Documente Academic

Documente Profesional

Documente Cultură

Well Completion

Încărcat de

Yesufu OluseyiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Well Completion

Încărcat de

Yesufu OluseyiDrepturi de autor:

Formate disponibile

Well Completion

Once a natural gas or oil well is drilled, and it has been verified that commercially viable quantities of natural gas are present for extraction, the well must be 'completed' to allow for the flow of petroleum or natural gas out of the formation and up to the surface. This process includes strengthening the well hole with casing, evaluating the pressure and temperature of the formation, and then installing the proper equipment to ensure an efficient flow of natural gas out of the well. There are two main types of conventional natural gas wells: natural gas wells and natural gas condensate wells. In addition, there are oil wells that contain associated natural gas. In an oil well with associated gas, the natural gas is often used to add pressure to the well and enhance the extraction of the well. Sometimes associated natural gas exists in large enough quantities to allow its extraction along with the oil. Natural gas specific wells are wells drilled exclusively for natural gas, and contain little or no oil. Shale-gas drilling is an example of wells being drilled for their natural gas resources. Condensate wells are wells that contain natural gas, as well as a liquid condensate. This condensate is a liquid hydrocarbon mixture that is often separated from the natural gas either at the wellhead, or during the processing of the natural gas. It is important to remember that natural gas, being lighter than air, will naturally rise to the surface of a well. Because of this, in many natural gas and condensate wells, lifting equipment and well treatment are not necessary. Completing a well consists of a number of steps: installing the well casing, completing the well, installing the wellhead, and installing lifting equipment or treating the formation should that be required. Click on the links below to learn about these aspects of the well completion process: Well Casing Completion The Wellhead Lifting and Well Treatment

Source: Anadarko Petroleum Corporation

Well Casing Installing well casing is an important part of the drilling and completion process. Well casing consists of a series of metal tubes installed in the freshly drilled hole. Casing strengthens the sides of the well hole, ensures that no oil or natural gas seeps out of the well hole as it is brought to the surface, and keeps other fluids or gases from seeping into the formation through the well. A good deal of planning is necessary to ensure that the proper casing for each well is installed. The type of casing used depends on the subsurface characteristics of the well, including the diameter of the well and the pressures and temperatures experienced throughout the well. The diameter of the well hole depends on the size of the drill bit used. In most wells, the diameter of the well hole decreases the deeper it is drilled, leading to a type of conical shape that must be taken into account when installing casing. To review the drilling of a natural gas well and the history of drilling practices, including casing, click here. There are five different types of well casing. They include: Conductor Casing Surface Casing

A Small Auger Drill

Source: USGS

S-ar putea să vă placă și

- Gas Storage in Aquifers and Salt CavernsDocument58 paginiGas Storage in Aquifers and Salt Cavernssaladinayubi1234100% (2)

- Gas Lift ReferenceDocument10 paginiGas Lift ReferenceabsherlockÎncă nu există evaluări

- ALKALOID With Some IsolationDocument24 paginiALKALOID With Some Isolationapi-3742263100% (23)

- Chapter 6-Well CompletionDocument49 paginiChapter 6-Well Completionjorge_h_rivero100% (2)

- Identification of Cations and Anions Present in ToothpasteDocument24 paginiIdentification of Cations and Anions Present in ToothpastePiyush SinghÎncă nu există evaluări

- Dual StringDocument14 paginiDual Stringomair babar100% (1)

- Process TrainingDocument49 paginiProcess TrainingMuddassar Mahmood0% (2)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!De la EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Evaluare: 5 din 5 stele5/5 (2)

- How an Oil & Gas Exploration & Production Company OperatesDe la EverandHow an Oil & Gas Exploration & Production Company OperatesÎncă nu există evaluări

- WellheadDocument39 paginiWellheadTahir Haroon50% (2)

- Fundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable EnginDocument29 paginiFundamentals of Petroleum Engineering WELL COMPLETION AND STIMULATION Mohd Fauzi Hamid Wan Rosli Wan Sulaiman Department of Petroleum Engineering Faculty of Petroleum & Renewable Enginqazim786Încă nu există evaluări

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDe la EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingEvaluare: 5 din 5 stele5/5 (3)

- Underground Gas Storage Facilities: Design and ImplementationDe la EverandUnderground Gas Storage Facilities: Design and ImplementationÎncă nu există evaluări

- Glossary of Oil and Gas Terms PDFDocument8 paginiGlossary of Oil and Gas Terms PDFgarry_dirakÎncă nu există evaluări

- Perforation GeometryDocument10 paginiPerforation GeometryJawaid HussainÎncă nu există evaluări

- BloodDocument5 paginiBloodKyla CarbonelÎncă nu există evaluări

- Steps of Oil Well DrillingDocument13 paginiSteps of Oil Well DrillingAbdelrahman Genedy0% (1)

- Introduction to underbalanced drilling techniquesDocument21 paginiIntroduction to underbalanced drilling techniquesMohamed Abd El-Moniem67% (6)

- Metals and AlloysDocument49 paginiMetals and Alloysmasterdol1983Încă nu există evaluări

- Oil & Gas Production, Separation & Gas Dehydration ProcessesDocument65 paginiOil & Gas Production, Separation & Gas Dehydration Processeskarthikv83Încă nu există evaluări

- Tank Battery Systems and Production Curve GuideDocument14 paginiTank Battery Systems and Production Curve Guidegermangsilva100% (2)

- Chem Study Guide Answer KeyDocument4 paginiChem Study Guide Answer Keyapi-240689882100% (1)

- Oil and Gas Artificial Fluid Lifting TechniquesDe la EverandOil and Gas Artificial Fluid Lifting TechniquesEvaluare: 5 din 5 stele5/5 (1)

- PETE 2050 - Introduction To Petroleum Engineering: Oil and Gas Production OperationsDocument61 paginiPETE 2050 - Introduction To Petroleum Engineering: Oil and Gas Production OperationsJaiyeola Solomon AdeniyiÎncă nu există evaluări

- Factors Influencing Well Completion DesignDocument6 paginiFactors Influencing Well Completion DesignMahesh sinhaÎncă nu există evaluări

- Life Stages of Oil & Gas WellsDocument18 paginiLife Stages of Oil & Gas WellsmsvaletÎncă nu există evaluări

- Condensate Wells Are Wells That Contain Natural Gas, As Well As A Liquid Condensate. ThisDocument7 paginiCondensate Wells Are Wells That Contain Natural Gas, As Well As A Liquid Condensate. ThisRuth OjileÎncă nu există evaluări

- Section 3, Drilling and Well CompletionDocument17 paginiSection 3, Drilling and Well CompletionhammamiÎncă nu există evaluări

- Types of WellsDocument9 paginiTypes of WellsMus'ab UsmanÎncă nu există evaluări

- Oil Well DrillingDocument21 paginiOil Well DrillingMoonking 03Încă nu există evaluări

- Types of WellsDocument2 paginiTypes of WellsSudeepto GogoiÎncă nu există evaluări

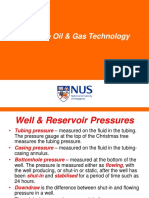

- Offshore Oil & Gas TechnologyDocument21 paginiOffshore Oil & Gas TechnologyMohammad Taha IrfanÎncă nu există evaluări

- OIL WELLDocument3 paginiOIL WELLAugustine AmutaÎncă nu există evaluări

- AL Selection - Draft of Document - 2d12 - Continuous Gas-LiftDocument23 paginiAL Selection - Draft of Document - 2d12 - Continuous Gas-LiftKonul AlizadehÎncă nu există evaluări

