Documente Academic

Documente Profesional

Documente Cultură

Sensors High Pressure

Încărcat de

Giuseppe DonatoDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sensors High Pressure

Încărcat de

Giuseppe DonatoDrepturi de autor:

Formate disponibile

B

Pressure sensors

45

Pressure sensors

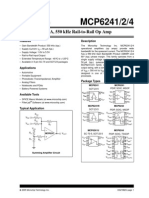

For pressures up to 1800 bar (180 Mpa)

b Ratiometric signal evaluation (referred to supply voltage). b Self-monitoring of offset and sensitivity. b Protection against polarity reversal, overvoltage, and short circuit of output to supply voltage or ground. b High level of compatibility with media since this only comes into contact with stainless steel. b Resistant to brake fluids, mineral oils, water, and air.

Application Pressure sensors of this type are used to measure the pressures in automotive braking systems, or in the fuel-distributor rail of a gasoline direct-injection engine, or in a diesel engine with Common Rail injection. Design and function Pressure measurement results from the bending of a steel diaphragm on which are located polysilicon strain-gauge elements. These are connected in the form of a Wheatstone bridge. This permits high signal utilisation and good temperature compensation. The measurement signal is amplified in an evaluation IC and corrected with respect to offset and sensitivity. At this point, temperature compensation again takes place so that the calibrated unit comprising measuring cell and ASIC only has a very low temperature-dependence level. Part of the evaluation IC is applied for a diagnostic function which can detect the following potential defects: Fracture of a bonding wire to the measuring cell. Fracture anywhere on any of the signal lines. Fracture of the bridge supply and ground.

Only for 0 265 005 303 This sensor differs from conventional sensors due to the following diagnostic functions: Offset errors Amplification errors can be detected by comparing two signal paths in the sensor. Storage conditions Temperature range 30...+60 C Relative air humidity 0...80 % Maximum storage period 5 years Through compliance with the above storage conditions, it is ensured that the sensor functions remain unchanged. If the maximum storage conditions are exceeded, the sensors should no longer be used. Explanation of symbols UA Output voltage Supply voltage UV bar Pressure

Characteristic curve. UA = (0.8 p / pNom. + 0.1)UV

V 4.5 4

Output voltage UA

0.5 0 0 0 0 0 35 50 250 300 100 500 600 750 900 70 150 105 200 140 250

1000 1250 1500

1200 1500 1800 bar Pressure p

46

Pressure sensors

Pressure sensors (contd.) For pressures up to 1800 bar (180 MPa)

Self-monitoring. Offset and sensitivity. Only for 0 265 005 303.

UA UV 96 % 90 % Measuring range Error range Offset error Sensitivity error 12 % 4% Error range Error band Pressure p 100 %

Error band Limitation, working signal

Diagnostic function during self-test (following switch-on). Only for 0 265 005 303. Correctness of the calibration values Function of the sensor signal path from the sensor to the A/D converter of the evaluation unit Check of the supply lines. Diagram: Characteristic of the output voltage following switch-on Function of the signal and alarm paths Detection of offset errors Detection of short circuits in wiring harness Detection of overvoltage and undervoltage If an error is detected during the sensors self-test, the signal output is switched to the voltage range > 96%UV. Diagnostic function during normal operation. Only for 0 265 005 303. Detection of offset errors Detection of sensitivity errors (with pressure applied) Wiring-harness function, detection of wiring-harness short circuits Detection of overvoltage and undervoltage If an error is detected during the sensors self-test, the signal output is switched to the voltage range >96%UV.

Measuring circuit.

