Documente Academic

Documente Profesional

Documente Cultură

Mechatronicsall Experiments

Încărcat de

Sidd SalDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Mechatronicsall Experiments

Încărcat de

Sidd SalDrepturi de autor:

Formate disponibile

Experiment No 1.

Direct Control of Sien?l Actine Cylinder

Aim:

i

A single acting cylinder of 25mm diameter is to clamp

Solution:

The control value used for single acting cylinder is the

a component when a push button

is pressed. As long as push button is related the clamp is to retract.

way value. In this case since the

a push

cylinder is of small capacity, the operation can be directly controlled by directional control value with spring return.

button

X*ut

Operating the push button the air passes through the valve from part 1 to 2 viathe value is into the piston chamber of cylinder 1 A. the presser build up and advance the piston rod against the force of cylinder retum spring. On release of the button, the valve spring retums the

valve to its initial position and cylinder retracts. The air retracts from the cylinder via the exhaust port3. Component which are the only one of their type are designed without 2 supplementary

numbers. Since the cylinder is the only working element in the circuit designed as 14.

way

Result:The experiment has been conducted successfully

'1,.;9.,fi1ffi1,ffiwmfig5iffiffi,.s$

iRr

id i rect mnnr,frrrnil.

u,

li$,g.ctu

ated

Experiment No 2.

CIRCUIT USING BISTABLE VALVES SPEED CONTROL OF CYLINDER Aim:

The piston rod of a double acting cylinder is to extend when a momentary push switch is actuated. The cylinder is to rejmain extended until a second switch is actuated and only if the initial position until a new start single is given. The speed of the cylinder is to be adjustable in

both direction of travel.

Solution:

Operating the moment any push button switch s, and a single is directly applied at solenoid coil Y, the J

way double solenoid valve 1.1 switches and the resultant single at part 4

1.0 even

fully extended the piston rod of cylinder

if S 1 is released the value i.1 remains in the switched position until the momentary push button switch 52 is operated. If switch S1 is still active the 52 single will not be effective. An unopposed single generated by 52 will return valve

initial position and signal from part 2 will reacted until a new signal is applied at Y1 by switch S 1 . If Y I and Y2 are energized due to both switches being operated, then the double solenoid valve with its memory characteristics will remain in the last position attained. This is bistable characteristic of the valve.

1.1 to its

Note that in the previous characteristics when using single solenoid valves it has been necessary to electrically latch the S1 signal to keep the Yl solenoid active for long period. This is not necessary here since the double solenoid pneumatic valve remains active due to its inherent memory characteristics. In most cases, it is preferable to operate the Y1 andY2 solenoid indirectly through relay contact. This prevent large from being carried at the switch contact and reduces arcing.

The flow control valves are

pilEd to throttle the exhausting air in both direction of

position travel. Supply air is transfened through of piston travel. Supply air is transferred through the bypass check valve with each control value given unrestricted supply to the cylinder. Valve 1.01 control the speed of retraction and 1.02 control the extension speed. This is referred to as exhaust throttling. The flow control valve control the speed of the cylinder in both the direction and is adjustable. a limit of this circuit is that for same application it is necessary to determine if this piston rod, has reached the extend of its travel before subsequent action occurs.

The solution to this requirement is to place a limit switch at the fully extended position of the piston rod, the contact of witch would be in series with the switch that initiates piston rod

retraction.! Way or

i *u,

double solenoid valve passes the required memory function.

Normally though the valve is utilized. The value retain its last switched position until an J opposing signal is received for this rez$on signals created by the push button signaling devices

can be short

duration.

Result:

The circuit has been designed and experiment has been conducted successfully

Experiment No 3

nocrble

Aim:

A double acting cylinder is to advance if one of two push button is operated. If the push button is then released, the cylinder is to retract.

Solution:

The (1) and 1(3) of the shuttle value IV are connected to the working connection of the value ISI and IS2. Upon operation of the push button, the corresponding valve iSl or IS2 is actuated and a single is generated at the 1 or 1(3) side of the shuttle valve.

