Documente Academic

Documente Profesional

Documente Cultură

Drill Floor Equipment 1

Încărcat de

John RongDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Drill Floor Equipment 1

Încărcat de

John RongDrepturi de autor:

Formate disponibile

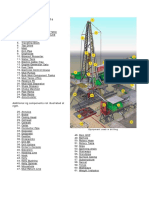

Drill Floor Equipment

Hydraulic Roughneck 1898 (Manual) Hydraulic Roughneck 1899 (Autom.)

The Hydraulic Roughneck (HRN) is a machine designed to spin in / make up / break out / and spin out drill pipe, drill collar and other drilling tools / drilling equipment, such as: drill bits, stabilizers, strainers and subs with sizes ranging from 2 7/8 up to and including 9 diameter, in well center and at both forward and backward tilted mouseholes. The gateless torque wrench (TW) is equipped with multi size jaws for easy and quick alternations between different tooljoint sizes. Optional features Revolving pipe spinner assembly (improves utilisation range and service access) Automatic lubrication system Inverted main frame Various rail systems (e.g. skiddable, hinged, bolted) Remote operated box end washer and doping unit Break out torque record gauge Stabbing guide arm Special jaws for odd tooljoint size / shape / material Control panel on machine Wireless remote control (radio) High friction spinner rollers available upon request

Optional 5,425 [4,000] Unit Nm [lbf ft] Nm [lbf ft] Nm [lbf ft] mm [inch] mm [inch] rpm Nm [lbf ft] mm [inch] Degr mm [inch]

HRN 1898. Operators view from remote control panel.

Technical data TW min. make-up torque TW max. make-up torque TW max. break-out torque TW min. stick-up height TW max. stick-up height SP max. speed (w/5 D.P) SP max. torque (w/5 D.P) SP travel height Mousehole tilt Rail span (outside/outside)

Standard 11,500 [8,500] 135,000 [100,000] 169,000 [125,000] 700 [2.30] 1,500 [4.92] 0-160 2,750 [2,028] 500 [17.9] 0-5bwd 1,850 [72.8]

700 [27.5] 2,200 [59.0] 0-80 5,500 [4,050] 900 [35.4] 0-15 bwd / 0-8fwd 1,120-2614 [44.1-102.9]

Weight will vary from 5900 (13,000 lb) kg to 6300 kg (13,900 lb) depending on configuration and options.

Main control valve cabinet with local control panel. Main control valve cover removed.

HRN 1898 front view, pipe spinner revolved

Automatic HRN with stabbing arm & wide track.

Automatic Roughneck with inverted main frame

www.marhyd.com

maritime hydraulics

23

Drill Floor Equipment

Hydraulic Roughneck 4160 (Light)

The Hydraulic Roughneck Light is designed to operate as the 1898 model, but due to its reduced size and weight it will fit on small sized drill floors (e.g. land rigs). It is capable of handling tubular sizes ranging from 2 7/8 up to and including 8 diameter in well center and mousehole. The gateless torque wrench (TW) is equipped with multi size jaws, for easy and quick alternations between different tooljoint sizes.

Technical data TW min. make-up torque TW max. make-up torque TW max. break-out torque TW min. stick-up height TW max. stick-up height SP max. speed (w/5 D.P) SP max. torque (w/5 D.P) SP travel height Mousehole tilt Rail span (inside/inside)

Data 5,300 [7,200] 84,000 [62,000] 105,000 [77,500] 700 [2.30] 1,500 [4.92] 0-160 2,750 [2,028] 500 [17,9] 0-5bwd 1,200 [47,2]

Unit Nm [lbf ft] Nm [lbf ft] Nm [lbf ft] mm [inch] mm [inch] rpm Nm [lbf ft] mm [inch] Degr mm [Inch]

Hydraulic Roughneck Light in front view break-out position

Optional features

Automatic lubrication system Break-out torque record gauge Special jaws for odd tooljoint size/shape/material Wireless remote control (radio)

Remote Control Panel

Operated (controlled) with Radio Remote Panel

24

maritime hydraulics

www.marhyd.com

Drill Floor Equipment

TorqueMasterTM

The TorqueMaster (TM) is a recently developed machine for making up and breaking out drill pipe, drill collars and casing ranging from 2 3/8 to 20. It is based on two tongs that can be separated and is thereby also capable of handling stabilisers and bits. Integrated into the design is a Mud Bucket and a Pipe Doper (optional), thus saving drill floor space and reducing the number of personnel on deck. The MH TM is equipped with a computer monitoring and executing system. The monitoring system monitors and stores makeup and break-out information. The executing system performs complete automatic sequences for making up and breaking out any kind of pipe, casing or tubular. Furthermore, this allows monitoring from any office connected to the system, even onshore.

