Documente Academic

Documente Profesional

Documente Cultură

Apple ImageWriter LQ Service Source

Încărcat de

BeTeck Soc CoopDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Apple ImageWriter LQ Service Source

Încărcat de

BeTeck Soc CoopDrepturi de autor:

Formate disponibile

K Service Source

ImageWriter LQ

K Service Source

Basics

ImageWriter LQ

Basics

General Information - 1

General Information

Paperless Printer Microviewer

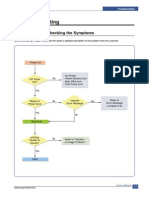

Troubleshooting

This manual contains only the Specifications, Symptom Charts and the Illustrated Parts List chapter for the ImageWriter LQ. The rest of the procedures are in the form of a Paperless Printer file located in the Printables folder.

Take Apart

Adjustments

K Service Source

Troubleshooting

ImageWriter LQ

Troubleshooting

General/ - 1

General

The Symptom Charts included in this chapter will help you diagnose specific symptoms related to your product. Because cures are listed on the charts in the order of most likely solution, try the first cure first. Verify whether or not the product continues to exhibit the symptom. If the symptom persists, try the next cure. (Note: If you have replaced a module, reinstall the original module before you proceed to the next cure.) If you are not sure what the problem is, or if the Symptom Charts do not resolve the problem, refer to the Flowchart for the product family. For additional assistance, contact Apple Technical Support.

Troubleshooting

Symptom Charts /Power - 2

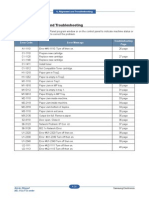

Symptom Charts

Power

Power light off and no carrier motion 1 2 3 4 5 6 7 8 Check external power source and connection. Verify the setting of voltage selector switch (International units only). Test primary fuse, and replace if defective. Test three secondary fuses, and replace any defective fuses. Test power switch, and replace if defective. Replace main board. Replace transformer. Replace noise filter PCA.

Troubleshooting

Symptom Charts /Communication - 3

Communication

No printing or garbled printing 1 2 3 4 No communication with option card installed Make sure printer is selected in Chooser. Verify correct DIP switch settings. Verify that interface cable between printer and computer is tightly connected. Perform printer selftest. If the test passes, run diagnostics on the main board; if the test fails, replace the main board.

Verify that DIP switch 2 position 4 is set to ON.

Troubleshooting

Symptom Charts /Paper Feed Problems - 4

Paper Feed Problems

No paper feed 1 2 3 4 1 2 3 Make sure paper feed gear train is clear of obstructions. Test paper-handling change switch, and replace if defective. Test paper feed motor, and replace if defective. Replace main board. Make sure paper thickness lever is set correctly. Make sure paper path is clear of obstructions. Check that paper is installed correctly and, if using tractor feed paper, that sprocket holes are engaged on tractor sprockets. Test auto-load solenoid, and replace if defective. Replace main board.

Paper feed difficulties: binding, tearing, etc.

Paper bail doesnt automatically open and close

1 2

Troubleshooting

Symptom Charts /Carrier - 5

Carrier

Carrier moves at power on, but doesnt return to home position Power light on, no carrier motion Carrier strikes right-side frame when printing on 4part carbonless forms, printing on perforated edge of tractor-feed paper 1 2 3 1 2 3 1 2 3 4 Test home position switch, and replace if defective. Perform Home Position Switch Adjustment in Adjustments. Replace main board. Make sure carrier area is clear of obstructions. Test carrier motor, and replace if defective. Replace main board. Make sure 4-part carbonless forms are within specifications (maximum thickness 0.55 millimeters). Check that paper is inserted/aligned properly. Make sure paper thickness lever is set correctly. Perform Card Guide Adjustment in Adjustments.

Troubleshooting Carrier strikes leftside frame on power up home position 1 2 3 4

Symptom Charts /Carrier - 6 Test home position switch, and replace if defective. Perform Home Position Switch Adjustment in Adjustments. Make sure deflector pan is seated against platen bar. Replace main board.

Troubleshooting

Symptom Charts /Printing - 7

Printing

Dots missing 1 2 3 4 1 2 3 1 2 Replace Replace Replace Replace print head. main board. print head to relay PCB cables. relay PCB to main board logic cables.

