Documente Academic

Documente Profesional

Documente Cultură

TDV 100

Încărcat de

林育豪Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

TDV 100

Încărcat de

林育豪Drepturi de autor:

Formate disponibile

Stackable Directional Control Valve System

The TDV100 is a closed center, load sensing, sectional control valve with pre-compensation.

The TDV100 can be congured with 1 to 10 working sections and can be used with xed displacement or with pressure/ow compensated

variable displacement pumps.

When multiple functions are selected, the TDV100 will automatically resolve the highest function load pressure which is then

transmitted to the pump or inlet unloader/by-pass compensator and drained to tank once all spools are returned to neutral.

Each TDV100 sectional valve is crossed by a pilot pressure supply line and a return rail to feed 16-20 bar to the MULTIDROM* electro-

hydraulic actuators system.

Manual and Electro-hydraulic Controls

MLM - Multi-function / Manual control lever

MLT - Multi-function / Manual control lever and MLT/FD5 feedback (closed loop) type electro-hydraulic proportional actuators

MPP - Multi-function / Double-sided proportional non feedback (open loop) pilot pressure control actuators with screw type

manual overrides

MOP - Multi-function / Manual control lever and ON-OFF actuators

SPO - Single function ON-OFF selection with pressure compensated 3-way proportional meter-in control of pump

ow with manual overrides.

Specications

Max. operating ow: 90 lt/min

Max. ow per section: 70 lt/min

Max. working pressure: 280 bar

Min. stand-by & pilot pressure: 14 bar

Spool stroke: +/- 6.5 mm

Section width: 39 mm

P & T Ports: 3/4- BSP (1.1/16-UNF)

Work ports (A & B): 1/2- BSP (7/8-UNF)

Fluid: Mineral based oil

Fluid temperature range: -25C/+115C

Optimum uid viscosity range: 3<cSt<648

Max. uid contaminiation level: 19/16 (ISO 4406)

Seals: BUNA-N (Std) / Viton (optional)

Product Features and Benets

Load-independent simultaneous control of two or more functions, within pumps ow saturation limits

Proportional ow control extended to 95% of spool stroke

Special craning spool conguration for overhung load control in conjunction with counterbalance valves

MLT/FD5 proportional actuators have built-in electronics requiring only variable voltage signals from a joystick

Internal closed loop position control conguration makes the valve spool achieving the desired position with accuracy levels

approaching the performance of a servo-valve

Built-in CANbus interface working on SAE J1939 protocol

Non-feedback proportional and ON-OFF pilot pressure control actuators available

Electro-hydraulic, pressure compensated meter-in control of pump ow is available for cost-effective applications

TDV 100 DIRECTIONAL PROPORTIONAL CONTROL VALVE SYSTEM

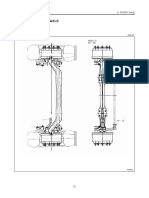

TDV 100 Cutaways

TDV 100 Series

Inlet comes standard with 1/2 or 3/4 BSP inlet P and outlet T ports.

Inlet comes standard with a load sense relief valve cavity

TDV 101-IFC version for xed displacement pumps incorporates an unloader

valve with a 15 bar bias spring to create a pump-to-LS differential pressure

TDV 101-IV0 version for variable displacement pumps incorporates a pilot-

operated system relief valve

TDV 101-IFC-EH versions incorporate a mechanical pressure reducing valve and

a 3w-2p, solenoid operated cut-off valve for pilot pressure control of electro-

hydraulic actuators MLT or MPP

TDV 102-MLM Spool section with manual control lever

Closed center conguration for proportional ow control extended to 95% of

spool stroke

Individual pressure compensator for load-independent simultaneous control of

two or more functions

LS Relief valve

Anti-shock / Anti-cavitation checks on A and B ports

TDV 102-MOP Spool section with manual control lever and ON-OFF

solenoid - operated pilot pressure control

Single-sided dual ON-OFF cartridge valves for bidirectional control

of a built-in servo-piston

TDV 102-MLT Spool section with manual control lever

and electro-hydraulic proportional actuator

with position sensor and built-in electronics

Proportional remote control requires a variable voltage signal for a MLT/FD5 D/A

versions or CAN H/L connections for D/CAN versions

(consult Tecnord engineering dpt for details)

