Documente Academic

Documente Profesional

Documente Cultură

Kumar Et Al 2005

Încărcat de

Zhigang FengDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kumar Et Al 2005

Încărcat de

Zhigang FengDrepturi de autor:

Formate disponibile

Technovation 25 (2005) 477488 www.elsevier.

com/locate/technovation

Computers in manufacturing: towards successful implementation of integrated automation system

K. Dhinesh Kumara,*, L. Karunamoorthya, Hubert Rothb, T.T. Mirnalineec

a b

Department of Mechanical Engineering, Anna University, Chennai, India Institute of Control Engineering, University of Siegen, Siegen, Germany c CSI Institute of Technology, Thovalai, TamilNadu, India

Abstract Survival of industries depends on the integration of new technologies and business management processes. The objective of this research is to provide some important factors on the key technologies of information technology, managerial and communication issues that must be addressed for designing and implementing integrated CIM systems that lead to the concept of totally integrated automation system (IAS). The research also identies a set of critical success factors for the development of totally integrated exible automation systems. Success in implementation becomes a reality when the set goals and objectives stipulated by the adoption strategy are fully realized. The factors that are critical to the successful implementation of IAS have been identied and discussed, based on a review of literature, a eld study that surveyed different types of manufacturing rms and series of interviews with a number of working professionals and managers in three automation and system components exhibitions held in Europe. The data collected on critical factors were then summarized and compared to four specic sets of critical success factors in related areas. These studies assess the impacts of the identied factors on the benets of IAS and develop a conceptual framework for measuring success and highlight the relationship among the success factors in the development and implementation of IAS. q 2004 Elsevier Ltd. All rights reserved.

Keywords: Computer integrated manufacturing; Control technology; Information technology; Integrated automation; Critical success factors

1. Introduction In todays competitive global market, for the survival of any industry, manufacturing companies need to be exible, adaptive, responsive to changes, proactive and be able to produce a variety of products in a short time at a lower cost (Nagalingam and Lin, 1999). Hence, manufacturing companies are compelled to seek advanced technologies by integrating manufacturing facilities and systems in an enterprise through computers, its peripherals and communication networks to transform islands of enabling technologies into a highly interconnected manufacturing system (Lin, 1976). Today, the capability of producing high quality products according to diverse customer requirements with shorter delivery times has become the characteristic of order-qualiers for manufacturing industries. Fig. 1 shows

* Corresponding author for correspondence. Address: 22-Pattisson Street, Nagercoil, Kanyakumari District, Tamil Nadu, India 629 001. Tel.: 914652-237473; fax: 91-4652-233509.. E-mail address: dhinesh123@yahoo.com (K. Dhinesh Kumar). 0166-4972/$ - see front matter q 2004 Elsevier Ltd. All rights reserved. doi:10.1016/j.technovation.2003.09.004

the drivers for the change management. Furthermore, nonprice factors, such as quality, product design, innovation and delivery services are the primary determinants of product success in todays global arena (Shaw, 2000). Implementing integrated advanced technologies is an effective approach towards solving the problems of decreased productivity, labor costs and consequent rise in unit costs, which are continually plaguing present day manufacturing managers (Lin, 1976). Implementation of advanced manufacturing technologies (AMTs) provides opportunities to achieve competitive advantage in an intermediate- to long-term time frame (Sohal, 1997).When necessary, if enterprises decide to change their manufacturing systems, modications to current manufacturing systems are required because of changing market requirements, business objectives, business requirements, improved manufacturing concepts or available technologies. The decision to manufacture new products might result in change in the existing computer integrated manufacturing (CIM) systems. The manufacturing systems that are in operation today will be re-engineered at some point in time to turn into

478

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

Fig. 1. Drivers for change management.

next-generation manufacturing systems, so that current integrated systems become future heritage systems (Zwegers and Gransier, 1995). It would seem that to satisfy the evolving market needs, the manufacturing facilities would need to integrate the plant automation layer with enterprise business systems (Dhinesh Kumar et al., 2002b) in order to bring their manufacturing facilities under control and to satisfy the demanding supply chain requirements of global e-commerce (which is still evolving). Technology alone is only a piece of solution and integrated automation is an essential success factor in automation, control and information systems (Dhinesh Kumar et al., 2002a). It is important to recognize that previous research did not seek to identify the critical success factors (CSFs) specic to the development of integrated automation solutions for the manufacturing industries. This paper describes the control technology based on personal computers (PCs), and the CSFs for the implementation of integrated automation systems (IAS).

2. Historical developments in industrial automation and control Around the year 1900, factory mechanization facilitated mass production to meet the consumers demands for improved products. In the year 1930, transfer lines and xed automation were created to facilitate mass production. This resulted in the development of programmable automation. By the year 1950, numerical control (NC) was developed as an innovative approach to programmable automation. With the developments in commercially available computer technology, the application of computers in manufacturing started to emerge by producing a variety of new technologies. By the year 1955, the introduction of computer aided

design (CAD) and developments of NC resulted which led to the evolution of systems like computer NC (CNC) and direct NC (DNC). By the year 1970, developments in CAD applications and computer aided manufacturing (CAM) based systems introduced the concept of CIM, which are collectively named as AMTs (Nagalingam and Lin, 1999). AMTs provide exibility as well as data driven computer integration for a manufacturing organization, in which the manufacturing technology utilized is intelligent enough to process the activities with less human intervention. The need for integration became a necessity by the advanced systems in CAM, computer aided process planning (CAPP), computer aided quality control (CAQC), exible manufacturing system (FMS) and CIM in 1980s, in response to the problems faced by traditional manufacturing processes of industrial automation. Individual automation leads to islands of automation. These islands of automation did not facilitate communication between the functional units and plagued the manufacturing industry (Shaw, 2000). In order to integrate islands of automation, the United States Air Force initiated the Integrated Computer Aided Manufacturing (ICAM) programme in 1983 (Foston et al., 1991). The European Strategic Programme for Research and Development in Information Technologies (ESPRIT)and Consortium European Computer Integrated Manufacturing Architecture (AMICEin reverse) initiated the computer integrated manufacturing open system architecture (CIMOSA) concepts in 1983 (ESPRIT, 1993). As discussed by Segarra (1999), the advanced information technology (IT) road map for the European manufacturing industry initiative was launched by Daimler Benz in 1993, for technological integration through the development of integration platforms, and the usage of generic networked enterprise (re)engineering methodologies.

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

479

International standards related to CIM such as electronic data interchange (EDI), distributed ofce application model (DOAM), manufacturing automation protocol (MAP), technical and ofce protocol (TOP), open distribution processing (ODP), open system interconnection (OSI) and standard for exchange of product data (STEP) started to bridge the communication gap. Some of the major standardization organizations within this eld are the International Electrotechnical Commission (IEC), the International Standards Organization (ISO), the Open Systems Foundation (OSF), the American National Standards Institute (ANSI), and the Institute of Electrical and Electronics Engineers (IEEE) (Rahkonen, 1995). The generic Internet based utility hooks up host computers (which handle high-level decisions) and dedicated process controllers. This gives the controllers various facilities to interact, report, query, and coordinate activities with computers located anywhere in the Internet (Fuertes et al., 1999; Jagdale and Merchant, 1996). The new possibilities for connectivity, sharing and coordination have shifted the way manufacturing enterprises are run (Shaw, 2000). Client/server architecture and groupware tools attempt to coordinate the anarchy created by the PC revolution, and provide means for traveling users who want to connect their own Web from anywhere in the world, for storing, analyzing, and coordinating their activity (Dessy, 1996). Distributed computing technologies motivate scientists and industries to develop modular architectures, distributed and linked through specic networks in contrast to centralized and rigid organizations. Advances in software technology have been transforming the world of integration into compatible systems and devices by establishing an open connectivity standard, agreed by the manufacturers, which will provide plug-and-play communication and interoperability between eld devices, control systems, and enterprise-wide business applications. In the year 2000, the Venture Development Corporation reported that PC-based control application products are forecasted to have double-digit growth rates through 2005. The Siemens Automation and Drives group forecast that the number of PC-based automation solutions will grow rapidly by 20% each year.