Printing continues on paper-out condition Carrier moves but no printing Nothing printed, carrier doesnt move, and power light is on

Test paper-out sensor, and replace if defective. Replace main board. Replace paper detect sensor. Replace main board. Replace print head.

Perform printer self test. If the test passes, see Communications in this chapter; if the test fails, replace main board.

Troubleshooting Printing garbage Printing too light Replace main board. 1 2 3 4 1 2 3

Symptom Charts /Printing - 8

Make sure paper thickness lever is set correctly. Replace ribbon. Perform Print Head Gap Adjustment in Adjustments. Perform Platen Gap and Parallelism Adjustment in Adjustments. Make sure paper thickness lever is set correctly. Perform Print Head Gap Adjustment in Adjustments. Perform Platen Gap and Parallelism Adjustment in Adjustments.

Printing too dark

Printing less than best quality

Make sure system file has correct fonts. For non-TrueType fonts the system file must have the desired output font size and its 3times equivalent.

Troubleshooting Printing continues with front cover open Uneven print pattern on self-test (four lines light, three dark) Printing has squashed lines; misregistration problems when using pin feed paper 1 2

Symptom Charts /Printing - 9 Test cover-open sensor, and replace if defective. Replace main board.

Printer is sensing color ribbon carriage. Make sure black ribbon carriage is pressed down completely on left side to activate ribbon microswitch. 1 Instruct customer to use pull tractor and bottom feed slot with paper stacked at least 12 inches below the printer. (The straightness of this paper path combined with the pull tractor helps keep paper securely around platen.) Make sure power cord or printer cable does not obstruct paper path, and instruct user to avoid printing in top and bottom one inch of paper.

Troubleshooting Problems using labels or multipart forms

Symptom Charts /Printing - 10 Instruct customer to use pull tractor and bottom feed slot, and to avoid backing-out paper (especially labels). Cut the paper at a perforation, and advance the paper forward to remove pin feed paper from printer. Make sure DIP switch 2-8 ON is set to load paper beneath the bail (about 1 inch beyond the print line).

Printing on platen or over perforation when using push tractor Words touching or slightly overlapping Page setup problems between different printers

Update LQ driver to version 2.0 or higher. Use Page Setup from File menu each time different printer is used (different printers have varying imageable areas).

Troubleshooting

Symptom Charts/Cut Sheet Feeding - 11

Cut Sheet Feeding

No access to second or third bin Printer doesnt recognize bin 3 Paper from expansion bin 3 is skewed (bent) Documents going into wrong bins Make sure DIP switches 2-5 and 2-6 are set for number of bins installed. (These switches have to be set only once.) Check for gear configuration pin. If gear configuration pin is in, bin 2 becomes the expansion bin; if plug is removed, expansion bin becomes bin 3. Add 3.1 mm rubber bumpers to bottoms of expansion bins 2 and 3.

Check whether application supports multiple-bin feeding. If not, each page of a file is treated as separate job and all pages come out of bin selected under First Sheet From in the Print dialog box (under Options button).

Troubleshooting Envelope feeding problems 1

Symptom Charts /Cut Sheet Feeding - 12 With envelopes (which are thicker) the user must: (a) adjust paper thickness lever; (b) reset paper thickness lever when done printing envelopes, (c) not run cut sheets and envelopes in same print job.

Troubleshooting

Symptom Charts /Color Printing - 13

Color Printing

Color bleeding 1 2 Wrong color printed 1 2 3 4 Only one color is printed 1 2 If bleeding is consistent across page, perform Color Ribbon Home Position Adjustment in Adjustments. If bleeding increases or decreases across page, perform Color Ribbon Parallelism Adjustment in Adjustments. Test color ribbon detect switch, and replace if defective. Test color ribbon home position switch; if defective, replace color ribbon motor assembly. Test color ribbon motor, and replace if defective. Replace main board. Test color ribbon motor, and replace if defective. Replace main board.

Troubleshooting

Symptom Charts /Miscellaneous - 14

Miscellaneous

Control panel switches dont work Intermittent network problemsprint head resets when idle and/ or printer stops printing Error light blinks Error light on, Select light off 1 2 Test control panel switches; if defective, replace control panel PCA. Replace main board.

Replace ROM 02 on logic board with ROM 03.

Close front cover. Add paper, or check for improperly inserted paper.