TorqueMaster assembly

The MH TM travels on rails welded to the drill floor (hinged if required), thus reaching the center of rotary table. The MH TM is made retrofit to MH deliveries, by using the same type and dimensions of rails. The wheels are hydraulically driven, thus giving positive drive for the travel by means of constant mesh sprocket to rail. Main features

The main tong is a gateless tong able to rotate 360 degrees

continuously with a torque capacity of 203,000Nm (150,000 lbf ft). As a free floating equipment, the tong is able to measure torque via two load cells in a reaction system between the main tong and backup tong in accordance with API recommendations In addition to being a conventional spinner, the spinner also holds a guide and stabbing function Integrated mud bucket (optional) Integrated pipe doper (optional) Mousehole tilt (optional)

TorqueMaster casing running mode

Performance data Maximum make-up/break-up torque Maximum vertical travel (tong/spinner) Vertical independent spinner travel Minimum grip area Maximum grip area Maximum diameter stabilizers Maximum bit modem size (optional) Minimum MU/BO stick up Maximum distance between tongs Hydraulic power requirements Rail span Weight 203,000 Nm (150,000 lbf ft) 1500 mm (59 in.) 500 mm (19.7 in.) 2 3/8 in. 20 in. 36 in. 17 in. 450 mm (17.7 in.) 1500 mm (59 in.) 207 bars (3000 Psi) 500 l/min (132gal/min) 1850 mm (72.8 in.) 15,000 kg (33,000 lb)

TorqueMaster parked/standby position

www.marhyd.com

maritime hydraulics

25

Drill Floor Equipment

Mud Bucket

The Mud Bucket is designed for safe and smooth transportation of drilling mud to the mud tank. It latches onto the drill string by means of two hydraulic cylinders. The mud bucket then leads the mud through the drain hose, to the low-built bend on the drill floor near the mud tank. The extension arm suspends the Mud Bucket to the foundation. The foundation comprises a pedestal suspension with guiding column, bolted to a foundation plate. The extension arm enables extension and retraction of the bucket between parked position and the well centre by means of a hydraulic cylinder.

Technical data Range Time working cycle open/close Extend/Retract Mud drain hose Hydraulic flow Working pressure Size 2 7/8 in., 3 in., 4 in., 5 in., 5 in., 5 7/ 8 & 6 5/8 in. DP 1 2 sec. 6 - 9 sec. 6 in. Q = min. 50 l/min.(13 gallon/ min.) min. 160 bar (2320 psi) 2000 x 800 x 2900 mm (L x W x H)

Mud Bucket retracted

Mud Bucket extended

Multi Manipulator Arms (MMA)

A large range of drill floor mounted MMAs are available. The arms are tailor made to ease and secure safe and handsfree operations in the drill floor area. Main Functions Guiding the lower end of drill pipe and casing from V-door to well center Controlling/guiding riser, slip joint, etc. when beeing lifted with the drawworks Acting as a racking arm when other machines are occupied or out of commission Lifting bottom hole assembly components or similar, this operation may be done with a sling or with a gripping claw. The machines may be delivered with several easily interchangeable tools, each specially designed for its task.

Multi Manipulator Arm

26

maritime hydraulics

www.marhyd.com

Drill Floor Equipment

Multi Manipulator Arms (continued)

Technical data Gripping head range Gripping head capacity Guide head range Lifting capacity Main slew data Maximum slewing moment Maximum push / pull force

Multi Manipulator Arm

27/8 in. to 9.3/4 in. 2000 kg (4400 lb) 32 (25 with adapter)* 5000 kg (11023 lb)*

75 kNm (55315 lbf ft) 30 kN (6740 lbf)

Head slew data Maximum slewing moment Slewing Sector Weight MMA (including foundation)

9 kNm (6630 lbf ft) 2 rpm +/- 90oC

dry 4790 kg (10560 lb) (incl. gripper head) operational (approx. 850 kg) (1874 lb)

Guide head 32

(*On lifting shackle with Gripping Head or Guiding head removed)

Riser Tilting Arm

Performance data Service weight Max. gripper OD Reach Telescope Push force Pull force Slew CW / CCW Tilt 6200 kg (13670 lb) 60 7900 mm 1415 + 1415 = 2830 mm (9.2 ft) 95 kN (70,000 lbf. ft) 48 kN (35,400 lbf. ft) 240 kNm (177,000 lbf. ft) 16o up, 7.5o down

Riser Tilting Arm w/Guide for Riser

Monkey Tail

Technical data Tubular sizes Service weight Required oil flow Required oil pressure Reach

Monkey Tail

2 7/8 in. to 20 in. 2285 kg (5640 lb) 0-270 l/min 160 bar (2320 psi) 3.5m (11.5 ft)

Control functions may be incorporated in the Tubular Feeding Machine (TFM) on request, thus saving space at drill floor.

www.marhyd.com

maritime hydraulics

27

Drill Floor Equipment

Hydraulic Cathead

The Hydraulic Cathead is a tool for making up and breaking out drill collar and drill pipe. It is a floor mounted unit, bolted to the floor. It can be delivered with a pneumatic or electric control system, and is equipped with intergrated tong post and / or back-up post.

