Documente Academic

Documente Profesional

Documente Cultură

Spot Welding Formula

Încărcat de

Selvakumaran Dhandapani100%(4)100% au considerat acest document util (4 voturi)

10K vizualizări2 paginiDrepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

100%(4)100% au considerat acest document util (4 voturi)

10K vizualizări2 paginiSpot Welding Formula

Încărcat de

Selvakumaran DhandapaniDrepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

FFA # 23

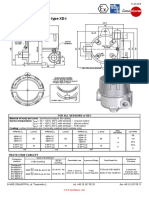

GENERAL FORMULAS FOR SPOT WELDING

ELECTRODE FORCE = 6000 x (T1 +T2) 6000 = constant T1 = thickness of first sheet T2 = thickness of second sheet Example: two pieces of .050* 6000 x (.050 + .050) = 600 600 = necessary electrode force in lbs. WELD TIME = 100 x (T1 +T2) 100 = constant Example: two pieces of .050* 100 x (.050 + .050) = 10 10 = necessary weld time in cycles WELD CURRENT = 100,000 x (T1 +T2) 100,000 = constant Example: two pieces of .050* 100,000 x (.050 + .050) = 10,000 10,000 = necessary secondary current In amperes.

TIP FACE DIA. = 0.1 + (T1 +T2) 0.1 = constant Example: two pieces of .050* .1 + (.050 + .050) = .2 .2 = tip face diameter in inches

*For thickness above .080, the calculated value for the welding current becomes somewhat exaggerated. A reduction of 20% becomes necessary.

W R O N G W R O

FIG.2

SPOT WELDING IF UNEQUAL THICKNESS

Resistance Welding Equipment & Supply Co.

2045 East 46th Street Indianapolis, IN 46205-1472 Phone: (317) 251-9406 Fax: (317) 251-9407 e-mail: rwesco@iquest.net Visit us on the World Wide Web at: www.spotweldequip.com

FFA # 23

FFA # 23

RELATIVE RESISTANCE VALUES OF SPOT WELD ZONES.

ELECTRODE

R R R R R

ELECTRODE

CONTACT MATERIAL INTERFACE

MATERIAL

CONTACT

R

FFA # 23

HIGHEST HEAT IS PRODUCED AT HIGHEST RESISTANCE POINT! SHOULD BE AT...WELD INTERFACE

S-ar putea să vă placă și

- Introduction of Spot Welding (040706)Document24 paginiIntroduction of Spot Welding (040706)fadz8050% (2)

- Spot Welding Strength CalculationDocument14 paginiSpot Welding Strength CalculationVenkateswaran venkateswaranÎncă nu există evaluări

- Sheet Metal Per Stroke Cost CalculationDocument1 paginăSheet Metal Per Stroke Cost CalculationBharat100% (2)

- The Role of Tip DressingDocument4 paginiThe Role of Tip DressingLutfi Ismail100% (1)

- Handbook For Resistance Spot WeldingDocument20 paginiHandbook For Resistance Spot WeldingsatebekicotÎncă nu există evaluări

- Costing Format - Press ToolDocument6 paginiCosting Format - Press ToolVineet Pandey Vlogs67% (3)

- Presstool Design Tutorial - MisumiDocument166 paginiPresstool Design Tutorial - Misumiazadsingh1Încă nu există evaluări

- JIS-standard G3113 PDFDocument11 paginiJIS-standard G3113 PDFMahesh KumarÎncă nu există evaluări

- Resistance Projection Welding Design, Calculation, Process AssuranceDocument20 paginiResistance Projection Welding Design, Calculation, Process AssuranceHemant75% (4)

- Tool Design Data Book PDFDocument124 paginiTool Design Data Book PDFbmvinay74% (19)

- BSK 46 Materials - For - Automobiles11Document62 paginiBSK 46 Materials - For - Automobiles11shuklahouse100% (1)

- Ford Spot Weld SpecDocument12 paginiFord Spot Weld SpecJonathan Davies0% (1)

- Formulas For Designing Press ToolsDocument21 paginiFormulas For Designing Press ToolsKarthik Gopal86% (35)

- Spot Welding ParametersDocument12 paginiSpot Welding ParametersGabriel Rojas ValenzuelaÎncă nu există evaluări