3. Research objectives and methodology The developments of the personal computer and subsequent quality improvements have fuelled the explosion in information processing equipment (Barua and Lee, 1997). The mystery is why this massive computer investment has not resulted in measured productivity gains in the service sector. Based on the observation, not every rm that tried CIM was successful and the fact that many manufacturing concerns are signicantly declining in their expectations about CIM (Gupta, 1996) leads us to the possibility that the success of integrated CIM requires some

critical factors. The primary objective of this research is to provide some important factors on the key technologies of information technology, managerial and communication issues that must be addressed for designing and implementing integrated CIM systems that lead to the concept of totally integrated automation system and to identify a set of CSFs for the development and implementation of totally integrated exible automation systems called totally integrated automation systems. The factors that are critical to the successful implementation of IAS are identied and discussed based on a review of literature, a eld study that surveyed different types of manufacturing rms and series of interviews with a number of working professionals and managers of three leading automation and system components exhibitions held in Europe. (An automation and system components exhibition, where more than 690 exhibitors from almost 20 countries exhibited their product developments and solutions; another exhibition where more than 8000 companies from 60 countries exhibited their products with an impressive array of trends, innovations and future markets in information technology, telecommunications and automation, embracing almost every type of equipment, as well as systems, stand-alone solutions, integrated solutions and concepts projected the supply and demand of the global market; and in an another machine building and automation exhibition where nearly 28,000 visitors ocked through the aisles to see 750 exhibits.) The eld study consists of an interview instrument. Within each rm, a plant manager was identied as the target for the questionnaire. The study variables are the type of industry, the relationship of the project to organizational structure, the criteria used to measure the success, and the factors related to the project, project manager, project team members, organization, and the environment. Success is measured by indicators as better return on equity, reduced throughput, reduced cost, improved quality, enhanced competitiveness, better control and quick response. These factors were then summarized and compared to four specic sets of CSFs in related areas. These studies assess the impacts of the identied factors on the benets of IAS and develop a conceptual framework for measuring success and show the relationship among the success factors in the development and implementation of IAS. Due to the fact that control and automation systems are characterized by constant technological change and that CSFs in integrated automation system development have not been published, the chosen research strategy is ideally suited to the dened problem.

4. PC-based control and automationfuture proof technology In the 1980s, with the advent of the PC, every computer had the necessary hardware and software for operation.

480

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

The new client/server technology makes the processing power of a PC comparable with midrange systems as well as mainframes (Johnny et al., 1998). The client/server conguration also provided scalability so that hundreds of computers could be linked. Client/server architecture facilitates the application of PC-based systems to all the islands of automation on the typical plant oor. Open system architecture allows enterprises to build distributed applications that provide true enterprise resource planning and customer-oriented manufacturing system capabilities (Martin, 1995). Low cost communication technology, congurable local area networks (LANs) and congurable wide area networks (WANs) produce a exible, scalable, distributed system to make CIM become a reality. Architecture: Formerly, the manufacturers had been forced to use a multi-layered hierarchy in their operations. New technological advances in client/server architecture have allowed them to utilize PCs with terminal server capabilities in order to create highly networked automation solutions. The users can now mix Windows and Linux based PC control systems to create integrated automation solutions that rely on standard hardware and software. The PC, an excellent all around solution: The number of PC-based automation solutions is growing because no other system has such a large selection of hardware and software options (Siemens, 2001). Many automation tasks, including open- and closed loop control and motion control, have been added to the classic PC tasks. PCs are now breaking down the boundaries between technical and ofce-based IT. PC-based automation, brilliant perspectives: One of the most important requirements that the manufacturers of automation systems have to meet is an open platform. Only PCs offer a totally open platform; no other system exists in the market with so many hardware and software options for any automation task such as technology interface, open and closed control, operator control, process control and monitoring, visualization, measured value recording, data processing, industrial image processing, communication, motion control, or input output distribution (Siemens, 2001). PC-based control offers the connection to master control systems via industrial Ethernet and to the eldbus peripheral. Visualization and PC-based control can be ideally united in one PC. The enormous range of PC hardware and software options makes PCs amazingly versatile. The availability of interfacing cards suitable for motion control systems and other functions allows PCs to be used for mass applications in an ofce and factory environment. Bringing together the worlds of technical and commercial IT by interfacing with high-level management systems, the so-called manufacturing of execution systems becomes easy. The options for upgrading automation solutions to integrated Intranet and Internet technologies have been improving all the time. It is already possible to control and monitor remote systems and installations. Systems

capable of transmitting vital information via the Internet reduce maintenance time, optimize manufacturing sequences and capacity planning. PC-based control offers software for quality functionality including the denitions and benets of applying statistical process control and statistical quality control. PCs can now perform automation functions that once required dedicated controllers such as programmable logic controllers.

5. Open system, eldbus and Ethernet technology Open system: One of the most important requirements for an open control system is the ability to integrate offthe-shelf hardware and software components into a control system which supports standard environments. The development of an open control system, which operates on a standard PC hardware, enables end users to optimize their electronic equipment according to their custom requirements (Pritschow et al., 1997). An open architecture controller can only achieve the integration of control software from different controller manufacturers into a manufacturing system. The characteristics of the reference architecture are modularity, interoperability, portability, and scalability (Pritschow et al., 1994). From a user point of view, the main advantages of open systems can be grouped into increased interactivity of systems from different vendors and the ability to upgrade components to provide increased performance, availability, etc. when the need arises (Rahkonen, 1995). Hence computers, which provide the controller functions, communication, and operating functions, play an important role in modern manufacturing. A well-dened interface can be achieved (Rahkonen, 1995) either as a de jure standard dened by a formally recognized standardization organization or by the fact that a product becomes widely adopted and used as a de facto standard. Fieldbus: Optimizing a plant requires that the typical hierarchy of networks, gateways and systems be attened to allow fast, easy integration of sensors/actuators, automation systems and plant application software packages. The development of a new, advanced network communication technology, a foundation for digital control systems, which came to be known as eldbus in the mid-1980s, has had a profound effect on plant automation strategies (Fieldbus, 2001). Bi-directional, multi-drop eldbus systems operating at the device level of the plant network hierarchy are used to interconnect transmitters, positioners and other eld devices. Fig. 2 illustrates the eldbus concept and the components that can be connected (Tian et al., 2000). Major end users have found that eldbus provides up to 75% reduction in instrumentation and control maintenance costs. The availability of remote device diagnostic information in a eldbus system ensures that maintenance personnel only work on equipment that is actually in need of repair. In addition, eldbus improves single loop integrity