Pressure sensor 3 ECU + 5 V (UV)

Pull up resistor Signal (UA) 2 A/Dconverter and C 1 GND

Range

Pressure range bar (MPa) 140 (14) 250 (25) 1500 (150) Sensor Type KV2 BDE RDS2 RDS3 1800 (180) RDS2 RDS3 Thread M 10x1 M 10x1 M 12x1.5 M 12x1.5 M 12x1.5 M 12x1.5 M 12x1.5 M 18x1.5 M 18x1.5 M 18x1.5 Connector Compact 1.1 PSA Working circuit Compact 1.1 Working circuit Compact 1.1 Compact 1.1 Compact 1.1 Compact 1.1 Working circuit Pin Gold-plated Silber-plated Gold-plated Silber-plated Gold-plated Gold-plated Gold-plated Gold-plated Silber-plated Dimens. drawing 1 2 3 4 5 6 4 7 8 9 Page 47 48 48 48 48 49 48 49 49 49 Part number 0 261 545 006 0 265 005 303 0 281 002 238 0 281 002 405 0 281 002 498 0 281 002 522 0 281 002 398 0 281 002 472 0 281 002 534 0 281 002 504

Accessories

For 0 265 005 303 Plug housing Quantity required: 1 AMP No. Contact pins for 0.75 mm2 Quantity required:3 AMP No. Gaskets for 1.4...1.9 mm2 Quantity required: 3 AMP No. 1) To be obtained from AMP Deutschland GmbH, Amperestr. 711, D-63225 Langen, Tel. 0 61 03/7 09-0, Fax 0 61 03/7 09 12 23, E-Mail: AMP.Kontakt@tycoelectronics.com 2-967 642-1 1) 2-965 907-1 1) 2-967 067-1 1)

Pressure sensors

47

Technical data

Pressure sensor Pressure-sensor type Application/Medium Pressure range Offset accuracy Sensitivity accuracy at 5 V In range 0...35 bar In range 35...140 bar In range 35...250 bar In range 35...1500 bar bar (MPa) UV FS 2) of measured value 0 261 545 006 0 265 005 303 0 281 002 238 0 281 002 405 KV2 BDE RDS2 Unlead. fuel Brake fluid Diesel fuel or RME 1) 140 250 1500 (14) (25) (150) 0.7 % FS 2.0 % 1.0 % FS 1.5 % FS 1.5 % 16 5 0.25 9...15 13 40...+130 180 > 300 22 2 2 0.7 % 5.0 % 3) 5 0.25 20 100...3 40...+120 350 > 500 20 2 1.0 % FS 1.5 % FS 2.0 % FS 2.5 % FS 16 5 0.25 9...15 2.5 mA 4) 10 40...+120 5) 1800 3000 35 5 5 0 281 002 498 0 281 002 522 RDS3 Diesel fuel or RME 1) 1500 (150) 0.7 % FS 0 281 002 398 0 281 002 472 RDS2 Diesel fuel or RME 1) 1800 (180) 1.0 % FS 0 281 002 534 0 281 002 504 RDS3 Diesel fuel or RME 1) 1800 (180) 0.7 % FS

0.7 % FS 1.5 % FS 16 5 0.25 9...15 13 40...+130 2200 4000 35 5 2

1.0 % FS 2.3 % FS 16 5 0.25 9...15 2.5 mA 4) 10 40...+120 5) 2100 3500 70 2 5

0.7 % FS 1.5 % FS 16 5 0.25 9...15 13 40...+130 2200 4000 70 2 2

In range 35...1800 bar Input voltage, max. Us V Power-supply voltage UV V Power-supply current IV mA Output current IA A...mA Load capacity to ground nF Temperature range C Overpressure max. pmax bar Burst pressure pburst bar Tightening torque Ma Nm Response time T10/90 ms Note: All data are typical values 1) RME = Rapeseed methyl ester 2) FS = Full Scale 3) Of measured value 4) Output current with pull-up resistor 5) +140 C for max. 250 h

Dimension drawings Space required by plug, approx. 25 mm Space required when plugging/unplugging, approx. 50 mm SW = A/F size

59,8 8,5 0,3 2,8 0,1

Connector-pin assignment Pin 1 Ground Pin 2 Output voltage UA Pin 3 Supply voltage UV

