Documente Academic

Documente Profesional

Documente Cultură

Technical Specification Saket Court Complex-Nit 108

Încărcat de

Manoj RanaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Technical Specification Saket Court Complex-Nit 108

Încărcat de

Manoj RanaDrepturi de autor:

Formate disponibile

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33/11 KV SAKET COURT COMPLEX SUBSTATION AT NEW DELHI

(SPEC NO: BRPL EHVTS10-1101)

BSES RAJDHANI POWER LTD

Prepared by Reviewed Approved by Samarjit Chowdhury ACP P R Kumar AS Rev: 1 Date: 6th August, 2010

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI TABLE OF CONTENTS Volume I : Technical Specifications

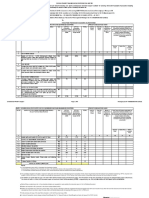

Sr No. Name Intent of Specification Auxiliary Supplies Scope of Supply Completion Schedule Work by Others Co-ordination with statutory bodies & outside agencies Co-ordination with other contractor, purchaser & owners system 1 Terminal Points Salient features, Basic Design Criteria and Minimum Technical Requirements of 33KV Substation / Substation Equipments Terminal Points Codes & Standards Engineering Deliverables Submission of Drawings Approved Vendor List Deviation Civil Work HT Indoor Switchgear Power Transformer Station Transformer 11KV Capacitor Bank Battery Chargers Ni Cd Battery Bank 415 V AC Distribution Board LT Power Cable Control Cable SCADA Interface Works & Automation Cable Installation & Accessories Grounding & Lightning Protection System Illumination System Exhaust & Ventilation System Fire Detection & Alarm System Fire Extinguisher Packing & Transportation Materials Workmanship & Tests Other Specifications 1.1 1.10 Page

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

2.1 2.26 3.1 3.15 4.1 4.35 5.1 5.36 6.1 6.9 7.1 7.7 8.1 8.4 9.1 9.4 10.1 10.4 11.1 11.4 12.1 12.6 13.1 13.4 14.1 14.8 15.1 15.7 16.1 16.3 17.1 17.4 18.1 18.3 19.1 19.3 20.1 20.5 21.1 21.7

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

Volume II : Schedules & Annexure

Sr. No. Schedule A Schedule C1 Schedule C2 Schedule C3 Schedule C4 Schedule C5 Schedule C6 Schedule C7 Schedule C8 Schedule C9 Schedule C10 Schedule C11 Schedule C12 Schedule C13 Schedule E1 & E2 Schedule F Schedule G Schedule H Schedule I Schedule J Schedule K Schedule L Annexure Annexure A Annexure S Annexure L Schedule of General Information Technical Data Sheets of HT Indoor Switchgear Technical Data Sheets of Power Transformer Technical Data Sheets of Station Transformer Technical Data Sheets of 11KV Capacitor Bank Technical Data Sheets of Battery Chargers Technical Data Sheets of Ni Cd Battery Bank Technical Data Sheets of 415 V AC Distribution Board Technical Data Sheets of LT Power Cable Technical Data Sheets of Control Cable Technical Data Sheets of Cable & Accessories Technical Data Sheets of Cable Trays & Accessories Technical Data Sheets of Grounding & Lightning Protection System Technical Data Sheets of Illumination System Deviation from Specification List of Drawings enclosed with Bid Schedule of Tests List of instruments, Testing Equipment, Tools & Tackles for Erection & Maintenance List of Installation Delivery, Terms and Conditions Schedule of Recommended Spares Declaration Project Data Main Single Line Diagram Substation Layout Plan (Suggestive) Name

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

VOLUME I TECHNICAL SPECIFICATION

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

1.0 INTENT OF SPECIFICATION

This specification is intended to cover complete design, engineering, manufacturer, assembly, testing at manufacturers works, supply and Transportation for site of all equipment and accessories, steel structures, all structural work, substation building, Civil and architectural work, complete erection, testing, commissioning & putting into successful commercial operation of 33/11KV substation inclusive of supply of all Labour, supervision, tools, implements and supplies as required. The 33KV Air insulated indoor substation with two (02) nos Incomer Panels, two (02) nos Transformer Panels, one (01) no Bus Coupler Panel and two (02) nos Bus PT Panel. For general layout and single line diagram of the substation the enclosed drawing shall be followed. This specification shall be read and constructed in conjunction with other sections of bidding document. In the event of any discrepancy with the listed document, the most stringent one shall govern.

