Documente Academic

Documente Profesional

Documente Cultură

RCCM Notes Final

Încărcat de

Adil AzeemDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

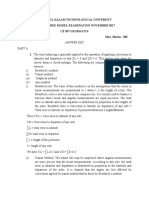

RCCM Notes Final

Încărcat de

Adil AzeemDrepturi de autor:

Formate disponibile

Bezier Curves and Surfaces

Refer to the book Mathematical Elements in Computer Graphics

by Rogers and Adams. The subject is given a good treatment

there. Also the book by B K Choi (Surface modeling for CAD

CAM, may be referred to)

Bezier Curves and Surfaces

= ) u ( Q

) u ( J ) u ( B

i , n

n

0 i

i

A Bezier surface is given by

= ) , ( w u Q

) ( ) (

,

0 0

, ,

w K u J B

j m

n

i

m

j

i n j i

=

,

0 u s 1 s

and

0 w s 1 s

Where J

i n,

(u) and K

j m,

(w) are the Bernstein basis functions

in the

u

and

w

parametric directions and are given by the

following equations

=

i n

J

,

|

|

.

|

\

|

i

n

i n i

) u 1 ( u

=

j m

K

,

|

|

.

|

\

|

j

m

j m j

w w

) 1 (

|

|

.

|

\

|

i

n

=

)! ( !

!

i n i

n

|

|

.

|

\

|

j

m

=

)! ( !

!

j m j

m

With the assumptions 0 to the power 0 is 1 and factorial 0 is 1.

Bezier curve

Control Point

Bezier surface fitting

Suppose we have to pass a Bezier curve through a number of data points (the blue points

in the figure). Let the data points be D

i

. We have to find out the control points (as yet

unknown, shown by red points in the fig) B

i

that would produce a curve which would be

passing through the data points. In such a case, we may write that

(

(

(

(

(

(

(

(

=

(

(

(

(

n

n n n n

B

B

B

B

u J u J u J u J

u J u J u J u J

u J u J u J u J

u J u J u J u J

Dn

D

D

D

2

1

0

3 , 3 2 , 3 1 , 3 0 , 3

2 3 , 3 2 2 , 3 2 1 , 3 2 0 , 3

1 3 , 3 1 2 , 3 1 1 , 3 1 0 , 3

0 3 , 3 0 2 , 3 0 1 , 3 0 0 , 3

3

2

1

) ( ) ( ) ( ) (

) ( ) ( ) ( ) (

) ( ) ( ) ( ) (

) ( ) ( ) ( ) (

Or in short -

] ][ [ ] [ B C D =

If ] [C is square, the control points are obtained directly by

matrix inversion, i.e.,

] [ ] [ ] [

1

D C B

=

C will not be square if the number of data points is not

equal to the number of control points considered. In fact, it

is very common to have a huge number of data points and

consider very few control points. For example, there might

be 100 data points and only 6 (say) control points

considered by the design engineer to develop the curve that

would pass through all of these points. In such a case, the

problem is overspecified and the solution can only be

obtained in some mean sense. In particular the solution is

given by

] [ ] [ ]] [ ] [[ ] [

1

D C C C B

T T

=

This is just the matrix version of the mathematical

implementation of the least square fit, which ensures that

if the curve is not going to pass through all the points, it

would be such that the sum of the square of errors at all

data points would be the least. Error at a point is nothing

but the distance between the data point and the developed

curve (corresponding to the same parameter value as that of

the data point).

The u parameter value for each data point is obtained using

a chord length approximation where the parameter value u

i

at a data point D

i

is (please refer to fig)

1 3 2 1

3 2 1

... ...

...

+ + + + + +

+ + + +

=

n i

i

i

l l l l l

l l l l

u

Where the chords are the pink lines joining the data points.