5,3 2 21,5 3,8 Pin 2 S 90

2 1 3

0 261 545 006 140 bar

1

SW 27

25

13

2 1 3

M 10x1-6g

6 16,5 3

Pin 1

Pin 3

24,4

30

48

Pressure sensors

Pressure sensors (contd.) For pressures up to 1800 bar (180 MPa)

Dimension drawings Space required by plug, approx. 25 mm Space required when plugging/unplugging, approx. 50 mm SW = A/F size

D F S

Gasket Date of manufacture 3-pin plug

Connector-pin assignment Pin 1 Ground Pin 2 Output voltage UA Pin 3 Supply voltage UV

0 265 005 303 250 bar

2

10 0,1 SW 24

41 B 24,3 A 53,3 38 0,6 20,9 0,5 17,1 0,2 3 2,8 - 0,5

Pin 2

25 - 0,1

M10x1

22,1

90

8,5 - 0,1 2,8 0,1

5,3 0,2 15,3 0,1 Pin 1 Pin 3

0 281 002 238 1500 bar

3

R

SW 27

29 2 7

1,5

Pin 2

25

2 1 3

D M 12 x1,5 0,6 - 0,1 12,5 16 69 2 F

2 1 3

Pin 1

Pin 3

30

0 281 002 405 1500 bar 0 281 002 398 1800 bar

4

29 2 7

R

SW 27

2 3

1,5

Pin 2

25

13

2 1

D 0,6 - 0,1 12,5 16 68 2 F

M 12x1,5

Pin 1

Pin 3

24,4

30

0 281 002 498 1500 bar

5

21,5 2 6 0,5 S Pin 2

SW 27

0,1

24,8

2 1 3

2 1 3

M 12 x1,5

2,15 0,15 12,5 16,6 0,7 60,5 2 F Pin 1 Pin 3

30

Pressure sensors

49

Dimension drawings Space required by plug, approx. 25 mm Space required when plugging/unplugging, approx. 50 mm SW = A/F size

D F S

Gasket Date of manufacture 3-pin plug

Connector-pin assignment Pin 1 Ground Pin 2 Output voltage UA Pin 3 Supply voltage UV

0 281 002 522 1500 bar

6

21,5 2 6

R 1

Pin 2

27 SW

25

13

2 1 3

D 0,6 - 0,1 12,5 2 16 59,3 2 F

M 12 x1,5- 6g

Pin 1

Pin 3

24,4

30

0 281 002 472 1800 bar

7

3,8 - 2 3 M 18x1,5-6g

SW

29 2 7 Pin 2 S 15,5 12,6

2 1 3

27

25

60

13

F 24,4

Pin 1

Pin 3

30

17,1 69 2

0 281 002 534 1800 bar

8

17,1

15

21,5 2 Pin 2 S

M 18x1,5-6g

25

60

13

15,5

12,6

SW 27

2 1 3

2,5 24,4 6 F 60,4 2

Pin 3

Pin 1

30

0 281 002 504 1800 bar

9

SW

17,1

15

21,5 2 Pin 2 S

M 18x1,5-6g

15,5

12,6

27

25

2 1 3

60

2 1 3

2,5

30

6 60,8 2

Pin 1

Pin 3

S-ar putea să vă placă și

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Bosch Pressure SensorsDocument5 paginiBosch Pressure SensorsCatalin NiculescuÎncă nu există evaluări

- Map Sensor Technical SpecificationDocument13 paginiMap Sensor Technical SpecificationEdward Fisher100% (2)

- 0281002238Document3 pagini0281002238Ricardo UrioÎncă nu există evaluări

- MPX10DPDocument8 paginiMPX10DPsuperpuma86Încă nu există evaluări

- Metrahit 15 SDocument12 paginiMetrahit 15 SJohn JohnÎncă nu există evaluări

- Transmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsDocument4 paginiTransmitter For Pressure and Temperature Atm/T: Features Typical ApplicationsJoseph TaylorÎncă nu există evaluări

