Documente Academic

Documente Profesional

Documente Cultură

Fat Analysis N CCP

Încărcat de

Syazmi MohdDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fat Analysis N CCP

Încărcat de

Syazmi MohdDrepturi de autor:

Formate disponibile

Determination of Fat Content (Soxhlet Method)

Lipids, proteins, and carbohydrates constitute the principal structural components of foods. Lipids are organic substances that are relatively non-polar. Lipid such as triacylglycerols, are very hydrophobic while other lipids, such as di-and monoacylglycerol have both hydrophobic and hydrophilic moieties in their molecules and thus, are soluble in relatively polar solvents. Water insolubility is the essential analytical property used as the basis for the separation of lipids from proteins, water and carbohydrates in food.

Milk fat is mainly composed of the triglycerides of fatty acids, and occurs naturally in milk as oil in water emulsions. Fats are crucially important to the human diet, not just for their nutritive contributions but because of their influence on texture and mouthfeel and hence their ability to make much of our food palatable. Lipids are also important carriers or precursors of some flavor and odor compounds. Therefore, an accurate and precise quantitative analysis of lipids in foods is important for nutrition labeling and to understand the effects and oils on the functional of foods.

Soxtec method represent the new generation of manual Soxhlet extraction systems. It is used for maximum user convenience through batch handling of six samples at a time, giving a minimum of system handling. Soxtec system is flexible and suitable for a wide variety of applications in the food, feed, environmental and industrial segments. Soxtec is a new patented version of the Soxhlet extraction technique combined with integral solvent handling. The system consists of an Extraction Unit and a Control Unit. The sample to be analyzed is weighed into thimbles and inserted in the Extraction Unit. The solvent is added in a closed system. The cups are heated by the electrical heating plate. The 4-step extraction procedure consists of boiling, rinsing, recovery and pre-drying.

Procedure I. Sample Preparation

1. 1-2g of homogenized dried sample was weighted on filter paper. 2. Sample was then placed into thimbles. 3. Thimbles were placed to the thimbles holder. 4. Thin layer cotton was placed on top of the sample. 5. The thimbles were move to the thimbles supports.

II.

Fat Collection Preparation

1. Pre-dried extraction cup was weighted. 2. 50ml of hexane was pour into extraction cup using the measuring cylinder. 3. The extraction cup was placed into cup holder. 4. The holder cup was attached to the extraction unit.

III.

Extraction Procedure using Soxtec System (2043)

1. The POWER key on the control unit was pressed. 2. Water tap was opened for the reflux condensers. 3. PRE-HEAT button was pressed. The hot plate will be warm up to the set temperature program (130C) 4. The thimbles were attached to the extraction unit. 5. Thimbles supports were removed. 6. The extraction cup was attached to the cup holder. 7. START key was pressed. 8. Thimbles were moved to BOILING position and the TIMER key was pressed. (the BOILING timer already set, 20 minutes) 9. The thimbles were then moved to RINSING position and the TIMER key was pressed. (the RINSING timer already set, 40 minutes) 10. Condenser valve was closed and the AIR PUMP automatically started. 11. The extraction cup was removed and transferred to oven at 100C for 30 minutes. 12. Thimbles were removed. 13. Waste solvent was removed. 14. Tap water and POWER were closed.

IV.

Fat Collection Procedure

1. The cup was dried at 103C about 30 minutes. 2. Cup extraction was let to cool down in desiccators. 3. Cup extraction was weighted.

4. Crude fat in the sample was calculated.

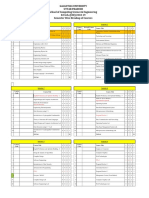

Result Percentage of Fat in the Brown Rice Pudding Sample 1 Weight of brown rice pudding (g) Weight of boiling flask (g) Weight of boiling flask + fat (g) Weight of extracted fat (g) Percentage of fat (%) 1.0074 25.1897 25.2402 0.0505 5.01 Sample 2 1.0091 26.1275 26.1598 0.0323 3.20

Calculation % Fat = [(weight of flask + fat) (weight of flask)] x 100 Weight of sample Sample 1 % Fat = = (25.2402 - 25.1897) x 100 1.0074 5.01

