Documente Academic

Documente Profesional

Documente Cultură

Etch Rates... Michael

Încărcat de

Mark SchvartzmanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Etch Rates... Michael

Încărcat de

Mark SchvartzmanDrepturi de autor:

Formate disponibile

Home

Search

Collections

Journals

About

Contact us

My IOPscience

Etch rates of crystallographic planes in Z-cut quartz - experiments and simulation

This article has been downloaded from IOPscience. Please scroll down to see the full text article. 1998 J. Micromech. Microeng. 8 1 (http://iopscience.iop.org/0960-1317/8/1/001) View the table of contents for this issue, or go to the journal homepage for more

Download details: IP Address: 132.77.4.43 The article was downloaded on 21/02/2011 at 12:31

Please note that terms and conditions apply.

J. Micromech. Microeng. 8 (1998) 16. Printed in the UK

PII: S0960-1317(98)82025-1

Etch rates of crystallographic planes in Z -cut quartzexperiments and simulation

Pelle Rangsten, Christer Hedlund, Ilia V Katardjiev and Ylva Backlund

Department of Materials Science, The Angstrom Laboratory, Uppsala University, Box 534, S-751 21 Uppsala, Sweden Received 20 February 1997, accepted for publication 25 November 1997 Abstract. The anisotropic etching behaviour of monocrystalline quartz is studied both experimentally and with computer simulations. The etch rate minima were identied as the crystal planes m , r , r2 , s and s4 . Various shapes and initial structures, both concave and convex, have been produced by etching quartz wafers in an HF:NH4 F solution. These have been subsequently analysed with a scanning electron microscope (SEM). Etch rates of both slow- and fast-etching crystal planes have been measured. The data thus obtained were fed into topography evolution software and a number of experimental proles were compared with the simulated ones. To verify the work, a 3.5 m thick membrane was manufactured in a two-step double-sided etching process. This illustrates the usefulness of the data obtained, as well as the power of the simulations.

1. Introduction Quartz is a material of great interest in microsystems technology [16]. It exhibits interesting properties which complement those of silicon. A major obstacle limiting the wide use of quartz is that there exists a limited variety of suitable processing methods for producing structures with desired shapes. Wet chemical etching is a classical processing method, but the high degree of anisotropy and the trigonal symmetry of the quartz crystal hinders its study and use. Wet etching of quartz is mainly done in aqueous hydrouoric acid (HF), often in combination with ammonium uoride (NH4 F) as a buffer. The etched proles vary greatly with process conditions, most notably the etchant concentration and temperature. The etch rate is always much larger along the Z-axis as compared to other directions [711]. The most complete etching diagram so far was established by Ueda et al, who systematically studied the normal etch rate of 21 substrates, all cut with different crystallographic orientations. The etchant was ammonium biuoride HF:NH4 F (2:3), at 82 C [12]. This paper concentrates on experimental etch studies of quartz with wet chemical etching in an etchant mixture of HF:NH4 F (2:3) at 55 C. Our earlier investigations showed that this etchant solution produces smooth surfaces and still possesses an interesting anisotropic behaviour [13]. The long-term goal of these studies is to collect comprehensive and reliable data on the crystallographic dependence of

E-mail address: Pelle.Rangsten@Material.uu.se 0960-1317/98/010001+06$19.50 c 1998 IOP Publishing Ltd

the etch rate of quartz. These data can be used for various purposes: to stimulate and complement theoretical studies of the etch mechanisms, to acquire practical know-how in view of industrial applications, as well as for use in computer simulations of general structures in quartz. The latter is an important part of modern research. The research community would benet substantially from sharing experience and utilizing advanced methods for the description of surface evolution already widely used in microelectronics [14]. Although efforts are being made in this direction, they are lagging far behind the advances in microelectronics [15, 16]. 1.1. Wet etching and prole simulations 1.1.1. Measurement methods. When anisotropic wet etching is performed through a mask opening a concave structure develops dened by the slowest-etching planes. Once the dependence of the dissolution rate with respect to the orientation is known, it is possible to predict the resulting prole by graphical methods such as the WulffHerringJacodine construction [17, 18]. This will sufce in many cases if the micromachined structures are bounded by slow-etching planes only, which is true in most cases of micromachining of silicon. Nevertheless, there is a growing number of situations where prediction of the evolution of a general shape (not only concave) would be very advantageous both for process optimization and development cost. In the quartz case, for instance, simultaneous etching from both sides of the wafer is much