- Formula For Press Tool DesignDocument2 paginiFormula For Press Tool DesignJimmy Clavel100% (2)

- Press Tool PDFDocument5 paginiPress Tool PDFElaine Johnson50% (6)

- Strip LayoutDocument29 paginiStrip LayoutAnishMendis100% (3)

- FormingSuite Training PDFDocument90 paginiFormingSuite Training PDFNarendra ThippeswamyÎncă nu există evaluări

- StandardDocument65 paginiStandardavinashchauhan2695100% (1)

- Press Tool: Calculation For Die & Punch SizeDocument4 paginiPress Tool: Calculation For Die & Punch Sizemayank12379% (19)

- Resistance Welding Manual (RWMA)Document27 paginiResistance Welding Manual (RWMA)Ahmadreza Aminian83% (6)

- FES MTG Welding Fixture F7222910Document11 paginiFES MTG Welding Fixture F7222910Sekar NaikÎncă nu există evaluări

- Lab10 Final Progressive Die PDFDocument7 paginiLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Design of Spot WeldDocument15 paginiDesign of Spot Weldkaustubh girgasÎncă nu există evaluări

- Cutting ParametersDocument12 paginiCutting ParametersИлияИванов50% (8)

- Skill Matrix WeldersDocument1 paginăSkill Matrix WeldersRavikant Pandey100% (1)

- Spot Welding Manual PDFDocument50 paginiSpot Welding Manual PDFVanderli AlvesÎncă nu există evaluări

- One-Dimensional Assembly Tolerance Stack-UpDocument26 paginiOne-Dimensional Assembly Tolerance Stack-UpKakoDa100% (2)

- 2 Piles Pilecap DesignDocument4 pagini2 Piles Pilecap Designwun chwenÎncă nu există evaluări

- Design of Const Dia RCC ChimneyDocument16 paginiDesign of Const Dia RCC ChimneyVadirajNHalgeri100% (3)

- 50 Kva Distibution Transformer DesignDocument11 pagini50 Kva Distibution Transformer DesignJemal MusaÎncă nu există evaluări

- Design of BeamsDocument19 paginiDesign of BeamssnsatyanarayanaÎncă nu există evaluări

- Thermal StrainDocument14 paginiThermal StrainMavrix AgustinÎncă nu există evaluări

- DPT Numericals For Production EngineeringDocument8 paginiDPT Numericals For Production Engineeringprithvi shettyÎncă nu există evaluări

- Butterfly Valve Chamber Design - 300 - 700mm DIDocument6 paginiButterfly Valve Chamber Design - 300 - 700mm DIRamakanth Putty100% (1)

- Base Plate DesignDocument8 paginiBase Plate DesignANANDA D SÎncă nu există evaluări

- Reinforced ConcreteDocument12 paginiReinforced ConcreteluckywaysÎncă nu există evaluări

- Irrigation Division Chunar, Mirzapur: Design of BeamDocument3 paginiIrrigation Division Chunar, Mirzapur: Design of Beamgovind narayan ShuklaÎncă nu există evaluări

- Design of BeamsDocument14 paginiDesign of BeamsNoor MohdÎncă nu există evaluări

- Slab Design 3BHKDocument14 paginiSlab Design 3BHKharshÎncă nu există evaluări

- Case 9: Four Edges DiscontinuousDocument2 paginiCase 9: Four Edges DiscontinuousEvonne LeeÎncă nu există evaluări

- Liquid Retaining Reinforced Concrete Section To BS 8007& BS 8110Document15 paginiLiquid Retaining Reinforced Concrete Section To BS 8007& BS 8110tttmm100% (1)

- Design Calculation - OhtDocument11 paginiDesign Calculation - OhtINNOVATIVE ENGINEER100% (1)

- Design of GLSRDocument263 paginiDesign of GLSRBattula Sridhar100% (2)

- Steel DesDocument5 paginiSteel DesJhan SeenÎncă nu există evaluări

- At Very Low Cutting SpeedsDocument40 paginiAt Very Low Cutting SpeedsThulasi Ram100% (1)

- Bus Cal - 2500aDocument11 paginiBus Cal - 2500aPCE PROJECTS PVT. LTD.Încă nu există evaluări