The or condition is fulfilled and the single passes through the shuttle valve and is emitted at part 2. The single pressure is prevented from escaping via the exhaust of the unachieved valve by

closing the line in the shuttle valve. The single effect the switching of the control element IV2. The piston side of the cylinder is pressurized and piston rod advances.

When the activated push button is released the single pressure is relieved by the valves IS 1 and IS 2 and the control element is switched back to its initial position. The pressure now building upon the piston rod side ensures the retraction of the piston rod.

Result

:-

The circuit has been designed and experiment has been conducted successfully

tve

+li _

lgt l-tr--

,ls)

tHz

tr.

Circuit diasram

d

j

L: 1,

!l ltl

,,4-{

t-ffi:

l.]} I

r**

ts$

$r

F{.

Circuit diagram

F-ts -4

Experiment No 4

Actuation of Two DouEle Actins Cylinder in Sequgnce A*B* A-BAim:

Two cylinders are used to transfer part from amagazine on to a chute. When a push button is pressed, the first cylinder extends, pushing the part from the magazine and position. in preparation for transfer by the second cylinder on the out feed chute. Once the part is transferred. The first cylinder retracts followed by the second.

If

Solution:

Roller lever values from the with idle return are to be used as limit switches to defect the

return and advance position of the piston rod the manual single input is effected via a valve. In the initial position, both cylinders are in the retracted state, the limit switches 25 are actuated.

*ay

and 152

The start condition for a cycle is that the limit switch 25l and push button @Sl must be actuated, the motion cycle can be determined from the displacement. Step diagram and is sub divided into the following step. Step

l:

1Sl and lS2 actuated

Cylinder lA advances

Cylinder

2,A.

Step

2:l53 actuated

advances

Step 3:252 actuated

Step 4:1 52 actuated

Cylinder lA retracts.

Cylinder

2,A.

retracts.

Step 5:2Sl actuated

Initial position

Result :-

The circuit has been designed and experiment has been conducted successfully

E *"4

xP

*'r

gdvil*vt* dsffi Irie&d33uuslfi

q{"

\h

Experiment No 5

Aim:

Two cylinders are used to transfer part form amagazine onto a chute. When a push button is pressed, cylinder 1.0 extends, pushing the part form the magazine and position it in preparation for transfer by cylinder 2.0 onto the out feed chute. Once the part is transferred, the first cylinder is to be adjustable confirmation of all extended and related position is required.

Solution:

Control of the sequence of action for this task depends on need switches. The start condition for the control is that the last action in the operating sequence has accrued, that is cylinder 2.0 is retracted and the start button is pressed. Step in the operating sequence are shown on the displacement step diagram. To define the placement of switches that control the sequence of action, two factors should be considered.

a o

The current action The desired action. This can be represented by

ACTION

2.0 retracts

S3 pressed

REACTION

s2 actuated

1.0 extends

52 actuated 54 actuated

S1 actuated

2.0 extends

1.0 extends

2.0 extends

Result

:-

The circuit has been designed and experiment has been conducted successfully

*fllvc

.${ rtol,l

rv3

Ffiwes Cssre*L

SECTrsru

roIhi*R ,**fPLg. grrr0r'{

Circuit diagram

e*+ 'e

Experiment No 6

Actuation of Sinele Acting Cylinder (Hydraulic cvlinder) Aim:

Actuation of a single hydraulic cylinder acting cylinder.

Solution:

The circuit diagram describes the functional structure of the hydraulic system.

filter (0Zl) pressure relief value (022),pump (0Pl) and electric motor (0Ml) is depicted in the lower part of the circuit diagram shown for the hydraulic device of the circuit diagram shown for the hydraulic device of the tempering services.

The power supply section of the system with The power control section with non-return value

(1Vl) the way value (1V3) with the hand J

level for single input form the "system person" interface. Like the drive section, the power control section is assigned to the power section. in hydraulic devices, the drive section consist of the single acting cylinder 1A.

