Documente Academic

Documente Profesional

Documente Cultură

ODORIZADOR

Încărcat de

Juanc Lu VaDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ODORIZADOR

Încărcat de

Juanc Lu VaDrepturi de autor:

Formate disponibile

03/10/98

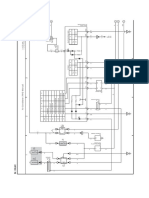

PNEUMATIC CHEMICAL PUMPS FOR THE GAS AND OIL INDUSTRIES

MODEL 225DS-TR2 / 235DS-TR2

AIR ACTUATED POSITIVE DISPLACEMENT PUMP

NOTE 2

NOTE 1

12"

8 1/4"

NOTE:

1. 2-1/2" DIA. MODEL 225DS/235DS

3-1/4" DIA. MODEL 325DS/335DS

2. 7-5/8" MODEL 225DS/235DS

7-7/8" MODEL 225DS/335DS

MODEL

(WITH TIMER) DISPLACEMENT

PUMP

RATIO

STROKE

LENGTH

in. - cm.

CONNECTIONS

ALL NPT

INPUT / OUTPUT

MAXIMUM

DISCHARGE

PSI - BAR

OUTPUT

PER HOUR

GAL. / LTS.

225DS-TR2

.8 cc

69:1

1 - 2.54

1/4 - M / 1/4 - F

10000 - 689

.06 -.63 / .24 - 2.4

235DS-TR2

1.8 cc

31:1

1 - 2.54

1/4 - M / 1/4 - F

4650 - 320

.15 -.1.5 / .55 - 5.5

MORGAN PRODUCTS INC. 28103 Ave. Stanford / Valencia, CA 91355

(805) 257-3022 - (800) 421-8910 - FAX (805) 257-3385

www.morganproducts.com - E-Mail info@morganproducts.com

04/17/97

PNEUMATIC CHEMICAL PUMPS FOR THE GAS AND OIL INDUSTRIES

Parts List Model 225DS, 325DS, 425DS

NO

1

2

3

4

NAME

Stroke Adjuster

Locknut

O-Ring Seal

Air Chambers

5

6

7

Piston Locknut

O-Ring Seal

Pistons

8

9

10

Spring Guide

2oz. Oil

Piston Seals

11

12

13

14

Plungers:

17-4 TN

316 SS

Carpenter 20

Piston Stop

Return Spring

Air Chamber Rings

15

16

17

Reservoir

Back Up Ring

Faceplates

18

Pressure Seals:

TG

Buna- N

Viton

Fluoraz

Nipples

19

20

21

22

23

24

25

PART NO.

100-1

100-2

100-3

200-4

300-4

400-4

100-7

100-11

200-8

300-8

400-8

200-10

100-24

200-9

300-9

400-9

O-Ring Seal

Oil Chamber

Bleeder Plugs

Fluid Chambers

Double Seal Body

1/8 NPT Plug

1oz. Grease

Elbow

Lock Screw

1/4" Washer

Repair Kits:

17-4 TN Plunger

INSTALLATION INSTRUCTIONS

1.

2.

3.

4.

5.

Discard all red plastic closures.

Connect suction check valve, to a gravity fed chemical source.

Connect discharge check valve, to process line.

Connect a regulated air or gas supply, to the timing relay.

Fill oil reservoir with oil provided.

** This must be done BEFORE start up.**

6. Open bleeder valve until chemical flows from bleeder.

7. Set regulator at 10 to 15 psi ABOVE the pressure required.

(See discharge pressure graph).

8. Set cycle rate in strokes per minute.

(See volume graph)

10

S

P

M

50

40

30

20

10

0

15

20

VOLUME

QTS/ DAY

25 30 35

316 SS Plunger

Seal Sets:

TG

Buna- N

Viton

Fluoraz

14

19

24

28

33

LITERS / DAY

*

*

*

100-65

125-67

100-68

200-69

200-13

200-5

300-5

400-5

3000-25

100-19

200-6

300-6

400-6

100-20

100-20B

100-20V

100-20F

100DS-32

3000-32

4000-32

100-21

200-14

125-22

125-23

125-64

5000-38

*

400-27

400-28

400-29

(2)

(2)

ALL

Optional

Optional

ALL

ALL

200DS/225DS

300DS/325DS

400DS/425DS

ALL

ALL (2)

200DS/225DS

300DS/325DS

400DS/425DS

ALL (2)

Optional

Optional

Optional

200DS/225DS

300DS/325DS

400DS/425DS

ALL (2)

ALL

ALL

ALL

ALL

ALL

ALL

400DS/425DS

400DS/425DS

400DS/425DS

200-70

300-70

400-70

225-70

325-70

425-70

200DS/225DS

300DS/325DS

400DS/425DS

200DS/225DS

300DS/325DS

400DS/425DS

100-48

100-48B

100-48V

100-48F

ALL

ALL

ALL

ALL

* = Included in Repair Kit

DISCHARGE PRESSURE

40

45

50

55

60

PSI.

