Documente Academic

Documente Profesional

Documente Cultură

Filtration Process Description

Încărcat de

Joy Das MahapatraDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Filtration Process Description

Încărcat de

Joy Das MahapatraDrepturi de autor:

Formate disponibile

Filtration

The regenerable water filters category is split into five different categories, each filter with its own removal properties:

carbon filters sand-anthracite filters (also known as multi-media filters) sand filters birm filters and iron removal filters pH neutralising filters

What is a carbon filter?

A carbon filter, or activated carbon filter as it is sometimes called, is primarily used for its absorbent capacities and the removal of dissolved organics. Tastes and Odours: an activated carbon filter will also remove chlorine and other halogens and low-molecularweight substances (below 100mm). Activated carbon filters are very prone to infection from bacteria and can become somewhat of a breeding ground. All activated carbon filters must be periodically sterilised to avoid bacterial growth and contamination. An activated carbon filter is backwashed frequently with a reverse flow wash but will eventually exhaust, unless fitted after a reverse osmosis plant or after ultra-filtration. Activated carbon can be re-activated once completely exhausted but this requires a heat treatment process which cannot always be undertaken on site and, owing to its relatively low cost, is usually just replaced.

How does a carbon filter work?

A carbon filter consists 3 main components: 1) a composite pressure vessel 2) a carbon filter control valve (usually low voltage) 3) carbon media The water filters down through the carbon filter media, up through a riser tube in the centre of the composite pressure vessel and out through the carbon filter control valve to service. Periodically, the carbon filter will backwash, which changes the water flow through the carbon filter. The water in the backwash cycle flows in from the inlet, down the centre riser tube, up through the carbon bed and out of the control valve to drain. The next step in a carbon filter regeneration cycle is rinse. The water in a rinse cycle of a carbon filter flows as in service, down through the composite pressure vessel and carbon filter media, up through the centre riser tube, through the carbon filter control valve and to drain. The carbon filter then returns to its normal service position. Please note that the above relates only to the smaller simplex carbon filters which we supply. For other types of carbon filters, such as multi-media filters, duplex carbon filters, triplex carbon filters and cartridge carbon filters, please contact us.

How often does a water filter / carbon filter require servicing?

We recommend that a water filter is serviced at least twice a year to keep it in good working order.

Does a carbon water filter use any re-agents?

No. A carbon water filter regenerates entirely on the feed water.

What is a sand-anthracite filter?

A sand-anthracite filter or dual media filter/multi-media filter is primarily used for the removal of turbidity and suspended solids as low as 10-20 microns. Inside a sand-anthracite filter is a layered bed of filter media. The bed is graded from bottom to top as follows:

1st layer 2nd layer 3rd layer 4th layer

= = = =

gravel support bed 2mm filter sand fine filter sand anthracite

Having the filter media graded this way enables the sand anthracite filter to run for longer times before a backwash is necessary.

How does a sand-anthracite filter work?

A sand anthracite filter or multi-media filter consists of 3 main parts:

a composite pressure vessel a sand-anthracite filter control valve (usually low voltage) graded beds of sand and anthracite

The water filters down through the sand-anthracite filter media, up through a riser tube in the centre of the composite pressure vessel and out through the sand-anthracite filter control valve to service. Periodically, the sand-anthracite filter will backwash, which changes the water flow through the sand-anthracite filter. The water in the backwash cycle flows in from the inlet, down the centre riser tube, up through the sand and anthracite bed, and out of the control valve to drain. The next step in a sand-anthracite filter regeneration cycle is rinse. The water in a rinse cycle of a sandanthracite filter flows as in service, down through the composite pressure vessel and sand-anthracite filter media and up through the centre riser tube, through the sand-anthracite filter control valve and to drain. The sandanthracite filter then returns to its normal service position. Please note that the above relates only to the smaller simplex sand-anthracite filters which we supply. For other types of sand-anthracite filters, such as multi-media filters, duplex sand-anthracite filters, triplex sand-anthracite filters and cartridge sand-anthracite filters, please contact us.

How often does a sand-anthracite / multi-media filter require servicing?

We recommend that a water filter is serviced at least twice a year to keep it in good working order.

What is a birm filter?

The word BIRM is an acronym for Backwashable Iron Removal Media. The media birm is a manganese-coated aluminium silicate, used primarily for the removal of dissolved ferrous iron in a water supply. It is worth noting at this point that a birm filter will not work if the pH is below 7, as the iron will not drop out of solution. To change the water-soluble ferrous iron to an insoluble ferric iron, an oxidising agent or oxygen is introduced to the system which then enables the birm to remove the iron from the water.