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

481

6. Modular concepts with distributed intelligence Distributed object computing paradigm allows objects to be distributed across a heterogeneous network, and allows each of the components to interoperate as a unied system. Modular approach can radically simplify systems development. Distributed object models and tools extend an object-oriented programming system (Szyperski, 1998; Yau and Xia, 1998). The objects may be distributed in different computers throughout a network, which resides within their own dynamic library outside of an application, and yet appear as though they were local within the application. This is the essence of plug-and-play software. Component-based development substance the industrialization of software development. This principle applies equally to software system development for manufacturing process, allowing unpredicted quality, speed of development, and highly effective change management. The major advance in modular plant and machine construction is distributed intelligence to eld devices, drives and peripheral devices with programmable intelligence, such as a programmable logic controller (PLC) core. The automation architecture provides mechanisms for composing modular components and allows distributed objects to refer to one another by function and capability, irrespective of their location (Griss, 1997; IBM 2000). Objects communicate using a universal streaming data bus standard. They can move around, be re-connected dynamically, and seamlessly resume previously established connections with one another. The designer has to group functions in modules in such a way that their interdependence is minimized. Among the available component infrastructure technologies, the standardized technologies are Object Management Groups CORBA (Common Object Request Broker Architecture), Microsofts Component Object Model (COM), Object Linking and Embedding (OLE) and Distributed COM (DCOM), and Suns JavaBeans and Enterprise JavaBeans (Kozaczynski and Booch, 1998).

Fig. 2. Fieldbus architecture.

by locating device scheduling and proportional integral derivative (PID) control in the eld, and provides built-in redundancy with a backup link active scheduler. Ethernet: Industrial Ethernet has emerged as a major component in todays plant network hierarchy. The Ethernet network, which is used at the host level as a high-speed plant backbone, is intended for subsystem integration and high performance control applications. Just as eldbus at the device level revolutionized modern control schemes, Ethernet dramatically simplies the host level of the system by simplifying enterprise control and remote input output networking. Because Ethernet at the host level takes the place of the control and plant networks, it is often regarded as more of a hostbus than a eldbus. Together, Ethernet and device-level eldbus provide an open solution for sensors to the boardroom integration, by supplying a common specication for access to automation systems in the eld (Tian et al., 2000). Using this common specication, data servers can easily access plant data and provide the client/server communications needed for corporate management information system and business application packages. This tight integration of plantwide data also allows manufacturers to realize additional benets from enterprise resource planning. Because high speed (100 Mbit/s) Ethernet networks use standard Ethernet cabling and low-cost commercial off-the-shelf (COTS) equipment, plants can migrate to this technology economically. Combining high performance and low-cost, COTS Ethernet technology with device-level eldbus provides the architecture needed for cost-effective, plantwide information integration. Ethernet and the TCP/IP protocol have also been achieving more and more acceptance (Siemens, 2001) in industrial automation technology. Major technical advances such as fast Ethernet switching and full duplex communication have turned the Ethernet into a powerful communication system with many benets for industrial users and manufacturers.

7. Information-based manufacturing Factory production processes have matured to a stage where the manufacturing of product families in small batch sizes is becoming increasingly economically viable. This achievement can be largely attributed to the tremendous advances in information technology over the past two decades (Aggarwal, 1995). The ow of information from one process to another can be considered as a lubricating force, which improves both productivity and product quality. As the existing islands of technology are pulled together and the understanding of process dynamics improves, a more controlled manufacturing process is

482

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

Fig. 3. Components of information-based manufacturing.

exercised. It is this tighter process control that is shaping the path towards truly congurable manufacturing. The Web infrastructure: Manufacturing and automation have always gone hand in hand. Moving from manual labor to relays and toggle switches to todays smart application software, manufacturing industries have embraced automation as a means of increasing productivity. With the advent of the Internet, the demands on manufacturing are shifting again and the pace of change is accelerating. As people have become used to information at their ngertips, markets now want products to arrive more quickly with greater customization. Manufacturing information portals provides customizable user windows for moving plant data from the factory to any global user who needs them. Portal visibility on this information provides awareness of problems to minimize downtime and optimize equipment effectiveness. By using todays portal technology such as the Internet and Intranets, information-based manufacturing uses the right information to know what products to make, when to make them, and then making them at the best possible means. The key components of informationbased manufacturing (Shaw, 2000) are shown in Fig. 3. Organizations, information-sharing, and coordination: Information-based manufacturing is characterized by the ready availability of information and a focus on connectivity and its capability to adapt and react. Consequently, the organizations structure is more agile. Quick-response, adaptability, exibility, and fault tolerance make such a framework appealing (Shaw, 2000). The Web facilitates coordination among the units, reducing the inventories and the cycle times. Many companies have perfected elements of the virtual factory but few companies have exhibited the fully functional environment required. This is the hope and challenge of information-based manufacturing.

industrys structure and thus creating new rules of competition, by creating competitive advantage through the development of new ways of outperforming the companys competitors, and by creating entirely new business, often from within a companys existing operations (Spyros, 1997). The impacts of modern information technology on enterprise provide intelligent and autonomous decision-making processes; and enable distributed operations with collaboration along communication networks. All three categories lead to agility (Huang et al., 2000). IT enables enterprises to intelligently alter themselves and the way they interact, collaborate with each other to best adapt to various customer demand changes in tastes, design, time, and quantity, while keeping the cost at a reasonable level. Such enterprises are hence termed agile enterprises. For decades, researchers have been seeking to develop an agile enterprise that can cope with the above limitations, while keeping costs at a reasonable level. Modern IT seems to have paved a way to achieve this goal. However, to effectively benet from IT for agility, an enterprise must still rely on detailed and systematic design and implementation.

9. Integrated automation To satisfy the conicting and competitive demands of todays market, the research trends in manufacturing automation and control realized the effective integration of a number of available advanced manufacturing technologies. Technology integration includes the management strategy, enterprise integration, network communication, implementation of advanced tools and technologies, system modeling and application of articial intelligence (Hoffman, 1992). All components and tools are coordinated and integrated with one another for easy programmable controls, communications and operator interfaces. All tools access a single, shared database. Communication is integrated throughout the company from the control level to the eld level and communication is consistent with IA with the use of eldbus and Ethernet (Siemens, 2001). Fig. 4 illustrates the integration of different levels of enterprise.

8. Information technology and CIM IT helps in the enhancement of a CIM companys competitive advantage in three major ways: by changing

Fig. 4. Totally integrated automation.