2.0 AUXILIARY SUPPLIES

Following auxiliary power supplies will be made available by the Owner, at one agreed location for the construction of the Substation. AC : 415V 10%, 50Hz 5%, 3 phase, 4 wire construction power supply with solidly earthed neutral, one feeder at a mutually agreeable point at chargeable rates.

3.0 SCOPE OF SUPPLY

3.1

This scope of work shall include design, engineering, manufacture, shop testing, inspection, packing, dispatch, loading, unloading and storage at site, transit/storage and construction insurance, assembly, erection, civil structural, architectural work, complete precommissioning checks, testing & commissioning at site, obtaining statutory clearance & certification from State Electrical Inspector, Municipal corporation department, Fire officer, and handing over to the owner after satisfactory commissioning, of complete 33KV Indoor substation at Saket Court Complex, New Delhi of BSES Rajdhani Power Ltd. Page 1.1 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

The scope includes all material, equipment and works required for the construction of the Substation complete with all items considered essential for safe and trouble-free continuous commercial operation of the system in a manner acceptable to the Owner and complying with latest revision of national and international standards Codes & Practices, Indian Electricity Rules and Indian Electricity Act. The scope of supply broadly includes the following: A. Major Equipments: 33/11KV, 20 / 25 MVA ONAN/ONAF Power Transformer Two (2) Nos 11KV, 5.4MVAR, Capacitor Bank Two (2) Nos DCDB One (1) no ACDB One (1) no Station Aux. Transformer, 11/0.433KV, 400KVA One (1) no. SCADA RTU

B. Item as System 33KV Air Insulated Switchgear with protection relays 11KV Air insulated Switchgear with protection relays. Grounding and earthing of entire substation including fence of transformer and capacitor bank. 220V Battery bank, two sets of Battery charger. Outdoor illumination including street lighting with Poles. Indoor illumination including emergency lighting. Exhaust and Ventilation for complete substation building. Fire detection and alarm system. Direct stroke lightning protection by shielding spikes.

C. Items as Lot LT Power & Control cables supply and termination. HT Power cable laying and termination (11KV & 33KV cable will be supplied as free issue item to the contractor). Galvanised steel structure, junction boxes etc. Cable trays. Maintenance tools & tackles including testing instruments. Cabling between equipments and RTU.

D. Civil Works Substation Building. Power Transformer foundation, oil soak pit, Fire Wall. Foundation of lighting poles, bay-marshalling panel. Page 1.2 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

Capacitor bank foundation, Aux Transformer foundation and fencing. Road and drainage within switchyard fence. Anti weed treatment and gravel surfacing of the substation area. Substation fencing and gates. Indoor and Outdoor Cable Trenches with cable trays and covers for 33KV, 11KV & Control Cables. Road, rainwater storm and drainage system for outdoor switchyard. All civil work required for installation and erection of equipments inside and outside building. Supply of material required for above works. Landscaping. Boundary wall with concertina wire & Guard room.

Following equipment and services are specifically listed for the guidance of the Bidder. However, it is to be understood that the Contractors scope is not limited to the items specifically listed above but covers all items required for the completion of a safe, functional and complete Substation. E. Design Work

Design documentation in sufficient copies including design memos, calculations, general arrangement, plans, elevations and sectional drawings, sag/tension calculations, short circuit calculations, electrodynamics force calculations, single line diagrams, schematic interconnection drawings, wiring diagrams, foundation calculations, foundation plans/details, cable schedules, bill of materials, lighting system design calculations, earthing system design calculations, illumination.

Lot

Operation & Maintenance Manuals and As-built drawings. (Seven sets hard copy & two sets soft copy) Documentation required by State Electrical Inspector for statutory approval/certification of the Substation installation. (as required) Temporary sheds for storage of equipment, tools & tackles, construction offices etc. with required fittings & furnishings.