1

P Rangsten et al

more common, especially when fabricating oscillating tuning forks. All this motivates the development and the use of topography simulators. The latter require knowledge about the full angular dependence of the etch rate, not only for slow-etching planes. Fast-etching planes develop if a sphere or some other convex structure is etched. A sphere exposes all crystallographic orientations to the etchant and hence the evolving shape of an etched sphere is dictated by the fastetching planes. Acquiring a complete angular dependence of the etch rate is by no means a trivial task. The theoretical understanding of the anisotropy i.e. the behaviour of the etch rate is still being debated in the literature [19]. Different experimental techniques have been presented to determine the etch rate as a function of crystallographic orientation: the wagon wheel method [20], etching of spheres [21] or direct measurement of the etch rate of a planar surface with a specic crystallographic orientation [12]. All methods mentioned above have their advantages and drawbacks, but none quite suits the purposes of this study. Therefore, it was decided to study the etch rate using specially designed concave and convex structures formed by etching through rectangular mask openings oriented along specic crystallographic directions. 1.1.2. Prole simulations. The data obtained from the above measurement method were then fed into a twodimensional topography simulator called 2DINESE. The latter is built on a solid and widely accepted theoretical model of surface evolution [14] and uses robust numerical methods specially developed to numerically solve the equations in the theoretical model. The basic notion of this theory is that the motion of the surface (or an interface) is equivalent to that of an advancing wavefront and as such obeys general geometrical wave propagation laws. Specically, evolution of smooth surfaces is described by the following non-linear hyperbolic differential equation: S + c gradr S = 0 t (1)

model allows the construction of powerful numerical methods for surface reconstruction and is shown to correctly treat edge and surface propagation. The two-dimensional topography simulator 2DINESE is built on the basis of this model and is used for the simulations in this work. 1.2. Quartz crystal structure Quartz has numerous crystalline phases. The stable phases with crystallization points below 573 C are called -quartz. If crystallization takes place between 573 and 870 C instead, -quartz is formed. This phase has a hexagonal crystal symmetry in contrast to the trigonal symmetry of -quartz. When making the phase transition from -quartz to -quartz, so-called twinning occurs and the piezoelectric properties of -quartz are lost. Quartz is enantiomorphous, i.e. -quartz occurs in both right- and left-handed crystals. We study right-handed -quartz exclusively which in the remainder of this work is referred to as quartz. -quartz belongs to the trigonal holoaxial class, No 18, in the trigonal system. It is characterized by one axis of threefold symmetry, called the optical axis (Z-axis). Perpendicular to the Z-axis are the three electrical X-axes, each with a twofold symmetry. Each X-axis bisects the angle between two prismatic faces and, together with one mechanical Y -axis which emerges orthogonal from a prismatic face, constitute a rectangular system [23]. Figure 1 shows the natural crystallographic planes and a projection on the XY -plane in a right-handed -quartz crystal. The R- and r-planes are rhombohedral planes, m-planes are the hexagonal prism planes, the trigonal trapezoid is denoted as x and the trigonal bipyramidal planes as s. The natural planes can also be given in crystallographic indices (hkil) as exemplied in gure 1(b). Higher-order planes, such as the r2 -plane, are dened by multiplying the Z-component of the crystallographic index with an integer. Resonating structures for frequency control are batch fabricated from quartz wafers. If the wafers are cut perpendicularly to the Z-axis (Z-cut) the oscillation frequency is temperature dependent. To overcome this, one uses a different cut which compensates this frequency drift. The most popular compensation cut is called ATcut and is close to the rhombohedral plane R. There exist a large number of other compensation cuts each suitable for its specic purposes. Although these cuts are the most interesting for industrial applications, etch rate measurements of different crystallographic planes are most conveniently made on Z-cut quartz. 2. Experiments In this study Z-cut monocrystalline quartz wafers were used. The wafers were rectangular 1.5 in 1.5 in samples, 200 m thick, polished, and coated with Cr/Au on both sides by the supplier Micro Crystal (ETA SA, CH-2540 Grenchen, Switzerland). The etching patterns were dened in the mask layer by standard photolithographic techniques using positive photoresist (Shipley 1813). The Au and Cr

where gradr = (/x, /y, /z) and where c is the normal erosion/growth rate (which is a function of the crystallographic orientation of the surface) and the function S describes surface position at all times through the algebraic equation: S(x, y, z, t) = 0. (2)