TDV 102-MPP Spool section with open loop /non-feedback

proportional pilot pressure control

Double-sided screw-type manual overrides in lieu of bidirectional manual lever

control

Proportional remote control requires PWM external drivers

TDV 101 - Inlet Sections

TDV 102 - Spool Sections

Pressure cut off valve

Unloader valve

Pilot pressure cut off valve

Pressure reducing valve

Relief valve

Anti-shock/anti-cavitation valve

Individual pressure compensator

Check valve

Manual control lever

DT04-4P connector

Proportional/on-off

electro hydraulic actuator

Spool

Proportional

pilot pressure valve

DT04-2P connector

Spring cap with

manual operator

Inlet & End Sections Assembly Options

TDV 100 Series

0

5

10

15

20

10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95

Inlet flow (l/min)

P

(

b

a

r

)

P (

IFC/IVO inlet section with auxiliary valves

IFR inlet section with meter-in proportional control of pump ow

IFC/IVO inlet section without auxiliary valves

Inlet section designation

TDV 101 - IFCLG34 - C15R28 - E49E9 - 12VDT - NNN

Inlet section

IFC= with pump unloader valve for xed

displacement pumps

IVO= without pump unloader valve

for variable displacement pumps

IFR= with meter-in proportional control

of pump ow

LG12= 1/2-BSP / LH sided version

LG34= 3/4-BSP / LH sided version

C15= 15 bar unloader valve setting

C00= no unloader valve

R07= 70 bar min. relief valve setting

R28= 280 bar max. relief valve setting

0000= without auxiliary valves

E4900= with 2w/2p NO full pump dump valve

E3900= with 2w/2p NO LS signal dump valve

E49E9= with 2w/2p NO full pump dump valve

RPM pressure reducing valve

3w/2p pilot pressure cut-off valve

E39E9= same as above with 2w/2p NO LS signal

dump valve

12V= 12VDC

24V= 24VDC

DT= Deutsch connector

3 digits var.

End section designation

TDV 103 - ERS

End section Blank / RH sided version

Inlet to outlet stand-by differential pressure (bar) vs. pump ow (l/min) Meter-in prop. control characteristic (IFR version) at various compensator settings

0

10

20

30

40

50

60

0 200 400 600 800 1000 1200 1400 1600

I (mA)

Q

(

l/

m

in

)

5 bar

14 bar

20 bar

P (in-out)

0

10

20

30

40

50

60

70

80

90

1,5 2 2,5 3 3,5 4 4,5 5 5,5 6 6,5

Spool travel (mm)

F

lo

w

(

l/

m

in

)

20 l/min

70 l/min

40 l/min

0

5

10

15

20

25

30

35

40

10 20 30 40 50 60 70 80 90

Inlet flow (l/min)

P

IN

-

A

-

O

U

T

(

b

a

r

)

P (IN-A

P (IN-A

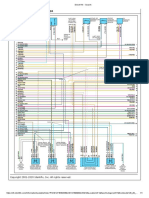

Spool Section Assembly Options

TDV 100 Series

Work port ow (l/min) vs. spool travel (mm)

TDV 102 MLM manual lever control

Inlet (P) to outlet (T) pressure drop at full ow through work port A&B of section 1 and 8

TDV 102 MOP on-off type pilot pressure control

Spool section designation

TDV 102 - MLMG12 - Y40 - A07B28 - 12VDT - NNN

Spool section

MLM= manual lever only

MOP= on-off pil. op. actuator

MLT= closed loop proportional actuator

MPP= open loop proportional actuator

G12= 1/2 BSP

A00= no port relief on A

A07= port A / 70 bar

B28= port B / 280 bar

B00= no port relief on B

12V= 12VDC

24V= 24VDC

DT= Deutsch connector

3 digits var.