S-ar putea să vă placă și

- Black Gospel Music in SDA ChurchDocument4 paginiBlack Gospel Music in SDA ChurchHeather Capps100% (3)

- Canon Pixma Mp258 Error Code and Possible SolutionDocument9 paginiCanon Pixma Mp258 Error Code and Possible SolutionMaizatul Nabillah100% (1)

- General Printer TroubleshootingDocument3 paginiGeneral Printer TroubleshootingMarah Lovelle Dela CruzÎncă nu există evaluări

- Blackout - ScriptDocument9 paginiBlackout - Scriptapi-295129288Încă nu există evaluări

- FlashArray XR2 & XR3 Cabling GuideDocument21 paginiFlashArray XR2 & XR3 Cabling GuideluckyÎncă nu există evaluări

- Breath of Fire II (SNES) - Prima Authorized Game SecretsDocument227 paginiBreath of Fire II (SNES) - Prima Authorized Game Secretsspadira100% (2)

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingDe la EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingÎncă nu există evaluări

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationDe la EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationEvaluare: 5 din 5 stele5/5 (4)

- How To Play Guqin 1Document21 paginiHow To Play Guqin 1glassyglassÎncă nu există evaluări

- Vestiaire Collective The Challenges of Second-Hand LuxuryDocument13 paginiVestiaire Collective The Challenges of Second-Hand LuxuryNikith NatarajÎncă nu există evaluări

- Past Simple and Past ContinuousDocument4 paginiPast Simple and Past ContinuousRosa Sousa100% (1)

- Imagewriter LQ: Service SourceDocument18 paginiImagewriter LQ: Service SourceMassimo Del GaudioÎncă nu există evaluări

- Apple Portable StyleWriter Service SourceDocument49 paginiApple Portable StyleWriter Service SourceAdrian Iulius BujenițăÎncă nu există evaluări

- Color StyleWriter 2200Document93 paginiColor StyleWriter 2200czakanÎncă nu există evaluări

- Laser Printer Print DefectsDocument30 paginiLaser Printer Print DefectsGurpal Singh Kalsi50% (2)

- Troubleshooting: 7.1 Procedure of Checking The SymptomsDocument15 paginiTroubleshooting: 7.1 Procedure of Checking The SymptomsleolamiaÎncă nu există evaluări

- LJ 3050 3052 3055 - TroubleshootingDocument85 paginiLJ 3050 3052 3055 - Troubleshootingfd106Încă nu există evaluări

- Ta Print QualityDocument4 paginiTa Print QualityHon Haing EÎncă nu există evaluări

- Apple Color Printer Service SourceDocument166 paginiApple Color Printer Service SourceSilviu MusinaÎncă nu există evaluări

- Quick Reference: Understanding The Operator PanelDocument11 paginiQuick Reference: Understanding The Operator PanelJoseph RiveraÎncă nu există evaluări

- MX 3070Document56 paginiMX 3070Hoang Minh Pham NguyenÎncă nu există evaluări

- Manual e Servicio Mx340 - 350-SsmDocument38 paginiManual e Servicio Mx340 - 350-SsmalemanÎncă nu există evaluări

- Printer Is Making A Beeping Noise: ProblemDocument2 paginiPrinter Is Making A Beeping Noise: ProblemRas HidÎncă nu există evaluări

- Error 02 Warming Up: Density Adjusting PCADocument9 paginiError 02 Warming Up: Density Adjusting PCAlansystem01Încă nu există evaluări

- Stylewriter 1200Document72 paginiStylewriter 1200Massimo Del GaudioÎncă nu există evaluări

- 9xx TR Maint PDFDocument8 pagini9xx TR Maint PDFerick_ssÎncă nu există evaluări

- MXB355W MXB455W Trouble ShootingDocument62 paginiMXB355W MXB455W Trouble ShootingGaeliusEnvoyÎncă nu există evaluări

- QrefDocument2 paginiQrefreggieflockaÎncă nu există evaluări

- Macintosh SeDocument125 paginiMacintosh SeDallasDeckardÎncă nu există evaluări

- Stylus Pro 4800 User GuideDocument16 paginiStylus Pro 4800 User GuidewbjethroÎncă nu există evaluări

- Common Problems On CLP Printers or FAQsDocument19 paginiCommon Problems On CLP Printers or FAQsJonathan LongÎncă nu există evaluări