1000

150

120

90

60

30

0

9.5

PUMP MODEL

ALL

ALL

ALL

200DS/225DS

300DS/325DS

400DS/425DS

ALL

ALL

200DS/225DS

300DS/325DS

400DS/425DS

ALL

ALL

200DS/225DS

300DS/325DS

400DS/425DS

38

43

47

52

2500 4000

5500

7000

200/225

8500 10000 11500 15000

300/325

400/425

69

57

173

276

380

483

587

689 794

MORGAN PRODUCTS INC. 28103 Ave. Stanford / Valencia, CA 91355

(805) 257-3022

(800) 421-8910

FAX (805) 257-3385

10.4

8.4

6.3

4.2

2.1

1055

BAR

03/98

PNEUMATIC CHEMICAL PUMPS FOR THE GAS AND OIL INDUSTRIES

Parts List Model 235DS, 335DS, 435DS

NO

1

2

3

4

NAME

Stroke Adjuster

Locknut

O-Ring Seal

Air Chambers

5

6

7

Piston Locknut

O-Ring Seal

Pistons

8

9

2oz. Oil

Piston Seals

10

11

12

13

Plungers:

17-4 TN

316 SS

Carpenter 20

Piston Stop

Return Spring

Air Chamber Rings

14

15

16

Reservoir

Back Up Ring

Faceplates

17

Pressure Seals:

TG

Buna- N

Viton

Fluoraz

Nipples

18

19

20

21

22

23

24

O-Ring Seal

Oil Chamber

Bleeder Plugs

Fluid Chambers

Double Seal Body

1/8 NPT Plug

1oz. Grease

Elbow

Lock Screw

1/4" Washer

Repair Kits:

17-4 TN Plunger

INSTALLATION INSTRUCTIONS

1.

2.

3.

4.

5.

Discard all red plastic closures.

Connect suction check valve, to a gravity fed chemical source.

Connect discharge check valve, to process line.

Connect a regulated air or gas supply, to the timing relay.

Fill oil reservoir with oil provided.

** This must be done BEFORE start up.**

6. Open bleeder valve until chemical flows from bleeder.

7. Set regulator at 10 to 15 psi ABOVE the pressure required.

(See discharge pressure graph).

8. Set cycle rate in strokes per minute.

(See volume graph)

VOLUME

.25

S

P

M

50

40

30

20

10

0

.5

GAL/ HR

.75

1.0

1.25

316 SS Plunger

Seal Sets:

TG

Buna- N

Viton

Fluoraz

1.8

2.8

LITERS / HR

3.7

4.6

PUMP MODEL

ALL

ALL

ALL

230DS/235DS

330DS/335DS

430DS/435DS

ALL

ALL

230DS/235DS

330DS/335DS

430DS/435DS

100-24

200-9

300-9

400-9

ALL

230DS/235DS

330DS/335DS

430DS/435DS

*

*

*

230-65

235-67

230-68

200-69

200-13

200-5

300-5

400-5

3000-25

230-19

200-6

300-6

400-6

230-20

230-20B

230-20V

130-20F

100DS-32

3000-32

4000-32

100-21

230-14

125-22

235-23

235-64

5000-38

*+

*+

ALL

Optional

Optional

ALL

ALL

230DS/235DS

330DS/335DS

430DS/435DS

ALL

ALL (2)

230DS/235DS

330DS/335DS

430DS/435DS

400-27

400-28

400-29

ALL (2)

Optional

Optional

Optional

230DS/235DS

330DS/335DS

430DS/435DS

*

ALL (2)

ALL

ALL

ALL

ALL

ALL

*

ALL

430DS/435DS

(2) 430DS/435DS

(2) 430DS/435DS

230-70

330-70

430-70

235-70

335-70

435-70

230DS/235DS

330DS/335DS

430DS/435DS

230DS/235DS

330DS/335DS

430DS/435DS

230-48

230-48B

230-48V

230-48F

ALL

ALL

ALL

ALL

* = Included in Repair Kit

+ = Included in Seal Set

DISCHARGE PRESSURE

1.5

PSI.

.9

PART NO.