How does a birm filter work?

A birm filter consists of four main parts:

a composite pressure vessel a birm filter control valve usually low voltage birm filter media an eductor system

The water filters down through the birm filter media, up through a riser tube in the centre of the composite pressure vessel and out through the birm filter control valve to service. Oxygen is introduced to the inlet water via an ejector to raise the oxygen level to 15%. This aids the oxidisation of the iron and helps it to precipitate. This, in turn, lets the birm remove the now ferric iron from the water. Periodically, the birm water filter will backwash, which changes the water flow through the birm water filter. The water in the backwash cycle flows in from the inlet, down the centre riser tube, up through the birm media bed and out of the control valve to drain. The next step in a birm iron removal filter regeneration cycle is rinse. The water in a rinse cycle of a birm iron removal filter flows as in service, down through the composite pressure vessel and sand birm filter media, and up through the centre riser tube through the birm filter control valve and to drain. The birm iron removal filter then returns to its normal service position. Please note that the above relates only to the smaller simplex birm or iron removal filters which we supply. For other types of birm or iron removal filters, such as duplex birm or iron removal filters, triplex birm or iron removal filters and cartridge filters, please contact Derwent Water Systems Limited.

How often does an iron removal filter or birm filter require servicing?

All water filters, including iron removal or birm filters, require servicing twice a year to ensure that they are kept in good working order.

Does a birm filter / iron removal filter require any chemicals?

A birm filter or iron removal filter does not usually require any chemicals for standard use. However, if the pH is below 7, some pH correction using chemicals may need to be considered.

What is a sand filter?

Sand filters are one of the water filtration methods primarily used for the control and removal of turbidity. Sand water filters can economically process large volumes of water to service. Sand filters can only remove relatively large suspended solids. Therefore, secondary water filters of a finer media grade are sometimes installed as necessary.

How does a sand water filter work?

A sand water filter or consists of 3 main parts: a composite pressure vessel a sand water filter control valve (usually low voltage) graded beds of sand The water filters down through the sand water filter media, up through a riser tube in the centre of the composite pressure vessel and out through the sand filter control valve to service. Periodically, the sand filter will backwash, which changes the water flow through the sand filter. The water in the backwash cycle flows in from the inlet down the centre riser tube, up through the sand bed and out of the sand water filter control valve to drain. The next step in a sand filter regeneration cycle is rinse. The water in a rinse cycle of a sand filter flows as in service, down through the composite pressure vessel and sand filter media, up through the centre riser tube through the sand filter control valve and to drain. The sand filter then returns to its normal service position. Please note that the above relates only to the smaller simplex sand water filters which we supply. For other types

of sand filters, such as multi-media filters, duplex sand water filters, triplex sand water filters and cartridge sand filters, please contact us.

Does a sand filter use any regenerants or chemicals?

No. A sand filter regenerates entirely on the incoming feed water.

What is a pH neutralising filter?

Many borehole water or spring supplies have a pH of less than 7. If your water supply has a pH of less than 7, it is considered to be acidic and must be treated. Acidic water can cause various problems, such as staining and corrosion. The water filter media used in a pH neutralising filter is crushed and processed limestone, called Magnadol. Magnadol can usually raise a pH from 6 to 7. The Magnadol dissolves into water as it passes through the filter and the natural alkalinity of the Magnadol (pH neutralising water filter media) raises the pH. Because of the calcium level in the Magnadol, the hardness of the water is affected. The hardness would be expected to rise around 50ppm.

How does a neutralising filter work?

A water neutralising filter consists 3 main components:

a composite pressure vessel a neutralising filter control valve (usually low voltage) neutralising media (Magnadol).

The water filters down through the Magnadol filter media, up through a riser tube in the centre of the composite pressure vessel and out through the neutralising water filter control valve to service. Periodically, the pH neutralising filter will backwash, which changes the water flow through the water filter. The water in the backwash cycle flows in from the inlet down the centre riser tube, up through the Magnadol bed and out of the control valve to drain. The next step in a pH neutralising filter regeneration cycle is rinse. The water in a rinse cycle of a pH neutralising filter flows as in service, down through the composite pressure vessel and Magnadol filter media and up through the centre riser tube through the neutralising filter control valve and to drain. The pH neutralising filter then returns to its normal service position. Please note that the above relates only to the smaller simplex water filters which we supply. For other types of neutralising filters, such as large simplex water filters, duplex water filters, triplex water filters and cartridge neutralisers, please contact us.