The idea is something like this in curve modeling, the

parameter value at a particular point on the curve is

frequently taken as length of curve (from beginning of

curve) till that point / total length of curve. Here, we dont

have a curve to start with, so we have to go for some kind

of approximation. The approximation is: approximate the

lengths of the curve segments between the data points by

the respective chords (that is, the straight lines between the

data points).

d

i

l

1

l

2

l

3

l

i

l

n-1

Free form surface machining : a brief overview

A free form surface or shape is that which is free of any particular mathematical form. In other

words, it is not described by any standard mathematical expression like trigonometric formulae

or some such relation.

Our problem here is to generate such free form shapes out of a blank or raw material. Free form

shapes can be generated in a variety of ways. It can be machined out of a solid body with a

cutting tool, it could be bent into shape from a sheet metal with impressioned dies. EDM or ECM

with conjugate shaped electrodes could also be employed. Last and probably the most promising

and versatile method, rapid prototyping, can be used to generate free form surfaces. However, in

most instances (except in machining and in rapid manufacturing), it is a case of copying the free

form shape from a pre-existing one, so that, a free form surface would have to physically exist,

from which the required shape would be derived. This is true in case of impressioned die forging,

EDM and ECM. In these cases, the initial shapes (from which the copying is done) is generally

obtained by CNC machining.

Hence CNC machining is the one of the most prevalent methods of generating free form surfaces

and shapes and it will be discussed in detail here.

In free form surface machining, a ball end milling cutter can be employed. However, flat end

milling can also be employed and it can prove to be better than ball end milling. But, for flat end

milling cutter to be used in curved surface machining, ideally, 5-axis machine is required.

Fig

A ball nose milling cutter enables a near-point contact between the cutter and the work piece

surface. This eliminates to a great extent, an undesirable phenomenon called gouging.

The basic idea of free form surface machining with a ball nose cutter is to traverse the whole

surface in to-and-fro (zig-zag) or spiral paths. The cutter actually moves through some points on

the curved surface. In between these points, the cutter moves in straight lines. These points on

the surface are called cutter contact points or CC points. The point on the cutter that comes in

contact with the surface (as the cutter moves along the cutter path) is not a fixed point on the

Fig 1 FFSM with ball

ended milling cutter

cutter (the blue points). In comparison, the red and black points are always fixed on the cutter. If

the cutter has to be moved through the CC points, then for every CC point, we need to find out

the location of the some fixed point on the cutter (like center or bottom most point for example)

and provide it to the CNC machine for movement. For example, in the figure, if the blue points

are the cutter contact points, a movement of radius along the outward normal of the surface at

those points would give us the center locations of the cutter (red points). These are frequently

called the cutter location points. Black points may also be used. The normal can easily be

determined by the cross product of two tangents to the surface at the CC points. In case of Bezier

surface, we can make use of the u- and v- tangents that can be found just by differentiating the

surface wrt u and v.

There are some specific problems encountered during the calculation of cutter paths in free form

surface machining, These are listed as below :

1. Forward step determination

2. Side step determination

3. Gouging

a. External

b. Internal

c. Side

Forward step calculation : The cutter does not actually move continuously along the chosen

cutter paths but through discrete points on such paths or lines.

There has to be a proper criterion for the choice of the length of forward step (i.e., the distance

between the discrete points along the cutter path). This criterion is based on the deviation of the

cutter path from the actual surface. The maximum deviation is made equal to the tolerance on

surface form ( e in fig. 4).

Successive Cutter Positions

Cutter Center Locus

r e r

s

R R

Bezier Surface

Fig 2 Forward Step Calculation

The forward step may be determined in an iterative manner or directly with some

approximations.

There are various ways of determining the forward step. These will be discussed in more detail

after this brief overview of free form surface machining.

Side step determination :

Tool Path Interval

Scallop Height h

Side Step g

Bezeir Surface

Fig 3 Side Step Calculations

Once a cutter has completed a cut from one edge of the surface to another, it shifts by a specific

distance to one side and starts a fresh cut. This is side shift or side step. Side shift has to be

provided so that the cutter can start a fresh cut on the uncut portion of the work surface.