Lot

Lot

4.0 COMPLETION SCHEDULE

The contractor shall be fully responsible to complete the project in time. It is desired that the total project should complete in six months from the date of LOI. The major completion schedule is attached here under for reference. The detail completion schedule shall be prepared by contractor in Ms-project or Primavera software and shall be submitted at the time Page 1.3 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

of detail engineering for approval. The detail schedule shall be finalized with the help of schedule given by owner. Handing over or charging of two power transformer and its accessories shall be 190 days from the LOI issue date. Sl.No. 1 2 3 4 5 6 7 Description of Work Zero Date (Letter of Award) Engineering Approval Civil Works Procurement Equipment Erection Testing & Commissioning of Substation Handing Over 45 days from Zero Date 90 days from Zero Date 135 days from Zero Date 160 days from Zero Date 180 days from Zero Date 190 days from Zero Date Duration

5.0 WORK BY OTHERS

The following facilities will be provided by Owner / Others: 1. Electricity for construction purpose (415V; 3 phase, 4 wire) shall be provided by BRPL on chargeable basis at one mutually agreeable location & rates (on request of vendor) 2. Water connection from respective municipal / water agency shall be provided by vendor.

6.0 CO-CORDINATION WITH STATUTORY BODIES & OUTSIDE AGENCIES

The contractor shall be fully responsible for carrying out all co-ordination and liaison work as may be required with Electrical Inspector, MCD, Fire officer or any other statutory bodies for implementation of the work. The application on behalf of BRPL for submission to the Electrical Inspector and other statutory bodies along with copies of drawings complete in all respects shall be done by the contractor & approval / certificates taken well ahead of time so that the actual commissioning of equipment is not delayed for want of inspection and approval by the inspector & statutory bodies. The contractor shall arrange the actual inspection work by Electrical Inspector. However official fees paid electrical inspector / statutory bodies shall be borne by th owner.

Page 1.4 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

7.0 COORDINATION WITH OTHER CONTRACTOR & PURCHASER & OWNERS

SYSTEM

The contractor shall be fully responsible for carrying out all the co-ordination work required with the contractors as well as with owners system for execution and completion of his work.

8.0 TERMINAL POINTS

8.1 8.2 8.3 8.4 8.5 33KV Connections Cable Trenches Lighting Earthing : : : : Incoming cables at two line Panels. Upto the boundary wall of substation Within Outdoor Substation Within Substation area and building.

Water supply and drainage at suitable point near the substation boundary wall at location to be decided later.

8.6

Exclusion Laying and termination of 33KV, XLPE incomer cables at the two line bays. Supply of 33KV (3CX400 mm2) & 11KV (1CX1000mm2 & 3CX300 mm2) HT Power Cables. However the laying and termination of these free issue cables shall be in the contractors scope. Soil investigation and soil resistivity test

Note: 11KV cable laying and its termination for outgoing feeders from 11KV Switchgear to load center will be in Owners scope. However the cable trenches inside substation for these outgoing cables will be in the contractors scope.

9.0 SALIENT FEATURES, BASIC DESIGN CRITERIA AND MINIMUM TECHNICAL

REQUIREMENTS OF 33KV SUBSTATION/SUBSTATION EQUIPMENTS

9.1 Introduction BRPL is setting up a 33/11KV Grid substation in Saket Court Complex at New Delhi. It shall be connected with 220/33 Mosjid Moth (Delhi Transco Limited) substation. Two nos Infeed circuit shall be comprised two runs of XLPE cable of size 3CX400mm2. The laying of infeed cables, termination in 33KV Incomer panel and erection / commissioning at upstream level will be in the owners scope Page 1.5 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

Since the Substation is to be constructed on turnkey EPC execution, the EPC contractor is responsible for detailed design also. In this paragraph only salient features, basic design criteria and Owners minimum technical requirements are enumerated for the guidance of the Bidder. 9.2 Substation Capacity Due to limitation of space the 33/11KV substation shall be designed with capacity of 3X25MVA, yet the initial installed capacity shall be 2X25MVA. As such the n-1 capacity of substation will be 25MVA. 9.3 33KV and 11KV Switchgears The 33KV & 11KV Switchgear shall be installed inside the substation building. The switchgears shall be equipped with Vacuum circuit breaker. The metering and protection relays shall be part of switchgear only. Control voltage shall be 220 V DC. 9.4 33/11KV Power Transformer The Outdoor Power transformer shall be 20/25MVA, ONAN/ONAF Rating with OLTC. The microprocessor based Transformer monitoring relay eberley relay model T060D201-00 or equivalent shall be provided in place of RTCC panel. 9.5 Battery Charger and Battery Bank The Control supply shall be 220V DC. The Ni-Cd Battery bank shall be installed in separate room with proper ventilation system as per safety requirement. The battery charger shall be thyristor controlled installed inside control room building. 9.6 Capacitor Bank Two sets of Capacitor bank shall be installed outdoor. Each set shall be 5.4MVAR rated at 11KV comprising sub banks of 3.6 and 1.8MVAR. Each sub bank shall be provided with motorized 11KV Isolator. 9.7 Control, Monitoring and Protection Concepts: It is intended to provide State of Art substation control, protection and metering system and shall be integrated with SCADA. All the relays shall be on IEC 103 protocol 9.8 Substation Building Page 1.6 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