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

483

Integrated CIM system consists of three levels of integration covering physical system integration, application integration and business integration (Spyros, 1997) leading to the total integration of the manufacturing enterprise and is called integrated automation system. System integration has several objectives (Shaw et al., 1997) such as establishing good communication and coordination procedures, promoting collaboration among a group of networked participants, sharing information among different entities across an information system, maintaining a variety of functional modules to make an information system exible and adaptive, efciently managing the coordination between different information systems in an enterprise, and consolidating various business functions in information systems to make the processes more efcient. Some crucial issues in system integration involve the identication of coordination mechanisms, the representation of different roles and functions, and performance measures. IA capabilities enable rms to turn environmental threats (rapid market changes, increasing complexity, declining opportunities, economics of sale) into opportunities for gaining a competitive advantage (Gupta, 1996). The easy availability of production and eld data facilitates quick product design changes, resulting in better engineering and quality. Connection to the IT world, integration of all business processes: The new industrial framework vertical IT integration connects the automation level of IA with the operational control and plant management level up to corporate management and planning level, and links conventional IT applications with the real-time world of the automation level. IA achieves transparency and creates a consistent ow of data (Siemens, 2001). The Internet makes it possible for manufacturing processes to be incorporated in a worldwide ow of information. Openness and modularity: IA is open for a broad spectrum of eld devices. Modular machine and system structures to automation solutions consist of technological modules with their own control intelligence resulting in shorter commissioning times and greater exibility. Component-based automation: Networking and eldbus technology considerably simplies automation in plant and machine construction. By dividing the machines or systems into manageable, autonomous groups, operating units can be tested in advance. This dramatically reduces the cost of on-site commissioning. At the interface, access is only made available to those variables that are required for the interaction with other components as well as for diagnostics, visualization and connection to the planning and execution systems. A component-based system supports elements conforming to certain standards and allows instances of these elements to be plugged into the framework (Szyperski, 1998). Flexible reactions: Instead of stand-alone machines, the individual modules are combined to suit customer requirements. Even plant expansions can be completed

quickly, as the modules operate independent of one another to a great extent. E-manufacturing offers the opportunity to shorten the order-to-fulllment cycle and to guarantee high product quality. Although the benets of integrated technologies are very difcult to quantify, PCs provide a competitive advantage by linking new and existing hardware and software of the technologies, together with database management systems and data communications systems into a coordinated and efciently managed process.

10. CSFs for the implementation of integrated automation system Several authors have identied CSFs that deal with subjects related to manufacturing automation. For example, CSFs have been identied for new product development (Lynn et al., 1998, IT planning and requirements determination (Farrell, 1996, enterprise wide information management system projects (Sumner, 1999), the alignment of information system (IS) plans with business plans (Thompson and Ang, 1999) factory automation (Takanaka, 1991), and software maintenance issues (Ettlie and Getner, 1989). We identied a set of CSFs for the development/ implementation of IAS. Discussion of CSFs: The following is a summary of the identied CSFs. Each CSF is accompanied by a short description and is compared to similar ndings reported in the related literature. Critical Success Factor 1: Formulate a simplied and standardized project plan prior to the design of Integrated Automation System. The effective integration of available advanced manufacturing technologies starts with project planning. Before introducing new technologies, a company must assess whether these technologies will direct the organization to specic goal, primarily to improve the competitive position. This assessment should lead to the development of a master plan that directs the allocation of resources and day-to-day operation of the company as it strives to implement IASs. This CSF is supported by Aggarwal (1995) and Takanaka (1991). Critical Success Factor 2: Develop an organization structure with effective interface for communication, coordination, monitoring, and documentation. One of the most critical factors for the successful implementation is top management support. Such a support can be achieved if the organization structure is built in such a manner to provide an effective interface for effective communication, coordination, monitoring, feedback and

484

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

documentation. This CSF is supported by Pinto and Slevin (1987) and Sayles and Chandler (1971). Critical Success Factor 3: Assemble personnel teams with the necessary experience and motivation to properly implement IA solutions. A well-organized and good managerial team is necessary to properly coordinate implementation activities. Personnel with the experience necessary to effectively utilize the available resources and technology are needed to design and build IA systems. A well-dened work breakdown system should be developed to allow project teams to function effectively. Team behavior with regard to performance and information sharing should be emphasized. Team members responsible for the implementation of IA must have a clear understanding of the goals and needs of company management. Communication between group members must be dynamic and be able to relate the goals of management, the results and progress of their implementation. Documentation that details these plans and their results should be available to all members of these projects so that they can understand both their responsibilities and see the results of the project development. This factor is described by the work of Aggarwal (1995), Pinto and Slevin (1987) and the work of Gupta (1996). Critical Success Factor 4: The functional structure of both manufacturing and management should be developed as modular units. It is necessary to divide processes and projects into manageable, autonomous operating units called modules. The modules should be constructed independently by individual teams and be tested independently. This reduces the cost of on-site commissioning. Aleri and Brandimarte (1997) stress the importance of this concept. Their work is also supported by that of Cho et al. (1996). Critical Success Factor 5: The manufacturing and management system modules developed previously must be integrated in a hybrid of both bottom up and top down approach. A well-dened development plan is essential for the successful implementation of IA. This approach must be accompanied by a clearly dened vision of the system that is communicated not only to management but also to the individual project members who will ultimately be responsible for the successful implementation of the plan. Aleri and Brandimarte (1997) and Takanaka (1991) discuss this factor in their work. Critical Success Factor 6: The performance of the nished system should be evaluated and modications

based on the evaluation should be made to keep the system operation efcient. Once implemented, the system should be subjected to evaluations that will allow the effectiveness of the system to be gauged. After evaluations have been completed, modications must be made that will allow the system to be maintained properly. Future evaluations should include updated software, new manufacturing technology, and personnel changes must also be taken into account. Aggarwal (1995) also discusses this factor as does Takanaka (1991).

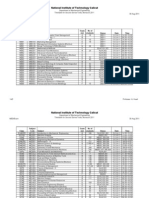

11. Study of critical success factors in related areas of IAS In this section, the six CSFs for IAS development are compared to those in related areas: project management, factory automation, managing large systems and new product development. These four areas are closely related to integrated automation system development. This comparison is used to support the CSFs identied in this paper and to identify issues that are unique to integrated automation system development. Table 1 displays six CSFs of project management as determined by Pinto and Slevin (1987), six CSFs of factory automation determined by Takanaka (1991) and ve CSFs for managing large systems (1971) and ve CSFs for new product development (1998). These CSFs were chosen for their comprehensiveness in scope and for their project-level focus. A comparison of these four lists with the six CSFs for IAS development identied in this study is summarized below: CSF 1: Takanakas (1991) CSF (4) identies the need to standardize and simplify parts, modules and products which may lead to simplication of the process as well as broader issues such as plant layout. Pinto and Slevin (1987) CSF (1) address the need of a clearly dened goal. The simplication of the mechanical components and processes of an IAS is particularly important. CSF 2: Lesters (1998) CSF (2,5), and Sayles and Chandlers (1971) CSF (3,4,5) suggest the need for welldened organizational structure showing control and responsibilities, monitoring and feedback system, and addressing the need for effective interface with top management, for effective communication and coordination. This will improve the shared vision of the project and due reorganization of the individual. CSF 3: Pinto and Slevins (1987) CSF (2,4) and Lesters CSF (4) suggest that effective teams are critical. This study identied the need for a specic method to design teams, which is directly related to the design of the system. In addition, communication is improved and conicts are reduced due to cross-functional membership. Lesters (1998) CSF (2) and Takanakas (1991) CSF (3) suggest

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488 Table 1 A comparative study of CSFs in project management, factory automation, managing large systems and new product development Project management (Pinto and Slevin (1987)) Clearly dened goals Factory automation (Takanaka (1991)) Strategy for systematic integration with clearly dened objectives Analysis and evaluation of resource requirements Establish milestones and inform the people involved Standardization and simplication of parts, modules and products Evaluation: identify advantages and disadvantages Change the management accounting system Managing large systems (Sayles and Chandler (1971)) Project managers competence New product development (Lester (1998)) Senior management commitment