Cathead in operation

Standard Cathead and Cathead with low torque kit

Technical data

Operating pull Maximum torque on pipe w/ 4 ft. rig tong Maximum torque on pipe w/ 5 ft. rig tong Pull regulation Stroke of wire Line speed, pneumatically operated Wire data Operational angle of swing sheave: Lug pull force Hydraulic flow, pneumatically operated Working pressure Size Weight

Standard

140,000 N (31,000 lb) 170,000Nm (125,000 lbf ft) 210,000 Nm (157,500 lbf ft) 12,000 - 140,000 N (2,698-31,500 lbf) 2000 mm (6.5 ft) 0.15 m/sec. (0.49 ft./sec.) 10.7m of 22 wire (35ft. of 7/8 in. wire) 20 each side 140,000 N (31,500 lbf) Q = min. 100 l/min. (26.4 gallon/min.) 140 bar (2030 psi) 450 x 1950 x 830mm (18 x 77 x 33in.) 710 kg (1565 lb)

High Torque

165,000 N (37,125 lb) 200,000Nm (147,000 lbf ft) 250,000 Nm (185,000 lbf ft) 20,000 165,000 N (4,500-37,000 lbf) 2000 mm (6.5 ft) 0.15 m/sec. (0.49 ft/sec.) 10.7 m of 24 wire (35ft. of 7/8 in. wire) 20 each side 165.000 N (37,100 lbf) Q = min. 100 l/min. (26.4 gallon/min.) 140 bar (2030 psi) 450 x 1950 x 830mm (18 x 77 x 33in.) 710 kg (1565 lb)

Low Torque

13,000 N (2,930 lb) 16,000Nm (11,720 lbf ft) 19,800 Nm (14,650 lbf ft) 1300 13,000 N (290-2,900 lbf) 2000 mm (6.5 ft) 0.15 m/sec. (0.49 ft/sec.) 10.7 m of 12 wire (35ft. of 7/8 in. wire) 20 each side 13.000 N (2,922 lbf) Q = min. 100 l/min. (26.4 gallon/min.) 140 bar (2030 psi) 220 x 1950 x 500mm (9 x 77 x 20in.) 95 kg (210 lb)

Optional features

Electric remote control system. Low torque kit is available for installation on the left or right

hand side. 2 meter (6.5 ft) stroke. Pull from 1300 N (290 lb) to 13,000 N (2,900 lb). Total weight is 100 kg (220 lb). Integrated low torque mode for Cathead (el. contr. only). Pull from 4,000N to 44,000 N (900 to 9900 lbf)

28

maritime hydraulics

www.marhyd.com

Drill Floor Equipment

Winches

MHs portfolio covers complete Stand-Alone and Package Integrated Winch Units/Systems designed with special emphasis on safe, efficient and reliable operation: Utility Winches Manriding Winches Guideline Winches Podline Winches

Manrider Winch

Description MHs winches are delivered as complete units, fully tested and ready for horizontal mounting by means of bolting to substructure and connection to hydraulic ringline systems. Commonly, the winches comprise Gearbox Drum Failsafe brake system Hydraulic motor Counter balance valve Local control panel Short-time installation is achieved as no special tools are required for this operation. All winches are fitted with lifting lugs for safe and easy handling. Safe, smooth and user friendly operation & control is performed from the local control panel. Due to high reliability, maintenance is briefly limited to periodic lubrication and filter replacements. Optional Hydraulic remote control panel (portable or fixed) Portable wireless control panel Hydraulic Power Unit Wire spooling system Snatch block An extensive range of alternatives & options completes our portfolio with the intention to suit any specific or special requirement.

Utility Winch

Podline Winch

Technical data

Model

MH UW - 5mT MH MW - 150 kg MH GLW - 10mT MH PLW- 10mT MH GLWS-10mT

SWL

5mT(11020 lbf) 0.15mT (330 lbf) 10mT(22050 lbf) 10mT(22050 lbf) 10mT(22050 lbf)

Rope dia. x length

19mm (0.74) 150m (492) 10mm (0.39) 140m (460) 26mm (1.02) 1200m (3940) 26mm (1.02) 1200m (3940) 19mm (0.74) 1500m (4925)

Weight (Incl. Rope)

1500 kg (3300 lb) 1050 kg (2300 lb) 9600 kg (21150 lb) 9600 kg (21150 lb) 9600 kg (21150 lb)

REF.