The substation shall have single storied building with all the equipments installed on ground floor. The Cables shall be laid in cable trench with cable trays, inside and outside of the building. Trenches shall be covered with trench cover. 9.9 Salient Features of 33KV Substation Site Parameters a) Design Ambient temperature b) Seismic Condition c) Wind Pressure : : : 50 deg C Zone IV as per IS 1893 195 Kg/sq M upto elevation of 30 M as per IS 875 100%

d) Max. Relative Humidity

Parameters Nominal Voltage (kV) Rated Voltage (kV) Rated Frequency (Hz) System Neutral Earthing Short Circuit rating (for 3 sec) Basic Insulation Level i) Impulse frequency (kVp) withstand voltage Power frequency (kV rms) withstand voltage 170 33 36

HV Side 11 12

LV Side

50 +/- 5% Solidly Grounded 1500 MVA / 26.3 kA

50 +/- 5% Solidly Grounded 500 MVA / 26.3 kA

75

ii)

70

28

10.0 CODES & STANDARDS

The contractor shall follow latest Indian Standards or international standard. Refer respective equipment specification for applicable standards. Page 1.7 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

11.0 ENGINEERING DELIVERABLES

The Bidder shall submit following minimum Engineering Deliverables after award of the Contract. Any other drawing / calculation which is not listed below and may be required for execution of the job shall also be submitted by the bidder.

S. No. A. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 16 S. No. 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Drawing Title Electrical Drawing Main Single Line Diagram indicating bus/breaker rating, cable/overhead conductor size, fault levels of different voltage grade, Transformer details, metering and protection with CT / PT cores / ratio / burden / accuracy class / knee point voltages. Complete BOQ of the substation with technical details. Single Line Diagram of 415 V AC Distribution board Single Line Diagram of 220V DC Distribution board Battery Sizing Calculation Overall Site Layout Plan Maximum & Minimum fault level calculation for the substations. Insulation coordination. Switchgear/Control building layout Plan Switchgear/Control building layout Section Cable trench layout Plan & Section outdoor. Cable tray layout Plan & Section Indoor. BOQ of Cable trays and accessories. Sizing calculation of LV Cables Power cable schedules. Control cable schedules. BOQ of Cables. Drawing Title Codification of cable trays and cable tray/cable tag marking concept. Calculation of underground earth mat design after actual site soil investigation. Drawing of Underground ground mat along with BOQ. Drawing of Indoor equipment grounding details. Outdoor equipment grounding arrangement and details. BOQ of Grounding Materials. Input/Output list of SCADA system. Outdoor Illumination system design Calculation. Indoor Illumination system design Calculation. Drawing of Outdoor Illumination with erection details. Drawing of Indoor Illumination with erection details. Complete BOQ indoor and outdoor illumination system CT/PT sizing/detail calculation of burden, knee point voltage All major equipment sizing calculation Page 1.8 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

31 32 33 34 35 B. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 16 17 18 19 20 21 22 23 Cabling, earthing & lightning concept Power Transformer foundation details, soak pit arrangement, firewall segregation Fire fighting arrangement of Transformers and indoor equipments Relay setting with calculations As built documentation of the drawing / documents Civil Drawing Layout Plan For Control Building Equipment and Gantry Foundation Details and calculations. Cable Trench Details (Concrete & Reinforcement) including trench cover Capacitor Bank (GA, Concrete & Reinforcement) Transformer foundation & Oil Separator Tank Plan and section. Transformer foundation & Oil Separator Tank Reinforcement Details. Structural detail of Gantry Tower with and without peak. Structural Detail of "LA" Structural Detail of "CVT" Structural Detail of "CT" Structural Detail of "PT" Structural Detail of "PHC" Structural Detail of "BPI" Structural Detail of girder Structural Details of Isolator Over all layout plan indication landscaping. Trench layout for switch yard Sectional Details for Trenches Conduit plan for Control room building. Switch yard layout Rainwater Harvesting details of Recharging well with bore well. Under Ground Water Tank Details GA and Details of fencing GA and Details of Road

12.0 SUBMISSION OF DRAWINGS

BOQ etc shall be on A4 size paper. All the drawings shall be to the scale drawings as far as possible. The submission shall be

Two (02) Sets of approved and released for construction drawings/BOQ/Calculation for Owners reference. Six (06) Sets of final As Built drawings, design, BOQ, Calculation. O&M manual for each equipment supplied shall also be submitted in 6 sets. Soft copies of all drawings/Documents/calculation in Auto CAD and Microsoft office file format as applicable.