Now, just as in case of forward step determination, there has to be a criterion for the proper

choice of the side step. The main effect of the side step on the work piece surface quality is the

resulting roughness. If too large a side step is chosen, high roughness of the work piece surface

would be obtained. If too low a side step is chosen, it yields a very high surface finish, but

consequently requires a higher machining time. Hence, the choice of the side step should be such

that the roughness of the surface at any point is always equal to (ideally) or less than the

recommended surface roughness.

There are various strategies for the choice of the side shift. They will be discussed in the

appropriate section.

Different strategies of cutter path generation

There are different strategies of cutter path generation in free form surface machining. These

strategies have their own relative advantages and disadvantages.

Some of the methods are :

1. Isoparametric method

2. Isoplanar method

3. Isoscallop method

In the isoparametric method, just as the name suggests, the cutter is made to move along

isoparametric lines as cutter paths. The main advantage of this method is that the determination

of the cutter paths is not computationally intensive. For determining the cutter paths, we only

need to determine points on isoparametric lines on a free form surface. This is simple, non-

iterative and straightforward. Isoparametric method, that way, serves its purpose quite

satisfactorily for surfaces where these lines are more or less parallel.

However, in case of surfaces which deviate from the typical rectangular shape

Fig 7 Clustering and diverging of isoparametric lines in ff surfaces

As shown in fig 7, the isoparametric liones are bunched up or clustered at one end and tend to

diverge at the other. If the cutter is made to follow these lines for machining out the job, it results

in drastic variation of surface roughness from one side of the surface to the other.

Surface roughness, as can be seen from the figure, is unacceptably high at the broad end of the

work piece while it is low at the narrow end. If a number of cutter paths are generated to obtain

Isoparametric lines

Broad end

acceptable surface roughness at the broad end as well, it would result in redundant machining at

the narrow end and subsequently higher machining time.

Side step in isoparametric machining method was determined by a shift along isoparametric lines

orthogonal (in the parametric u-v space) to the one serving as the present cutter path. Side shifts

are calculated at different points on a cutter path along orthogonal (in parametric plane)

isoparametric lines and the next isoparametric lines is chosen as the next cutter path on the basis

of least side shift. However, orthogonality in parametric space does not necessarily imply

orthogonality in physical space. Hence the side shift, which has to necessarily be orthogonal to

the cutter path, might not be so in the physical space and is thus not perfectly correct. However,

sidestep can always be calculated by any other method, to be discussed later in connection to

other strategies.

Isoparametric method finds wide applications simply because it is one of the very first of its kind

to be developed, implemented and commercialized. Further, the aesthetic applications, where

surface roughness is not a limiting criteria, or where a secondary surface finishing process is

possible, isoparametric method of machining is just as good a strategy as the others.

Forward step in isoparametric machining :

The method described under isoscallop machining with co-planar assumption can be followed

here.

Isoplanar machining :

Isoplanar machining is another strategy of cutter path generation in free form surface machining.

In this method, the cutter paths are obtained by the intersection lines between a free form surface

and a number of parallel vertical planes. As the planes are parallel, successive cutter paths are

equispaced when viewed along Z axis. However, this does not necessarily mean that the

roughness (=scallop height) is also the same throughout the lengths of the cuts. This is because

roughness depends not only on the radius of the cutter but also on side step and the radius of

curvature of the surface in a plane normal to the direction of the cutter velocity vector (tangent to

cutter path) at that point. So, of the three (that is, cutter radius, side step and surface curvature),

the first two are made constant in case of isoplanar machining. This ensures that for irregularly

shaped surfaces, machining can be completed by a reasonable (i.e., not so many as in

isoparametric machining) number of cutter paths. Still, the problem is roughness wont be the

same everywhere.