CX04-SA00-0201 CX07-SA00-0201 YD10-SA00-0201 YD10-SA00-0202 YD10-SA00-0301

www.marhyd.com

maritime hydraulics

29

Drill Floor Equipment

Drill Pipe Elevators

The MH Elevators are DnV type approved and designed in accordance with API specifications. The well proven Drill Pipe elevator is pneumatically operated. 5" - rated to 350 tons 3 " - rated to 350 tons - weight 550 kg (1220 lb) - weight 570 kg (1270 lb)

Drill Pipe Elevator

Power Slips Frames

The MH Power Slips Frames consist of a frame with standard slip segments, ranging from 3 in. to 7 in. An air pressure of 7 bar (125 psi) is required for operation. A foot pedal located in the Drillers House is used for opening and closing. In combination with the Pipe Racking System, the result is fast and safe pipe handling.

Option: Power slips frames for Drill collar slips 3-7 is available.

Power Slips in retracted position

Hydraulic Rotary Tables

The Hydraulic Rotary Tables are based on a standard table for electric drive, modified to include one or four hydraulic motors. Considerable weight and space is saved by installing a hydraulic rotary table instead of an electric one, as the electric motor requires an extended skid for installation of the transmission box, brake assembly and motor. The Hydraulic Rotary Table can be driven by the same power unit as the MH hydraulic Top Drive 345 bar system, or can be hydraulically powered from the ringline 210 bar system. Considerable weight and space savings can be obtained for hydraulic power unit(s) if a hydraulically driven drawworks is installed, as these consumers do not require full power at the same time.

Options: Kits for conversion or electrically driven rotary tables. Range: 371/2 , 49 1/2 , 60 1/2

Hydraulic Rotary Table from below

30

maritime hydraulics

www.marhyd.com

Drill Floor Equipment

Drill Line Drum

The MH Drill Line Drum features hydraulically driven drums for the purpose of: Safe and reliably Drill Line handling in a heavy duty offshore working environment Enabling Safe and Smooth Slip & Cut operation

Drill Line Drum

Technical data

Pull capacity Rope speed (max.) Drum capacity: 35 Drum capacity: 38 Drum capacity: 42 Drum capacity: 45 L x W x H (Excl. prot.

MH 1780 095 11.2 kN 2 500 lb 20 m/min 65 f/min 1 950 m 6 400 1 646 m 5 400 2.0 x 2.2 x 2.3 m 6-7 x 7-3 x7 -7 3 000 kg 6 600 lb

MH 1780 096 11.2 kN 2 500 lb 20 m/min 65 f/min 2 743 m 9 000 2 286 m 7 500 1 829 m 6 000 1 424 m 5 000 2.2 x 2.2 x 2.4 m 7-3 x 7-3 x 7-10 3 100 kg 6 835 lb

MH 1780 097 11.2 kN 2 500 lb 20 m/min 65 f/min 3 810 m 12 500 3 048 m 10 000 2 591 m 8 500 2 286 m 7 500 2.2 x 2.6 x 2.4 m 7-3 x 8-6 x 7-10 3 350 kg 7 385 lb

MH 1780 098 11.2 kN 2 500 lb 20 m/min 65 f/min 5 029 m 16 500 4 267 m 14 000 3 505 m 11 500 3 048 m 10 000 2.2 x 3.2 x 2.4 m 7-3 x 10- 6 x 7-10 3 650 kg 8 050 lb

(1 3/8) (11/2 ) (1 5/8) (13/4 ) cover)

Weight (excl. wire rope)

Description The MH Drill Line Drum comprises a hydraulically driven Drum installed in a Cradle ready for installation on drill floor or another suitable location. Operator Friendly Overview Drum drive is done by means of a flange mounted short version type hydraulic motor with brake and brake valve. This system gives a smooth and easy drive during slip and cut operations. In addition, the drum has a manual parking brake. The drum is operated locally by an operation handle, which gives a user-friendly overview during the operation.

Drill Line Drum

The motor, brake, valves and instrumentation are bracket mounted on the cradle, which gives a user-friendly overview and easy access during inspection or maintenance. An extensive range of alternatives & options completes the MH portfolio with the intention to suit specific or special requirements as for example: Wire cutter Pneumatically or electrically powered drum Automatic or remote operation and control depending on customer preferences Protective cover Aluminum weather protection

www.marhyd.com

maritime hydraulics

31

Drill Floor Equipment

Deadline Anchor

MHs Deadline Anchors are DnV type approved and designed/ manufactured in accordance with API specifications. They are built to accommodate tension type load cell.