Result :-

The circuit has been designed and experiment has been conducted successfully

Hu4arqul\c Pouter Sechon

'[*"* *ot';**l

fuu*r ffil socr'on

cnnhot

Sach*n

t

l

str5*l F*rt**lrg

_J

hwer s.*Ppry -l

f *i le

,d,

f*tg

Cenhol

g

E,

"erg$

$uPf

+J

{snves'nn I !orrtadiqrtr fugsure

Prgfarulion

Result :The circuit has been designed and experiment has been conducted successfully

rT

Experiment No

AqTUATION OF HYDRAULIC DOUBLE, ACTING CYLINDER

^f

im:

Actuation of a Double Acting hydraulic Cylinder.

Solution:

The above section of a hydraulic system is the part of the system which execute the

various working movement of a machine or manufacturing system. The energy obtains in the hydraulic of forces (e.g. Clamping process). This is achieved using following components.

a

a

Cylinder

Motor

N*rr refurn

wle

Frtss*Yf *eJue

Prtlsr,'rg

g*rEr

Frltinq lt\tlt{IW

t'rel

Experiment No

ADDITION OF TWO 8 BIT NUMBER

Aim:

Addition of two 8 bit using 8085 microprocessor numbers.

Program me

ADDRESS

HEX CODE

MNEMONICS

LXl.H

OPERAND

c200

21

c201 c202 c203 c204 c205 c206 c207 c208

00 c0

7E

MOV

INX INX

A,M

H

23

86

23

M

H

77 76

MOV

HLT

M,A

Result:

Addition of two 8 bit numbers was performed successfully using 8085 microprocessor

Experiment No

SUBTRACTION OF TWO 8 BIT NUMBER Aim:

Subtraction of two 8 bit numbers. programme

ADDRESS

HEX CODE 2T

MNEMONICS

OPERAND

H

c200 c201 c202 c203 c204 c205 c206 c207 c208

c0

7E

MOV

INX

SUB

A,M

H

23 96

23

M

H

INX

77 76

MOV

HLT

M,A

Result:

{naaitioh of two 8 bit numbers was performed \*-." " !vt:l Xary*,;5^

successfully using 8085 microprocessor

S-ar putea să vă placă și

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- VersionDocument1 paginăVersionSidd SalÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- ERP Vs BPR, Enterprise Resource Planning .Document2 paginiERP Vs BPR, Enterprise Resource Planning .Sidd SalÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- BEST Practice in ErpDocument47 paginiBEST Practice in ErpSidd SalÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- HVAC Systems Analysis and DesignDocument67 paginiHVAC Systems Analysis and DesignSidd SalÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Ch30 Fusion WeldingDocument38 paginiCh30 Fusion WeldingSidd Sal100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

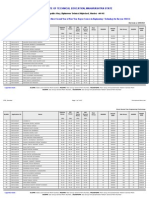

- Provisional Merit List DSE OverAll2010Document1.107 paginiProvisional Merit List DSE OverAll2010Sidd SalÎncă nu există evaluări

- Color SensorDocument0 paginiColor SensorSidd SalÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- EnvironmentalFactSheets PDFDocument2 paginiEnvironmentalFactSheets PDFSidd SalÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Sample Issue Essays: Essay No. 1Document8 paginiSample Issue Essays: Essay No. 1rajatkrpalÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Features of Guano IslandDocument2 paginiFeatures of Guano IslandSidd SalÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Thermal Analysis On Various Fin ProfilesDocument4 paginiThermal Analysis On Various Fin ProfilesSidd SalÎncă nu există evaluări

- HTB1YUPsGpXXXXbhXpXX PRXFXXXBDocument89 paginiHTB1YUPsGpXXXXbhXpXX PRXFXXXBFabio Andres Plata TorresÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- BW211D-40 SVC TRG PDFDocument150 paginiBW211D-40 SVC TRG PDFjono100% (1)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Product Manual 03108 (Revision B) : 3161 GovernorDocument24 paginiProduct Manual 03108 (Revision B) : 3161 GovernorHashmat AliÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Marine Lubrication For ULSFO, VLSFO and Safeguarding EnginesDocument33 paginiMarine Lubrication For ULSFO, VLSFO and Safeguarding EnginesmanojvarrierÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Smallblockv 8 BalancingDocument2 paginiSmallblockv 8 Balancingapi-239528001100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- GMS60CSDocument6 paginiGMS60CSAustinÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Xado FaqDocument18 paginiXado FaqJoey MadoloraÎncă nu există evaluări