Parallel

Vertical

Planes

u

v Bezeir

Surface

Cutter Paths

Fig 8 Isoplanar Method : The Surface-plane intersection lines

The side step in isoplanar machining method is decided on worst case consideration (like in

isoparametric). At different points along the cutter path, side steps are calculated for acceptable

surface roughness. That step, which is the minimum among these, is chosen. Hence, as

mentioned before, the surface roughness is not uniform but everywhere lower than or equal to

the allowable roughness.

For determining the cutter paths by isoplanar method, intersection curves between free form

surface and planes need to be determined. No straightforward algebraic solution by direct

substitution is possible as the planes are defined in cartesian variables and the freeform surface in

parametric variables. An iterative numerical procedure is employed for determining these

intersection curves. This makes the procedure computationally intensive. In order to determine

the surface-plane intersection curve, first, the intersection point between the plane and one edge

(boundary curve) of the surface is found out. This is done by a curve-plane intersection

algorithm. Once the intersection point is found out, the intersection curve is determined point by

point by a marching process. This is called the surface-plane intersection algorithm.

The curve-plane intersection algorithm

The intersection between a curve and an implicit plane (t) is given by the following

equation

d p r = . with 1 = p

Where, ) , , ( z y x r = : coordinates variables,

) , , ( c b a p = : Unit normal vector of the plane (t) and 1

2 2 2

= + + c b a .

Then the intersection with the isoparametric curve is given by

d p t r = ). ( 0

. ) ( ) ( ) ( d t cz t by t ax + + =

For general parametric curve ) (t r , an intersection point if it exists can be obtained by

using a Newton-Raphson iteration scheme starting from an initial guess point ) (t r .

Assuming linearity of the curve between the initial guess point

0

t and a estimated

intersection point t :

,

.

r , . ( t -

0

t ) u cos / e ~

Where, ) ) ( . (

0

d t r p e = ,

= u cos (

.

r . p ) / ,

.

r ,.

From the above relation, the estimated intersection point t

is obtained as t =

0

t - {( r p. (

0

t ) d )} / (

.

r . p )

Where,

.

r = dt t dr / ) (

at

0

t ,

a,b,c: Cofficients of plane equation.

Fig 9 Curve/plane intersection

Intersection between a surface and a plane

The intersection curve between the a isoparametric surface ) , ( v u r and the plane (t)

given by

d p v u r = ). , ( 0

d v u cz v u by v u ax + + = ) , ( ) , ( ) , (

Where c b a , , and d are the cofficients of implicit plane.

Two cases may arise in intersecting the parametric surface ) , ( v u r with the plane (t). The

resulting intersection may be either an open curve or a closed curve. In either case, the

overall procedure for solving above equation consists of three steps:

(a) detection of initial guess points,

(b) marching , and

(c) refinement.

The initial intersection points are obtained by finding intersection points between patch

boundary curves and the plane. For this, the CPI (curve/plane intersection) procedure

may be employed. Having determined initial points, the next step is to define a marching

vector. The unit marching vector c is taken to be a vector perpendicular to both the

surface normal and plane normal.

Namely,

p n p n c = / ) (

Where,

v u v u

r r r r n = / ) ( is the unit normal to surface and p is the unit normal to

plane (t).

The next step is to determine a guess point for the next intersection along the intersection

curve. The increments u A and v A of the domain values are determined by solving the

following linear equations:

0 ) . ( ) . ( = +

v u

r p v r p u A A (1)

o A A = + ) . ( ) . (

v u

r c v r c u (2)

Where, o : 3D stepping distance ,

c : Marching vector,

v u

r r , : Partials of the surface ) , ( v u r .

Let ) , (

0 0

v u denote the current intersection point, then the guess point for the next

intersection point is given by

0

u u u + = and

0

v v v + =

Finally the estimated intersection point ) , ( v u is refined to obtain a true intersection point

) , (

- -

v u . For this, one of the isoparametric curves which is more parallel to p is selected

and then the CPI is applied along that isoparametric curve to get exact intersection point.