- Oil Well Technology: Presented By, Dhanyashree.B.CDocument25 paginiOil Well Technology: Presented By, Dhanyashree.B.CdhanyaÎncă nu există evaluări

- Well Completion: Basic OperationDocument53 paginiWell Completion: Basic Operationhasan sabahÎncă nu există evaluări

- Production PDFDocument20 paginiProduction PDFFada BobÎncă nu există evaluări

- Well DrillingDocument2 paginiWell DrillingHazraien Abdullah HashimÎncă nu există evaluări

- Introduction to Petroleum Well Completion and StimulationDocument25 paginiIntroduction to Petroleum Well Completion and StimulationDeniz AkoumÎncă nu există evaluări

- En Wikipedia OrgDocument6 paginiEn Wikipedia OrgMashudi FikriÎncă nu există evaluări

- Gas Metering Presentation by SNGPL Covers Exploration, Extraction & DistributionDocument10 paginiGas Metering Presentation by SNGPL Covers Exploration, Extraction & DistributionbrianÎncă nu există evaluări

- Production Assignment 1Document4 paginiProduction Assignment 1Khalid Waheed ShaikhÎncă nu există evaluări

- Petroleum Transportation and StorageDocument13 paginiPetroleum Transportation and StorageFabianÎncă nu există evaluări

- Natural Gas Production: FormationDocument11 paginiNatural Gas Production: FormationmohamedÎncă nu există evaluări

- Tight Gas ppt2Document14 paginiTight Gas ppt2Malugu JohnÎncă nu există evaluări

- Practico Gas LiftDocument11 paginiPractico Gas LiftKendo MountainousÎncă nu există evaluări

- Pee 403 Pep IiDocument10 paginiPee 403 Pep IiFabianÎncă nu există evaluări

- ConvectionalDocument11 paginiConvectionalMalugu JohnÎncă nu există evaluări

- Oil and Gas Wellsite Production Operations ExplainedDocument37 paginiOil and Gas Wellsite Production Operations ExplainedMahmoud EidÎncă nu există evaluări

- GEOMECHANICS Notams 02Document5 paginiGEOMECHANICS Notams 02kennedy antwiÎncă nu există evaluări

- Crude Oil Production BUK - LECTUREDocument6 paginiCrude Oil Production BUK - LECTUREEmmanuelÎncă nu există evaluări

- Introduction to Petroleum Engineering Rock & Fluid PropertiesDocument32 paginiIntroduction to Petroleum Engineering Rock & Fluid PropertiesDeniz AkoumÎncă nu există evaluări

- Oil Related Terms and MeasurementsDocument5 paginiOil Related Terms and Measurementsابوالحروف العربي ابوالحروفÎncă nu există evaluări

- Tight Gas ppt3Document13 paginiTight Gas ppt3Malugu JohnÎncă nu există evaluări

- Primary RecoveryDocument20 paginiPrimary RecoveryMohammed OmranÎncă nu există evaluări

- Well Intervention: Christmas TreeDocument4 paginiWell Intervention: Christmas TreeAnonymous p6pNOLu670Încă nu există evaluări

- How Does Formation Testing WorkDocument4 paginiHow Does Formation Testing WorkCris TinaÎncă nu există evaluări

- Underbalanced Drilling: Removing Uncertainty From Tight Gas ReservoirsDocument11 paginiUnderbalanced Drilling: Removing Uncertainty From Tight Gas ReservoirsAnene Ifeanyi CyprianÎncă nu există evaluări

- Well Planning: Petro-BoosterDocument37 paginiWell Planning: Petro-BoosterSHOBHIT KUMARÎncă nu există evaluări

- About Drill CasingDocument2 paginiAbout Drill CasingMmadu Vivian ChiamakaÎncă nu există evaluări

- The Language of DrillingDocument3 paginiThe Language of DrillingAntonio Jose da CostaÎncă nu există evaluări