How often does a pH neutraliser require servicing?

We recommend that all water filters need servicing every six months, including water neutraliser and pH correction filters.

Does a neutralising filter require any chemicals?

No. A neutralising filter does not require any chemical for standard use.

S-ar putea să vă placă și

- Get Started With Calisthenics. Ultimate Guide For Beginnerss.Document178 paginiGet Started With Calisthenics. Ultimate Guide For Beginnerss.kevin97% (64)

- Eastern Railway Ussor 2011Document288 paginiEastern Railway Ussor 2011Sunny Singh11% (9)

- Ir Ussor-2019 - 15 - 01 - 2020 PDFDocument878 paginiIr Ussor-2019 - 15 - 01 - 2020 PDFJoy Das Mahapatra75% (4)

- Ir Ussor-2019 - 15 - 01 - 2020 PDFDocument878 paginiIr Ussor-2019 - 15 - 01 - 2020 PDFJoy Das Mahapatra75% (4)

- 2012 A6 Self Study Program Part 1Document44 pagini2012 A6 Self Study Program Part 1Soriteu Sorin100% (2)

- CPWD Specifications - Speci - Vol2Document512 paginiCPWD Specifications - Speci - Vol2Vijay KanugantiÎncă nu există evaluări

- Laborator Chimie DIYDocument11 paginiLaborator Chimie DIYotonel100% (1)

- 2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFDocument28 pagini2012, WWW - Buydonaldson.com, Hydraulic Filtration - Technical Reference PDFVelibor Karanović100% (1)

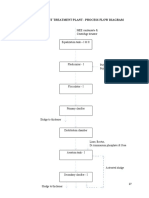

- Effluent Treatment Plant - Process Flow DiagramDocument45 paginiEffluent Treatment Plant - Process Flow DiagramAmarnath PÎncă nu există evaluări

- Water Treatment Plant Performance Evaluations and OperationsDe la EverandWater Treatment Plant Performance Evaluations and OperationsÎncă nu există evaluări

- CPWD Speci Civil 2009 Vol1Document544 paginiCPWD Speci Civil 2009 Vol1supriyo.podder100% (2)

- Lesson Plan: How Do We Clean Polluted Water?Document15 paginiLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyÎncă nu există evaluări

- PRP CML Placement TestingDocument30 paginiPRP CML Placement TestingMohamed Al-Amir Al-KhayatÎncă nu există evaluări

- Uf 500 LPHDocument6 paginiUf 500 LPHSimbu ArasanÎncă nu există evaluări

- Flint WTP O-M Manual With SOPs 553219 7Document83 paginiFlint WTP O-M Manual With SOPs 553219 7Omkar BharankarÎncă nu există evaluări

- DesignDocument3 paginiDesigntata_77Încă nu există evaluări

- RODocument10 paginiROShahrooz Leo QureshiÎncă nu există evaluări

- Wastewater TrainDocument3 paginiWastewater TrainLester Mercado100% (1)

- MF Uf NFDocument69 paginiMF Uf NFNguyen Huu HieuÎncă nu există evaluări

- Power System Stability Vol II KimbarkDocument296 paginiPower System Stability Vol II KimbarkShashidhar Kasthala100% (11)

- Physico-Chemical Wastewater Treatment IntroductionDocument27 paginiPhysico-Chemical Wastewater Treatment IntroductionmsinsigneÎncă nu există evaluări

- Filtration Process DescriptionDocument4 paginiFiltration Process DescriptionJoy Das MahapatraÎncă nu există evaluări

- BIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeDocument26 paginiBIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeK SASIKUMAR100% (1)

- Summary Report: RO System Flow DiagramDocument3 paginiSummary Report: RO System Flow Diagramjugal ranaÎncă nu există evaluări

- 2010 SMR ClarifierDocument60 pagini2010 SMR ClarifierRohan KakdeÎncă nu există evaluări

- Tube Settlers CatalogueDocument10 paginiTube Settlers CatalogueIlu Singh100% (1)

- For Reduction of Iron/or Manganese From Water SuppliesDocument2 paginiFor Reduction of Iron/or Manganese From Water SuppliesMadalina Luca ZambreaÎncă nu există evaluări

- Water Treatment PlantsDocument16 paginiWater Treatment PlantsKaten MistryÎncă nu există evaluări

- Sand FiltrationDocument5 paginiSand FiltrationMa Vichelle Torrejos-UyÎncă nu există evaluări