Sample 2 % Fat = = (26.1598 26.1275) x 100 1.0091 3.20

Average % Fat = =

(5.01+3.20) 2 4.11

Discussion Based on the result obtained, the fat percentage in our sample is 8.43%, thus our product can be defined as ice cream according to the legal definition of ice cream from UK which define ice cream as a frozen product containing a minimum of 5 % fat. Another composition standard for ice cream proposed by the International Ice-cream Association (ICA), was described as follow, non fat product < 0.8%, low fat, 2-4%, reduced fat, 7-9%, and full fat, 10-12% ( Farooq, 1997). Therefore, our product is categorized as reduced fat ice cream. In our ice cream, the fat content is mostly contributed by the milk fat. Milk fat is the most important ingredient in ice cream. It contributes a characteristic richness and mellowness to produce a full, rich creamy flavor which ice cream should have. Furthermore, milk fat also affects textural attributes such as viscosity, tenderness, elasticity, ice crystallization and other desire attributes such as richness, and smoothness. (Marshall and Arbuckle 1996).Milk and milk products are nutritious food items containing numerous essential nutrients, such as oleic acid, conjugated linoleic acid, omega-3 fatty acids, shortand medium chain fatty acids, vitamins, minerals and bioactive compounds that may promote positive health effects. Conjugated linoleic acid which is a naturally occurring fatty acid found in dairy fats, exhibits a number of health benefits. Reported beneficial health-related effects of CLA include anticarcinogenesis, antiatherogenic, antidiabetagenic and immune modulating properties. Omega-3 fatty acids on the other hand, are essential for optimal brain health and cognitive function development. It is also able to reduce the risk factors of heart disease by decreasing the bad cholesterol (LDL) and increasing the good cholesterol (HDL) which in turns promotes heart health.

8.7.2.5 Conclusion By using Mojonnier method, the crude fat content in Roselle sherbet with milk ice cream is 8.43 % and is categorized as reduced fat ice cream according to International Ice-cream Association (ICA).

8.4.2 Critical Control Point Processing of the roselle sherbet with ice cream

Weighing and Measuring ingredients

Mixing composition of ingredients by phases

*Pasteurisation of mixture 80 0C at 25 seconds

Homogenization at 800-850 Ib

*Aging at 5 0C for overnight

*Freezing below 18 0C in ice cream maker machine

*Packaging at 6 0C to 7 0C

*Hardening and storage at 20 0C

FIGURE 8.2 Flow Chart of Processing Steps of Sherbet and Ice Cream Guidelines: critical control point *

Critical Control Point 1 The mixture is pasteurized in water bath at 80C for 25 seconds. Person in-charge Line Operator Temperature should be maintained at 80oC during the process of pasteurization. Person in-charge should make sure the temperature is 80OC for 25 seconds. Temperature 80oC is the

Monitor process

Hazard risk

temperature

which is able to kill the pathogenic microorganism in the ice cream mix for sherbet and ice cream. If the temperature is lower, there may be a posibility that the pathogenic

microorganism to survive and cause food spoilage. If the temperature is too high, the nutrient such as protein, vitamin and mineral will be denatured and cannot function. If the pasteurization time is less than 25 seconds, there will be a possibilty of the survived pathogenic microorganism. If the pasteurization time exceed 25 seconds, it will destroy the nutrient in the ice cream mix.

Corrective action

If temperature is lower or greater than the temperature range, increase or decrease the temperature as soon as possible.

If the pasteurization time is less than 25 seconds, increase the holding time. If the

time is more than 25 seconds, decrease the holding time. If the heater is broken down, immediately report to the supervisor, quality control manager or product manager as soon as possible.

Critical Control Point 2 Aging in fridge at 5C for 2 days Person in-charge Line operator

Monitor process

Monitor and check the temperature is at 5oC in the fridge. 5oC

Hazard risk

Temperature

is

the

optimum

temperature for the aging. If the temperature is too low, freezing will occur which is not the intention of aging. If the temperature is too high, there will be a chance for the microorganism to grow as the milk is a rich media for the microorganism.

Corrective action

If temperature is lower or greater than the temperature range, increase or decrease possible. the temperature as soon as

If the fridge does not function well, immediately report to the supervisor,

quality control manager or product manager as soon as possible.

Critical Control Point 3 The freezing of ice cream mix is at -18OC. Person in-charge Line operator

Monitor process

Monitor and make sure the temperature is 18oC. Immediately freezing to -18OC is crucial to form a good texture ice cream with small and fine ice crystal. Slow freezing will have a big and coarse ice crystal which will affect the texture of ice cream.

Hazard risk

Corrective action

If the temperature has not reached -18oC, immediately decrease the temperature. If the ice cream machine is broken down, immediately report to the supervisor, quality control manager or product

manager as soon as possible.

Critical Control Point 4 Packaging is done at -6OC to -7OC.