- Novajet 750Document32 paginiNovajet 750Manuel Manu CastroÎncă nu există evaluări

- HP CP6015, CM6040, CM6030 PQ Defect Guide, v1.0Document40 paginiHP CP6015, CM6040, CM6030 PQ Defect Guide, v1.0Kārlis Spreslis0% (1)

- Important Adjustment Program Utilities For Your Fast T-Jet 3Document6 paginiImportant Adjustment Program Utilities For Your Fast T-Jet 3Nae CarÎncă nu există evaluări

- TTP-246M/344M: Thermal Transfer / Direct Thermal Bar Code PrinterDocument33 paginiTTP-246M/344M: Thermal Transfer / Direct Thermal Bar Code PrinterhtalesÎncă nu există evaluări

- Info 1312 Depot Repair Rev052306Document14 paginiInfo 1312 Depot Repair Rev052306jmm2009us100% (2)

- ADF Second Page LightDocument6 paginiADF Second Page Lightvisual619Încă nu există evaluări

- Alignment & TroubleshootingDocument58 paginiAlignment & TroubleshootingМартин АнгеловÎncă nu există evaluări

- Samsung Ml-3310-3710 4623 Error CodesDocument16 paginiSamsung Ml-3310-3710 4623 Error CodesCutare ZafycomÎncă nu există evaluări

- CLJ CM3530MFP SolveProblemDocument139 paginiCLJ CM3530MFP SolveProblemlutryÎncă nu există evaluări

- Errores HP Laserjet 1300 PDFDocument6 paginiErrores HP Laserjet 1300 PDFarkittoÎncă nu există evaluări

- mx4050n Ex FaqDocument60 paginimx4050n Ex FaqRobin EeftingÎncă nu există evaluări

- Ricoh 8120Document517 paginiRicoh 8120conmanhahohua69Încă nu există evaluări

- Chapter 8. Troubleshooting: 8.1 Procedure of Checking The SymptomsDocument26 paginiChapter 8. Troubleshooting: 8.1 Procedure of Checking The SymptomsAivars LīpenītsÎncă nu există evaluări

- SRP350 User ManualDocument35 paginiSRP350 User ManualHaïthem BEN SALEMÎncă nu există evaluări

- HP PageWide Printer Theory and Troubleshooting FundamentalsDocument40 paginiHP PageWide Printer Theory and Troubleshooting FundamentalsAlves CarvalhoÎncă nu există evaluări

- documentatieCP1210 1510Document26 paginidocumentatieCP1210 1510Taur1968Încă nu există evaluări

- HP LaserJet P3015 - 13.01.00 Jam in Tray X Displays When Printing From Tray 2, 3, or 4Document1 paginăHP LaserJet P3015 - 13.01.00 Jam in Tray X Displays When Printing From Tray 2, 3, or 4sagitarius_heverÎncă nu există evaluări

- Seiko Troubleshooting Error CodesDocument24 paginiSeiko Troubleshooting Error CodesSandIÎncă nu există evaluări

- AB-58C ManualDocument15 paginiAB-58C Manualrafiknet10Încă nu există evaluări

- Deskjet 9Xx Maintenance and TroubleshootingDocument8 paginiDeskjet 9Xx Maintenance and TroubleshootingLucas Suelen Isabela JoaquimÎncă nu există evaluări

- 7075 - All Active Solutions: September 2007Document139 pagini7075 - All Active Solutions: September 2007Sunny SaahilÎncă nu există evaluări

- HP Single-Function Printers - 'Out of Paper' Error Message Displays On The Computer, and The Printer Does Not Pick Up or Feed PaperDocument4 paginiHP Single-Function Printers - 'Out of Paper' Error Message Displays On The Computer, and The Printer Does Not Pick Up or Feed PaperTROY2ARCHILLESÎncă nu există evaluări

- HP 2550 CPL Perform Regular MaintenanceDocument13 paginiHP 2550 CPL Perform Regular MaintenanceMahmudAlGezaÎncă nu există evaluări

- Service Manual LJ1018Document30 paginiService Manual LJ1018phkranz100% (1)

- Canon Ip4600Document21 paginiCanon Ip4600pcboygr100% (1)

- 7075 - All Active Solutions: September 2007Document139 pagini7075 - All Active Solutions: September 2007Sunny SaahilÎncă nu există evaluări