- Ad8421 PDFDocument28 paginiAd8421 PDFsoft4gsmÎncă nu există evaluări

- Atm Ii: Features Typical ApplicationsDocument4 paginiAtm Ii: Features Typical ApplicationsJoseph TaylorÎncă nu există evaluări

- MS4600 Datasheet en 201507 F266I-E-01Document7 paginiMS4600 Datasheet en 201507 F266I-E-01Eliezer DominguezÎncă nu există evaluări

- Rish Multi 12S - 18S4Document7 paginiRish Multi 12S - 18S4Navin MathewÎncă nu există evaluări

- 2SMPP-03 Sensor PresionDocument10 pagini2SMPP-03 Sensor PresionGerman GodiÎncă nu există evaluări

- AD590Document0 paginiAD590Alvaro Mompi RuizÎncă nu există evaluări

- OpAmp - MCP6244Document38 paginiOpAmp - MCP6244Ludwig SchmidtÎncă nu există evaluări

- Pressure Transmitter For Precision Measurements Model P-30, Standard Version Model P-31, Flush VersionDocument8 paginiPressure Transmitter For Precision Measurements Model P-30, Standard Version Model P-31, Flush VersionAnonymous 4MwmDaNbÎncă nu există evaluări

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 paginiHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileÎncă nu există evaluări

- MC1458 OnDocument8 paginiMC1458 OnDanteLupuÎncă nu există evaluări

- Apr 2000alwDocument5 paginiApr 2000alwhandlitoÎncă nu există evaluări

- Medical Ecg Ina326Document23 paginiMedical Ecg Ina326ronny5525Încă nu există evaluări

- MPX10GSDocument9 paginiMPX10GSJoseph BurgosÎncă nu există evaluări

- TECSIS Pressure TransmitterDocument4 paginiTECSIS Pressure TransmitterVijendraAgarÎncă nu există evaluări

- Tradutor Diferencial PD-9 DRUCKDocument2 paginiTradutor Diferencial PD-9 DRUCKjcbizarretaÎncă nu există evaluări

- P3251 TecsisDocument4 paginiP3251 TecsisJHONNJANÎncă nu există evaluări

- MPX200Document8 paginiMPX200Hugo ContrerasÎncă nu există evaluări

- Atm/Hd: Features Typical ApplicationsDocument4 paginiAtm/Hd: Features Typical ApplicationsJoseph TaylorÎncă nu există evaluări

- Vibration MonitoringDocument8 paginiVibration MonitoringKrzysiek PodsiadłoÎncă nu există evaluări

- Low Noise, Precision CMOS Amplifier AD8655/AD8656: Features Pin ConfigurationsDocument20 paginiLow Noise, Precision CMOS Amplifier AD8655/AD8656: Features Pin Configurationsjeperezo_1351370Încă nu există evaluări

- Kistler 9602AADocument6 paginiKistler 9602AAJenni JosephÎncă nu există evaluări

- Digital Protective RelaysDocument34 paginiDigital Protective Relayssubho7297648100% (3)

- DatasheetDocument8 paginiDatasheetkunal5959Încă nu există evaluări

- Ada4661 2Document32 paginiAda4661 2Pravin MevadaÎncă nu există evaluări

- Measuring and Monitoring Relay CM-PVS: Three-Phase Monitor For Over-And Undervoltage Data SheetDocument6 paginiMeasuring and Monitoring Relay CM-PVS: Three-Phase Monitor For Over-And Undervoltage Data SheetMahmood ZizoÎncă nu există evaluări

- Datasheet Sensitec CDS4010 DSE 07Document12 paginiDatasheet Sensitec CDS4010 DSE 07Núñez D. PauliÎncă nu există evaluări

- Measuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetDocument6 paginiMeasuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetJJGÎncă nu există evaluări