Drawings shall be treated as submitted, only if provided with BOQ. (If applicable)

Page 1.9 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specification

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

13.0 APPROVED VENDOR LIST

S No 1. 2. 3. 4. 5. 6. 7. 8. Equipment 11KV Switchgear 33KV Switchgear Power Transformer Protection Relays DC Batteries Battery Chargers Illumination fixtures LT Power & Control Cables 9. 10. Cable Trays Capacitor Bank Approved Vendor ABB, Siemens, Areva ABB, Siemens, Areva Bharat Bijlee, CGL, EMCO, ABB, Areva, Kanohar Areva, ABB, Siemens, E&R HBL nife, Amco, Exide Hblnife, AMCO, Chhabi, Hirel, Caldyne, Amararaja,Masstech Bajaj, Philips, CGL, Wipro, GE FGIL,UCL,Finolex,Paramount, Lapp Kabel, ICC RPG, Polycab, KEI, Cords, Gemscab, Delton, Special Cables Pareikh, Indiana, Dolphin, Patni, Metalemm, Techno-fab, Globe ABB, L&T, Manohar Brothers, UCL, Shreem.

14.0 DEVIATIONS

Deviation from this specification, if any, shall be clearly bought out in the offer. Unless owner explicitly accepts such deviations, it shall be constructed that the offer fully complies with the specification.

Page 1.10 of 1.10

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

TECHNICAL SPECIFICATION FOR CIVIL WORK

BSES RAJDHANI POWER LTD

Prepared by Reviewed Approved by Samarjit Chowdhury ACP PKG AS S Verma Rev: 1 Date: 6th August, 2010 Page 2.1 of 2.26

P R Kumar

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI 1.0 INTENT:

The specification covers following. 1.1 Design, engineering, and construction of all civil works at 33/11KV Sub-Station. All civil works shall also satisfy the general technical requirements specified in other Sections of this Specification and as detailed below. They shall be designed to the required service condition / loads as specified elsewhere in this Specification or implied as per National and International Standards. All civil works shall be carried out as per applicable Indian Laws, CPWD Specifications, and Codes. All materials shall be of best quality conforming to relevant Indian Standards and Codes. The Contractor shall furnish all design, drawings, labour, tools, equipment, materials, temporary works, constructional plant and machinery, fuel supply, transportation and all other incidental items not shown or specified but as may be required for complete performance of the Works in accordance with approved drawings, CPWD Specifications and direction of Owner. The work shall be carried out according to the design / drawings to be developed by the Contractor and approved by the Owner based on Tender Drawings supplied to the Contractor by the Owner. For all building, structures, foundations etc. necessary layout and details shall be developed by the Contractor keeping in view the functional requirement of the Sub-Station facilities and providing enough space and access for operation, use and maintenance based on the input provided by the Owner. Certain minimum requirements are indicated in this specification for guidance purposes only. However, the Contractor shall quote according to the complete requirements.

1.2

1.3

1.4

2.0

GEOTECHNICAL INVESTIGATION

The Owner will carry out Geo Technical Investigation for the entire Sub-Station including switchyard. The copy of the report will be given as input to the successful contractor for his Civil Design work.

3.0

3.1

SITE PREPARATION Scope

This clause covers the design and execution of the work for site preparation, such as clearing of the site, the supply and compaction of fill material, excavation and compaction of backfill for foundation, road construction, drainage, trenches and final topping by stone (broken hard stone).