Person in-charge

Line operator

Monitor process

Monitor and make sure the packaging is done at -6OC to -7OC.

Hazard risk

The

packaging

container

is

being

sterilized before the filling of the ice cream and sherbet. The temperature of packaging is at -6OC to -7OC so the ice cream and sherbet will not melt to prevent re-crystallization at the hardening stage. Corrective action If the temperature is not at -6OC to -7OC, adjust the temperature to the range. If there is a crack on the container cannot closed tightly, immediately report to the supervisor, quality control manager or product manager as soon as possible.

Critical Control Point 5 Hardening and storage of our product at -20oC

Person in-charge

Line operator

Monitor process

Monitor and make sure the temperature is 20oC all the time. Cold chain is maintained from hardening to the storage and also delivery.

Hazard risk

The rise of temperature will cause recrystallization when our product melt and refreeze again. Higher temperature will

melt our product and give the chance for microorganism to grow.

Corrective action

If the temperature has not reached 20oC, immediately decrease the

temperature. If the freezer is broken down,

immediately report to the supervisor, quality control manager or product manager as soon as possible.

S-ar putea să vă placă și

- Introduction To Milk ProcessingDocument8 paginiIntroduction To Milk ProcessingMintesnot Bogale100% (1)

- Dareeeeee SeeeminaarDocument16 paginiDareeeeee SeeeminaarAsfawu BekelaÎncă nu există evaluări

- Usmp15 22Document8 paginiUsmp15 22Hitesh JassalÎncă nu există evaluări

- Operations Plan General Approach To OperationsDocument12 paginiOperations Plan General Approach To OperationsLiz Lee100% (2)

- Enzyme Final ExamDocument16 paginiEnzyme Final ExamThuy AnhÎncă nu există evaluări

- Senior Seminar Daraje Abdeta 2016Document24 paginiSenior Seminar Daraje Abdeta 2016Asfawu BekelaÎncă nu există evaluări

- Production of Ice CreamDocument9 paginiProduction of Ice CreamAnimesh harshÎncă nu există evaluări

- Anaysis of MilkDocument14 paginiAnaysis of MilkSaman AkramÎncă nu există evaluări

- Food Jam ProcessingDocument11 paginiFood Jam ProcessingVienna Chan100% (1)

- Industrial Visit Report On Dairy IndustryDocument11 paginiIndustrial Visit Report On Dairy IndustrySammyAdhÎncă nu există evaluări

- Tra Ducci OnDocument22 paginiTra Ducci OnBellaÎncă nu există evaluări

- Lab Report Exp 2Document12 paginiLab Report Exp 2Syuhada Aminuddin0% (2)

- Cheese Technology HandbookDocument77 paginiCheese Technology HandbookTieu Hac100% (3)

- Nestlé: Ice Cream Product LineDocument31 paginiNestlé: Ice Cream Product LineMary Anne AntenorÎncă nu există evaluări

- Ice Cream ProductionDocument10 paginiIce Cream ProductionRana ShahzaibÎncă nu există evaluări

- Lab Report - SugarDocument7 paginiLab Report - SugarPeter AndrewÎncă nu există evaluări

- ESL Milk Production - 2014 - 4 - Expertenwissen - ESLDocument6 paginiESL Milk Production - 2014 - 4 - Expertenwissen - ESLsyalcinkayaÎncă nu există evaluări

- ProductionDocument4 paginiProductionShashi ReddyÎncă nu există evaluări

- Milk Analysis: Food and Agriculture Organization of The United NationsDocument5 paginiMilk Analysis: Food and Agriculture Organization of The United NationsAkhil Singh KushwahaÎncă nu există evaluări

- 6 Pengolahan Susu 2Document46 pagini6 Pengolahan Susu 2Nadila Zulfa FithriyaÎncă nu există evaluări

- Yogurt DefinitionsDocument7 paginiYogurt DefinitionsmohsinÎncă nu există evaluări

- DairyDocument6 paginiDairyPravin BiyaniÎncă nu există evaluări

- Pengolahan Susu Part 2Document46 paginiPengolahan Susu Part 2Farhan JamilÎncă nu există evaluări

- Dairy QNS and AnsDocument19 paginiDairy QNS and Ansaadnanafridi76Încă nu există evaluări

- Ice Cream Industry Class LectureDocument31 paginiIce Cream Industry Class Lecturenabil100% (1)

- Pasturization, Sterilizationo and FermentationDocument36 paginiPasturization, Sterilizationo and Fermentationkwagala joshuaÎncă nu există evaluări

