Documente Academic

Documente Profesional

Documente Cultură

HE AWN: RDP Technologies, Inc

Încărcat de

Ashwani KumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

HE AWN: RDP Technologies, Inc

Încărcat de

Ashwani KumarDrepturi de autor:

Formate disponibile

T H E D AW N

OF A

NEW

BIOSOLIDS PROCESS

RDP Technologies, Inc.

Hybrid Evaporator

Air Discharge Hot Oil

Solids Feed

Slide Gates

Load Cells

Discharge

The Hybrid Evaporator can be operated as a dryer or as a pasteurizer. In both cases, biosolids are automatically loaded from a storage bin. The biosolids are processed on a batch basis. The Hybrid utilizes a rotor mounted in a stationary drum, both of which are heated using a thermal

fluid. The entire assembly is mounted on load cells. When the predetermined final solids content is achieved, the bottom slide gates automatically open, and the end product is conveyed to storage. The entire system is totally enclosed to minimize odors and dusting.

RDP Technologies, Inc.

DRYERS

D I S A D VA N T A G E S Dusty end product High capital cost High operating cost Complicated operation A D VA N T A G E S Volume reduction Class A end product Easy end product to handle, store and convey

H Y B R I D E VA P O R A T O R

A D VA N T A G E S

Volume reduction Low capital cost Class A end product Long-term stable product

PA S T E U R I Z AT I O N

D I S A D VA N T A G E S No volume reduction Wet end product A D VA N T A G E S Low capital cost Low operating cost Class A end product Long-term stable product Easy to operate

Easy product to handle, store and convey Moderate operating cost Easy to operate

The Hybrid Evaporator addresses both vector attraction reduction and pathogens in a single vessel. The process starts by automatically loading biosolids into the heating chamber. If the desired end product solids content is 90% or greater, then the biosolids are simply dried. If the desired end product is 75 90% solids, then vector attraction is achieved by drying. Pathogens are destroyed by exceeding the timetemperature requirements for Class A biosolids, alternative #1.

When the desired end product is between 20 75% solids, vector attraction is achieved by the addition of a small amount of lime, typically 5%. Pathogens are destroyed through the Class A time and temperature requirements. The end product solids concentration is then achieved by further heating of the pasteurized solids The load cells allow the operation to be precisely controlled and produce consistent final solids content.

RDP Technologies, Inc.

Hybrid Evaporators can be run using natural gas, methane, heating oil or electricity. The boiler provides hot oil to both the heating drum and the rotating rotor.

Load cells provide precise control of the end product solids content. For each batch, input cake solids and desired final solids are entered into the control system. The system calculates the final weight, to produce the final solids content, and operates until evaporation produces the final weight. By precisely controlling moisture content of the final product, the Hybrid Evaporator avoids dusting problems caused by overly dried biosolids.

RDP Technologies, Inc.

2495 Boulevard of the Generals Norristown, PA 19403 www.rdptech.com Phone: (610) 650-9900 Fax: (610) 650-9070

RDP is a registered trademark of RDP Technologies, Inc. The Hybrid Evaporator is protected by one or more U.S. and foreign patents, with additional patents pending.

S-ar putea să vă placă și

- Se Downloads Paddle Dryer DataDocument16 paginiSe Downloads Paddle Dryer DataJignesh PanchalÎncă nu există evaluări

- Alphakat CY Presentation-1Document20 paginiAlphakat CY Presentation-1Niko Koja0% (1)

- Fazlani RetortDocument23 paginiFazlani RetortVishal Naveen ShettyÎncă nu există evaluări

- Alkyd GBDocument2 paginiAlkyd GBAhmad HamoudaÎncă nu există evaluări

- Fertilizer Industry Tcm11-16156 Rotary DryerDocument4 paginiFertilizer Industry Tcm11-16156 Rotary DryerwenigmaÎncă nu există evaluări

- Brochure RDF Drying UKDocument2 paginiBrochure RDF Drying UKMauliddani 'Milly' LatifahÎncă nu există evaluări

- Two-Phase Anaerobic Digestion For Class A Biosolids: Epa CertifiedDocument2 paginiTwo-Phase Anaerobic Digestion For Class A Biosolids: Epa CertifiedLTE002Încă nu există evaluări

- Falling Film Evap For DairyDocument8 paginiFalling Film Evap For DairysamirdudhandeÎncă nu există evaluări

- Agitated Thin Film Dryer Manufacturer-CentPro EngineeringDocument6 paginiAgitated Thin Film Dryer Manufacturer-CentPro EngineeringAbhay RoyÎncă nu există evaluări

- Freeze DryingDocument10 paginiFreeze Dryingmamun_ru50% (2)