X= closed center spool

Y= motor spool

K= A to T / B blocked

S= SE spool / P to A

20= 0 to 20 l/min

40= 0 to 40 l/min

70= 0 to 70 l/min

TDV 102 MLT closed loop proportional actuator with built-in electronics TDV 102 MPP open loop non feedback proportional pilot pressure control

Spool type: Y K X S

P (IN-A8-OUT)

P (IN-A1-OUT)

Sectional Valve Assembly Options

TDV 100 Series

Sectional valve designation example (ordering code)

Hydraulic and electrical characteristics of operating parts

Position A/1 A/2 C1 C2 C3 C4

Mnemonic code IFC / IFV IFR MLM MLT MPP MPO

Part description Inlet section Inlet section Spool section Spool section Spool section Spool section

Hydraulic configuration

Fixed or variable

displacement

pump

Proportional

meter-in ctrl of

pump flow

Manual lever

control

X/Y/K/S spool

proportional actuator

X/Y/K/S spool

proportional

actuator

X/Y/K/S spool

on-off actuator

Typical flow rate 90 l/min 90 l/min 20/40/70 l/min 20/40/70 l/min 20/40/70 l/min 20/40/70 l/min

Max. work pressure 280 bar 280 bar 280 bar 280 bar 280 bar 280 bar

Pressure compensator

setting

15 bar @ 40 bar 15 bar 13 bar 13 bar 13 bar 13 bar

Servo actuator pilot flow

requirement

// // // 0,2 l/min 0,2 l/min 0,2 l/min

Servo actuator pressure

requirement

// // // 15-18 bar 15-18 bar 15-18 bar

BSP (Gas) port threads 1/2 - 3/4 1/2 - 3/4 3/8 - 1/2 3/8 - 1/2 3/8 - 1/2 3/8 - 1/2

UNF port threads 1.1/16 1.1/16 7/8 7/8 7/8 7/8

Number of sections in the

assembly

1 1 1-8 1-8 1-8 1-8

Electrical configuration Electro-hydraulic Proportional

Manual lever

control

Closed loop ctrl with

built-in electronics

Open loop

proportional

control

On-off pilot

pressure control

Supply voltage 12-24 VDC 12-24 VDC 12-24 VDC 12-24 VDC 12-24 VDC 12-24 VDC

Max. current

consumption

4A @ 12VDC 4A @ 12VDC // 0,75A 1,5A 1,2A @ 12VDC

Analogical input

impedance

// // // < 40 Kohm // //

Analogical input signal // // // 0-5V // //

Current command ctrl //

0.2-1.5A/PWM

dither:100Hz

// //

0.2-1.5A/PWM

dither:100Hz

//

Typical control

potentiometer resistance

// 1-10 Kohm // 1-10 Kohm 1-10 Kohm //

DT04 pin connection #1 (+)12-24 VDC PWM / 1 // (+) power source PWM / 1 (+)12-24 VDC

DT04 pin connection #2 (-) ground PWM / 2 // +5V output V to pot. PWM / 2 (-) ground

DT04 pin connection #3 // // // Var. ctrl signal // //

DT04 pin connection #4 // // // (-) power source // //

TDV 100 - IFCLG12 - 1MLM/1MLT/1MMP/1MOP - 12VDT - NNN

Valve family Inlet section

IFCLG12= for xed displacement pumps

IV0LG12= for variable displacement pumps

IFRLG12= with meter-in prop. ow control

Inlet section

MLM= manual lever only

MOP= on-off pil. op. actuator

MLT= closed loop proportional actuator

MPP= open loop proportional actuator

Voltage

12V= 12VDC

24V= 24VDC

DT= Deutsch connector

3 digits var.

Configuration example

RC DBR

Combined on-off and proportional radio

control system with single hand wander

EC PWM A1 MPC1

Microprocessor based PWM

electronic driver

Fingertip proportional levers

Potentiometric and hall effect

single-axis control levers and roller

switches

Ecomatic

GPS ground-speed oriented salt

spreader control systems

Ergonomic grips

Multi-function ergonomic grips with

on-off and proportional switches

RC PCM

Multi-function proportional radio

control system with shoulder-strap

transmitter

EC MMS

Microprocessor-based Machine Manage-

ment Systems for the integrated control

of electro-hydraulic and safety functions

Heavy duty joysticks

Potentiometric and hall effect

multi- axes control joysticks

Customized control units

Customized microprocessor-based,

multi-functions control units

TECNORD comprehensive range of remote

control electronics

M

a

r

c

h

2

0

1

0

e

d

i

t

i

o

n

Via Malavolti, 36 - 41122 Modena - Italy

Tel. +39-059-254895 - Fax +39-059-253512 - www.tecnord.com - e-mail: tecnord@tecnord.com

S-ar putea să vă placă și

- SD 6 eDocument16 paginiSD 6 eseaqu3stÎncă nu există evaluări

- METRUS Test Bench Overview 2017Document8 paginiMETRUS Test Bench Overview 2017Ozawa MagooÎncă nu există evaluări