- Ate Huber-1Document47 paginiAte Huber-1Ravena RemaditaÎncă nu există evaluări

- Troubleshooting STP's IssuesDocument34 paginiTroubleshooting STP's IssuesAshish A ArbaleÎncă nu există evaluări

- DM PlantDocument9 paginiDM Plantsohag97Încă nu există evaluări

- Thermal Rehabilitation (Azuma House)Document47 paginiThermal Rehabilitation (Azuma House)Haseeb Uz Zaman67% (6)

- Crits Notes On Water and Ion Exchange PDFDocument55 paginiCrits Notes On Water and Ion Exchange PDFAlfredo HernandezÎncă nu există evaluări

- HYDRAcap MAX Presentation - Abril 2012Document32 paginiHYDRAcap MAX Presentation - Abril 2012PC VSÎncă nu există evaluări

- Design ManualDocument8 paginiDesign ManualIrvin jose100% (1)

- Enpro Project ReportDocument51 paginiEnpro Project ReportYadav VirendraÎncă nu există evaluări

- Science8 q1 Mod3 Potential-And-kinetic-Energy v2Document23 paginiScience8 q1 Mod3 Potential-And-kinetic-Energy v2Keith Genesis Ruiz AglubaÎncă nu există evaluări

- 61R Compact Raise Borer Technical Specification WorksheetDocument4 pagini61R Compact Raise Borer Technical Specification WorksheetRoiÎncă nu există evaluări

- Slow Sand Filtration Dwfsom40 PDFDocument4 paginiSlow Sand Filtration Dwfsom40 PDFjose03Încă nu există evaluări

- N Removal: CIE4485 Laboratory ExperimentDocument13 paginiN Removal: CIE4485 Laboratory ExperimentAbass MarrakchiÎncă nu există evaluări

- Textile Environmental PresentationDocument52 paginiTextile Environmental PresentationNayeem RahmanÎncă nu există evaluări

- 02.12.21 90m3hr Euroclean-DHV MaithonDocument16 pagini02.12.21 90m3hr Euroclean-DHV MaithonSagnik DasÎncă nu există evaluări

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDocument47 paginiDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALAÎncă nu există evaluări

- Hydraulic Design of Sewage Treatment PlantDocument9 paginiHydraulic Design of Sewage Treatment PlantSCR_010101Încă nu există evaluări

- Ammonia and NitrificationDocument8 paginiAmmonia and NitrificationLionel MenezesÎncă nu există evaluări

- WaterSoftner - Opened by M.gh.Document4 paginiWaterSoftner - Opened by M.gh.Hamdy AdelÎncă nu există evaluări

- Potassium Permanganate As Oxidant in The Cod Test For Saline Water SamplesDocument11 paginiPotassium Permanganate As Oxidant in The Cod Test For Saline Water SampleskomodobutaÎncă nu există evaluări

- Operation and Control of STPDocument11 paginiOperation and Control of STPHari Krishna.MÎncă nu există evaluări

- PlantDocument32 paginiPlantZafar IqbalÎncă nu există evaluări

- Lecture37 PDFDocument6 paginiLecture37 PDFNico Aumento Jr.Încă nu există evaluări

- 13 Tertiary TreatmentDocument27 pagini13 Tertiary TreatmentMohammed BarniÎncă nu există evaluări

- Unit-III Secondary Treatment Processes-Suspended Growth: Instructor: Prof. (DR.) Gaurav Saini Sharda UniversityDocument66 paginiUnit-III Secondary Treatment Processes-Suspended Growth: Instructor: Prof. (DR.) Gaurav Saini Sharda UniversityAkbar Hamid100% (1)

- Low Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterDe la EverandLow Cost Wastewater Bioremediation Technology: Innovative Treatment of Sulfate and Metal-Rich WastewaterÎncă nu există evaluări

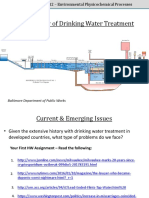

- 02 Overview of Drinking Water TreatmentDocument36 pagini02 Overview of Drinking Water TreatmentCharlie CB PortnerÎncă nu există evaluări

- Dual MediaDocument12 paginiDual MediaPraveen Kesavan NairÎncă nu există evaluări

- Tertiary TreatmentDocument26 paginiTertiary TreatmentNirra IndriiÎncă nu există evaluări

- Nitrates Removal StrategiesDocument12 paginiNitrates Removal Strategiesharoon_siyech_enggÎncă nu există evaluări