- OMICRON CMC 256plus Technical Data ENUDocument3 paginiOMICRON CMC 256plus Technical Data ENUDuško TovilovićÎncă nu există evaluări

- RM35TF30Document4 paginiRM35TF30J raymond FÎncă nu există evaluări

- AMP02Document12 paginiAMP02ivan bragaÎncă nu există evaluări

- LVDT Displacement SensorsDocument8 paginiLVDT Displacement SensorslelixÎncă nu există evaluări

- REF3012 REF3020 REF3025 REF3030 REF3033 REF3040 50ppm/ C Max, 50 A in SOT23-3 Cmos Voltage ReferenceDocument17 paginiREF3012 REF3020 REF3025 REF3030 REF3033 REF3040 50ppm/ C Max, 50 A in SOT23-3 Cmos Voltage ReferenceachtashÎncă nu există evaluări

- MAG3 SMT Datasheet RevD1Document4 paginiMAG3 SMT Datasheet RevD1lgrome73Încă nu există evaluări

- Bf966 DatasheetDocument9 paginiBf966 DatasheetPablo MolinariÎncă nu există evaluări

- Jameco Part Number 1390194: Distributed byDocument31 paginiJameco Part Number 1390194: Distributed byfox7878Încă nu există evaluări

- T 1000 PLUS: Secondary Injection Relay Test SetDocument8 paginiT 1000 PLUS: Secondary Injection Relay Test SetKrisada ThongkamsaiÎncă nu există evaluări

- Uc 2526Document9 paginiUc 2526Nguyen HienÎncă nu există evaluări

- 331-1KF01 - AI 8x13bit - Technical Data: Chapter 6 Analog Input ModulesDocument5 pagini331-1KF01 - AI 8x13bit - Technical Data: Chapter 6 Analog Input ModulesIgor TusjakÎncă nu există evaluări

- High Performance, Wide Bandwidth Accelerometer ADXL001: FeaturesDocument16 paginiHigh Performance, Wide Bandwidth Accelerometer ADXL001: FeaturesMago ChinesÎncă nu există evaluări

- Agilent 4155CDocument14 paginiAgilent 4155CBennyavÎncă nu există evaluări

- OpAmp - MCP6241Document28 paginiOpAmp - MCP6241Ludwig SchmidtÎncă nu există evaluări

- Data SheetDocument35 paginiData SheetvvvssssvvvÎncă nu există evaluări

- MPX5100Document17 paginiMPX5100Andri PaoÎncă nu există evaluări

- CA3080, CA3080A: Features DescriptionDocument11 paginiCA3080, CA3080A: Features DescriptionBatos1Încă nu există evaluări

- AD8302Document24 paginiAD8302Uday KumarÎncă nu există evaluări

- Mic 29310Document12 paginiMic 29310chingatucolaÎncă nu există evaluări

- Apr 2000G Al PDFDocument3 paginiApr 2000G Al PDFvan_dall_2Încă nu există evaluări

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- P9000 Schaevitz-990Document6 paginiP9000 Schaevitz-990Asadollah KhakpourÎncă nu există evaluări

- Presio 769 NDocument16 paginiPresio 769 NMasab QadirÎncă nu există evaluări

- Transdutor de PressãoDocument10 paginiTransdutor de PressãodalmohvacÎncă nu există evaluări

- A P Mining Diaflex Coating 01-2012Document2 paginiA P Mining Diaflex Coating 01-2012johnÎncă nu există evaluări

- Project Proposal in Pipe Loss ApparatusDocument25 paginiProject Proposal in Pipe Loss ApparatusAnthony Justin EdmaÎncă nu există evaluări

- Training Hyd System in Cement IndustriDocument36 paginiTraining Hyd System in Cement IndustriNatsuko KayamaÎncă nu există evaluări