Page 2.2 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

3.2

General

3.2.1 The Owner shall make fairly leveled land available to the Contractor. The layout and levels of all structure etc shall be made by the Contractor at his own cost from the general grids of the plot and benchmarks set by the Contractor and approved by the Owner. The Contractor shall give all help in instruments, materials and personnel to the Owner for checking the detailed layout and shall be solely responsible for the correctness of the layout and levels. The Contractor shall develop the site area to meet the requirement of the intended purpose. The site preparation shall conform to the requirements of relevant sections of this specification or as per stipulations of standard specifications. If fill material is required, the fill material shall be suitable for the above requirement. The fill shall be such a material and the site so designed as to prevent the erosion by wind and water of material from its final compacted position or the in-situ position of undisturbed soil. Material unsuitable for casting of foundations shall be removed and replaced by suitable fill material and to be approved by the Owner. Backfill material around foundations or other works shall be suitable for the purpose for which it is used and compacted to the density described under Compaction. Excavated material not suitable or not required for backfill shall be disposed off by the contractor, in areas as directed by Owner. The few old existing foundations shall be dismantled by the contractor.

3.2.2

3.2.3

3.2.4

3.2.5

3.3

Excavation and Backfill

3.3.1 3.3.2 Excavation and backfill for foundations shall be in accordance with the relevant code. Whenever water level is met during the excavation, it shall be dewatered and water level shall be maintained below the bottom of the excavation level during excavation, concreting and backfilling. When embankments are to be constructed on slopes of 15% or greater, benches or steps with horizontal and vertical faces shall be cut in the original slope prior to placement of embankment material. Vertical face shall measure not more than 1 m in height. Embankments adjacent to abutments, culverts, retaining walls and similar structures shall be constructed by compacting the material in successive uniform horizontal layers not exceeding 15 cm in thickness. (of loose material before compaction). Each layer shall be compacted as required by means of mechanical tampers approved by Page 2.3 of 2.26

3.3.3

3.3.4

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

the Owner. Rocks larger than 10cm in any direction shall not be placed in embankment adjacent to structures. 3.3.5 Earth embankments of roadways and site areas adjacent to buildings shall be placed in successive uniform horizontal layers not exceeding 20 cm in thickness in loose stage measurement and compacted to the full width specified. The upper surface of the embankment shall be shaped so as to provide complete drainage of surface water at all times.

3.4

Compaction

3.4.1 The density to which fill materials shall be compacted shall be as per, relevant IS and as per direction of Owner. All compacted sand filling shall be confined as far as possible. Backfilled earth shall be compacted to minimum 95% of the Standard Proctor's density at OMC. The sub grade for the roads and embankment filling shall be compacted to minimum 95% of the Standard Proctor's density at OMC. Cohesion less material sub grade shall be compacted to 70% relative density (minimum). At all times unfinished construction shall have adequate drainage. Upon completion of the roads surface course. Adjacent shoulders shall be given a final shaping, true alignment and grade. Each layer of earth embankment when compacted shall be as close to optimum moisture content as practicable. Embankment material which does not contain sufficient moisture to obtain proper compaction shall be wetted. If the material contains any excess moisture, then it shall be allowed to dry before rolling. The rolling shall begin at the edges overlapping half the width of the roller each time and progress to the center of the road or towards the building as applicable. Rolling will also be required on rock fills. No compaction shall be carried out in rainy weather.

3.4.2

3.4.3

3.5

Requirement for fill material under foundation

The thickness of fill material under the foundations shall be such that the maximum pressure from the footing, transferred through the fill material and distributed onto the original undisturbed soil will not exceed the allowable soil bearing pressure of the original undisturbed soil. For expansive soils the fill materials and other protections etc. to be used under the foundation is to be got approved by the Owner.

4.0

4.1

ANTIWEED TREATMENT & STONE SPREADING or PCC: Scope

4.1.1 The Contractor shall furnish all labour, equipment and materials required for complete performance of the work in accordance with the drawings specification and direction of the Owner. Page 2.4 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

4.1.2

Stone spreading shall be done in the Outdoor Sub-Station area, Power Transformer, Capacitor Bank and wherever equipments and or structures are to be provided under present scope of work.

General Requirement

The material required for site surfacing / stone filling shall be free from all types of organic materials and shall be of standard quality, and as approved by the Owner. The material to be used for stone filling / site surfacing shall be uncrushed / crushed / broken stone of 20 mm nominal size (ungraded single size) conforming to Table 2 of IS:383 - 1970. Hardness, Flakiness shall be as required for wearing courses are given below: Sieve Analysis (Gradation)

(IS: 383 - Table - 2)