- Exp 3Document15 paginiExp 3mjunaidÎncă nu există evaluări

- Filter Ion ExchangeDocument10 paginiFilter Ion Exchangemanjunath hrÎncă nu există evaluări

- Anaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System WhichDocument6 paginiAnaerobic Processes: Rate Systems. Thus One Can Have A Low-Rate, Suspended-Growth Anaerobic System Whichnickao123Încă nu există evaluări

- MB 11 BrochureDocument7 paginiMB 11 BrochurePhliip StaintonÎncă nu există evaluări

- M13 - L17 Grit ChamberDocument6 paginiM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Environmental Engineers Hand Book (7 Chapter, Reference Page No 943) FiltrationDocument7 paginiEnvironmental Engineers Hand Book (7 Chapter, Reference Page No 943) FiltrationrajanandguruÎncă nu există evaluări

- Monitoring, Operation and Control of Ion Exchange Plant: Mel HallDocument73 paginiMonitoring, Operation and Control of Ion Exchange Plant: Mel HallefasaravananÎncă nu există evaluări

- Filtration: Typical ConstructionDocument10 paginiFiltration: Typical ConstructionraniÎncă nu există evaluări

- 21857, Issue 24 Water Softener Elution STDocument2 pagini21857, Issue 24 Water Softener Elution STVương Đình NamÎncă nu există evaluări

- TMF Lime SofteningDocument2 paginiTMF Lime SofteningRachel HechanovaÎncă nu există evaluări

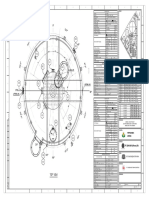

- Degasifier 18-02-2017 Sheet 1Document1 paginăDegasifier 18-02-2017 Sheet 1Abu SuraisyÎncă nu există evaluări

- EE-2 Mini Project ReportDocument7 paginiEE-2 Mini Project Report63GANESH SINGHCIVILÎncă nu există evaluări

- 225 Na Engg DataDocument8 pagini225 Na Engg DatadeyprasenÎncă nu există evaluări

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationDe la EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationÎncă nu există evaluări

- Phosphorus Removal: University of Kansas 100 Annual Water and Wastewater School Lawrence, Kansas July 30, 2019Document61 paginiPhosphorus Removal: University of Kansas 100 Annual Water and Wastewater School Lawrence, Kansas July 30, 2019Joy Das MahapatraÎncă nu există evaluări

- State Health & Family Welfare Society, Tripura (National Health Mission)Document2 paginiState Health & Family Welfare Society, Tripura (National Health Mission)Joy Das MahapatraÎncă nu există evaluări

- Ozone 1Document9 paginiOzone 1Joy Das MahapatraÎncă nu există evaluări

- Ozone As A Disinfecting Agent in The Reuse of WastewaterDocument9 paginiOzone As A Disinfecting Agent in The Reuse of WastewaterJoy Das MahapatraÎncă nu există evaluări

- Nitrogen RemovalDocument80 paginiNitrogen RemovalJoy Das MahapatraÎncă nu există evaluări

- Unified SOR Inte RevisedDocument70 paginiUnified SOR Inte RevisedAncil AlexÎncă nu există evaluări

- Nitrogen RemovalDocument80 paginiNitrogen RemovalJoy Das MahapatraÎncă nu există evaluări

- KDHE Advanced Wastewater Treatment August 2019Document31 paginiKDHE Advanced Wastewater Treatment August 2019Joy Das MahapatraÎncă nu există evaluări

- Nutrient Removal Introduction and OverviewDocument60 paginiNutrient Removal Introduction and OverviewJoy Das MahapatraÎncă nu există evaluări

- KDHE Advanced Wastewater Treatment August 2019Document31 paginiKDHE Advanced Wastewater Treatment August 2019Joy Das MahapatraÎncă nu există evaluări

- Osiris BrochureDocument4 paginiOsiris BrochureJoy Das MahapatraÎncă nu există evaluări

- Phosphorus Removal: University of Kansas 100 Annual Water and Wastewater School Lawrence, Kansas July 30, 2019Document61 paginiPhosphorus Removal: University of Kansas 100 Annual Water and Wastewater School Lawrence, Kansas July 30, 2019Joy Das MahapatraÎncă nu există evaluări

- Iruss 2019 PDFDocument189 paginiIruss 2019 PDFPrasanta ParidaÎncă nu există evaluări

- PWD Sor-2015-16Document91 paginiPWD Sor-2015-16Anban Guna0% (1)