Equation (1) is a HamiltonJacobi equation which is readily solved through the method of characteristics [22]. Commonly, however, the surface either possesses or consequently develops edges (angular discontinuities) during etching/growth in which case the above formalism is inapplicable. This is commonly the case of anisotropic etching of quartz, silicon etc. A further generalization of the wave approach to surface evolution has been recently developed by Katardjiev et al [14], which uses a modied version of the Huygens wavefront reconstruction principle to accommodate anisotropic propagation processes. This

2

Etch rates in Z -cut quartz; experiments and simulation

Figure 2. The denition of X - and Y -grooves and the measured parameters.

Figure 1. Schematic drawings of a right-handed -quartz crystal (a) and its projection on the XY -plane (b). The three X -axes in the gure show the trigonal symmetry. Only one of the Y -axes is shown in the gure. The letters R , r , m , x and s denote the natural main crystal planes in quartz. The dimensions in the unit cell are a = 4.904 A and c = 5.394 A.

the indices of the crystallographic planes as well as measure the etch rates of a number of slow-etching planes. This was done by direct measurements from cross-sectional SEM micrographs. To obtain the etch rates and orientations of fast-etching planes, we continued to process these concave structures as follows. The masks were stripped and the convex structures (convex top edges) thus obtained were etched further to determine the etch rates of fast-etching planes. By varying the etch time between 60 and 180 minutes one or more fast-etching planes developed at various convex corners. The wafers were then diced perpendicularly to the etched grooves and cross-sectional SEM micrographs were taken. In this way, by varying the initial shapes of the etched structures as well as their orientation, we obtained a relatively comprehensive set of data describing the crystallographic dependence of the etch rates in the X- and Y -directions. 3. Results and discussion As far as we know, nobody has been able to identify the crystal planes that appear when etching Z-cut quartz through a mask. In this study we not only identify these planes as planes m, r, r2 , s and s4 , but also have determined the following relative etch rates of the crystal planes: m < r < s < r2 < s4 . Two of the triangular openings are shown in gure 3. The slow-etching vertical m-planes are not seen from this angle of view. As noted above the absolute etch rates and orientations were extracted from SEM micrographs. To illustrate that the slowest-etching planes dictate the shape of concave structures, gure 4(a) shows the evolution of four Xgrooves with four different initial widths, 105, 75, 55 and 35 m respectively. Figure 4(b) represents the 2DINESE simulation of the same structure. It is also evident that slightly faster-etching planes gradually disappear with time and the nal shape is solely determined by the two slowestetching planes. This indicates that fast-etching local minima may appear for very short times; others may not appear at all. Hence, this measurement method, as most others, does not guarantee that the data obtained form a complete set. However, all dominating minima and maxima

3

layers were etched in a KI solution and a chromium etch (Merck) respectively. The quartz etchant was a mixture of HF (aqueous solution of 49.5 wt%) and NH4 F (aqueous solution of 39.5 wt%) in proportions HF:NH4 F = 2 : 3. The etchant was kept at a constant temperature of 55 C in a Teon beaker with a cooled lid, in a water bath with stirring. To identify the relative etch rates for some crystal planes a mask pattern with triangular openings of different sizes was produced. The mask openings were aligned along the three X- and Y -axes respectively. The etch times were chosen so that the largest openings displayed all crystal planes of interest. By studying smaller openings and longer etch times we noted which of the planes still remained in the concave structure. This allowed determination of the relative etch rates since the fastest-etching planes disappear rst. To gather more quantitative information of the etch rates for the different crystallographic planes, cross-sections of rectangular openings aligned in the same directions as the triangles (further referred to as X- and Y -grooves) were examined and etch rates of surviving planes determined (see gure 2). By etching such rectangular openings of various widths for various times, from 90 to 270 minutes, we could identify

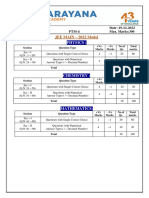

P Rangsten et al Table 1. Measured angular dependence of the etch rate in the Y - and X -directions respectively together with the indices of the identied planes. Angle [ ] Etch rate [m h1 ] Plane Index (hkil )

Y -groove

0 36 70 90 98 118.8 135 155.5 165.5 180 0.85 32 30 27 27.5 11.1 12 1.73 5 1.23

1120 z s4 s 0001 1124 1121 1120

X -groove

Figure 3. Triangles, 500 m in side, aligned along the X -axes, etched in 6 hours, verify the etch rates when the planes gradualy disappear. 0 10 38.2 50 57.6 90 134 147 180 0.85 4 0.98 20 4.11 27 11.9 19.5 0.85

m r r2 z m

0110 0111 0112 0001 0110

Figure 5. Polar plot of the measured angular dependence of the etch rate in the X - and Y -directions respectively. Additional points as suggested by the simulations are represented as dashed vectors.

