Documente Academic

Documente Profesional

Documente Cultură

Lathe Modelling 2

Încărcat de

cesargramckoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lathe Modelling 2

Încărcat de

cesargramckoDrepturi de autor:

Formate disponibile

will need tools and equipment. The first essential is the cutting bit.

For a generaluse tool, it is best to have a clearance angle of lo0,a back slope of 5" and side slope of 10". Experience will teach just how much to vary these for different kinds of work. Material for these bits can be purchased in the form of high-speed steel bars, already hardened and ready to grind, from supply houses handling jewelersy equipment. The rough bit for the lathe described should be l/a in. square and about 1in. long. Of course, boring tools will have to be longer to suit each case. Next in importance, from the standpoint of frequent use, is a small drill chuck for the tailstock. This will be used whenever holes are drilled in a piece held in the headstock chuck. Any type chuck of %-in. capacity will suffice. Only enough of the inside threaded shaft is required to cover the full range of chuck adjustments, and a small taper shank is turned up and pressed into a hole drilled in the chuck. The taper must fit the'hole in the spindle. The faceplate is another part used frequently. This is best made in two pieces. The hub can be made from a nut, or from

a similar piece, a hole being threaded to

A er's lathe, previously described, you

FTER building the small model mak-

fit the shaft. The plate is laid out for the holes, and these are drilled and tapped before being mounted on the hub. Although the illustration shows the use of screws in

mounting, pressing, riveting or soldering are equally good. True up the plate by facing and turning the diameter. Centers are made from drill rod hardened after turning. They are polished with fine emery cloth after hardening. Two sizes are shown, together with an adapter, to make the small ones fit the large taper. The larger fit the spindles, and the lesser ones are used in the small driving plates and centers. At this time a taper hole is drilled and reamed in the headstock spindle, as you now have the tailstock chuck to hold the drill and reamer for this operation. This hole is identical with that in the tailstock, so that all tapers will be interchangeable.

-; q:

i

driving plate and dog are used when diameters are turned between cen. It is well to have more than one size, suit your own conditions. The smaller size fits in the tapered hole, while the larger is screwed on like the faceplate. Arbors are used in innumerable ways, and for this reason it is advisable to have quite a range of sizes. They make good mountings for saws, small emery wheels and cutters, and may be used to hold small pieces

for turning when these have a concentric hole in them. Collars or spacers are included with each arbor to accommodate varying thicknesses to be held on them. Light milling or slotting can b the saws and cutters by clampi to the slide-rest top, with the moved; a few tapered holes top will aid in clamping. T makes a fine drillpress if provided with a plate having a taper shank. Make the plate of brass and solder the shank in. Face it true, and you will have a good surface to drill against. You are now equipped to do all kinds of ordinary metal-turning jobs of small size, and in special cases extra ac- cessories can be made to suit.

:I

-- This Simple Jig for Cutdng Tenons Fits Any Circular Saw

Here's a jig for safely cutting tenons on your circular saw. It consists of three blocks; one is 'the base and the other two are fastened together at right angles as in-. dicated. The underside of the base is slotted for an oak runner, which slides in the miter-gauge groove of the saw table. The upper surface of the base and the lower surface of the horizontal block that fits on the base, are each grooved at right angles to the f i s t groove, to fit a runner which permits lateral adjustment. The horizontal block is fastened to the base with bolts which slide in slots to permit adjusting the jig for cuttiig tenons of different thicknesses. A C-clamp will hold the work.

S-ar putea să vă placă și

- Building: LatheDocument60 paginiBuilding: LathePierre799es86% (7)

- Unimat Pages 26-30Document5 paginiUnimat Pages 26-30remendabÎncă nu există evaluări

- Building A Six-Inch Turret LatheDocument5 paginiBuilding A Six-Inch Turret LatheJan SteinmanÎncă nu există evaluări

- Ins Ha Per 1Document5 paginiIns Ha Per 1David SaylorÎncă nu există evaluări

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsDe la EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsÎncă nu există evaluări

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsDe la EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsÎncă nu există evaluări

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDe la EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingEvaluare: 5 din 5 stele5/5 (2)

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopDe la EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedÎncă nu există evaluări

- 16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopDe la Everand16 Metalworking Workshop Projects for Home Machinists: Practical & Useful Ideas for the Small ShopEvaluare: 5 din 5 stele5/5 (1)

- Decorative Wrought Ironwork Projects for BeginnersDe la EverandDecorative Wrought Ironwork Projects for BeginnersÎncă nu există evaluări

- Lathe Tool Post Grinder PlansDocument5 paginiLathe Tool Post Grinder Plansozland9Încă nu există evaluări

- How To Run A Horizontal Metalworking ShaperDocument43 paginiHow To Run A Horizontal Metalworking ShaperALLEN FRANCIS100% (2)