For this the following condition is tested:

If ] / ) . ( / ) . [(

v v u u

r p r r p r > then

Perform CPI between ) , ( ) ( v t r t r and plane (t) to obtain

* *

t u = and v v =

*

Else perform CPI between ) , ( ) ( t u r t r and plane (t) to obtain u u =

*

and

* *

t v =

Fig 10 Surface/plane intersection

Hence the steps followed for the cutter path generation (as the intersection of vertical plane and

surface)

1. Find out the first point of the cutter path by CPI between plane and edge curve of surface.

2. Find out the radius of curvature at that point on the surface in the direction of the

intersection with vertical plane (expression of radius of curvature would be provided in

next notes)

3. The form tolerance (=max deviation of cutter path from curved surface)

4. Find out the forward step (blue line of fig 2) that can be taken at that point by

approximating the local curved surface by a circle of radius of curvature found in 2.

5. Apply the forward step thus obtained in SPI algo to get delta u and delta v. Get next point

on intersection curve.

6. Refine next point as suggested by application of CPI between isoparametric through

solution of 5 and the vertical plane

7. Move to the next step

S-ar putea să vă placă și

- Diff Erential Geometry of Curves and Surfaces: Kristopher TappDocument370 paginiDiff Erential Geometry of Curves and Surfaces: Kristopher TappMarcus Vinicius Sousa Sousa100% (10)

- Creating A Hull Lines Plan With RhinoDocument17 paginiCreating A Hull Lines Plan With RhinoNadia Ordoñez100% (4)

- Module MODERN-geometry For 1ST MidtermsDocument90 paginiModule MODERN-geometry For 1ST MidtermsEUGENE D. GABRIEL, MSE100% (1)

- (Michael Farber) Invitation To Topological RoboticDocument145 pagini(Michael Farber) Invitation To Topological RoboticLeonora C. Ford100% (3)

- (Episteme 7) Roberto Torretti (Auth.) - Philosophy of Geometry From Riemann To Poincaré-Springer Netherlands (1978)Document472 pagini(Episteme 7) Roberto Torretti (Auth.) - Philosophy of Geometry From Riemann To Poincaré-Springer Netherlands (1978)Mário Raia NetoÎncă nu există evaluări

- Modern Geometric Structures and Fields ContentsDocument9 paginiModern Geometric Structures and Fields Contentsggl_plxÎncă nu există evaluări

- GibbsCAM TutorialDocument39 paginiGibbsCAM Tutorialrodrigodalvit0% (2)

- Freeform Surface Modeling 07Document44 paginiFreeform Surface Modeling 07Ali BirÎncă nu există evaluări

- 3D Tool OffsetDocument28 pagini3D Tool OffsetKiên Trung NguyễnÎncă nu există evaluări

- Basic Curves and Surface Modeling - CADDocument69 paginiBasic Curves and Surface Modeling - CADDr. Ajay M PatelÎncă nu există evaluări

- Slicing and Contour DataDocument16 paginiSlicing and Contour DataShubham SharmaÎncă nu există evaluări

- Surface Swept by A Toroidal Cutter During 5-Axis MachiningDocument10 paginiSurface Swept by A Toroidal Cutter During 5-Axis MachiningJulen MartinezÎncă nu există evaluări

- Survey QPDocument10 paginiSurvey QPRanjith KumarÎncă nu există evaluări

- Module 8 - Setting Out HZ Alignment - 10Document10 paginiModule 8 - Setting Out HZ Alignment - 10Hisham Abou HalimaÎncă nu există evaluări

- CG 5Document68 paginiCG 5pankajchandre30Încă nu există evaluări

- Freeform Surface Modelling: Freeform Surface Modelling Is The Art of Engineering Freeform Surfaces With ADocument4 paginiFreeform Surface Modelling: Freeform Surface Modelling Is The Art of Engineering Freeform Surfaces With ASahil SharmaÎncă nu există evaluări