- Processing of MilkDocument36 paginiProcessing of MilkSam ScariaÎncă nu există evaluări

- Seminar IngleseDocument119 paginiSeminar IngleseWilki SantanderÎncă nu există evaluări

- Materials Required: HydrometerDocument34 paginiMaterials Required: HydrometerNavÎncă nu există evaluări

- Milk PowderDocument14 paginiMilk PowderHoa Nguyen100% (1)

- Assignment #3: Baseline Principles of Puffed and Baked SnacksDocument9 paginiAssignment #3: Baseline Principles of Puffed and Baked SnacksAyesha KhanÎncă nu există evaluări

- Lecture ThreeDocument44 paginiLecture Threeሸዋረጋ ሀብታሙ ሀይሌÎncă nu există evaluări

- Lab Report 5: Lipid Analysis Sbl102 Group A Technique in Biology and Biochemistry Laboratory SEM 2 2022/2023 Lecture'S Name: DR Remmy Keong Bun PohDocument5 paginiLab Report 5: Lipid Analysis Sbl102 Group A Technique in Biology and Biochemistry Laboratory SEM 2 2022/2023 Lecture'S Name: DR Remmy Keong Bun Pohmuhammad hafizuddinÎncă nu există evaluări

- UK Powder StandardsDocument6 paginiUK Powder StandardsGajendra Singh Raghav100% (1)

- 4 Basic Food Molecules Interesting Food Systems 2013Document51 pagini4 Basic Food Molecules Interesting Food Systems 2013cutetamtam101Încă nu există evaluări

- Robsaan KootiDocument8 paginiRobsaan KootiDhugaan GalgalaafÎncă nu există evaluări

- Internship ReportDocument9 paginiInternship ReportTushaar Vishnu0% (1)

- 2014 BypdtsDocument14 pagini2014 BypdtsThe mettle knotsÎncă nu există evaluări

- Determination of Total Fat and Free Fat ContentDocument13 paginiDetermination of Total Fat and Free Fat ContentCesar Augusto Torres LinaresÎncă nu există evaluări

- PM, Tech. Pré-TraitemntsDocument9 paginiPM, Tech. Pré-TraitemntsAya SoussiÎncă nu există evaluări

- Cheese Technology: Module 15. Accelerated Ripening of CheeseDocument10 paginiCheese Technology: Module 15. Accelerated Ripening of CheeseAmit Kr GodaraÎncă nu există evaluări

- Milk TestDocument11 paginiMilk TestAshwani Kumar100% (1)

- Unit 5.FDMDocument11 paginiUnit 5.FDMAgam SindhwaniÎncă nu există evaluări

- Milk Powder ProductionDocument4 paginiMilk Powder ProductionHarish KannaÎncă nu există evaluări

- Ice Cream AAKDocument12 paginiIce Cream AAKAnonymous EAineTizÎncă nu există evaluări

- Lab 8 Ash Fat and Protein Addendum - 2018-5Document14 paginiLab 8 Ash Fat and Protein Addendum - 2018-5najwa0% (1)

- Homoginezer and UHT InfoDocument9 paginiHomoginezer and UHT InfoCarloÎncă nu există evaluări

- Production Process of JamsDocument3 paginiProduction Process of JamsElkhatibi Fatima-Ezzahra100% (1)

- Analytical Tools in Nutrition..Document5 paginiAnalytical Tools in Nutrition..Huzaifa CHÎncă nu există evaluări

- 10 1 1 392 7168Document3 pagini10 1 1 392 7168ashish.walleÎncă nu există evaluări

- Determination of Fat (Food Analysis)Document7 paginiDetermination of Fat (Food Analysis)Nabila Husna100% (2)

- Modeling and Controlling of Milk Fermentation Process Thesis - 2Document50 paginiModeling and Controlling of Milk Fermentation Process Thesis - 2ajithÎncă nu există evaluări

- Assignment Food ProcessDocument14 paginiAssignment Food ProcessIZWANA AINA NAZIRA BINTI SHUHAIMI BN20110125Încă nu există evaluări

- How Is Milk Made?: PasteurisationDocument3 paginiHow Is Milk Made?: PasteurisationKSHETRIMAYUM MONIKA DEVIÎncă nu există evaluări

- Experiment 1 - Cheese MakingDocument6 paginiExperiment 1 - Cheese MakingCha CanceranÎncă nu există evaluări

- 1-DAIRY PRODUCTS (Lecture 6)Document31 pagini1-DAIRY PRODUCTS (Lecture 6)inshirahizhamÎncă nu există evaluări