100-1

100-2

100-3

*

200-4

300-4

400-4

100-7

100-11

*

200-8

300-8

400-8

5.5

150

120

90

60

30

0

2000

3000 4000

230/235

5000

6000

7000

8000

9000 10000

10.4

8.4

6.3

4.2

2.1

330/335

430/435

138

207

276

345

414

483

552

621

MORGAN PRODUCTS INC. 28103 Ave. Stanford / Valencia, CA 91355

(805) 257-3022 - (800) 421-8910 - FAX (805) 257-3385

Web www.morganproducts.com - E-Mail info@morganproducts.com

690 BAR

S-ar putea să vă placă și

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Blind Flanges For FRP PipeDocument1 paginăBlind Flanges For FRP PipeNABEEL ABDUL GAFFARÎncă nu există evaluări

- FWDS 0236 ADocument2 paginiFWDS 0236 AAlanka PrasadÎncă nu există evaluări

- Content Dam LMC New-PDF LMC Flanges - Product RangeDocument11 paginiContent Dam LMC New-PDF LMC Flanges - Product RangebeneÎncă nu există evaluări

- Toyota Hilux 2018 Overall EWD Vehicle Interior Air Conditioner (RHD Manual)Document2 paginiToyota Hilux 2018 Overall EWD Vehicle Interior Air Conditioner (RHD Manual)gabrielzinho43Încă nu există evaluări

- Copia de ACCESORIOS BAUER EN FIERRO GALVANIZADO Bauer SpanishDocument1 paginăCopia de ACCESORIOS BAUER EN FIERRO GALVANIZADO Bauer SpanishVentasVarias AntofaÎncă nu există evaluări

- 38VTA030 (Malaysia)Document2 pagini38VTA030 (Malaysia)Leed ENÎncă nu există evaluări

- CAT 349E Electrical UENR04260001Document12 paginiCAT 349E Electrical UENR04260001BassieÎncă nu există evaluări

- Pump Design PresentationDocument9 paginiPump Design PresentationKayode Ijaola100% (1)

- Fire Detection and SuppressionDocument33 paginiFire Detection and Suppressionniti860Încă nu există evaluări

- ReciprocatingDocument15 paginiReciprocatingRohit soniÎncă nu există evaluări

- Accelertion Head PDFDocument5 paginiAccelertion Head PDFEng AlfÎncă nu există evaluări

- Condensate Water Pump: Product AccessoriesDocument2 paginiCondensate Water Pump: Product AccessoriesWai Lwin Ko50% (2)

- Bomba Paletas Eaton-VickersDocument38 paginiBomba Paletas Eaton-VickersChristian Ruben Corihuaman SotoÎncă nu există evaluări

- Arv Facts PDFDocument9 paginiArv Facts PDFReyÎncă nu există evaluări

- Fluid TurbomachineryDocument7 paginiFluid TurbomachinerySuraj YadavÎncă nu există evaluări

- Horizontal Transport of Dredged Mixtures Part 2 - ENDocument64 paginiHorizontal Transport of Dredged Mixtures Part 2 - ENedraket145Încă nu există evaluări

- Valve Selection Handbook - IntroductionDocument5 paginiValve Selection Handbook - IntroductionPalazzo345Încă nu există evaluări

- P100 Series: Portable Hydrostatic TesterDocument8 paginiP100 Series: Portable Hydrostatic TesterAwo Ni Orumila OsarosoÎncă nu există evaluări

- CMS TrainingDocument74 paginiCMS TrainingRamiro Joel Quiñonez Ramos100% (1)

- Ground Floor Fire Fighting Layout: Legends & AbbreviationsDocument1 paginăGround Floor Fire Fighting Layout: Legends & Abbreviationsahmad almasriÎncă nu există evaluări

- Apu Comparison in Igo Fleet PDFDocument19 paginiApu Comparison in Igo Fleet PDFRahul UnnikrishnanÎncă nu există evaluări

- DR Tipu Sultan: Department of Mechanical Engineering UMT LahoreDocument62 paginiDR Tipu Sultan: Department of Mechanical Engineering UMT LahoreUSMAN SARWARÎncă nu există evaluări

- Pressure Drop Calculation For EvaporatorDocument5 paginiPressure Drop Calculation For EvaporatorCaleb FalcoteloÎncă nu există evaluări

- GR180 Turbine NotesDocument4 paginiGR180 Turbine NotesJunior Batista100% (1)

- T Series Take ApartDocument4 paginiT Series Take ApartJak JoniÎncă nu există evaluări

- Spin Valves - Dual Plate Wafer Check ValveDocument4 paginiSpin Valves - Dual Plate Wafer Check ValvePablo HurtubiaÎncă nu există evaluări

- Minimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFDocument4 paginiMinimum Pipe Spacing Chart For Petrochemical & Refinery Plants PDFRamesh KumarÎncă nu există evaluări

- Catalog Derectional Valve EmersonDocument150 paginiCatalog Derectional Valve EmersonNurdiansyah Hadi DotÎncă nu există evaluări

- Steam Turbine Solutions Steam Turbine SolutionsDocument8 paginiSteam Turbine Solutions Steam Turbine SolutionsramakantinamdarÎncă nu există evaluări

- BC 0071Document1 paginăBC 0071Sebastian JesusÎncă nu există evaluări