- Heat Load in Refrigeration SystemsDocument72 paginiHeat Load in Refrigeration Systemsforeverdiesel100% (8)

- The Leader In: Gas Dehydration & FiltrationDocument8 paginiThe Leader In: Gas Dehydration & FiltrationMorteza SepehranÎncă nu există evaluări

- Hedrich Vacuum Systems Presentation on Vapour Phase Drying ProcessDocument78 paginiHedrich Vacuum Systems Presentation on Vapour Phase Drying ProcessDurgesh K. SrivastavaÎncă nu există evaluări

- Firmenbroschuere Mahler AGS GMBHDocument16 paginiFirmenbroschuere Mahler AGS GMBHConan AbernethyÎncă nu există evaluări

- Case Study Meat ProcessingDocument2 paginiCase Study Meat ProcessingChirag GoelÎncă nu există evaluări

- HTF DegradationDocument13 paginiHTF DegradationcarzanteÎncă nu există evaluări

- Pyrolysis of WaDocument6 paginiPyrolysis of WaRogen FancubitÎncă nu există evaluări

- Tech Memo 14Document8 paginiTech Memo 14LTE002Încă nu există evaluări

- Freeze Dryer Lyophilisation FishDocument4 paginiFreeze Dryer Lyophilisation FishcouvrefeuÎncă nu există evaluări

- Autoclave Validation MSPDADocument35 paginiAutoclave Validation MSPDAYessine Mrabet100% (1)

- Polyfoam 235L polyisocyanurate laminationDocument2 paginiPolyfoam 235L polyisocyanurate laminationA MahmoodÎncă nu există evaluări

- Penge Ring AnDocument75 paginiPenge Ring AnSondang Kiki RositaÎncă nu există evaluări

- Cold Storage & Pack House Presentation 1Document81 paginiCold Storage & Pack House Presentation 1Hsamb AbmÎncă nu există evaluări

- Se Downloads Sludge DryingDocument4 paginiSe Downloads Sludge Dryingkosmc1230% (1)

- Thermal Sludge Dryers for Wastewater TreatmentDocument8 paginiThermal Sludge Dryers for Wastewater TreatmentmuhammedÎncă nu există evaluări

- Se-Downloads-Drying Technologies For Sewage Sludge Web en - PDFFDocument9 paginiSe-Downloads-Drying Technologies For Sewage Sludge Web en - PDFFkosmc123Încă nu există evaluări

- HSAMB Cold Storage & Pack House PresentationDocument124 paginiHSAMB Cold Storage & Pack House PresentationHsamb AbmÎncă nu există evaluări

- Biodiesel Plant PDFDocument3 paginiBiodiesel Plant PDFJunaid MalikÎncă nu există evaluări

- Industrial Applications: Production EngineeringDocument6 paginiIndustrial Applications: Production EngineeringshsecoÎncă nu există evaluări

- MVS Hydrogen Generator Product CatalogueDocument4 paginiMVS Hydrogen Generator Product CatalogueRachit VemulaÎncă nu există evaluări

- Falcon Brochure 9-18-12Document2 paginiFalcon Brochure 9-18-12spalomosÎncă nu există evaluări

- Callidus-Honeywell Thermal Brochure 13Document8 paginiCallidus-Honeywell Thermal Brochure 13nay denÎncă nu există evaluări

- Flyer Sewage Sludge DryingDocument6 paginiFlyer Sewage Sludge Dryingkosmc123Încă nu există evaluări

- Vadeb Brochure GeneralDocument2 paginiVadeb Brochure GeneraljmpbarrosÎncă nu există evaluări

- Adiabatic Dryers PresentationDocument27 paginiAdiabatic Dryers PresentationJunaid IqbalÎncă nu există evaluări

- Maquina de Biodiesel A Partir de Aceite CaseraDocument2 paginiMaquina de Biodiesel A Partir de Aceite CaseraAndres Echeverri CastroÎncă nu există evaluări

- Magic Heating BoxDocument4 paginiMagic Heating BoxVisan GheorgheÎncă nu există evaluări

- HaarslevDocument12 paginiHaarslevjimdacalano1911Încă nu există evaluări

- Holstein Industrie EnglishDocument6 paginiHolstein Industrie Englishdejan.strbacÎncă nu există evaluări

- Climate Solutions HandbookDocument44 paginiClimate Solutions HandbookMARIVEL BASAÎncă nu există evaluări

- GEA Wiegand Distillation Technology GuideDocument16 paginiGEA Wiegand Distillation Technology GuideNurul AniraÎncă nu există evaluări

- Direct Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryDocument4 paginiDirect Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryInternational Aquafeed magazineÎncă nu există evaluări

