking PDFDocument7 paginiDesign Thinking PDFFernan SantosoÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Unified Power Quality Conditioner (Upqc) With Pi and Hysteresis Controller For Power Quality Improvement in Distribution SystemsDocument7 paginiUnified Power Quality Conditioner (Upqc) With Pi and Hysteresis Controller For Power Quality Improvement in Distribution SystemsKANNAN MANIÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Best-First SearchDocument2 paginiBest-First Searchgabby209Încă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Book of Dynamic Assessment in Practice PDFDocument421 paginiBook of Dynamic Assessment in Practice PDFkamalazizi100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Creative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12Document55 paginiCreative Nonfiction 2 For Humss 12 Creative Nonfiction 2 For Humss 12QUINTOS, JOVINCE U. G-12 HUMSS A GROUP 8Încă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Poet Forugh Farrokhzad in World Poetry PDocument3 paginiPoet Forugh Farrokhzad in World Poetry Pkarla telloÎncă nu există evaluări

- Nahs Syllabus Comparative ReligionsDocument4 paginiNahs Syllabus Comparative Religionsapi-279748131Încă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Nature, and The Human Spirit: A Collection of QuotationsDocument2 paginiNature, and The Human Spirit: A Collection of QuotationsAxl AlfonsoÎncă nu există evaluări

- CRM - Final Project GuidelinesDocument7 paginiCRM - Final Project Guidelinesapi-283320904Încă nu există evaluări

- Approved Chemical ListDocument2 paginiApproved Chemical ListSyed Mansur Alyahya100% (1)

- Exercise No.2Document4 paginiExercise No.2Jeane Mae BooÎncă nu există evaluări

- Karly Hanson RèsumèDocument1 paginăKarly Hanson RèsumèhansonkarlyÎncă nu există evaluări

- E TN SWD Csa A23 3 94 009 PDFDocument5 paginiE TN SWD Csa A23 3 94 009 PDFRazvan RobertÎncă nu există evaluări

- Butterfly Valve Info PDFDocument14 paginiButterfly Valve Info PDFCS100% (1)

- Mathsnacks05 InfiniteDocument1 paginăMathsnacks05 Infiniteburkard.polsterÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- ObliCon Digests PDFDocument48 paginiObliCon Digests PDFvictoria pepitoÎncă nu există evaluări

- Chapter 12 Social Structural Theories of CrimeDocument5 paginiChapter 12 Social Structural Theories of CrimeKaroline Thomas100% (1)

- Name Numerology Calculator - Chaldean Name Number PredictionsDocument2 paginiName Numerology Calculator - Chaldean Name Number Predictionsarunamurugesan7Încă nu există evaluări

- Marketing PlanDocument41 paginiMarketing PlanMark AbainzaÎncă nu există evaluări

- Affirmative (Afirmativa) Long Form Short Form PortuguêsDocument3 paginiAffirmative (Afirmativa) Long Form Short Form PortuguêsAnitaYangÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)