Figure 4. A SEM micrograph (a) showing the evolution in four X -grooves with four different widths. A DINESE simulation of the same mask openings is shown in (b).

in the etch rate, which determine the evolution of both concave and convex structures, were found. The results from the identication and indexation together with the measurements of slow- and fast-etching planes are summarized in table 1 and graphically presented in gure 5. The dashed line in the latter is drawn arbitrarily to guide the eye. The data set of etch rates thus obtained was fed into the topography simulator 2DINESE [14] to simulate the evolution in both convex and concave structures. As

4

indicated above, 2DINESE is built on a robust theoretical model of surface evolution and does not introduce numerical errors of its own. Hence the accuracy of the simulated proles is solely determined by the accuracy of the etch rate data as well as the completeness of the data set. Therefore, such simulations may also provide a kind of feedback information about the precision of the data, as well as whether there are signicant data points missing from the data set by comparing the simulated and the experimental proles. In almost all comparisons between experiment and simulation the agreement was more than satisfactory. In a few special cases, however, the simulated proles exhibited planes which were not observed during corresponding experiments. In order to suppress the appearance of planes not observed in the experimental proles a minimal set of additional data points was added between the minima and maxima to change the shape of the angular dependence. The positions as well as the

Etch rates in Z -cut quartz; experiments and simulation

4. Conclusions From the experimental and simulation results presented in this work one can draw the following conclusions. The various masks used, especially the rectangular mask openings, are well suited for studying the crystallographic dependence of the etch rates. By producing suitable initial structures for subsequent etching and analysis we could obtain a relatively comprehensive set of data on the anisotropic etching behaviour. The good agreement between experiments and simulations indicates that we have succeeded in identifying the signicant planes during etching in HF:NH4 F in our measurements. However the etch rate of the x- and R-planes could not be measured, since they did not appear in the Y -grooves. The advantage of combining experiment and simulation is demonstrated via a specic case where the simulations indicated the omission of signicant points in the data set. The positions as well as the magnitudes of the etch rates for these orientations were determined by iterative simulations and comparison with experiment. Thus computer simulations have proved very useful in searching for and localizing the position of signicant points other than maxima or minima. It is also clear from this work, however, that to obtain a full set of data for all directions in quartz, a combined theoretical [12, 25] and experimental approach is needed to avoid the time-consuming deductive comparison between experiment and simulation to establish the true shape of the angular dependence.

Figure 6. A comparison between a simulated membrane (a) and an etched verication structure (b). The wafer was rst etched in 210 min before stripping of the Au/Cr mask and another 135 min etching was performed in 2:3 HF:NH4 F, 55 C. The membrane thickness is 3.5 m.

Acknowledgments We would like to acknowledge Associate Professor Jan S derkvist for initiating and encouraging this project, o and the Swedish Board for Industrial and Technical Development (NUTEK) for nancial support.

magnitudes of additional points were improved through an iterative process of data modication and simulation until a satisfactory agreement with experimental proles was achieved. These additional points are represented by dashed vectors in gure 5. It is also noted that the added data points can be determined experimentally only by specically cutting the crystal along their corresponding planes and performing direct measurements. Such studies have not been performed by us at this stage. The disagreement between experiment and simulation in this particular case indicates that the shape of the etch rate minima is important. This has also been conrmed for etching of silicon with KOH, where some peculiarities around the 111 orientation have been observed [19]. In the silicon case the shape around this minimum is shown to be rather at, approximately 2 degrees wide [24]. To illustrate the usefulness of the data obtained in this work, as well as the power of the simulations, gure 6 shows a simulation of the evolution of etched grooves from both the top and bottom sides of the wafer, compared to the actual etched grooves. The resulting structure in this case is a membrane, 3.5 m thick, dened by the relatively slowly etching r-planes. Initially the wafer was etched for 210 min with a Au/Cr mask. This mask was then removed and the structure was etched for an additional 135 min.