- Maflosh 02 IngDocument44 paginiMaflosh 02 IngNicoleta CosteaÎncă nu există evaluări

- Mas 7 PDFDocument16 paginiMas 7 PDFAbbas ALhasnawyÎncă nu există evaluări

- Dimension K3V-K5VDocument4 paginiDimension K3V-K5VRafael RodriguezÎncă nu există evaluări

- AHP Serie20 PDFDocument24 paginiAHP Serie20 PDFeng130% (1)

- HY11-3362 Press Control PPCC UKDocument40 paginiHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- Relief Cartridge ValvesDocument16 paginiRelief Cartridge Valvesvivek_11111987Încă nu există evaluări

- CP CatalogDocument20 paginiCP CatalogCentral Hydraulics100% (1)

- Eaton: Medium Duty Piston PumpDocument20 paginiEaton: Medium Duty Piston PumpChristian StalinÎncă nu există evaluări

- Aa4v56 Series 1 Service Parts ListDocument36 paginiAa4v56 Series 1 Service Parts Listhamza HamzaÎncă nu există evaluări

- Legend: Hydraulic/Hydrostatic Schematic 320/320L (S/N 223811001 - 223812346) 322 (S/N 223511001 - 223514376)Document2 paginiLegend: Hydraulic/Hydrostatic Schematic 320/320L (S/N 223811001 - 223812346) 322 (S/N 223511001 - 223514376)Леонид Юртаев100% (1)

- Valve Ls LindeDocument24 paginiValve Ls Lindele100% (1)

- PVB PVBQ A10vso PVHDocument38 paginiPVB PVBQ A10vso PVHWilliam ValenciaÎncă nu există evaluări

- Re 15190Document24 paginiRe 15190Ahmed Abd ElhakeemÎncă nu există evaluări

- Service Manual E25 Compact Excavator: S/N AB8B11001 & AboveDocument41 paginiService Manual E25 Compact Excavator: S/N AB8B11001 & AboveSoban Reddy50% (2)

- Unidades Direção Rexroth PDFDocument12 paginiUnidades Direção Rexroth PDFmegatornadoÎncă nu există evaluări

- 89-100 11069970 PDFDocument44 pagini89-100 11069970 PDFeng13Încă nu există evaluări

- TLT35D Section e - HydraulicDocument112 paginiTLT35D Section e - HydraulicIgor Ferreira dos SantosÎncă nu există evaluări

- L20 Series: Service and Repair ManualDocument28 paginiL20 Series: Service and Repair ManualJoe CorreaÎncă nu există evaluări

- A10V Series 31 Eng DataDocument32 paginiA10V Series 31 Eng DataMARCO HernándezÎncă nu există evaluări

- Cat Hy14 1600 Denison Products PDFDocument438 paginiCat Hy14 1600 Denison Products PDFEmiliano MercadoÎncă nu există evaluări

- Denison Calzoni Type MRT Mrte MRTFDocument24 paginiDenison Calzoni Type MRT Mrte MRTFSilvio RomanÎncă nu există evaluări

- 520L0291 - Rev AA - Juli 07Document12 pagini520L0291 - Rev AA - Juli 07Sasko DimitrovÎncă nu există evaluări

- AirValves 2013 PDFDocument268 paginiAirValves 2013 PDFSergio Sebastian Ramirez GamiñoÎncă nu există evaluări

- A4VG - Data Sheet - Serie 40Document68 paginiA4VG - Data Sheet - Serie 40Aurimas Bendinskas100% (1)

- Repfllr Pflrts . . I: at BoschDocument4 paginiRepfllr Pflrts . . I: at BoschEng-Mohammed SalemÎncă nu există evaluări

- Axial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Document48 paginiAxial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Anonymous bVi38aVÎncă nu există evaluări

- D7150 en PDFDocument4 paginiD7150 en PDFSasko Dimitrov100% (1)

- Re92105 01 X b2 - 2017 08Document56 paginiRe92105 01 X b2 - 2017 08cln100% (1)

- Service Parts Manual: Series 40 M25 Axial Piston Tandem PumpDocument40 paginiService Parts Manual: Series 40 M25 Axial Piston Tandem Pumpjose manuel barroso pantojaÎncă nu există evaluări