- Galactic - An Innovative, Natural Acidification Solution For Fermented MeatsDocument8 paginiGalactic - An Innovative, Natural Acidification Solution For Fermented MeatsAdinandaÎncă nu există evaluări

- Milk ProductsDocument16 paginiMilk ProductsAniisahÎncă nu există evaluări

- Ice CreamDocument10 paginiIce Creamarchusaran7313Încă nu există evaluări

- Very Narrow Aisle MTC Turret TruckDocument6 paginiVery Narrow Aisle MTC Turret Truckfirdaushalam96Încă nu există evaluări

- Praise and Worship Songs Volume 2 PDFDocument92 paginiPraise and Worship Songs Volume 2 PDFDaniel AnayaÎncă nu există evaluări

- Zomato Restaurant Clustering & Sentiment Analysis - Ipynb - ColaboratoryDocument27 paginiZomato Restaurant Clustering & Sentiment Analysis - Ipynb - Colaboratorybilal nagoriÎncă nu există evaluări

- Pathogenic Escherichia Coli Associated With DiarrheaDocument7 paginiPathogenic Escherichia Coli Associated With DiarrheaSiti Fatimah RadÎncă nu există evaluări

- Practice - Test 2Document5 paginiPractice - Test 2Nguyễn QanhÎncă nu există evaluări

- Quality Control of Rigid Pavements 1Document58 paginiQuality Control of Rigid Pavements 1pranjpatil100% (1)

- SilmaDocument12 paginiSilmanobleconsultantsÎncă nu există evaluări

- View All Callouts: Function Isolation ToolsDocument29 paginiView All Callouts: Function Isolation Toolsمهدي شقرونÎncă nu există evaluări

- Module 6 Metal Properties and Destructive TestingDocument46 paginiModule 6 Metal Properties and Destructive TestingMiki Jaksic100% (6)

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesDocument2 paginiGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiÎncă nu există evaluări

- Saiva Dharma ShastrasDocument379 paginiSaiva Dharma ShastrasfunnybizÎncă nu există evaluări

- DirectionDocument1 paginăDirectionJessica BacaniÎncă nu există evaluări

- Immunity Question Paper For A Level BiologyDocument2 paginiImmunity Question Paper For A Level BiologyJansi Angel100% (1)

- PDFDocument40 paginiPDFAndi NursinarÎncă nu există evaluări

- Lesson 1 3 Transes in Reading in Philippine HistoryDocument17 paginiLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GOÎncă nu există evaluări

- John DrydenDocument3 paginiJohn DrydenDunas SvetlanaÎncă nu există evaluări

- Iguard® LM SeriesDocument82 paginiIguard® LM SeriesImran ShahidÎncă nu există evaluări

- Vitamins - CyanocobalaminDocument12 paginiVitamins - CyanocobalaminK PrashasthaÎncă nu există evaluări

- Session 1Document18 paginiSession 1Akash GuptaÎncă nu există evaluări

- A Comparative Study of Public Private Life Insurance Companies in IndiaDocument5 paginiA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalÎncă nu există evaluări

- AMICO Bar Grating CatalogDocument57 paginiAMICO Bar Grating CatalogAdnanÎncă nu există evaluări

- ADocument54 paginiActyvteÎncă nu există evaluări

- Contemporary Strategic ManagementDocument2 paginiContemporary Strategic ManagementZee Dee100% (1)

- 18 Composition Rules For Photos That ShineDocument20 pagini18 Composition Rules For Photos That Shinemahfuzkhan100% (1)

- Existentialism in CinemaDocument25 paginiExistentialism in CinemanormatthewÎncă nu există evaluări

- Python in Hidrology BookDocument153 paginiPython in Hidrology BookJuan david Gonzalez vasquez100% (1)

- ISA InTech Journal - April 2021Document50 paginiISA InTech Journal - April 2021Ike EdmondÎncă nu există evaluări

- Hanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NaDocument2 paginiHanwha Q Cells Data Sheet Qpeak L-g4.2 360-370 2017-10 Rev02 NazulfikarÎncă nu există evaluări

- 8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsDocument9 pagini8 A - 1615864446 - 1605148379 - 1579835163 - Topic - 8.A.EffectiveSchoolsYasodhara ArawwawelaÎncă nu există evaluări

- 25 Middlegame Concepts Every Chess Player Must KnowDocument2 pagini25 Middlegame Concepts Every Chess Player Must KnowKasparicoÎncă nu există evaluări