- One Way Slab and Standard HooksDocument21 paginiOne Way Slab and Standard Hooksmuhammad rid100% (1)

- Steel1 (26pages)Document26 paginiSteel1 (26pages)Kristin Brienne Leander-Renomeron50% (2)

- Canal Trough DesignDocument27 paginiCanal Trough DesignVenkatarathnam PulipatiÎncă nu există evaluări

- Design: Rigid Solutions - Final CoachingDocument11 paginiDesign: Rigid Solutions - Final CoachingEugene Ralph TimoteoÎncă nu există evaluări

- CorbelDocument4 paginiCorbelAnand SoniÎncă nu există evaluări

- Canal Trough DesignDocument33 paginiCanal Trough DesignNageswar Pattem100% (10)

- Example1 1-StraightsupportedDocument7 paginiExample1 1-StraightsupportedOmar BayouÎncă nu există evaluări

- Cable Trench DesignDocument24 paginiCable Trench DesignIrshad Khan100% (1)

- Unit 3 32,33,34,35Document3 paginiUnit 3 32,33,34,35Deepanshu VermaÎncă nu există evaluări

- Detail Design of Secondary BeamDocument5 paginiDetail Design of Secondary BeamAmit TharuÎncă nu există evaluări

- Calculation of Detailing of PileDocument2 paginiCalculation of Detailing of PileAsif Mostafa AnikÎncă nu există evaluări

- Canal DesignDocument35 paginiCanal DesignFranca-sp FrançaÎncă nu există evaluări

- Penulangan Dimensi - Manhole 1200x1800Document1 paginăPenulangan Dimensi - Manhole 1200x1800CDI EngineeringÎncă nu există evaluări

- Thirukkural PDFDocument138 paginiThirukkural PDFSelvakumaran DhandapaniÎncă nu există evaluări

- Autobiography of A SufiDocument130 paginiAutobiography of A SufispiralwavesÎncă nu există evaluări

- Daajis Address and QA To AAPI - Jan 5th 2022Document10 paginiDaajis Address and QA To AAPI - Jan 5th 2022Selvakumaran DhandapaniÎncă nu există evaluări

- Process Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaDocument4 paginiProcess Fmea: Table 6 Suggested Pfmea Severity Evaluation CriteriaSelvakumaran Dhandapani100% (1)

- Industry 4.0Document38 paginiIndustry 4.0Selvakumaran DhandapaniÎncă nu există evaluări

- Basics of Heat TreatmentDocument29 paginiBasics of Heat TreatmentSelvakumaran DhandapaniÎncă nu există evaluări

- Welding SymbolsDocument1 paginăWelding SymbolsSelvakumaran DhandapaniÎncă nu există evaluări

- SubmergedDocument32 paginiSubmergedSelvakumaran DhandapaniÎncă nu există evaluări

- Industry 4.0Document38 paginiIndustry 4.0Selvakumaran DhandapaniÎncă nu există evaluări

- Mmaw & GmawDocument54 paginiMmaw & GmawSelvakumaran DhandapaniÎncă nu există evaluări

- Close Your MouthDocument144 paginiClose Your MouthSelvakumaran Dhandapani100% (13)

- Weld DefectsDocument18 paginiWeld Defectsisaacthib100% (2)

- Mechatronics - Basics and Applications in RailwaysDocument25 paginiMechatronics - Basics and Applications in RailwaysSelvakumaran DhandapaniÎncă nu există evaluări

- With Grateful Thanks of Ms. Jyothsna Kethireddy: Presented By: Prof. V. ViswanadhamDocument17 paginiWith Grateful Thanks of Ms. Jyothsna Kethireddy: Presented By: Prof. V. ViswanadhamSelvakumaran DhandapaniÎncă nu există evaluări

- 5 S PRINCIPLESDocument14 pagini5 S PRINCIPLESSelvakumaran DhandapaniÎncă nu există evaluări

- With Grateful Thanks of Ms. Jyothsna Kethireddy: Presented By: Prof. V. ViswanadhamDocument17 paginiWith Grateful Thanks of Ms. Jyothsna Kethireddy: Presented By: Prof. V. ViswanadhamSelvakumaran DhandapaniÎncă nu există evaluări