Sieve Size 40mm 20mm 10mm % passing by weight 100 85 100 0 20 05

One test shall be conducted for every 50 Cum. Hardness Abrasion value (IS: 2386 Part-IV) - not more than 40% Impact value (IS: 2386 Part-IV) - not more than 30% and frequency shall be one test per 50 Cum with a minimum of one test per source 4.1.3 After all the structures/equipments are erected and antiweed treatment is complete, the surface of the substation area shall be maintained, rolled/compacted to the lines and grades as decided by Engineer-in-Charge. De-weeding including removal of roots shall be done before rolling is commenced. Engineer-in-Charge shall decide final formation level so as to ensure that the site appears uniform free from undulations. The final formation level shall however be very close to the formation level using manual or machine roller with suitable water sprinkling arrangement to form a smooth and compact surface. After antiweed treatment & compaction of earth providing and laying in position cement concrete of specified grade excluding the cost of centring and shuttering- All Page 2.5 of 2.26

4.1.4

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

work upto plinth level 1 : 5 :10 (1Cement : 5 Coarse Sand :10 Graded stone agg. 40mm nominal size).100 mm thick. 4.1.5 After laying lean concrete 1:5:10 providing and laying in position layer of ready mix concrete M20 graded. All works up to floor V level 80 mm thick. Over the base layer of site surfacing material, a final surface course of minimum 50 mm thickness of 20 mm nominal size (single size ungraded) broken stone as specified above shall be spread and compacted. The water shall be sprinkled in such a way that bulking does not take place. Before taking up the above mentioned treatment (4.1.4 & 4.1.5), stone filling, antiweed treatment shall be applied in the switchyard area wherever Yard Treatment is to be done, and the area shall be thoroughly de-weeded including removal of roots. The recommendation of local agriculture or horticulture department shall be sought wherever feasible while choosing the type of chemical to be used. Nevertheless the effectiveness of the chemical shall be demonstrated by the contractor in a test area of 10M x 10M (approx.) and monitored over a period of two to three weeks by the Engineer-in-Charge. The final approval shall be given by Engineer-in-Charge and final approval given based in the results. The antiweed chemical shall be procured from reputed manufacturers. The dosage and application of chemical shall be strictly followed. as per manufacturer's recommendation. The contractor shall be required to maintain the area free of weeds for a period of 1 year from the date of application of 1st dose of antiweed chemicals.

4.1.6

4.1.7

4.1.8

5.0

5.1

SITE DRAINAGE:

Adequate site drainage system shall be provided by the Contractor. The Contractor shall design the storm water drainage system. On the basis of maximum rainfall intensity of (culverts, ditches, drains etc.) to accommodate run off due to the most intense rainfall that is likely to occur over the catchments area in one hour period on an average of once in ten years. The surface of the site shall be sloped to prevent the ponding of water. Outfall of drainage shall be suitably selected. The maximum velocity for pipe drains and open drains shall be limited to 2.4m/sec and 1.8m/sec. respectively. However, minimum non-silting velocity of 0.6m/sec shall be ensured. Longitudinal bed slope not milder than 1 in 1000 shall be provided. For design of RCC pipes for drains and culverts, IS: 456 and IS: 783 shall be followed. The Contractor shall ensure that water drains are away from the site area and shall prevent damage to adjacent property by this water. Adequate protection shall be given to site surfaces, roads, ditches, culverts, etc. to prevent erosion of material by water. Page 2.6 of 2.26

5.2

5.3 5.4

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

5.5 5.6

The drainage system shall be adequate without the use of cable/pipe trenches For pipe drains, concrete pipe of class NP2 shall be used. However, for road crossings etc. higher strength pipe of class NP3 shall be provided. For rail crossings, pipes conforming to railway loading standards or at least NP4 class shall be provided. Manholes shall be provided at every 30m interval, at connection points and at every change of alignment. Open surface drains shall be provided with Cement Concrete 1:2:4 of minimum thickness of 100 mm or more as per design condition. Pipe drains shall be connected through manholes at an interval of max.30m. Effluents shall be suitably treated by the Contractor to meet all the prevalent statutory requirements and local pollution control norms and treated effluents shall be conveyed to the storm water drainage system at a suitable location for its final disposal. Invert of the drainage system shall be decided in such a way that the water can easily be discharged above the High Flood Level (HFL) outside substation boundary at suitable location beyond boundary wall of substation or actual whichever occurs earlier and approved by Owner.

5.7

5.8

5.9

5.10 All internal site drainage system, including the final connection/disposal to Owner acceptance points shall be part of contractors scope including all required civil work, mechanical & electrical systems. The Contractor shall connect drain(s) at one or more points to outfall points as feasible at site. The drainage layout of the substation building approval shall be taken from the owner & all works to be carried out by contractor. 5.11 The drainage scheme and associated drawings shall be got approved.