- Cat Rex A10VO Series52Document44 paginiCat Rex A10VO Series52Angel Sanchez VilcaÎncă nu există evaluări

- Power Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Document64 paginiPower Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Irina VarzouÎncă nu există evaluări

- Hagglunds Viking MK 64 163000 Bo LN 0100 PDFDocument26 paginiHagglunds Viking MK 64 163000 Bo LN 0100 PDFKOSTAS100% (1)

- Field Testing of A Closed Loop PumpDocument4 paginiField Testing of A Closed Loop Pumpmagarmat1980Încă nu există evaluări

- Electro-Hydraulic Actuator Type PVEP / PVEP-F TechDocument16 paginiElectro-Hydraulic Actuator Type PVEP / PVEP-F TechHYDRAULICGURUÎncă nu există evaluări

- Series: K5V 200 DT H 100 R 9N 01Document1 paginăSeries: K5V 200 DT H 100 R 9N 01Stelian Crisan100% (1)

- Gear PumpsDocument7 paginiGear PumpsPrince ShanÎncă nu există evaluări

- гидро PDFDocument22 paginiгидро PDFАлександр НовиковÎncă nu există evaluări

- Atos Servo Valve TFS330Document10 paginiAtos Servo Valve TFS330back1949Încă nu există evaluări

- Vickers PVB MVB Piston PumpDocument29 paginiVickers PVB MVB Piston Pumppablo cofreÎncă nu există evaluări

- Aerius - VB 5.5-7.5 - Parts ManualDocument11 paginiAerius - VB 5.5-7.5 - Parts ManualLuis SilvaÎncă nu există evaluări

- M318S-Steering PumpDocument88 paginiM318S-Steering Pumpzeck28Încă nu există evaluări

- Gidronasosy Serii PMV10Document48 paginiGidronasosy Serii PMV10alsief1951Încă nu există evaluări

- Hitch Control Valves EHR5 and EHR23: EnglishDocument28 paginiHitch Control Valves EHR5 and EHR23: EnglishmetinÎncă nu există evaluări

- 135-En Telehandler Mobile06Document9 pagini135-En Telehandler Mobile06xxshÎncă nu există evaluări

- HNF Lagc Datasheet en PDFDocument16 paginiHNF Lagc Datasheet en PDFMira RedaÎncă nu există evaluări

- 1600 SERIES: Gear Pumps and MotorsDocument16 pagini1600 SERIES: Gear Pumps and Motorscoulibalyoumar100% (1)

- аксиальник 250Document70 paginiаксиальник 250anon_757712831Încă nu există evaluări

- A (A) 10vso18-140 Series 3x PDFDocument36 paginiA (A) 10vso18-140 Series 3x PDFR.Ranjan PradhanÎncă nu există evaluări

- A17FODocument16 paginiA17FOJose SalvadorÎncă nu există evaluări

- Re15209 03-95Document8 paginiRe15209 03-95Kaushik GhoshÎncă nu există evaluări

- E PUPI TM019 E HPR Conversion ManualDocument32 paginiE PUPI TM019 E HPR Conversion ManualxxshÎncă nu există evaluări

- 10 01 Breather Filters GBDocument8 pagini10 01 Breather Filters GBosuengÎncă nu există evaluări

- 520L0211 - PVG 32 - Ti - 12.2003 PDFDocument52 pagini520L0211 - PVG 32 - Ti - 12.2003 PDFjose manuel barroso pantojaÎncă nu există evaluări

- Aa2fm Model CodeDocument27 paginiAa2fm Model CodeCristianÎncă nu există evaluări

- Hagglunds CADocument84 paginiHagglunds CAVINAY VISHWAKARMAÎncă nu există evaluări

- NIMCO CV3000sDocument16 paginiNIMCO CV3000sBruno SamaeianÎncă nu există evaluări

- Re29564 2007-011Document12 paginiRe29564 2007-011engineer86Încă nu există evaluări

- Ont Axle 2 PDFDocument34 paginiOnt Axle 2 PDFFrezgi BirhanuÎncă nu există evaluări

- FAULT CODE 3559 - Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit - Voltage Below Normal or Shorted To Low SourceDocument7 paginiFAULT CODE 3559 - Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit - Voltage Below Normal or Shorted To Low SourceDouglas Lowe100% (2)

- Node Mcu NotesDocument3 paginiNode Mcu NotesIftekhar AlamÎncă nu există evaluări