Model MH 1083 080 150,000 lbs / Fix. Drum Floor mounted, tension cell MH 1083 065 140,000 lbs / Rot. Drum With hydraulic drive Leg mounted, tension cell MH 1496 010 140,000 lbs / Rot. Drum Floor mounted, compr. cell MH 1496 011 200,000 lbs / Rot. Drum Floor mounted, compr. cell MH 1496 015 140,000 lbs / Rot. Drum Floor mounted, tension cell MH 5018 844 160,000 lbs / Rot. Drum Leg mounted, compr. cell

Load Range 100,000 lb/150,000 lb (45,359 kg / 68,038 kg) 100,000 lb/140,000 lb (45,359 kg / 63,502 kg) 100,000 lb/140,000 lb (45,359 kg/ 63,502 kg) 150,000 lb/200,000 lb (68,038 kg/90,718kg) 100,000 lb/140,000 lb (45,359 kg / 63,502 kg) 100,000 lb/160,000 lb (45,359 kg/ 72,575 kg)

Drill Line Range 1 3/8 - 1 - 1 5/8 - 1

1 3/8 - 1 - 1 5/8 - 1

1 3/8 - 1 - 1 5/8 - 1 1 3/8 - 1 - 1 5/8 - 1 - 2 1 3/8 - 1 - 1 5/8 - 1 1 3/8 - 1 - 1 5/8 - 1

Travelling Blocks

MH Travelling Blocks have a well-proven design and have been in the market for more than 30 years. Travelling Blocks are available in various standard designs.

Model Type 1: 350 t (MH 1107) Type 1: 550 t (MH 1195) Type 1: 650 t (MH 1090) Type 2: 500 t (MH 11 12) Type 2: 650 t (MH 1068) Type 2: 750 t (MH 1199)

No. of sheaves 5 6 7 6 7 7

Dim. A/B/C (mm) A= 2235, B = 1140, C=250 A= 2650, B = 1600, C=310 A= 3023, B = 1600, C=360 A= 3087, B = 1600, C=360 A= 3105, B = 1600, C=442 A= 3105, B = 1600, C=442,

Dim. A/B/C (In.) A=88, B=45, C=10 A=104, B=63, C=12 A=119, B=63, C=14 A=121, B=63, C=14 A=122, B=63, C=17 A=122, B=63, C=17

Weight mT 7 mT 9 mT 10.5 mT 9 mT 10.5 mT 11 mT

Weight lb 15,400 lb 19,800 lb 23,000 lb 19,800 lb 23,000 lb 24,200 lb

Optional: 1000 tons. All blocks are available as split blocks.

32

maritime hydraulics

www.marhyd.com

S-ar putea să vă placă și

- 2000 HP Land Electric Drilling Rig Technical SpecificationDocument44 pagini2000 HP Land Electric Drilling Rig Technical SpecificationSteveih100% (5)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDe la EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÎncă nu există evaluări

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- Land Rig BrochureDocument9 paginiLand Rig Brochuresatya_dohare100% (1)

- 20200e Top Drive ECI 900 Electric Top Drive PDFDocument2 pagini20200e Top Drive ECI 900 Electric Top Drive PDFluisxxx1100% (2)

- Rig Components & Equipment ReviewDocument19 paginiRig Components & Equipment Reviewking ghÎncă nu există evaluări

- Top Drive Level I Course IntroductionDocument31 paginiTop Drive Level I Course IntroductionGiezy Daniela Velasquez Hernandez100% (2)

- 500 600 Eci 1350Document2 pagini500 600 Eci 1350Jack Yang100% (1)

- Top Drive Brochure PDFDocument6 paginiTop Drive Brochure PDFaldino020203100% (1)

- Trip TankDocument23 paginiTrip TankNaser KhanÎncă nu există evaluări

- AB-09-01 Drawworks Auxiliary BrakeDocument2 paginiAB-09-01 Drawworks Auxiliary BrakeAgohuvÎncă nu există evaluări

- MAS 7500 Operation Manual Bearing Clearance LimitsDocument2 paginiMAS 7500 Operation Manual Bearing Clearance Limitsmohamed salem100% (1)

- Rotary SystemDocument17 paginiRotary Systemgo25101992Încă nu există evaluări

- Nov Mission Drilling SolutionsDocument24 paginiNov Mission Drilling SolutionsahnafÎncă nu există evaluări

- Draw WorksDocument3 paginiDraw WorksUsman AhmedÎncă nu există evaluări

- Auto DrillerDocument2 paginiAuto DrillersrpadronÎncă nu există evaluări

- IDS 350PE Top DriveDocument2 paginiIDS 350PE Top Drivealan camposÎncă nu există evaluări