- RotothermDocument2 paginiRotothermLee HaagÎncă nu există evaluări

- Modular Hydrogen Plants: Hydro-ChemDocument12 paginiModular Hydrogen Plants: Hydro-ChemFahryPurnamaÎncă nu există evaluări

- Lyophilization BasicsDocument7 paginiLyophilization Basicsj.k.kumar100% (2)

- 03 Modular Skid SystemsDocument16 pagini03 Modular Skid Systemsjosethompson100% (2)

- ASU Packaged Brochure - LindeDocument12 paginiASU Packaged Brochure - LindeBayu KusumaÎncă nu există evaluări

- Biodiesel ESW06Document27 paginiBiodiesel ESW06mrbin45Încă nu există evaluări

- GEA - Refrigeration in Oil & Gas Industry - tcm11-33981Document4 paginiGEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dhroov SharmaÎncă nu există evaluări

- Modular Skid SystemsDocument16 paginiModular Skid SystemsFWICIP100% (1)

- Perfecting Thermal Processing Worldwide: Driers - Ovens - Roasters - Toasters - CoolersDocument20 paginiPerfecting Thermal Processing Worldwide: Driers - Ovens - Roasters - Toasters - CoolerskapokÎncă nu există evaluări

- Steam GenerationDocument2 paginiSteam GenerationSandip KeswaniÎncă nu există evaluări

- Brochure Fry Logic - EngelsDocument16 paginiBrochure Fry Logic - Engelsmikia15Încă nu există evaluări

- WWW Water Siemens ComDocument2 paginiWWW Water Siemens ComMashudi FikriÎncă nu există evaluări

- Lyophilization DetailsDocument33 paginiLyophilization Detailsj.k.kumar100% (4)

- Oilon Chillheat: Optimized Cooling and Heating PerformanceDocument12 paginiOilon Chillheat: Optimized Cooling and Heating PerformanceMarceloÎncă nu există evaluări

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDe la EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryÎncă nu există evaluări

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDe la EverandModeling, Control, and Optimization of Natural Gas Processing PlantsEvaluare: 5 din 5 stele5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- Hoho Map 2015Document1 paginăHoho Map 2015Anonymous uSezVd1LÎncă nu există evaluări

- Msds 9149 Conc SdsDocument8 paginiMsds 9149 Conc SdsAshwani KumarÎncă nu există evaluări

- London Guidebook EN FR DE PDFDocument96 paginiLondon Guidebook EN FR DE PDFAshwani KumarÎncă nu există evaluări

- Delivering Viable ProjectDocument24 paginiDelivering Viable ProjectAshwani KumarÎncă nu există evaluări

- EPA's New RFS RuleDocument195 paginiEPA's New RFS RuleAshwani KumarÎncă nu există evaluări

- Explore iconic London landmarks with a London PassDocument1 paginăExplore iconic London landmarks with a London PassAmber RileyÎncă nu există evaluări

- CH4 Recovery From Landfill - 01!11!08Document21 paginiCH4 Recovery From Landfill - 01!11!08Ashwani KumarÎncă nu există evaluări

- European Biogas Companies Catalogue PDFDocument29 paginiEuropean Biogas Companies Catalogue PDFAshwani KumarÎncă nu există evaluări

- Biomethane by GreenlaneDocument3 paginiBiomethane by GreenlaneAshwani KumarÎncă nu există evaluări

- FCT h2 Fuelcell Factsheet PDFDocument2 paginiFCT h2 Fuelcell Factsheet PDFKristian PardedeÎncă nu există evaluări

- Biogas HandbookDocument126 paginiBiogas HandbookmoemuneeÎncă nu există evaluări

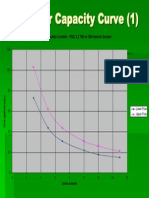

- Separator Capacity Curve Flow vs Solids Content PSS 3.2 780 500 micronDocument1 paginăSeparator Capacity Curve Flow vs Solids Content PSS 3.2 780 500 micronAshwani KumarÎncă nu există evaluări

- Lystek Presentation Sep 27 2012Document18 paginiLystek Presentation Sep 27 2012Ashwani KumarÎncă nu există evaluări

- FSP PresentationDocument35 paginiFSP PresentationAshwani KumarÎncă nu există evaluări

- Ammonia RecoveryDocument2 paginiAmmonia RecoveryAshwani KumarÎncă nu există evaluări

- Manufacturing Ammonium Sulphare From GypsumRich Flue GasesDocument7 paginiManufacturing Ammonium Sulphare From GypsumRich Flue GasesAshwani KumarÎncă nu există evaluări

- AshwaniKumar B3C PresentationDocument38 paginiAshwaniKumar B3C PresentationAshwani KumarÎncă nu există evaluări