485

Competent project management

Scheduling

Top management support

Control systems and responsibilities

Competent project team members

Monitoring and feedback

Organizational structure and processes that support the venture Attractive new product concepts being available for development Venture teams with appropriate stafng and resources Project management able to focus on reducing uncertainties

Sufcient resource allocation Adequate communication

Continuing involvement on the project

that effective communication between team members can promote a common understanding and can reduce conicts within personnel. It is also important in providing a shared vision of the project. Performance measures and selfcritiques are the feedback mechanisms to take corrective actions if they are needed. CSF 4: Takanakas CSF (4) deals with the need of designing automation systems that utilize standard modules. This standardization allows for the development of new parts, tools, and processes to be incorporated rapidly into product development. Standardized modules of the entire management and manufacturing system within a company will allow similar benets to be realized as new techniques and technologies that can be rapidly integrated without causing major downtime in corporate activities. CSF 5: This factor is identied in Takanakas (1991) CSF (1) for the effective integration of the modules into the proposed system. Initial automation is implemented with controllers in a stand-alone fashion, then integration of different components in a hybrid manner and higher-level control is established through communication networks. This is a specic strategy for systematic integration with clearly dened objectives. CSF 6: Takanakas (1991) CSF (5) identies the need for critical evaluation of the nished system. One cannot gauge the effectiveness of a nished solution without any standards by which it can be measured. The advantages found should be spread throughout the system and disadvantages should be corrected in a timely fashion to maintain system efciency. The comparison of ve sets of CSFs (integrated automation, project management, factory automation, managing large systems and new product development) indicates that some of the CSFs identied for IA are common with other similar elds of application. Common CSFs tend to deal with the need for simple communication

and planning within a company, proper team building and management, and resource allocation. However, the CSFs appear to address a larger eld of applicability. CSFs dealing uniquely with IA focus on the ability to treat individual manufacturing units and management processes as modules that must be standardized and integrated in order to achieve management goals.

12. A framework for measuring the success and the inuence on other factors This study assesses the impacts of the identied factors on the benets of IAS and develops a conceptual framework for measuring success and shows the relationship, inuence among the success factors in the development and implementation of IAS. We grouped the factors into: The factors related to the project. The factors related to the organization. The factors related to the project team. The factors related to the functional structure of the manufacturing system. The factors related to the system integration. The factors related to the performance evaluation. Fig. 5 shows a research model developed as a framework for empirically evaluating the successful integration, the critical performance indicators (CPIs) and critical performance measures (CPMs). Its success is a multidimensional attribute that may be expressed through various measures such as assessment of the success of the integration process and integrated systems, the ability to exploit opportunities arising from the merger, the ability to avoid problems stemming from the merger and the end user satisfaction with the integration process and integrated system. This results in

486

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

Fig. 5. A framework showing CSFs, CPIs, and CPMs.

effective planning and scheduling, effective communication and coordination, effective use of managerial skills, technology, effective control and monitoring, and availability of resources. Indicators of successful implementation of IA solutions include an increase in product quality, productivity and a decrease in equipment downtime, collection of new customers and widespread usage of IA procedures within the company. Some indicators of unsatisfactory IA implementation are an inefcient communication structure marked by frequent breakdowns in communication systems between management and manufacturing, the integration of new modules or technology which is excessively timeconsuming and expensive, the failure to produce meaningful reactions and lack of reduction in production lead-time. In order to successfully implement IA, the management must have a strong commitment to the design process and the ability to overcome interorganizational barriers and must also exercise effective program execution to ensure that managements implementation plan is successfully carried out. Neglected imperatives: The points that are ignored by many enterprises include lack of long-term goal, failure to carry out feasibility study, technical and behavioral uncertainty, lack of real vision, cost justication, vendor

selection, and insufcient employee training. A company must establish long- and short-term goals and standards against which the goals are measured. A detailed analysis of the current manufacturing process and supporting operations is needed to better understand how automation and integration will achieve both business and manufacturing goals. The ability and technical know-how should be analyzed before selecting the right vendor. There must be an initiative for people to update their technical and management skills. This is particularly important when new computers and communication technologies are introduced.

13. Conclusion Therefore, as not every factor will be of equal importance to an enterprise, it follows that a relatively limited number of factors will be critically important for the successful implementation of IAS and is derived from the enterprises internal and external operating environments, and arises from a wide variety of events, circumstances, conditions of activities which require special attention of the enterprise management. The knowledge and understanding of these factors will assist rms in the successful implementation of

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

487

IAS and enable them to further improve their condence and competitive ability to maximize their services and returns. The pitfalls in implementation come from neglecting CSFs and making unrealistic assumptions. The characteristics of these factors show that these CSFs are clearly actionable, measurable and controllable through the use of critical performance indicators (CPIs) and associated critical performance measures (CPMs). These ndings add to our academic understanding of the functional relationships among variables that affect the innovation adoption decision. These factors also reveal the fact that system integration should be achieved in a cohesive manner to provide a complete and intelligent solution to the manufacturing industries. Future research on issues such as simplication, standardization, and communication must be technically addressed using analysis and design methodologies, and software development tools. Flexible cost-effective distributed factory architecture will give the capability to survive and prosper in a competitive environment of continuous and unpredictable change, allowing companies to react quickly and effectively to rapidly changing markets.

Acknowledgements We express our sincere gratitude to the German DAADIQN program for providing facilities to carry out this research in the University of Siegen, Germany.

References

Aggarwal, S., 1995. Emerging hard and soft technologies: current status, issues and implementation problems, omega. International Management Science 23(3), 323 339. Aleri, A., Brandimarte, P., 1997. Object-oriented modelling and simulation of integrated production/distribution systems. Computer Integrated Manufacturing Systems 10(4), 261266. Barua, A., Lee, B., 1997. The information technology productivity paradox revisited: a theoretical and empirical investigation in the manufacturing sector. The International Journal of Flexible Manufacturing Systems 9, 145166. Cho, H., Jung, M., Kim, M., 1996. Enabling technologies of agile manufacturing and its related activities in korea. Computers Industrial Engineering 30(3), 323334. Dessy, E.R., 1996. Computer connections. Laboratory Automation and Information Management 32, 5362. Dhinesh Kumar, K., Karunamoorthy, L., Roth, H., Mirnalinee, T.T., 2002a. Proceedings of the 18th National Convention of Mechanical Engineers and National Conference on Emerging trends in Mechatronics for Automation, REC, Rourkela, Orissa, November. A modular approach for the implementation of integrated automation, pp. 49 59. Dhinesh Kumar, K., Karunamoorthy, L., Roth, H., Mirnalinee, T.T., 2002b. Proceedings of the Seventh International Conference on Control, Automation, Robotics and Vision, ICARCV 2002, December. Web based real-time mobile access to integrated automation, Nanyang Technical University, Singapore.