- Bahir Dar University School of Civil and Water Resource EngineeringDocument40 paginiBahir Dar University School of Civil and Water Resource EngineeringMichael AssefaÎncă nu există evaluări

- Catia Difference Tangent Curvature Curve and Surface AnalysisDocument14 paginiCatia Difference Tangent Curvature Curve and Surface AnalysismeteorATgmailDOTcomÎncă nu există evaluări

- Computer Analysis of Drill Point GeometryDocument14 paginiComputer Analysis of Drill Point GeometryLuis FelipeÎncă nu există evaluări

- GEE142 - Module 1Document7 paginiGEE142 - Module 1WENARD SESUELOSÎncă nu există evaluări

- Terminology Civil 3DDocument38 paginiTerminology Civil 3Dsachinsaklani23Încă nu există evaluări

- Assignment 2 CadmDocument15 paginiAssignment 2 CadmLowEnd GamerÎncă nu există evaluări

- Unit 2 (Detail)Document123 paginiUnit 2 (Detail)vishwajeet patilÎncă nu există evaluări

- 2.1. Representation of Curves: Geometric ModelingDocument88 pagini2.1. Representation of Curves: Geometric ModelingSrinith KumarÎncă nu există evaluări

- 2.1. Representation of Curves: Geometric ModelingDocument88 pagini2.1. Representation of Curves: Geometric ModelingSrinith KumarÎncă nu există evaluări

- Chapter 5 PDFDocument8 paginiChapter 5 PDFEngnr JavidiÎncă nu există evaluări

- Unit-1 (I) DESIGN OF PATTERNS, MOULDS, CORESDocument11 paginiUnit-1 (I) DESIGN OF PATTERNS, MOULDS, CORESTisha SetiaÎncă nu există evaluări

- Cad Cam R20 Unit 2Document71 paginiCad Cam R20 Unit 2ERRI TEJAKUMARÎncă nu există evaluări

- Lecture 4 (Compatibility Mode)Document26 paginiLecture 4 (Compatibility Mode)Anonymous dGnj3bZÎncă nu există evaluări

- Straightness With AutocollimatorDocument5 paginiStraightness With Autocollimatorash1968Încă nu există evaluări

- Civil 3D GlossaryDocument15 paginiCivil 3D GlossaryAh Naweed Najeeb SakhaÎncă nu există evaluări

- Tacheometry - Stadia System: KS SinDocument48 paginiTacheometry - Stadia System: KS SindoggyÎncă nu există evaluări

- 3-Axis NC Tool Path Generation and Machining Simulation For Subdivision Surface of Complex ModelsDocument9 pagini3-Axis NC Tool Path Generation and Machining Simulation For Subdivision Surface of Complex ModelssaaÎncă nu există evaluări

- Digital Image Processing WorkshopDocument50 paginiDigital Image Processing WorkshopAbhinav GuptaÎncă nu există evaluări

- Descriptive Geo NotesDocument12 paginiDescriptive Geo NotesAlven T BactadÎncă nu există evaluări

- CG 6Document26 paginiCG 6pankajchandre30Încă nu există evaluări

- Introduction To Open GL: by Rama Satish KV Visiting Professor, WASEDocument38 paginiIntroduction To Open GL: by Rama Satish KV Visiting Professor, WASEsatishkvrÎncă nu există evaluări

- Unit 3 More Output Primitives and Geometric TransformationsDocument24 paginiUnit 3 More Output Primitives and Geometric TransformationsMuhammad SahilÎncă nu există evaluări

- 202003281454236324akankhas Yadav Computer GraphicsDocument9 pagini202003281454236324akankhas Yadav Computer Graphicsparatevedant1403Încă nu există evaluări