- Samsung ML-1610 Service Manual - 06 - TroubleshootingDocument23 paginiSamsung ML-1610 Service Manual - 06 - Troubleshootingiraklitosp100% (2)

- CLX 6200 - Troubleshooting PDFDocument85 paginiCLX 6200 - Troubleshooting PDFTonyandAnthonyÎncă nu există evaluări

- Info 1422 Depot Repair Rev053106Document15 paginiInfo 1422 Depot Repair Rev053106Serge MaciaÎncă nu există evaluări

- Instruction - Zebra GK420t Tag PrinterDocument8 paginiInstruction - Zebra GK420t Tag PrinterLaura GallagherÎncă nu există evaluări

- Canon Pixma-Mg5220 SMDocument66 paginiCanon Pixma-Mg5220 SMGabi Dragomir100% (1)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142De la EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142Încă nu există evaluări

- Creality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.De la EverandCreality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.Evaluare: 3 din 5 stele3/5 (1)

- Apax EnglishDocument4 paginiApax EnglishJayzÎncă nu există evaluări

- I Can Describe Character (Idioms)Document3 paginiI Can Describe Character (Idioms)Rawda DamraÎncă nu există evaluări

- Rajat Wandkar (1) (2) - 4Document7 paginiRajat Wandkar (1) (2) - 4Vinay Moka, STRYDEÎncă nu există evaluări

- Rifani Zerlinda Putri Tugas Bahasa InggrisDocument18 paginiRifani Zerlinda Putri Tugas Bahasa InggrisARNODITA ZENOLAÎncă nu există evaluări

- Art Farm Programming 2023Document3 paginiArt Farm Programming 2023Sherri ScottÎncă nu există evaluări

- AlteonDocument13 paginiAlteonChuck CheungÎncă nu există evaluări

- Lesson A: Lifestyle Trends: DecreasedDocument3 paginiLesson A: Lifestyle Trends: DecreasedJean Pierre Sulluchuco ValentinÎncă nu există evaluări

- English Test Part A I. Choose The Best Answer by Crossing The Letter A, B, C or D!Document3 paginiEnglish Test Part A I. Choose The Best Answer by Crossing The Letter A, B, C or D!Yudi AsmoroÎncă nu există evaluări

- Music, Arts, Pe & HealthDocument7 paginiMusic, Arts, Pe & HealthKesh AceraÎncă nu există evaluări

- 05 - Driver For HVAC SamsungDocument9 pagini05 - Driver For HVAC SamsungGentrit FejzaÎncă nu există evaluări

- University of California PressDocument20 paginiUniversity of California PressJordan Hugh Sam100% (1)

- BreakawayDocument2 paginiBreakawayjessikaÎncă nu există evaluări

- Homework Englis Asa2km Past TenseDocument3 paginiHomework Englis Asa2km Past TenseDAVID STIVEN TORRES FALLAÎncă nu există evaluări

- Scanning and Editing Black and White NegativesDocument17 paginiScanning and Editing Black and White Negativescaro sturgesÎncă nu există evaluări

- AL Liars Night 2018Document2 paginiAL Liars Night 2018Mike LlamasÎncă nu există evaluări

- Last Six Months Important Sports Current Affairs PDFDocument67 paginiLast Six Months Important Sports Current Affairs PDFkumarÎncă nu există evaluări

- Complex SentencesDocument3 paginiComplex SentencesPilar Romero CandauÎncă nu există evaluări

- Multimaster 300 XDocument2 paginiMultimaster 300 Xcamelod555Încă nu există evaluări

- Adobe Scan 08-Sep-2023Document2 paginiAdobe Scan 08-Sep-2023Diptiranjan SahuÎncă nu există evaluări

- Jazzwise 10Document1 paginăJazzwise 10Mark KulobaÎncă nu există evaluări

- Epson Workforce Enterprise: Wf-C17590 Wf-C20590 Wf-M20590Document32 paginiEpson Workforce Enterprise: Wf-C17590 Wf-C20590 Wf-M20590Ahmed Farid GalyÎncă nu există evaluări

- How To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowDocument3 paginiHow To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowPonggey YabolÎncă nu există evaluări

- E9825c12 Unm Wsoc Box Score 1102Document13 paginiE9825c12 Unm Wsoc Box Score 1102Albuquerque JournalÎncă nu există evaluări