References

[1] Ueda T, Kohsaka F, Yamazaki D and Iino T 1985 Quartz crystal micromechanical devices Proc. 3rd Int. Conf. on Solid-State Sensors and Actuators, Transducers 85 (Tokyo, 1985) pp 1136 [2] Eernisse E, Ward R W and Wiggins R B 1988 A survey of quartz bulk resonator sensor technologies IEEE Trans. Ultrason. Ferroelectr. Frequency Control UFFC-35 32330 [3] Danel J S and Delapierre G 1991 Quartz: a material for microdevices J. Micromech. Microeng. 18798 [4] Toshiyoshi H, Fujita H, Kawai T and Ueda T 1993 A piezoelectrically operated optical chopper by quartz micromachining Proc. 7th Int. Conf. on Solid-State Sensors and Actuators, Transducers 93 (Yokohama, 1993) pp 12831 [5] S derkvist J 1994 Micromachined gyroscopes Sensors o Actuators A 43 6571 [6] Hjort K, Thornell G and Schweiz J-A 1996 Quartz micromachining by lithographic control of ion track etching Appl. Phys. Lett. 69 34356 [7] Lazorina E I and Soroka V V 1974 Etching of quartz and some features of the surface layer Sov. Phys.Crystallogr. 18 6513 5

P Rangsten et al [8] Soroka V V, Lazorina E I and Stepanchuk V N 1977 Theory of the etching of quartz in hydrouoric acid Sov. Phys.Crystallogr. 22 61921 [9] Suda P, Zumsteg A E and Zingg W 1979 Anisotropy of etching rate for quartz in ammonium biuoride Proc. 33rd Annu. Symp. on Frequency Control pp 35963 [10] Tellier C R 1982 Some results on chemical etching of AT-cut quartz wafers in ammonium biuoride solutions J. Mater. Sci. 17 134854 [11] Vondelig J K 1983 Fluoride-based etchants for quartz J. Mater. Sci. 18 30414 [12] Ueda T, Kohsaka F, Iino T and Yamaaki D 1987 Theory to predict etching shapes in quartz crystal and its application to design devices Trans. Soc. Instrum. Contr. Eng. 23 12338 (in Japanese) [13] Hedlund C, Lindberg U, Bucht U and S derkvist J 1993 o Anisotropic etching of Z-cut quartz J. Micromech. Microeng. 3 6573 [14] Katardjiev I V, Carter G, Nobes M J, Berg S and Blom H-O 1994 Three-dimensional simulation of surface evolution during growth and erosion J. Vac. Sci. Technol. A 12 618 (see also http://mises.teknikum.uu.se/ilia/) [15] Danel J S and Delapierre G 1992 Anisotropic crystal etching: a simulation program Sensors Actuators A 31 26774 [16] S quin C H 1992 Computer simulation of anisotropic e crystal etching Sensors Actuators A 34 22541 [17] Jacodine R J 1962 Use of modied free energy theorems to predict equilibrium growing and etching shapes J. Appl. Phys. 33 26427 [18] Shaw D W 1979 Morphology analysis in localized crystal growth and dissolution J. Cryst. Growth 47 50917 [19] Elwenspoek M 1996 The form of etch rate minima in wet chemical anisotropic etching of silicon J. Micromech. Microeng. 6 4059 [20] Seidel H, Csepregi L, Heuberger A and Baumg rtel H a 1990 Anisotropic etching of crystalline silicon in alkaline solutions J. Electrochem. Soc. 137 361226 [21] Ward R W 1993 Etching of quartz crystal spheres Proc. 46th Annu. Symp. on Frequency Control (Salt Lake City, UT, 1993) (New York: IEEE) pp 3906 [22] Whittam G B 1975 Linear and Nonlinear Waves (New York: Wiley) p 65 [23] Cady W G 1964 Piezoelectricity: an Introduction to the Theory and Applications of Electromechanical Phenomena in Crystals vol 1 (New York: Dover) [24] Uenishi Y, Tsugai M and Mehregany M 1995 Micro-optomechanical devices fabricated by anisotropic etching of (110) silicon J. Micromech. Microeng. 5 30512 [25] Tellier C R and Leblois T G 1993 Bi- and three-dimensional prediction of etching shapes in quartz micromachined structures Proc. 47th Annu. Symp. on Frequency Control (Salt Lake City, UT, 1993) (New York: IEEE) pp 397406