Ettlie, J.E., Getner, C.E., 1989. Manufacturing software maintenance. Manufacturing Review 2(2), 129133. ESPRIT Consortium AMICE (Ed.), 1993. CIMOSA: Open System Architecture for CIM, Second, revised and extended ed., SpringerVerlag, Berlin. Farrell, A., 1996. Proceedings of the Eighth Annual Quest for Quality and Productivity in Health Services Conference, Williamsburg, VA, USA. Critical success factors for tomorrows IT leaders, pp. 293301. Fieldbus Foundation, 2001. Fieldbus Online. Available at http://www. eldbus.org/. Foston, A.L., Smith, C.L., Au, T., 1991. Fundamentals of Computer Integrated Manufacturing, Prentice-Hall, Englewood Cliffs, NJ. Fuertes, J.M., Herrera, J., Arboleda, J.P., Heit, F., Casas, C., Company, J., 1999. Communication system for a distributed intelligent controller. Microprocessors and Microsystems 23, 8993. Griss, M.L., 1997. Proceedings of the Eighth Israeli Conference on Computer Systems and Software Engineering. Software reuse architecture, process, and organization for business success, pp. 8698. Gupta, M., 1996. Operations effectiveness for a successful implementation of CIM. Technovation 16(10), 589594. Hoffman, K.C., 1992. Proceedings of the Second International Conference on System Integration, Morristown, USA. Management of enterprise wide systems integration programs, pp. 413. Huang, C.-Y., Ceroni, J.A., Nof, S.Y., 2000. Agility of networked enterprisesparallelism, error recovery and conict resolution. Computers in Industry 42, 275287. IBM, 2000. Distributed Intelligence, Available at http://www4.ibm.com/ software/ad/sanfrancisco. Jagdale, S.S., Merchant, N., 1996. Implementing distributed controls for FMCs using Internet utilities. Computers Industrial Engineering 30(1/ 2), 87 90. Johnny, K.C., Ng, I.P.W.H., Lee, T.C., 1998. The development of an enterprise resources planning system using a hierarchical design pyramid. Journal of Intelligent Manufacturing 9, 385 399. Kozaczynski, W., Booch, G., 1998. Component-based software engineering. IEEE Software SeptemberOctober, 155. Lester, D.H., 1998. Critical success factors for new product development. Research Technology Management 41(1), 36 43. Lin, G.C.I., 1976. Proceedings of the Annual Engineering Conference, Townsville, Australia. Integrated computer aided design, manufacture and management, pp. 6876. Lynn, G.S., Mazzuca, M., Morone, J.G., Paulson, A.S., 1998. Learning is the critical success factor in developing truly new products. Research Technology Management 41(3), 4551. Martin, R., 1995. Turbocharging MRPII systems with enterprise synchronisation. IIE Solution November, 3234. Nagalingam, V.S., Lin, G.C.I., 1999. Latest developments in CIM, Robotics and Computer Integrated Manufacturing 15, 423 430. Pinto, J.K., Slevin, D.P., 1987. Critical factors in successful project implementation. IEEE Transactions on Engineering Management EM34(1), 2227. Pritschow, G., Uhl, A., Demel, P., 1994. Proceedings of the 25th International Symposium on Industrial Robots, Hanover, 25 27 April. Flexibility and cost efciency with and open multitasking control architecture for robots, pp. 395402. Pritschow, G., Tran, T.L., Hohenadel, J., 1997. International Symposium, Florence, Italy. Standalone PCcontroller on an open platform. Rahkonen, T., 1995. Distributed industrial control systemsa critical review regarding openness. Control Engineering Practice 3(8), 11551162. Sayles, L.R., Chandler, M.K., 1971. Managing Large Systems, Harper and Row, New York. Segarra, G., 1999. The advanced information technology innovation roadmap. Computers in Industry 40, 185 195. Siemens AG, 2001. Siemens Automation and Drives Group. Available at http://www.siemens.com/automation.

488

K. Dhinesh Kumar et al. / Technovation 25 (2005) 477488

Shaw, J.M., 2000. Information-based manufacturing with the web. The International Journal of Flexible Manufacturing Systems 12, 115 129. Shaw, M.J., Seidmann, A., Whinston, A.B., 1997. Information technology for automated manufacturing enterprises: recent developments and current research issues. The International Journal of Flexible Manufacturing Systems 9, 115 120. Sohal, A.S., 1997. A longitudinal study of planning and implementation of advanced manufacturing technologies. International Journal of Computer Integrated Manufacturing 10(1-4), 281295. Spyros, G.T., 1997. Computer Assisted Management and Control of Manufacturing Systems, Springer-Verlag, London. Sumner, M., 1999. Proceedings of the 1999 ACM SIGCPR Conference, New Orleans, LA, USA. Critical success factors in enterprise wide information management systems projects. Szyperski, C., 1998. Component Software: Beyond Object-oriented Programming, ACM Press, New York. Takanaka, H., 1991. Critical success factors in factory automation. LongRange Planning 24(4), 2935. Thompson, S.H.T., Ang, J.S.K., 1999. Critical success factors in the alignment of IS plans with business plans. International Journal of Information Management 19(2), 173185. Tian, G.Y., Zhao, Z.X., Baines, R.W., 2000. A eldbusbased intelligent sensor. Mechatronics 10, 835849. Yau, S.S., Xia, B., 1998. Proceedings of COMPSAC98. The TwentySecond Annual International. Object-oriented distributed component software development based on CORBA, pp. 246251. Zwegers, A.J.R., Gransier, A.G., 1995. Managing re-engineering with the CIMOSA architectural framework. Computers in Industry 27, 143 153.

Dr. L. Karunamoorthy, B.Sc., B. Tech, M.E., Ph.D., is an Assistant Professor in Mechanical Engineering Department, Anna University, Chennai, India. He has 17 years of teaching and research experience. He is a life member in ISTE, ISME and ISNDT. He is currently guiding 11 Ph.D. research scholars and two M.S. (by research) scholars. He has 33 research publications. His areas of interest are metal cutting, automation and mechatronics.

Prof. Dr. Hubert Roth studied Electrical Engineering at the University Karlsruhe, Germany, from 1974 until 1979. He did his Ph.D. at the Institute of Automatic Control Engineering at University Karlsruhe in 1983. Then, he worked for ve years in the space industry. In the year 1988, he became a Professor for Control Engineering at the University of Applied Sciences in Weingarten, Germany. Since 2001, he is the Head of the Institute for Automatic Control Engineering at the University of Siegen, Germany. His main interests are control of mechatronics systems, especially in the area of robotics and autonomous guided vehicles and remote control aspects.

K. Dhinesh Kumar is a full-time Ph.D. research scholar in Anna University, Chennai, India, under the guidance of Dr. L. Karunamoorthy, Assistant Professor in Mechanical Engineering. He has completed a part of his research under the guidance of Professor Dr. Hubert Roth, Professor and Director, Institute of Control Engineering, University of Siegen, Germany. He did his graduation in mechanical engineering, post-graduation in production engineering, and has about 10 years of industrial and teaching experience. He is now doing research in mechatronics, CIM systems, enterprise modelling and integration, and automation engineering.

T.T. Mirnalinee is a Lecturer in the Department of Computer Science and Engineering in C.S.I. Institute of Technology, Thovalai, Kanyakumari District, Tamilnadu, India. She did her graduation in computer engineering and post-graduation in software engineering. She has eight years of teaching experience and guiding students projects.