- DrillingDocument26 paginiDrillingHendou MohamedÎncă nu există evaluări

- Oil Absorption and Surface Area RelationshipDocument2 paginiOil Absorption and Surface Area RelationshipMarjorie Dulay DumolÎncă nu există evaluări

- Sulfur Magazine Ideas For Better Clean Up Jan 09Document0 paginiSulfur Magazine Ideas For Better Clean Up Jan 09Bharat VaajÎncă nu există evaluări

- Low Concentrations of Humic Substances Significantly Enhanced Plant GrowthDocument4 paginiLow Concentrations of Humic Substances Significantly Enhanced Plant GrowthShailendra RajanÎncă nu există evaluări

- 677 Aluminium Products Brochure E4Document2 pagini677 Aluminium Products Brochure E4MeteusÎncă nu există evaluări

- Experimental Study On Recycled AggregateDocument4 paginiExperimental Study On Recycled AggregateComet AstroÎncă nu există evaluări

- Polysilazane - CuringDocument8 paginiPolysilazane - CuringthuronÎncă nu există evaluări

- Catalog FEEL by THM AgencyDocument68 paginiCatalog FEEL by THM Agencykartika lestariÎncă nu există evaluări

- Naming Inorganic Compounds WorksheetDocument2 paginiNaming Inorganic Compounds WorksheetDaniah AllemaÎncă nu există evaluări

- Dehydrogenation To Produce Propylene From PropaneDocument3 paginiDehydrogenation To Produce Propylene From PropaneSamandar YuldoshevÎncă nu există evaluări

- Aluminium 6082Document2 paginiAluminium 6082senthilromÎncă nu există evaluări

- Jorge Menacho - ChileDocument45 paginiJorge Menacho - ChileBelen TapiaÎncă nu există evaluări

- UnfinishedDocument8 paginiUnfinishedDaniel TorralbaÎncă nu există evaluări

- Rashid Ali ReportDocument41 paginiRashid Ali Reportm bilalÎncă nu există evaluări

- Review On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingDocument3 paginiReview On Recycled Aluminium Dross and It's Utility in Hot Weather ConcretingIJARTETÎncă nu există evaluări

- Standard Specification For: ScopeDocument2 paginiStandard Specification For: Scopedong ganÎncă nu există evaluări

- THE ION PRODUCT CONSTANT OF WATER - StudentsDocument26 paginiTHE ION PRODUCT CONSTANT OF WATER - StudentsJanne Lorraine Garcia-EleazarÎncă nu există evaluări

- Dr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane CoatingDocument4 paginiDr. Fixit Flexicoat PU: Single Component, Cold Applied, Elastomeric Waterproofing Membrane Coatingkkundan52Încă nu există evaluări

- The Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear FluidDocument4 paginiThe Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear Fluidronahaniifah11Încă nu există evaluări

- Handbook Adhesive TechnologyDocument29 paginiHandbook Adhesive TechnologyVansala GanesanÎncă nu există evaluări

- Science: Quarter 1 - Matter Module 7: Concentration of SolutionsDocument37 paginiScience: Quarter 1 - Matter Module 7: Concentration of SolutionsCore GirlÎncă nu există evaluări

- Natural Waxes: Candelilla Wax CG-4 Candelilla Wax CG-7Document3 paginiNatural Waxes: Candelilla Wax CG-4 Candelilla Wax CG-7email kantorÎncă nu există evaluări

- Anaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)Document7 paginiAnaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)syafiqzainordinÎncă nu există evaluări

- Objectives: - Describe - Identify - Describe - CalculateDocument29 paginiObjectives: - Describe - Identify - Describe - CalculateJanaÎncă nu există evaluări

- Material Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding RodsDocument7 paginiMaterial Safety Data Sheet: MSDS No. GW001 Carbon Steel Gas Welding Rodssajeev27Încă nu există evaluări

- Complete List of Licensable ChemicalsDocument14 paginiComplete List of Licensable ChemicalsLukmannÎncă nu există evaluări