- Company Profile - TECH Automation PDFDocument6 paginiCompany Profile - TECH Automation PDFTECH AutomationÎncă nu există evaluări

- AVL MicroIFEM PiezoModuleDocument62 paginiAVL MicroIFEM PiezoModulescribd695Încă nu există evaluări

- Industrial Instrumentation: Dr. - Ing. Naveed RamzanDocument57 paginiIndustrial Instrumentation: Dr. - Ing. Naveed Ramzanfast4rohitÎncă nu există evaluări

- SAW As RFID Tags and Sensor Report FinalDocument22 paginiSAW As RFID Tags and Sensor Report FinalSHAIMA SUBRINAÎncă nu există evaluări

- P499VBS 401CDocument8 paginiP499VBS 401CHassan AshrafÎncă nu există evaluări

- MPX4250Document9 paginiMPX4250mohsihummerÎncă nu există evaluări

- Ashcroft Pressure Temperature Instrument Ordering HandbookDocument278 paginiAshcroft Pressure Temperature Instrument Ordering HandbookSilvester mario chaves100% (2)

- MeasurIT Tideflex & Series40 Application Flow 0806Document1 paginăMeasurIT Tideflex & Series40 Application Flow 0806cwiejkowskaÎncă nu există evaluări

- B. G. Clarke - Pressuremeters in Geotechnical Design-CRC Press (2022)Document407 paginiB. G. Clarke - Pressuremeters in Geotechnical Design-CRC Press (2022)JANDIRA NOVAISÎncă nu există evaluări

- Flowtracker2 Brochure PDFDocument7 paginiFlowtracker2 Brochure PDFNada HamidÎncă nu există evaluări

- CDB 3062 Chemical Engineering Lab 3 MAY 2016: Group: 03 Date Experiment Group MembersDocument14 paginiCDB 3062 Chemical Engineering Lab 3 MAY 2016: Group: 03 Date Experiment Group MembersZen AlkaffÎncă nu există evaluări

- Nabl 122 13 PDFDocument20 paginiNabl 122 13 PDFmahesh100% (1)

- Bosch Power-Train / Exhaust Sensors: Aravind KDocument41 paginiBosch Power-Train / Exhaust Sensors: Aravind KLjilja DavidovÎncă nu există evaluări

- Catalog: Hydraulic Diagnostic ProductsDocument32 paginiCatalog: Hydraulic Diagnostic ProductsRonald Luis Quisurco CardenasÎncă nu există evaluări

- Micromachined Pressure Sensors: Review and Recent DevelopmentsDocument1 paginăMicromachined Pressure Sensors: Review and Recent DevelopmentsRuchi SinghÎncă nu există evaluări

- Ata 77 Engine IndicatingDocument70 paginiAta 77 Engine IndicatingNguyen Bach GiaÎncă nu există evaluări

- Wika Pressure & Temperature HandbookDocument433 paginiWika Pressure & Temperature Handbookvadivel415100% (1)

- Code Error Cat Pc320Document19 paginiCode Error Cat Pc320Hartono Exca93% (15)

- VW Piezometers & Pressure Transducers: 4500 SeriesDocument4 paginiVW Piezometers & Pressure Transducers: 4500 SeriesANTONIO LOZANOÎncă nu există evaluări

- MPXM2010DT1Document9 paginiMPXM2010DT1Nery CorrêaÎncă nu există evaluări

- Lecture OneDocument17 paginiLecture OnerowlandmollÎncă nu există evaluări

- 1.0 J1415 QF200-2 PSA DatasheetDocument2 pagini1.0 J1415 QF200-2 PSA DatasheetCarlos MagÎncă nu există evaluări

- Closed-Loop Hydraulics: Workbook TP 511Document36 paginiClosed-Loop Hydraulics: Workbook TP 511zae nurdinÎncă nu există evaluări

- Electric Electronic CatalogDocument404 paginiElectric Electronic CatalogmaddabdulÎncă nu există evaluări