- Cougar DLLG Solutions FaqDocument5 paginiCougar DLLG Solutions FaqLenis CeronÎncă nu există evaluări

- Rig component definitions guide under 40 charactersDocument70 paginiRig component definitions guide under 40 charactersHarpreetk87Încă nu există evaluări

- How Does A Top Drive WorkDocument12 paginiHow Does A Top Drive WorkDanny VeitiaÎncă nu există evaluări

- Rig Upgrade Packs Brochure-NOVDocument12 paginiRig Upgrade Packs Brochure-NOVprabhakar2009100% (1)

- Career On Drilling RigDocument12 paginiCareer On Drilling RigAhmed BalochÎncă nu există evaluări

- TDS-3S Maint and Troubleshooting GuideDocument68 paginiTDS-3S Maint and Troubleshooting GuideSaid100% (1)

- Top Drive ModelDocument10 paginiTop Drive ModelJimy Barron100% (1)

- Mud PumpDocument21 paginiMud PumpJames Zhou100% (1)

- Drilling Rig Components GuideDocument153 paginiDrilling Rig Components GuideNilesh Singhal100% (4)

- Driller's Console Chapter 4 PDFDocument41 paginiDriller's Console Chapter 4 PDFpabloÎncă nu există evaluări

- Vendor B - Technical ProposalDocument136 paginiVendor B - Technical ProposalBilal Mehdi100% (1)

- OWI 1000 DrawworksDocument54 paginiOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- 6923 PDFDocument5 pagini6923 PDFMEHDIÎncă nu există evaluări

- Can Rig Top Drive 500 TonDocument688 paginiCan Rig Top Drive 500 TonAhmed Magd91% (11)

- TDS Manual-TescoDocument33 paginiTDS Manual-TescoQAMAR ALI KHAN100% (1)

- TDS-11SA Lubrication and Maintenance GuidelinesDocument1 paginăTDS-11SA Lubrication and Maintenance GuidelinesEduardo Vilela RomeroÎncă nu există evaluări

- Bop Chain Hoists: Subsea Handling EquipmentDocument2 paginiBop Chain Hoists: Subsea Handling EquipmentLeonardoViannaÎncă nu există evaluări

- DC Make-Up TorqueDocument5 paginiDC Make-Up TorquepatelsujanÎncă nu există evaluări

- Drawworks and Rig Sizing PDFDocument8 paginiDrawworks and Rig Sizing PDFAmine Mimo100% (1)

- Rig Move Brochure: Parker Drilling CompanyDocument39 paginiRig Move Brochure: Parker Drilling CompanyJonathan CustodioÎncă nu există evaluări

- Soft Torque System (Paper) - OME Paper 112Document18 paginiSoft Torque System (Paper) - OME Paper 112Odion Ikhajiagbe100% (1)

- Tesco 500 ESIDocument2 paginiTesco 500 ESIjlmunozv0% (1)

- 401 - 20900e - Dog House Manual Oct 06Document20 pagini401 - 20900e - Dog House Manual Oct 06babarmehboobaliÎncă nu există evaluări

- Drill Pipe Float Valve Catalog - WebDocument24 paginiDrill Pipe Float Valve Catalog - Webcaballero_tigreÎncă nu există evaluări

- 10 Driller Module Admin ManualDocument80 pagini10 Driller Module Admin Manualcpb dwo100% (2)

- Composite CatalogDocument128 paginiComposite Catalogmkwetco75% (4)

- H&P ARG Rig 335 Equipment List From Final WoDocument12 paginiH&P ARG Rig 335 Equipment List From Final WoJuan Miguel Robledo100% (1)

- Rig Components PDFDocument19 paginiRig Components PDFBalant AxÎncă nu există evaluări

- Tesco 750 ESIDocument2 paginiTesco 750 ESIjlmunozvÎncă nu există evaluări

- Rig Components: We LL Drilling Eng Dana MohammadDocument129 paginiRig Components: We LL Drilling Eng Dana Mohammaddana mohammedÎncă nu există evaluări

- 2000 HP SCR Drilling Rig SpecificationsDocument24 pagini2000 HP SCR Drilling Rig Specificationsfatehul alam100% (2)

- 500 Esi 1350Document2 pagini500 Esi 1350Jack YangÎncă nu există evaluări

- NOV 14-P-220 mud pump specsDocument2 paginiNOV 14-P-220 mud pump specsjoseluisvalera100% (1)

- USER & MAINTENACE MANUAL (189028) - Preliminary - Compressed PDFDocument182 paginiUSER & MAINTENACE MANUAL (189028) - Preliminary - Compressed PDFElsomarx Marx100% (1)

- Top Drive SpecificationDocument4 paginiTop Drive SpecificationDya PratamaÎncă nu există evaluări