- Manufacturing Ammonium Sulphare From GypsumRich Flue GasesDocument7 paginiManufacturing Ammonium Sulphare From GypsumRich Flue GasesAshwani KumarÎncă nu există evaluări

- Design Diesel-Photovoltaic Hybrid Power PlantDocument93 paginiDesign Diesel-Photovoltaic Hybrid Power PlantDaniel Okere100% (1)

- 1756 Controllogix I/O ModulesDocument7 pagini1756 Controllogix I/O ModulesminurajraÎncă nu există evaluări

- Prestige Bella VistaDocument27 paginiPrestige Bella VistaArun RajagopalÎncă nu există evaluări

- Eductor AgitationDocument2 paginiEductor AgitationNicolás Solano CondeÎncă nu există evaluări

- DLC3 Yaris 2016Document3 paginiDLC3 Yaris 2016kurnia wanÎncă nu există evaluări

- Laboratory Design Capacitive Displacement SensorDocument10 paginiLaboratory Design Capacitive Displacement SensorElizabethÎncă nu există evaluări

- Cam DynamicsDocument8 paginiCam DynamicsRitik PatelÎncă nu există evaluări

- Fengine S4800 Switch Datasheet-V30R203 PDFDocument7 paginiFengine S4800 Switch Datasheet-V30R203 PDFAriston SitanggangÎncă nu există evaluări

- Objective SAMPLEDocument4 paginiObjective SAMPLEAnnjen MuliÎncă nu există evaluări

- ROC800-Series IEC 62591 Interface: ScalabilityDocument10 paginiROC800-Series IEC 62591 Interface: ScalabilityBMÎncă nu există evaluări

- Re 29037Document12 paginiRe 29037BorisÎncă nu există evaluări

- Mechanics of A Diesel Fuel Injection SystemDocument8 paginiMechanics of A Diesel Fuel Injection Systemekitriandi0% (1)

- 363-5 Machine Ride Control Actuator - Current Below NormalDocument3 pagini363-5 Machine Ride Control Actuator - Current Below NormalArtin HykoÎncă nu există evaluări

- EI 6702-Logic and Distributed Control SystemDocument2 paginiEI 6702-Logic and Distributed Control SystemMnskSaro50% (2)

- Manufacturing Process of Piston Rings and Cylinder LinersDocument26 paginiManufacturing Process of Piston Rings and Cylinder Linersanish jain100% (6)

- Central Changing of Triggers in WinCC V6.2 Images (PDL)Document10 paginiCentral Changing of Triggers in WinCC V6.2 Images (PDL)www.otomasyonegitimi.comÎncă nu există evaluări

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocument24 paginiACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaÎncă nu există evaluări

- SEREP System Equivalent ReductionDocument2 paginiSEREP System Equivalent ReductiondogusÎncă nu există evaluări

- MLU Spec Sheet 250W 255WDocument2 paginiMLU Spec Sheet 250W 255WAdrian TurcanuÎncă nu există evaluări

- PackagesDocument2 paginiPackagesSteven MirandaÎncă nu există evaluări

- H2S ScavengerDocument7 paginiH2S ScavengerRizwan FaridÎncă nu există evaluări

- Terminal Blocks: KasugaDocument6 paginiTerminal Blocks: KasugaKs MuraliÎncă nu există evaluări

- Distance Measurement Methods & CalculationsDocument16 paginiDistance Measurement Methods & CalculationsAlfonso John AnthonyÎncă nu există evaluări

- Design and Safety Handbook 3001.5Document51 paginiDesign and Safety Handbook 3001.5phankhoa83Încă nu există evaluări

- TS1A-13A: Operation and Maintenance ManualDocument204 paginiTS1A-13A: Operation and Maintenance ManualJavier AponteÎncă nu există evaluări

- Relief/Unloading Valve: Spool, Pilot Operated 200 L/Min (52 Usgpm) - 350 Bar (5000 Psi)Document2 paginiRelief/Unloading Valve: Spool, Pilot Operated 200 L/Min (52 Usgpm) - 350 Bar (5000 Psi)Dragan LazicÎncă nu există evaluări

- Satellite 2755dvdDocument2 paginiSatellite 2755dvdeduinnÎncă nu există evaluări

- Fix Canon Pixma MP287 Printer Error CodesDocument7 paginiFix Canon Pixma MP287 Printer Error CodesBen BennyÎncă nu există evaluări

- Part 07 Digital Modulations - EEE309Document13 paginiPart 07 Digital Modulations - EEE309elon muskÎncă nu există evaluări

- Contact Inform 2002 PDFDocument24 paginiContact Inform 2002 PDFFrank AlmeidaÎncă nu există evaluări