- A Fine Vertical Steam Engine - Hobbies - Apr 1931Document8 paginiA Fine Vertical Steam Engine - Hobbies - Apr 1931dsdffgfgfssfdgsfgdÎncă nu există evaluări

- Belt SanderDocument2 paginiBelt SanderFrenchwolf420Încă nu există evaluări

- Bench MillDocument2 paginiBench MillEdward Elric2Încă nu există evaluări

- Precision PressDocument4 paginiPrecision PressFrenchwolf420Încă nu există evaluări

- Lathe Modelling1Document4 paginiLathe Modelling1Frenchwolf420Încă nu există evaluări

- Lathe-Milling AttachmentDocument4 paginiLathe-Milling AttachmentFrenchwolf420Încă nu există evaluări

- Shop Made SlotterDocument4 paginiShop Made Slotternevadablue100% (4)

- Home Workshop Milling Machine GuideDocument31 paginiHome Workshop Milling Machine Guidetaiwest100% (1)

- Mini-Lathe Cross Slide Extension and Thrust Bearing Mod PDFDocument7 paginiMini-Lathe Cross Slide Extension and Thrust Bearing Mod PDFCody McCormackÎncă nu există evaluări

- 6 in ShaperDocument4 pagini6 in ShaperRed Warrant100% (1)

- Uni MalikaDocument57 paginiUni MalikaInstruktur Mesin100% (1)

- ENGINEERING - MILL - Construction Plans For Horizontal Bench Mill. - (Ebook Diy Building How To Machine Tools 178848 PDFDocument2 paginiENGINEERING - MILL - Construction Plans For Horizontal Bench Mill. - (Ebook Diy Building How To Machine Tools 178848 PDFGlaucius Borba50% (2)

- Motor Driven HacksawDocument3 paginiMotor Driven HacksawJim100% (3)

- Shaper Gear CuttingDocument4 paginiShaper Gear Cuttingnevadablue100% (4)

- Miniature Machining TechniquesDocument40 paginiMiniature Machining Techniqueskriskee1376% (17)

- 4in Bench SlotterDocument4 pagini4in Bench SlotterTeresa Melanathy100% (1)

- Model EngineDocument432 paginiModel Enginejcrisso100% (4)

- (Diy) - Metalworking - Model Engineer Aug53' - Surface Grinding & Milling MachineDocument6 pagini(Diy) - Metalworking - Model Engineer Aug53' - Surface Grinding & Milling MachineFernanda Duarte100% (4)

- SphericalturninglathetoolDocument14 paginiSphericalturninglathetoolFrenchwolf420Încă nu există evaluări

- Popular Mechanics - Hobby Lathe#1Document19 paginiPopular Mechanics - Hobby Lathe#1sonofsilas100% (1)

- Lathe alignment test resultsDocument3 paginiLathe alignment test resultsRichardScribed100% (1)

- Lathe Chuck Backplate FittingDocument2 paginiLathe Chuck Backplate FittingAnonymous iYKTkmhpZ100% (3)

- Myford Dividing Head Attachment ManualDocument7 paginiMyford Dividing Head Attachment Manualsonytecho100% (1)

- 43 Horizontal Steam Engine PlanDocument4 pagini43 Horizontal Steam Engine Plannevadablue100% (1)

- Atlas 7B Know Your ShaperDocument6 paginiAtlas 7B Know Your ShaperColin FinkbeinerÎncă nu există evaluări

- Quorn: Tool and Cutter GrinderDocument5 paginiQuorn: Tool and Cutter GrinderDan HendersonÎncă nu există evaluări

- 3 in Shaper PDFDocument5 pagini3 in Shaper PDFRob NairÎncă nu există evaluări

- 1936 - How To Cut Screw Threads in The Lathe - Bulletin 36ADocument24 pagini1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AJason Bowman100% (1)

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningDe la EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningEvaluare: 2.5 din 5 stele2.5/5 (2)

- Spot Welder#2Document3 paginiSpot Welder#2isformeÎncă nu există evaluări

- Spot Welder PlansDocument4 paginiSpot Welder Planscesargramcko100% (2)

- Precision PressDocument4 paginiPrecision PressFrenchwolf420Încă nu există evaluări

- 14 - Making Small Workshop Tools PDFDocument49 pagini14 - Making Small Workshop Tools PDFhmanzillaÎncă nu există evaluări

- Power HackSawDocument6 paginiPower HackSawMike Nichlos100% (2)

- Lathe Modelling1Document4 paginiLathe Modelling1Frenchwolf420Încă nu există evaluări

- SandblasterDocument3 paginiSandblasterweldeyes100% (3)

- Popular Mechanics Plans-Homemade Sandblasting Cabinet BlueprintsDocument6 paginiPopular Mechanics Plans-Homemade Sandblasting Cabinet Blueprintsjlw2135554961% (28)

- Retenedor Central InstruccionesDocument2 paginiRetenedor Central InstruccionesFrancisco Rodriguez GarrigósÎncă nu există evaluări