- Drilling Supervisor: Passbooks Study GuideDe la EverandDrilling Supervisor: Passbooks Study GuideÎncă nu există evaluări

- Top Drives CanrigDocument8 paginiTop Drives Canrigthought001Încă nu există evaluări

- English CatalogDocument10 paginiEnglish Catalogcorsini999Încă nu există evaluări

- Measurement While Drilling: Signal Analysis, Optimization and DesignDe la EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignÎncă nu există evaluări

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersDe la EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersÎncă nu există evaluări

- Ship Structure DesignDocument215 paginiShip Structure DesignHashem GamÎncă nu există evaluări

- I DogDocument16 paginiI Doghuxley2378Încă nu există evaluări

- HERCULESDocument6 paginiHERCULESJohn Rong100% (3)

- Shipbuilding Process 1Document53 paginiShipbuilding Process 1tiwaripur100% (1)

- Anna Kostenko Paintings Not Photographs 11Document24 paginiAnna Kostenko Paintings Not Photographs 11John RongÎncă nu există evaluări

- UntitledDocument128 paginiUntitledapi-61200414Încă nu există evaluări

- Ship Constructor Autodesk Proposal To Canadian Gov NavyDocument12 paginiShip Constructor Autodesk Proposal To Canadian Gov NavyJohn RongÎncă nu există evaluări

- Ship Hull Design-420Document2 paginiShip Hull Design-420lgbrangelÎncă nu există evaluări

- Workboats or Warships A National Shipbuilding Strategy For CanadaDocument10 paginiWorkboats or Warships A National Shipbuilding Strategy For CanadaJohn RongÎncă nu există evaluări

- Philosophy For Old AgeDocument20 paginiPhilosophy For Old AgeJohn RongÎncă nu există evaluări

- Large Diameter Diaphragm Wall ShaftsDocument7 paginiLarge Diameter Diaphragm Wall ShaftsmeñoxÎncă nu există evaluări

- 2011 Heritage CalendarDocument28 pagini2011 Heritage CalendarJohn RongÎncă nu există evaluări

- Navtech Proposal To Canandian Gov NavyDocument12 paginiNavtech Proposal To Canandian Gov NavyJohn RongÎncă nu există evaluări

- Mid Fatigue Plastic Water Pipe 01-12-12Document44 paginiMid Fatigue Plastic Water Pipe 01-12-12John RongÎncă nu există evaluări

- PEX Vs PB Comparison 2-03Document1 paginăPEX Vs PB Comparison 2-03John RongÎncă nu există evaluări

- T I 83 GuidebookDocument446 paginiT I 83 GuidebookMarcelo AndradeÎncă nu există evaluări

- Pinniped Deterrents at Bonneville Dam 2005-2006: Fisheries Field UnitDocument27 paginiPinniped Deterrents at Bonneville Dam 2005-2006: Fisheries Field UnitJohn RongÎncă nu există evaluări

- User'S Guide: MFC-5460CNDocument151 paginiUser'S Guide: MFC-5460CNJohn RongÎncă nu există evaluări

- Gavric 1993Document15 paginiGavric 1993John RongÎncă nu există evaluări

- 28 CountriesDocument1 pagină28 CountriesJohn RongÎncă nu există evaluări

- Columbia River Inside StoryDocument80 paginiColumbia River Inside StoryArvind SrivastavaÎncă nu există evaluări

- Philosophy For Old AgeDocument20 paginiPhilosophy For Old AgeJohn RongÎncă nu există evaluări

- HTTP://WWW Slides Co Il/zoom Php?id 9628Document36 paginiHTTP://WWW Slides Co Il/zoom Php?id 9628www.slides.co.ilÎncă nu există evaluări

- Asme - Journal of Vibration and Acoustics - July 2003Document165 paginiAsme - Journal of Vibration and Acoustics - July 2003Johan Graffman100% (1)

- Science Cyclic Creep1Document7 paginiScience Cyclic Creep1John RongÎncă nu există evaluări

- Science-Fem Water HamerDocument14 paginiScience-Fem Water HamerJohn RongÎncă nu există evaluări

- 41 547Document16 pagini41 547John RongÎncă nu există evaluări

- 41 351Document20 pagini41 351John RongÎncă nu există evaluări

- 41 371Document26 pagini41 371John RongÎncă nu există evaluări

- A Simulation Approach For Prediction and Reduction of Radiated Noise of An Air Cleaner SnorkelDocument17 paginiA Simulation Approach For Prediction and Reduction of Radiated Noise of An Air Cleaner SnorkelJohn RongÎncă nu există evaluări