- Theoretical An Practical Aspects For Balancing Crankshafts 6 Cylinder v60Document22 paginiTheoretical An Practical Aspects For Balancing Crankshafts 6 Cylinder v60Davor MaricÎncă nu există evaluări

- ABSC-200 Blast Machine - 200 LTRDocument18 paginiABSC-200 Blast Machine - 200 LTRTamerGalhoumÎncă nu există evaluări

- Honda NSR125 JC22 Engine PDFDocument16 paginiHonda NSR125 JC22 Engine PDFOliverÎncă nu există evaluări

- Auto Expo Participants - 19jul10 PDFDocument25 paginiAuto Expo Participants - 19jul10 PDFAbhishek MoreÎncă nu există evaluări

- The Zero-Dimensional Model of The Scavenging Process in The Opposed-Piston Two-Stroke Aircraft Diesel EngineDocument10 paginiThe Zero-Dimensional Model of The Scavenging Process in The Opposed-Piston Two-Stroke Aircraft Diesel EngineAnbarasan RaviÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Design an automatic blacksmith hammer machineDocument77 paginiDesign an automatic blacksmith hammer machinePrithinga Vishnavi75% (4)

- Primera Entrega TR1 Ingles TecnicoDocument8 paginiPrimera Entrega TR1 Ingles TecnicoYolvi YsagaÎncă nu există evaluări

- Energy Lab Manual CompleteDocument54 paginiEnergy Lab Manual CompleteChaithra RÎncă nu există evaluări

- Escort Limited Champion F 11 Brand Name - FarmtracDocument12 paginiEscort Limited Champion F 11 Brand Name - Farmtrachugo fernandezÎncă nu există evaluări

- Sprite Service ToolsDocument18 paginiSprite Service Toolswardendavid5591Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Yamaha f250d - Parts CatalogueDocument83 paginiYamaha f250d - Parts Catalogueanon_674708607Încă nu există evaluări

- 62-02460 - Rev - C - Manual de Peças, Compressor 05KDocument19 pagini62-02460 - Rev - C - Manual de Peças, Compressor 05KBianca PinudoÎncă nu există evaluări

- FESTO Electro-Hydraulics - Basic LevelDocument203 paginiFESTO Electro-Hydraulics - Basic LevelAnonymous nOqqYoDvz100% (2)

- 2HD1 (1N2HD450E1) AL125FC Mio MX FIDocument55 pagini2HD1 (1N2HD450E1) AL125FC Mio MX FIjames abalosÎncă nu există evaluări

- SteamE MuncasterDocument29 paginiSteamE MuncasterchopenÎncă nu există evaluări

- Azdoc - Tips Solutions Manual Fundamentalsofthermodynamicssonntag Borgnakke VanwylenDocument427 paginiAzdoc - Tips Solutions Manual Fundamentalsofthermodynamicssonntag Borgnakke VanwylenEduarda Maksara MorineÎncă nu există evaluări

- Four Stroke Engine Cycles and TimingDocument27 paginiFour Stroke Engine Cycles and TimingOğuz Çavdar100% (1)

- Introduction To Vibration & Pulsation in Reciprocating Compressors (Beta)Document28 paginiIntroduction To Vibration & Pulsation in Reciprocating Compressors (Beta)FabbroxÎncă nu există evaluări

- Drill Jumbo Product Guide PDFDocument6 paginiDrill Jumbo Product Guide PDFchawki trabelsiÎncă nu există evaluări

- 02 Engine Mechanical System PICANTO 1.0Document131 pagini02 Engine Mechanical System PICANTO 1.0rectificamos100% (4)

- Parts Manual: EH63, EH64, EH65, EH72 EnginesDocument46 paginiParts Manual: EH63, EH64, EH65, EH72 EnginesJorge orellanaÎncă nu există evaluări

- ME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic CircuitsDocument49 paginiME8781 Mechatronics Lab Manual - Experiments on Hydraulic and Pneumatic Circuitsusiaf007100% (1)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Component FM200 2Document8 paginiComponent FM200 2awuawu86100% (1)