- Pen atDocument8 paginiPen atSkyr DabÎncă nu există evaluări

- CagdDocument9 paginiCagdjazzy075Încă nu există evaluări

- How To Calculate Cut and Fill AccuratelyDocument8 paginiHow To Calculate Cut and Fill AccuratelyWan MahiramÎncă nu există evaluări

- Computer Graphics Imp QuesDocument23 paginiComputer Graphics Imp QuesDr. MANU SINGH KEC (CSE)Încă nu există evaluări

- ECE 2306 NOTES I Jan2014Document22 paginiECE 2306 NOTES I Jan2014TinaÎncă nu există evaluări

- Lec 39Document30 paginiLec 39RamanÎncă nu există evaluări

- The Stencil Buffer Sweep Plane Algorithm For 5-Axis CNC Tool Path VerificationDocument14 paginiThe Stencil Buffer Sweep Plane Algorithm For 5-Axis CNC Tool Path VerificationHuy TranÎncă nu există evaluări

- Curves For Computer Aided Geometric DesignDocument21 paginiCurves For Computer Aided Geometric Designsri999Încă nu există evaluări

- Surface Roughness Significance and SymboDocument18 paginiSurface Roughness Significance and SymboStefan NikolićÎncă nu există evaluări

- GMSvadakara AnswerDocument22 paginiGMSvadakara AnswerirshadÎncă nu există evaluări

- Basic Surveying 15Cv34Document23 paginiBasic Surveying 15Cv34Ajeeth BÎncă nu există evaluări

- Parametric Spur GearDocument11 paginiParametric Spur GearGoutam AcharjeeÎncă nu există evaluări

- Measurement: Block FlatnessDocument16 paginiMeasurement: Block Flatnessفرح تامرÎncă nu există evaluări

- Harris-A Combined Corner and Edge DetectorDocument6 paginiHarris-A Combined Corner and Edge DetectorAfortunatovÎncă nu există evaluări

- CADM Unit Geometric Modeling - SurfacesDocument31 paginiCADM Unit Geometric Modeling - SurfacesWilsonÎncă nu există evaluări

- Coordinat Lines, and Point 2Document10 paginiCoordinat Lines, and Point 2yahya rizkiÎncă nu există evaluări

- Surface RoughnessDocument6 paginiSurface RoughnessIltefatÎncă nu există evaluări

- Contour SurveyingDocument14 paginiContour SurveyingAnkit JenaÎncă nu există evaluări

- Civil 3D, The ModernDocument60 paginiCivil 3D, The ModernCarlos Macedo CarvalhoÎncă nu există evaluări

- VR Unit 2& 3Document18 paginiVR Unit 2& 3WWE OFFICAL MATCH CARDS.Încă nu există evaluări

- Analytic SurfacesDocument50 paginiAnalytic SurfacesMayank Balu GhugretkarÎncă nu există evaluări

- Chapter 4 CurvesDocument21 paginiChapter 4 CurvesN Dhanunjaya Rao BorraÎncă nu există evaluări

- Bresenham Line Algorithm: Efficient Pixel-Perfect Line Rendering for Computer VisionDe la EverandBresenham Line Algorithm: Efficient Pixel-Perfect Line Rendering for Computer VisionÎncă nu există evaluări

- Standard-Slope Integration: A New Approach to Numerical IntegrationDe la EverandStandard-Slope Integration: A New Approach to Numerical IntegrationÎncă nu există evaluări

- Planar Linkage Synthesis: A modern CAD based approachDe la EverandPlanar Linkage Synthesis: A modern CAD based approachÎncă nu există evaluări

- Pinhole Camera Model: Understanding Perspective through Computational OpticsDe la EverandPinhole Camera Model: Understanding Perspective through Computational OpticsÎncă nu există evaluări

- MathDocument8 paginiMath66 SB jay gotiÎncă nu există evaluări

- CalcIII Complete PracticeDocument44 paginiCalcIII Complete PracticeKenÎncă nu există evaluări