- Basic Parts of A ComputerDocument36 paginiBasic Parts of A ComputerOtencianoÎncă nu există evaluări

- HT Metal Frame AnchorDocument4 paginiHT Metal Frame AnchorChirag SharmaÎncă nu există evaluări

- Home Manufacture & Quality Control Products Technical Supporting Contact UsDocument2 paginiHome Manufacture & Quality Control Products Technical Supporting Contact Usluisxxx1Încă nu există evaluări

- Raceway & Box CalculationDocument32 paginiRaceway & Box Calculationnadeem UddinÎncă nu există evaluări

- Trade Marks Search Result for "greenDocument65 paginiTrade Marks Search Result for "greenrajender RightsandMarksÎncă nu există evaluări

- Service Manual: Induction Slide-In RangeDocument97 paginiService Manual: Induction Slide-In Rangeccordobestexano100% (1)

- Equivalencias Sufijos RodamientosDocument1 paginăEquivalencias Sufijos RodamientosHector Maldonado100% (1)

- AEROI F2B-Parts 0930-038201Document22 paginiAEROI F2B-Parts 0930-038201Jonah RagleÎncă nu există evaluări

- 7MWT9601WW0 WhirlpoolDocument12 pagini7MWT9601WW0 WhirlpoolJuan CarlosÎncă nu există evaluări

- Starter (Valeo) (NA Only) - S450Document3 paginiStarter (Valeo) (NA Only) - S450Marcelo MarvalhoÎncă nu există evaluări

- Machining MechAnalysis CHPT 1Document98 paginiMachining MechAnalysis CHPT 1Brahim MouchaneÎncă nu există evaluări

- Answer Keys Scientist Engineer Recruitment Test 2017Document4 paginiAnswer Keys Scientist Engineer Recruitment Test 2017Aravind SivakumarÎncă nu există evaluări

- Zeuslap 15.6-inch Touch Screen Portable Monitor for PS4, Switch, Xbox & LaptopDocument26 paginiZeuslap 15.6-inch Touch Screen Portable Monitor for PS4, Switch, Xbox & LaptopsigniferÎncă nu există evaluări

- Bom Material MHG 5-8 PT - DssDocument1 paginăBom Material MHG 5-8 PT - DssAdeImanudinÎncă nu există evaluări

- D65EX-12 SN 60942-UP (S6D125E-2 (Emission) Eng. Installed)Document843 paginiD65EX-12 SN 60942-UP (S6D125E-2 (Emission) Eng. Installed)Ednaldo nabucoÎncă nu există evaluări

- Chelsea PTO 243 Series Parts ManualDocument17 paginiChelsea PTO 243 Series Parts ManualAnthony MoraÎncă nu există evaluări

- Drill PDFDocument27 paginiDrill PDFAlex ChancúsigÎncă nu există evaluări

- Aiwa Av D77Document80 paginiAiwa Av D77Ron DinÎncă nu există evaluări

- ASB 412-00-104 - EFIS VOR Indication Anomaly Correction Rev. A - 12-Aug-2002Document15 paginiASB 412-00-104 - EFIS VOR Indication Anomaly Correction Rev. A - 12-Aug-2002yu gangÎncă nu există evaluări

- C-L-X VFD Type MV-105 or MC-HL: Product DataDocument2 paginiC-L-X VFD Type MV-105 or MC-HL: Product DatacubarturÎncă nu există evaluări

- H.Flyer - SN Housings - Fno3036 - SN - eDocument4 paginiH.Flyer - SN Housings - Fno3036 - SN - epcesar777Încă nu există evaluări

- Hard To Start Marauder VZ800Document5 paginiHard To Start Marauder VZ800Bruno Pereira Gomes0% (1)

- Flowtite GRP Pipe and Fittings: InstallationDocument8 paginiFlowtite GRP Pipe and Fittings: InstallationMohammed khaleelÎncă nu există evaluări

- Adjust Timing Gear d12c PDFDocument11 paginiAdjust Timing Gear d12c PDFrayendraÎncă nu există evaluări

- Tajima TMFD-G920 PDFDocument73 paginiTajima TMFD-G920 PDFСанек АбверÎncă nu există evaluări

- Package AC Systems ExplainedDocument15 paginiPackage AC Systems Explainedosama alabsi100% (2)

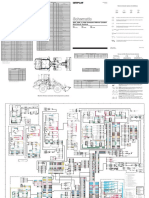

- 902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component LocationsDocument2 pagini902, 906, & 908 Compact Wheel Loader Electrical System: Machine Harness Connector and Component Locationsait mimouneÎncă nu există evaluări

- Sena centro para la industria petroquímicaDocument2 paginiSena centro para la industria petroquímicaLina perez limaÎncă nu există evaluări

- Price List of Goods in Belgium 001Document25 paginiPrice List of Goods in Belgium 001Gabriel N Gina GinÎncă nu există evaluări