- Test Adobe Scan PDFDocument1 paginăTest Adobe Scan PDFJoy Das MahapatraÎncă nu există evaluări

- PWD (W.B.) Schedule of Rates, 2012Document396 paginiPWD (W.B.) Schedule of Rates, 2012Paramanu Baidya82% (11)

- Kyoto ProtocolDocument23 paginiKyoto ProtocolAydın FenerliÎncă nu există evaluări

- IRUSSOR-Cement CoefficientsDocument11 paginiIRUSSOR-Cement CoefficientsLAXMI NARAYAN PRADHAN100% (1)

- Kyoto ProtocolDocument23 paginiKyoto ProtocolAydın FenerliÎncă nu există evaluări

- WhoDocument27 paginiWhoJoy Das MahapatraÎncă nu există evaluări

- En 609-1 PDFDocument14 paginiEn 609-1 PDFSURESHKUMARÎncă nu există evaluări

- Chapter 19 Weather Patterns and Severe StormsDocument7 paginiChapter 19 Weather Patterns and Severe StormsTherese Jan MangussadÎncă nu există evaluări

- Furnace Oil ProjectDocument16 paginiFurnace Oil ProjectRohit PÎncă nu există evaluări

- My M.SC Thesis ..Document33 paginiMy M.SC Thesis ..Mallika P. Shivam100% (1)

- Interrelated Function Bio MolecularDocument2 paginiInterrelated Function Bio MolecularAlifah SyarafinaÎncă nu există evaluări

- Electrochemistry, PPT 3Document33 paginiElectrochemistry, PPT 3Ernest Nana Yaw AggreyÎncă nu există evaluări

- Bca SyllabusDocument55 paginiBca Syllabusapi-349492533Încă nu există evaluări

- Kuhnke IA Series Relay DatasheetDocument4 paginiKuhnke IA Series Relay DatasheetKishore KÎncă nu există evaluări

- CIE IGCSE Forces Hookes Law OnlyDocument22 paginiCIE IGCSE Forces Hookes Law Onlyh aÎncă nu există evaluări

- TRC Unit SpecDocument12 paginiTRC Unit SpecJohn ChirinosÎncă nu există evaluări

- Assignment 1 Numerical ProblemsDocument3 paginiAssignment 1 Numerical ProblemsNetra PujarÎncă nu există evaluări

- Reporte HOMER WIND 5kW-PV 6.36kWDocument10 paginiReporte HOMER WIND 5kW-PV 6.36kWlandoa junÎncă nu există evaluări

- Revolution Wind (Deepwater Wind LLC) Public BidDocument130 paginiRevolution Wind (Deepwater Wind LLC) Public BidAndy TomolonisÎncă nu există evaluări

- Daily Activities Report Maintenance Baru Gas Plant & Teluk Lembu Delivery StationDocument30 paginiDaily Activities Report Maintenance Baru Gas Plant & Teluk Lembu Delivery StationMaintenance BentuÎncă nu există evaluări

- Engineering Solutions: Kolmetz Handbook of Process Equipment Design Cooling Tower Selection, Sizing and TroubleshootingDocument27 paginiEngineering Solutions: Kolmetz Handbook of Process Equipment Design Cooling Tower Selection, Sizing and Troubleshootingthexp0werÎncă nu există evaluări

- Radiation Production and Characteristics Lecture2021 22Document188 paginiRadiation Production and Characteristics Lecture2021 22Lei ClamorÎncă nu există evaluări

- Dampak Penempatan GroundsillDocument16 paginiDampak Penempatan GroundsillikienÎncă nu există evaluări

- Teilekatalog (VX800 VS51A 1990-1996)Document76 paginiTeilekatalog (VX800 VS51A 1990-1996)Andreas PauliÎncă nu există evaluări

- Hydraulic Construction EquipmentDocument24 paginiHydraulic Construction EquipmentAYUSH PARAJULIÎncă nu există evaluări

- Ee6211 - Electric Circuit LabDocument101 paginiEe6211 - Electric Circuit Labsujith100% (1)

- Radiography Procedure RNDTDocument27 paginiRadiography Procedure RNDTrashmibetuÎncă nu există evaluări

- Hydraulic Cylinder - Tie Rod DesignDocument8 paginiHydraulic Cylinder - Tie Rod DesignLe Van TamÎncă nu există evaluări

- 029 - Madho Ram v. Secretary of State (143-151)Document9 pagini029 - Madho Ram v. Secretary of State (143-151)Vinay Kumar KumarÎncă nu există evaluări