S-ar putea să vă placă și

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- TOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActDocument10 paginiTOPIC: Movable and Immovable Property Under Section-3 of Transfer of Property ActRishAbh DaidÎncă nu există evaluări

- Report Painter GR55Document17 paginiReport Painter GR55Islam EldeebÎncă nu există evaluări

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pagini2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusÎncă nu există evaluări

- Module 2 DIPDocument33 paginiModule 2 DIPdigital loveÎncă nu există evaluări

- Bosch Injectors and OhmsDocument6 paginiBosch Injectors and OhmsSteve WrightÎncă nu există evaluări

- Hunger Games Mini Socratic Seminar2012Document4 paginiHunger Games Mini Socratic Seminar2012Cary L. TylerÎncă nu există evaluări

- Evolution DBQDocument4 paginiEvolution DBQCharles JordanÎncă nu există evaluări

- INSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISDocument7 paginiINSTRUCTIONAL SUPERVISORY PLAN 1st Quarter of SY 2023 2024 Quezon ISayongaogracelyflorÎncă nu există evaluări

- List of Important Books of PhysicsDocument6 paginiList of Important Books of PhysicsAbubakar Mughal0% (1)

- Validación Española ADHD-RSDocument7 paginiValidación Española ADHD-RSCristina Andreu NicuesaÎncă nu există evaluări

- Sim Educ101Document101 paginiSim Educ101Rolando AmadÎncă nu există evaluări

- Distillation Column DesignDocument42 paginiDistillation Column DesignAakanksha Raul100% (1)

- APPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListDocument824 paginiAPPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListReviewKeys.comÎncă nu există evaluări

- EF3e Intplus Filetest 10aDocument4 paginiEF3e Intplus Filetest 10aLin Shufen100% (1)

- The Adoption of e Procurement in Tanzani PDFDocument5 paginiThe Adoption of e Procurement in Tanzani PDFDangyi GodSeesÎncă nu există evaluări

- FS-C8025MFP Release NotesDocument22 paginiFS-C8025MFP Release NotesFirmware SM-SHÎncă nu există evaluări

- 09-11-2016 University Exam PaperDocument34 pagini09-11-2016 University Exam PaperSirisha AsadiÎncă nu există evaluări

- The Logic of Repetition: A Guide To Trading, Thinking, and The Cycles of LifeDocument10 paginiThe Logic of Repetition: A Guide To Trading, Thinking, and The Cycles of LifeRaghvendra kÎncă nu există evaluări

- Case Study III - MichelinDocument15 paginiCase Study III - MichelinfreitzÎncă nu există evaluări

- DJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Document7 paginiDJF 41032 Manufacturing Workshop Practice 3 Plastic Lab: Mini Project (Transfer Moulding)Lokhman HakimÎncă nu există evaluări

- Practical Research 2.9Document22 paginiPractical Research 2.9Michael GabertanÎncă nu există evaluări

- Jazz PrepaidDocument4 paginiJazz PrepaidHoney BunnyÎncă nu există evaluări

- Slipform Construction TechniqueDocument6 paginiSlipform Construction TechniqueDivyansh NandwaniÎncă nu există evaluări

- Cultural Practices of India Which Is Adopted by ScienceDocument2 paginiCultural Practices of India Which Is Adopted by ScienceLevina Mary binuÎncă nu există evaluări

- Excavation Trench Permit Ex 1 F0206Document5 paginiExcavation Trench Permit Ex 1 F0206emeka2012Încă nu există evaluări

- Pressure-Dependent Leak Detection Model and Its Application To A District Water SystemDocument13 paginiPressure-Dependent Leak Detection Model and Its Application To A District Water SystemManjul KothariÎncă nu există evaluări

- Xii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Document13 paginiXii - STD - Iit - B1 - QP (19-12-2022) - 221221 - 102558Stephen SatwikÎncă nu există evaluări

- BC 672772 RBRS Service TraningDocument385 paginiBC 672772 RBRS Service TraningTeknik Makina100% (2)

- On The Importance of Learning Statistics For Psychology StudentsDocument2 paginiOn The Importance of Learning Statistics For Psychology StudentsMadison HartfieldÎncă nu există evaluări

- Jungles & SavannasDocument80 paginiJungles & SavannasJessica100% (1)