S-ar putea să vă placă și

- Revitalising The Manufacturing Industries Through CIMDocument7 paginiRevitalising The Manufacturing Industries Through CIMRosnani Ginting TBAÎncă nu există evaluări

- Digital Manufacturing: History, Perspectives, and Outlook: Special Issue Paper 451Document12 paginiDigital Manufacturing: History, Perspectives, and Outlook: Special Issue Paper 451Sounak DasÎncă nu există evaluări

- Bab Ice Anu 2006Document21 paginiBab Ice Anu 2006IslamSharafÎncă nu există evaluări

- Designing, Implementation, Evolution and Execution of An Intelligent Manufacturing SystemDocument9 paginiDesigning, Implementation, Evolution and Execution of An Intelligent Manufacturing SystemAnonymous pKuPK3zUÎncă nu există evaluări

- CIM evolution from automation islands to integrated manufacturingDocument3 paginiCIM evolution from automation islands to integrated manufacturingluis gerardoÎncă nu există evaluări

- 2005 - Wireless Technology and Its Application To Next Generation of Manufacturing SystemsDocument6 pagini2005 - Wireless Technology and Its Application To Next Generation of Manufacturing SystemsademargcjuniorÎncă nu există evaluări

- Computer-Integrated Manufacturing - WikipediaDocument24 paginiComputer-Integrated Manufacturing - WikipediaChauhan BhumilÎncă nu există evaluări

- Artigo de Usinagem e OPC UADocument14 paginiArtigo de Usinagem e OPC UARicardo AlbuquerqueÎncă nu există evaluări

- Design Choices For Next Generation IIoTDocument18 paginiDesign Choices For Next Generation IIoTankit srivastavaÎncă nu există evaluări

- Computer-Integrated Manufacturing (CIM) Is TheDocument5 paginiComputer-Integrated Manufacturing (CIM) Is TheanashussainÎncă nu există evaluări

- Manufacturing Control SystemDocument13 paginiManufacturing Control SystemVincentÎncă nu există evaluări

- Tahir ShahDocument9 paginiTahir Shahhubabshah12Încă nu există evaluări

- Computer Integrated ManufacturingDocument45 paginiComputer Integrated ManufacturingVinoth KumarÎncă nu există evaluări

- Arrangement of Nozzle Using Smart AutomationDocument51 paginiArrangement of Nozzle Using Smart AutomationSachinÎncă nu există evaluări

- Reference Architecture For Efficient Computer Integrated ManufacturingDocument7 paginiReference Architecture For Efficient Computer Integrated ManufacturingRosnani Ginting TBAÎncă nu există evaluări

- Advanced Manufacturing Technology: Implementation of Design AMTDocument8 paginiAdvanced Manufacturing Technology: Implementation of Design AMTnemi90Încă nu există evaluări

- CIMBenefitsChallenges OkpalaEzeanyimOgbodoDocument9 paginiCIMBenefitsChallenges OkpalaEzeanyimOgbodoTran Minh TriÎncă nu există evaluări

- CHP 2 IIOTDocument20 paginiCHP 2 IIOTParmar AkshatsinhÎncă nu există evaluări

- Seminar Term Thesis Report FormatDocument13 paginiSeminar Term Thesis Report FormatchaitanyakolkataagarwalÎncă nu există evaluări

- 152 - Paper DADocument9 pagini152 - Paper DAImiAlbertÎncă nu există evaluări

- Representações Do Gêmeo Virtual No Chão de FábricaDocument9 paginiRepresentações Do Gêmeo Virtual No Chão de FábricaRicardo AlbuquerqueÎncă nu există evaluări

- Wooten Paper1Document9 paginiWooten Paper1api-526395450Încă nu există evaluări

- Concurrent Engineering As An Integrated Comprehensive ApproachDocument5 paginiConcurrent Engineering As An Integrated Comprehensive ApproachRanveer RanjanÎncă nu există evaluări

- Computer-Integrated Manufacturing (CIM) - 305801Document4 paginiComputer-Integrated Manufacturing (CIM) - 305801Tran Minh TriÎncă nu există evaluări

- Applied Sciences: Modeling and Simulation of A Flexible Manufacturing System-A Basic Component of Industry 4.0Document20 paginiApplied Sciences: Modeling and Simulation of A Flexible Manufacturing System-A Basic Component of Industry 4.0ZakirUllahÎncă nu există evaluări

- Accepted Manuscript: Sven Plaga Norbert Wiedermann Simon Duque Anton Hans Schotten Thomas NeweDocument52 paginiAccepted Manuscript: Sven Plaga Norbert Wiedermann Simon Duque Anton Hans Schotten Thomas NeweUma TamilÎncă nu există evaluări

- Reconfigurable Manufacturing Systems - An Emerging Manufacturing ParadigmDocument6 paginiReconfigurable Manufacturing Systems - An Emerging Manufacturing ParadigmAdvanced Research PublicationsÎncă nu există evaluări

- AMT Adoption in Kenyan Manufacturing CompaniesDocument14 paginiAMT Adoption in Kenyan Manufacturing CompaniesJoseph AbrahamÎncă nu există evaluări

- Research ArticleDocument6 paginiResearch ArticleAbhijna AdigaÎncă nu există evaluări

- Cladding Sector Road Map For Realising The CIM VisionDocument20 paginiCladding Sector Road Map For Realising The CIM VisionEmeka AgbasiÎncă nu există evaluări

- Design Review Information - CIMOSA Product Design and Development QFD FMEADocument19 paginiDesign Review Information - CIMOSA Product Design and Development QFD FMEApersischatzÎncă nu există evaluări

- CEP Special IssueDocument12 paginiCEP Special IssuefikerykÎncă nu există evaluări

- A Study of Digital ManufacturingDocument7 paginiA Study of Digital ManufacturingAmrik SinghÎncă nu există evaluări

- Government College of Engineering Kalahandi, BhawanipatnaDocument26 paginiGovernment College of Engineering Kalahandi, BhawanipatnaRaghuÎncă nu există evaluări

- CAD/CAM/CIM IntroductionDocument17 paginiCAD/CAM/CIM IntroductionMallesham DevasaneÎncă nu există evaluări

- Computer Integrated ManufacturingDocument14 paginiComputer Integrated ManufacturingILAYAPERUMAL KÎncă nu există evaluări

- Computer-Integrated ManufacturingDocument5 paginiComputer-Integrated ManufacturingNhan LeÎncă nu există evaluări

- 智能制造的机遇Document15 pagini智能制造的机遇张天瑞Încă nu există evaluări

- Applications of Flexible Manufacturing Systems in Industry A ReviewDocument9 paginiApplications of Flexible Manufacturing Systems in Industry A ReviewIJRASETPublicationsÎncă nu există evaluări

- Machines 10 01137 v3Document43 paginiMachines 10 01137 v3qw BastiaÎncă nu există evaluări

- CIM Still the Solution for ManufacturingDocument13 paginiCIM Still the Solution for ManufacturingRoland Adi NugrahaÎncă nu există evaluări

- VTU NOTES, QUESTION PAPERS, NEWS, RESULTS & FORUMS ON CIMDocument29 paginiVTU NOTES, QUESTION PAPERS, NEWS, RESULTS & FORUMS ON CIMAbid YusufÎncă nu există evaluări

- Cloud-Based Industrial Cyber-Physical System For Data-Driven Reasoning. A Review and Use Case On An Industry 4.0 Pilot LineDocument9 paginiCloud-Based Industrial Cyber-Physical System For Data-Driven Reasoning. A Review and Use Case On An Industry 4.0 Pilot LineSrichandan SobhanayakÎncă nu există evaluări