- MM212 New Manual - FinalDocument30 paginiMM212 New Manual - FinalAbhishek KumarÎncă nu există evaluări

- Inventaa Hollow WallsDocument6 paginiInventaa Hollow WallsSumedh GuptaÎncă nu există evaluări

- Construction Cost Estimate: By: Engr. Erniel Dave A. GuyoDocument29 paginiConstruction Cost Estimate: By: Engr. Erniel Dave A. GuyoMica Joice FernandezÎncă nu există evaluări

- Aci Code ListDocument5 paginiAci Code ListM HAFEEZ RAJA100% (8)

- The Problem and Its BackgroundDocument4 paginiThe Problem and Its BackgroundSuzaku KururugiÎncă nu există evaluări

- DPL DripPanElbowDocument1 paginăDPL DripPanElbowPartha Sarathi SadhukhanÎncă nu există evaluări

- AITECH-Accredited Technology Nov. 2019Document12 paginiAITECH-Accredited Technology Nov. 2019Jesus Villaflor Jr.100% (1)

- Vci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesDocument2 paginiVci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesJaya RidwantoÎncă nu există evaluări

- Piping QC Inspector Resume 2020Document5 paginiPiping QC Inspector Resume 2020Omprakash Yadav100% (1)

- Minfm66645 Astm A312 Grade s32615Document4 paginiMinfm66645 Astm A312 Grade s32615Oleg ShkolnikÎncă nu există evaluări

- Logbook CEBDocument36 paginiLogbook CEBAnonymous ICo9rpfVt0Încă nu există evaluări

- Pipe ChartDocument2 paginiPipe ChartabdulÎncă nu există evaluări

- SERVICE MANUAL Whirlpool Front Load Drum WasherDocument27 paginiSERVICE MANUAL Whirlpool Front Load Drum Washerronald christian mendiguarin50% (2)

- Poon 2001Document10 paginiPoon 2001Al CaponeÎncă nu există evaluări

- PlasticsDocument15 paginiPlasticsKunalKumarSinghÎncă nu există evaluări

- Anaconda, Fatflot & Sludgeway Toro Wastewater EquipmentDocument16 paginiAnaconda, Fatflot & Sludgeway Toro Wastewater EquipmentDavidQueridoÎncă nu există evaluări

- Fdocuments - in - Automatic Ingot Feeder For BoundaryDocument5 paginiFdocuments - in - Automatic Ingot Feeder For BoundaryPooja BanÎncă nu există evaluări

- Data Sheet - IECExDocument3 paginiData Sheet - IECExAndreas PalalanganÎncă nu există evaluări

- Teflon Ptfe NXT 85 Product InfoDocument2 paginiTeflon Ptfe NXT 85 Product InfocvfÎncă nu există evaluări

- Whirlpool Energy Smart Electric ManualDocument15 paginiWhirlpool Energy Smart Electric Manualgiovannycarlos2Încă nu există evaluări

- Prince Product Catalogue 26-08-2021Document44 paginiPrince Product Catalogue 26-08-2021Abhi LyngdohÎncă nu există evaluări

- Post Tensioned SlabsDocument25 paginiPost Tensioned SlabsTolu AdegbenjoÎncă nu există evaluări

- European Steel and Alloy Grades: 50crmov13-15 (1.2355)Document2 paginiEuropean Steel and Alloy Grades: 50crmov13-15 (1.2355)farshid KarpasandÎncă nu există evaluări

- RRS Full NotesDocument164 paginiRRS Full NotesAzhar KhanÎncă nu există evaluări

- MP 0024Document4 paginiMP 0024Loren Viejay100% (1)

- Clearance For Plaster by MEPDocument63 paginiClearance For Plaster by MEPAnonymous LnJVtahyRÎncă nu există evaluări

- Ghu PDFDocument28 paginiGhu PDFGautam ChaudhuryÎncă nu există evaluări

- Vinyl Floor InstallDocument10 paginiVinyl Floor InstallMoose112Încă nu există evaluări

- Fronius Cold Metal TransferDocument16 paginiFronius Cold Metal Transferbonmarche28Încă nu există evaluări

- Encofrado Meva Alufix AvaDocument42 paginiEncofrado Meva Alufix AvapablopelaÎncă nu există evaluări