- Mathematical Methods of Physics-Collection of Problems and SolutionsDocument30 paginiMathematical Methods of Physics-Collection of Problems and Solutionskateey27100% (1)

- ATT13 IeconDocument6 paginiATT13 IeconJohn ArvanitakisÎncă nu există evaluări

- Analysis, Construction and Design of Origami Inspired StructuresDocument151 paginiAnalysis, Construction and Design of Origami Inspired Structuresrahulvaish123Încă nu există evaluări

- From at Sheets To Curved Geometries: Origami and Kirigami ApproachesDocument24 paginiFrom at Sheets To Curved Geometries: Origami and Kirigami ApproachesAnish PradeepÎncă nu există evaluări

- Eleven Properties of The Sphere: David Hilbert Stephan Cohn-Vossen PlaneDocument25 paginiEleven Properties of The Sphere: David Hilbert Stephan Cohn-Vossen Planegilda ocampoÎncă nu există evaluări

- An Introduction To Differential Geometry by TJ Willmore Oxford at The Clarendon Press 1959 317 Pages 35 ShillingsDocument3 paginiAn Introduction To Differential Geometry by TJ Willmore Oxford at The Clarendon Press 1959 317 Pages 35 ShillingsYaksha AllolaÎncă nu există evaluări

- Alagappa University, Karaikudi M.SC., Mathematics - Programme StructureDocument33 paginiAlagappa University, Karaikudi M.SC., Mathematics - Programme StructureMathan NaganÎncă nu există evaluări

- Static Electric FieldsDocument175 paginiStatic Electric FieldsAli Ahmad100% (1)

- M.a.M.sc. Part I Mathematics (Ext - Reg I) 09Document23 paginiM.a.M.sc. Part I Mathematics (Ext - Reg I) 09nabakumarj9Încă nu există evaluări

- 3778 - Advances in Architectural Geometry 2016 - OA PDFDocument408 pagini3778 - Advances in Architectural Geometry 2016 - OA PDFJhon BeltranÎncă nu există evaluări

- Developable Compliant-Aided Rolling-Contact MechanismsDocument19 paginiDevelopable Compliant-Aided Rolling-Contact MechanismsShaira BuenaaguaÎncă nu există evaluări

- A Note On Planar Hexagonal MeshesDocument13 paginiA Note On Planar Hexagonal MeshesparatinadanaÎncă nu există evaluări

- Surfaces Of Revolution With Prescribed Mean Curvature: Tδhoku Math. Journ. 32 (1980), 147-153Document8 paginiSurfaces Of Revolution With Prescribed Mean Curvature: Tδhoku Math. Journ. 32 (1980), 147-153Jhon Edison Bravo BuitragoÎncă nu există evaluări

- Minobb Jylanki 2015 06 01 PDFDocument13 paginiMinobb Jylanki 2015 06 01 PDFHistoric Shi Tpa TownÎncă nu există evaluări

- Calculus Expert TOCDocument10 paginiCalculus Expert TOCAnaLuManoleÎncă nu există evaluări

- Surveying: For Environmental Health Science StudentsDocument191 paginiSurveying: For Environmental Health Science StudentsJairos Shinzeh100% (1)

- MATDocument26 paginiMATSadekur RahmanÎncă nu există evaluări

- Oodesign Fem JavaDocument10 paginiOodesign Fem JavaKo Than SoeÎncă nu există evaluări

- MATH3968 Lecture 1: DR Emma Carberry 28 July 2009Document5 paginiMATH3968 Lecture 1: DR Emma Carberry 28 July 2009TOM DAVISÎncă nu există evaluări

- Textbook On SP Her I 033273 MBPDocument88 paginiTextbook On SP Her I 033273 MBPShivendra DixitÎncă nu există evaluări

- 01 Csikos Differential GeometryDocument354 pagini01 Csikos Differential GeometryAqua100% (1)

- Differential Geometry of SurfacesDocument21 paginiDifferential Geometry of Surfacesjosgau100% (1)