- Week12 02411940000179 D Muhammad Ardhan AnshariDocument4 paginiWeek12 02411940000179 D Muhammad Ardhan AnsharianshariÎncă nu există evaluări

- SMART MANUFACTURING KnowledgeDocument4 paginiSMART MANUFACTURING KnowledgeDipankar GhoshÎncă nu există evaluări

- Atde 15 Atde210050Document7 paginiAtde 15 Atde210050rizkiÎncă nu există evaluări

- CAD/CAM/CIM Course OverviewDocument21 paginiCAD/CAM/CIM Course OverviewBizuayehu TadesseÎncă nu există evaluări

- Need and Scope of Flexible Manufacturing SystemsDocument4 paginiNeed and Scope of Flexible Manufacturing SystemsIJRASETPublicationsÎncă nu există evaluări

- Intelligent Machinery Product Service BLDocument16 paginiIntelligent Machinery Product Service BLRachana ParheÎncă nu există evaluări

- FUTURE CONSTRUCTION INNOVATION THROUGH TECHNOLOGY AND KNOWLEDGE FUSIONDocument10 paginiFUTURE CONSTRUCTION INNOVATION THROUGH TECHNOLOGY AND KNOWLEDGE FUSIONVikram PrasadÎncă nu există evaluări

- 2014 New Thinking Paradigm For Maintenance Innovation Design Jay LeeDocument6 pagini2014 New Thinking Paradigm For Maintenance Innovation Design Jay Leeuamiranda3518Încă nu există evaluări

- Digital Factory SolutionsDocument10 paginiDigital Factory SolutionsAlexÎncă nu există evaluări

- CIMS Computer Integrated Manufacturing SystemDocument14 paginiCIMS Computer Integrated Manufacturing SystemarunagkÎncă nu există evaluări

- A Systematic Development Method For Cyber-Physical Machine ToolsDocument13 paginiA Systematic Development Method For Cyber-Physical Machine Toolsjjj ljljÎncă nu există evaluări

- Embedded System Design in Intelligent Industrial AutomationDocument97 paginiEmbedded System Design in Intelligent Industrial Automationraskarasta6Încă nu există evaluări

- Unit - 1 Computer Integrated Manufacturing SystemsDocument29 paginiUnit - 1 Computer Integrated Manufacturing Systemsbest4reverÎncă nu există evaluări

- FlexsimDocument11 paginiFlexsimAxel MartinezÎncă nu există evaluări

- Concurrent Engineering Techniques and Applications: Advances in Theory and ApplicationsDe la EverandConcurrent Engineering Techniques and Applications: Advances in Theory and ApplicationsC. T. LeondesEvaluare: 5 din 5 stele5/5 (1)

- UTM Grraduate StudentDocument11 paginiUTM Grraduate StudentdhrghamÎncă nu există evaluări

- Is PDFDocument340 paginiIs PDFashwini k benagiÎncă nu există evaluări

- Suvetha Devi Muthu Priya: S.No Batch NO Name of The Participants Name of The College Topic of The Paper Contact NODocument2 paginiSuvetha Devi Muthu Priya: S.No Batch NO Name of The Participants Name of The College Topic of The Paper Contact NOmanoj3e3790Încă nu există evaluări

- Neutrosophic Soft Sets With Applications in Decision MakingDocument20 paginiNeutrosophic Soft Sets With Applications in Decision MakingDon HassÎncă nu există evaluări

- Naval Architecture & Marine Engineering MEng - University of StrathclydeDocument13 paginiNaval Architecture & Marine Engineering MEng - University of StrathclydeMyo Zin AungÎncă nu există evaluări

- BTechII I 6Document4 paginiBTechII I 6api-3712398Încă nu există evaluări

- PHD FT PT Selection List July 2017Document7 paginiPHD FT PT Selection List July 2017Midhun VcÎncă nu există evaluări

- APRCET 2021Document5 paginiAPRCET 2021Eswara SaiÎncă nu există evaluări

- Aa-Matrix Company ProfileDocument23 paginiAa-Matrix Company ProfileBilly Joe BreakfastÎncă nu există evaluări

- Tab Digitization Construction Industry e FinalDocument16 paginiTab Digitization Construction Industry e Finalabhiroopbose100% (1)

- Statement of Marks For: F.Y.D.P.A. Examination Held in April 2013Document27 paginiStatement of Marks For: F.Y.D.P.A. Examination Held in April 2013Mukesh BishtÎncă nu există evaluări

- Oracle SQL Fundamental Lab Questions SolutionsDocument3 paginiOracle SQL Fundamental Lab Questions SolutionsuserÎncă nu există evaluări

- WRC 302Document38 paginiWRC 302Dang Nhat100% (3)

- Oregon Start Up OrganizationsDocument69 paginiOregon Start Up OrganizationsAntonio CoronaÎncă nu există evaluări

- De Huckin StepsDocument2 paginiDe Huckin Stepsmaarten31Încă nu există evaluări

- IIT BHU Brochure 2016Document16 paginiIIT BHU Brochure 2016smeilyÎncă nu există evaluări

- Course Structure IIUM Aerospace EngineeringDocument5 paginiCourse Structure IIUM Aerospace EngineeringMir Owais AliÎncă nu există evaluări

- Why Romanian Journal of Food ScienceDocument2 paginiWhy Romanian Journal of Food ScienceAna Vitelariu - RaduÎncă nu există evaluări

- ACADEMIC TRANSCRIPT (Undergraduate) : National University of Sciences and TechnologyDocument1 paginăACADEMIC TRANSCRIPT (Undergraduate) : National University of Sciences and TechnologyMuhammad Hashim KhanÎncă nu există evaluări

- Chemical and Process Engineering Department at University of MoratuwaDocument1 paginăChemical and Process Engineering Department at University of MoratuwaSiran MarayoÎncă nu există evaluări

- Month - Attendance B.E FY Semester1 SectionE ELEMENTSOFMECHANICALENGG. 17EME14 PDFDocument2 paginiMonth - Attendance B.E FY Semester1 SectionE ELEMENTSOFMECHANICALENGG. 17EME14 PDFenggsantuÎncă nu există evaluări

- ACTRANDocument3 paginiACTRANVijendra Kumar DubeyÎncă nu există evaluări

- HNC Instrumentation GuideDocument28 paginiHNC Instrumentation Guidemohamedhamdy001Încă nu există evaluări

- 2011 Monsoon Second TestDocument2 pagini2011 Monsoon Second TestK Nagarjunan ReddyÎncă nu există evaluări

- Big Data Means Big IT Job Opportunities - For The Right PeopleDocument4 paginiBig Data Means Big IT Job Opportunities - For The Right Peoplescribd_jprÎncă nu există evaluări

- Waves and Vibrations in SoilDocument2 paginiWaves and Vibrations in SoilpetmiraÎncă nu există evaluări

- Engr. Prof. Peter OnwualuDocument35 paginiEngr. Prof. Peter OnwualuOladimeji TaiwoÎncă nu există evaluări

- SSM ENGINEER Contractors RevisedDocument3 paginiSSM ENGINEER Contractors Revisedchaitanya12299Încă nu există evaluări

- Tentative Schedule of PH.D Coursework Examination (Regular & Back) 2017-18Document6 paginiTentative Schedule of PH.D Coursework Examination (Regular & Back) 2017-18Himansu Sekhar SahuÎncă nu există evaluări