- Dpla 01 MDocument10 paginiDpla 01 MzohaibshabirÎncă nu există evaluări

- Manual HT001Document13 paginiManual HT001andrija_ganzbergerÎncă nu există evaluări

- Line Following Robot ReviewDocument9 paginiLine Following Robot ReviewSree Krishna Nimmagadda ChowdaryÎncă nu există evaluări

- Connecteur EN3645Document13 paginiConnecteur EN3645FredÎncă nu există evaluări

- Valve Type Used in Power PlantDocument14 paginiValve Type Used in Power PlantGourav Choudhuri0% (1)

- Doosan D12T and P126ti Workshop Manual PDFDocument186 paginiDoosan D12T and P126ti Workshop Manual PDFMuhammad rizki100% (4)

- Electro Válvula Del CompresorDocument4 paginiElectro Válvula Del CompresorneumaticoÎncă nu există evaluări

- Sands GPS DocumentsDocument7 paginiSands GPS Documentsrpaliwal1967100% (1)

- Light Commercial (Eu) : Ningbo Electric Co.,LtdDocument32 paginiLight Commercial (Eu) : Ningbo Electric Co.,LtdAlexandru AÎncă nu există evaluări

- ID-N-CG-YY4-PRT-PL-25-0002 - Constructability Review ReportDocument16 paginiID-N-CG-YY4-PRT-PL-25-0002 - Constructability Review ReportadjiÎncă nu există evaluări

- Shanghai YuanYi Pressure Switches & Explosion-Proof ModelsDocument4 paginiShanghai YuanYi Pressure Switches & Explosion-Proof ModelsIrham Banua PratamaÎncă nu există evaluări

- Multiactuator CircuitsDocument38 paginiMultiactuator CircuitsMeda AdimurthyÎncă nu există evaluări

- Vortex Wireless User Guide v1.1Document52 paginiVortex Wireless User Guide v1.1RamitÎncă nu există evaluări

- VEHICLE MAINTENANCE TIPSDocument89 paginiVEHICLE MAINTENANCE TIPSjalda srikaranÎncă nu există evaluări

- NuMicro Nano DMA OverviewDocument13 paginiNuMicro Nano DMA OverviewThienÎncă nu există evaluări

- ELEC 344 - Module 2 Lecture NotesDocument45 paginiELEC 344 - Module 2 Lecture NotesMax HornerÎncă nu există evaluări

- H2 Power Bank ManualDocument19 paginiH2 Power Bank ManualMarcantonio Infascelli100% (1)

- DISH Pro-DISH Pro Plus Installation Quick Reference GuideDocument6 paginiDISH Pro-DISH Pro Plus Installation Quick Reference GuideRichard ParvinÎncă nu există evaluări

- Dieselec Doosan DD-625 KVADocument4 paginiDieselec Doosan DD-625 KVAJay Tolentino100% (1)

- 2 WaydistributorDocument53 pagini2 WaydistributormbhaditÎncă nu există evaluări

- Microcor Datalogger ML-9500A - Man Rev NCDocument13 paginiMicrocor Datalogger ML-9500A - Man Rev NCfelio ossoÎncă nu există evaluări

- Brochure A60h t4f en 22 Voe2260009418-ADocument13 paginiBrochure A60h t4f en 22 Voe2260009418-AamelÎncă nu există evaluări

- Industrial Electrician ResumeDocument5 paginiIndustrial Electrician Resumee768938t100% (1)

- Steering Wheel Control Switch PDFDocument2 paginiSteering Wheel Control Switch PDFJairo Rodriguez A.Încă nu există evaluări

- Polaris B767 AMM Supplement 31 MAR 2014 REV 2 PDFDocument287 paginiPolaris B767 AMM Supplement 31 MAR 2014 REV 2 PDFEdwin GarayÎncă nu există evaluări

- Mini Truck RFI Seeks Bids for 2,958 VehiclesDocument10 paginiMini Truck RFI Seeks Bids for 2,958 VehiclesAMIT KUMAR DAGAR APACHE DAGGERÎncă nu există evaluări

- Specifications, Applications, Service Instructions & Parts: Gas Detectors, Controller & Alert SystemsDocument22 paginiSpecifications, Applications, Service Instructions & Parts: Gas Detectors, Controller & Alert Systemsjcastell100Încă nu există evaluări

- ArgusRadar ISM EN 988-10187-003 WDocument154 paginiArgusRadar ISM EN 988-10187-003 WJeffrey SlaninaÎncă nu există evaluări

- Wecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalDocument226 paginiWecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalJose Gregorio Lira SerranoÎncă nu există evaluări

- Alliance Technical Catalog Aug 2022 - LR - 1672742721Document236 paginiAlliance Technical Catalog Aug 2022 - LR - 1672742721Will CreÎncă nu există evaluări