- Diagram 2 Data Link ConnectorDocument1 paginăDiagram 2 Data Link ConnectorJoycee Lázaro ReyesÎncă nu există evaluări

- SP E Grundfosliterature - KatalogDocument72 paginiSP E Grundfosliterature - KatalogMarinko MarinkovicÎncă nu există evaluări

- TWH LED Sell Sheet PDFDocument2 paginiTWH LED Sell Sheet PDFPablo TlazaloÎncă nu există evaluări

- V Semester B.C.A. Examination, March/April 2021 (CBCS) (F+R) (Y2K14) Computer ScienceDocument2 paginiV Semester B.C.A. Examination, March/April 2021 (CBCS) (F+R) (Y2K14) Computer ScienceNâñè DévrûÎncă nu există evaluări

- Tutorial UnifiDocument5 paginiTutorial UnifiDanielTylerÎncă nu există evaluări

- HVAC Product Brochure Ilovepdf CompressedDocument79 paginiHVAC Product Brochure Ilovepdf CompressedSameera Sri VidurangaÎncă nu există evaluări

- 12 Terminologies Used For Power of The Ship's Marine Propulsion EngineDocument9 pagini12 Terminologies Used For Power of The Ship's Marine Propulsion EngineGerald HandersonÎncă nu există evaluări

- R1A4016R B12A1H1A A: Q Series PumpsDocument40 paginiR1A4016R B12A1H1A A: Q Series Pumpseaglego00Încă nu există evaluări

- NEPLAN B03 MotorStarting EnglDocument2 paginiNEPLAN B03 MotorStarting EnglsdiamanÎncă nu există evaluări

- Manual de LiofilizadorDocument18 paginiManual de Liofilizadormartha veronika blas herreraÎncă nu există evaluări

- ABB WaterMaster User GuideDocument48 paginiABB WaterMaster User GuideJan Richardo GultomÎncă nu există evaluări

- ZL50CN-maintemance ManuelDocument128 paginiZL50CN-maintemance ManuelHillal Tamsaouete67% (3)

- Industrial Control Transformers (Machine Tool) - 9070T500D1Document4 paginiIndustrial Control Transformers (Machine Tool) - 9070T500D1Luis Eduardo Vargas NeriÎncă nu există evaluări

- Hub Motor Hall Sensor ReplacementDocument5 paginiHub Motor Hall Sensor ReplacementFausto SelettiÎncă nu există evaluări

- Seminar PresentationDocument2 paginiSeminar Presentationthurabudeen98Încă nu există evaluări

- IVECO Product Training PT. Chakra JawaraDocument26 paginiIVECO Product Training PT. Chakra JawaraBroCactusÎncă nu există evaluări

- Digital Main Voltage IndicatorDocument2 paginiDigital Main Voltage IndicatorchakralabsÎncă nu există evaluări

- Power Break Breakers A Vac: Circuit FramesDocument27 paginiPower Break Breakers A Vac: Circuit FramesDÎncă nu există evaluări

- MTH 2603 AwaauuvDocument7 paginiMTH 2603 Awaauuvwilliam2001lebelÎncă nu există evaluări

- Off-Grid Wind Power Bill of QuantityDocument3 paginiOff-Grid Wind Power Bill of QuantityericmuyaÎncă nu există evaluări

- Why Compressors Fail?Document83 paginiWhy Compressors Fail?Neil LachicaÎncă nu există evaluări

- LG GW-305 Service ManualDocument153 paginiLG GW-305 Service ManualCah NgaloefÎncă nu există evaluări

- Cat G3516A: Natural Gas Generator SetsDocument5 paginiCat G3516A: Natural Gas Generator SetsRecovery MailÎncă nu există evaluări

- TTR100 1 DS Us V01Document6 paginiTTR100 1 DS Us V01andyÎncă nu există evaluări

- IT2007D Trouble ShootingDocument8 paginiIT2007D Trouble ShootingSaid TouhamiÎncă nu există evaluări

- To The Digital Storage Oscilloscope (Dso) : A Consulab PresentationDocument28 paginiTo The Digital Storage Oscilloscope (Dso) : A Consulab Presentationala100% (3)

- Rooftop Package PRC-MYADocument8 paginiRooftop Package PRC-MYAMMMSLOUHÎncă nu există evaluări