Page 2.7 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI 6.0

6.1

ROADS AND CULVERTS

Within substation fencing, roads to be provided for access along with Car parking for three cars and two wheeler parking for three vechicles, to equipment and building and parking are in the scope of bidder. Layout of the roads shall be based on Layout drawing for the substation. Parking areas shall be provided for Site personnel and visitors as per layout drawing. Adequate turning space for vehicles shall be provided and bend radius shall be set accordingly. It has to be connected suitably with roads. All substation roads be constructed so as to permit transportation of all heavy equipment upto 50MT. The roads shall be provided of PAVER Blocks. On the approach road upto Control Room Building and other relevant roads will be Cement Concrete Roads The pavers blocks used for the roads shall be minimum 80mm thick with compressive strength not less than 450Kg/cm2. Road Standard shall be as per IRC standard. Adequate provision shall be made for road drainage. All the culverts and its allied structure (required for road/rail, drain trench crossings etc.) shall be designed for class AA loading as per IRC standard/IS code. All roads shall be designed for class 'E' of traffic as per IRC-37 Guidelines for the design of flexible pavements. 2 nos rails of requisite length should be grouted at distance of 1.67 M for dragging of power transformer during installation & dismantling.

6.2

6.3 6.4 6.5

6.6

6.7

7.0

7.1

CABLE & PIPE TRENCHES

The cable trenches and precast removable RCC cover (with lifting arrangement) shall be constructed using RCC of M25 grade. The cable trench wall shall be designed for the following loads. Dead load of 155 kg/m length of cable support + 75 Kg on one tier at the end. Triangular earth pressure + uniform surcharge pressure of 2T/m2.

7.2

Cable trench covers shall be designed for self weight of top slab + UDL of 2000 Kg/m2 + concentrated load of 200 kg at centre of span on each panel. with 3mm flat all round and upto the width of trench cover. Cable trench crossing the road/rails shall be designed for class AA loading of IRC/relevant IS Code and should be checked for transformer/reactor loading.

7.3

Page 2.8 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

7.4 Trenches shall be drained. Necessary sumps be constructed and sump pumps if necessary shall be supplied. Cable trenches shall not be used as storm water drains. The top of trenches shall be kept at least 100 mm above the finished ground level. The top of cable trench shall be such that the surface rain water does not enter the trench. All metal parts inside the trench shall be connected to the earthing system. HT, LT & Control Cables from trench to equipments shall run in hard conduit pipes. The trench bed shall have a perpendicular to the run. Trench wall shall not foul with the foundation. Suitable clear gap shall be provided. The trench bed shall have a slope of 1/500 along the run & 1/250 perpendicular to the run.

7.5

7.6 7.7 7.8

7.9

7.10 All the construction joints of cable trenches i.e. between base slab to base slab and the junction of vertical wall to base slab as well as from vertical wall to wall and all the expansion, joints shall be provided with approved quality PVC water stops of approx. 230 x 5 mm size for those sections where the ground water table is expected to rise above the junction of base slab and vertical wall of cable trenches. 7.11 Cable trenches shall be blocked at the ends if required with brick masonry in cement sand mortar 1:6 and plaster with 15mm thick 1:6 cement and mortar.

8.0

8.1

FOUNDATION / RCC CONSTRUCTION General

8.1.1 Work covered under this Clause of the Specification comprises the design and construction of foundations and other RCC constructions for switchyard structures, equipment supports, trenches, drains, jacking pad, pulling block, control cubicles, bus supports, Power transformer/Reactors, marshalling kiosks and auxiliary equipments, tanks or for any other equipment or service and any other foundation required to complete the work. This clause is as well applicable to the other RCC constructions. It may also be noted by the contractor that all existing equipment foundations in the outdoor area shall be dismantled by him. Concrete shall conform to the requirements mentioned in IS: 456 and all the tests shall be conducted as per relevant Indian Standard Codes as mentioned in Standard field quality plan appended with the specification. A minimum grade of M25 concrete shall be used for all structural/load bearing members as per latest IS: 456 (latest revision). If the site is sloppy, the foundation height will be adjusted to maintain the exact level of the top of structures to compensate such slopes. Page 2.9 of 2.26

8.1.2

8.1.3

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

8.1.4 The switchyard foundation's plinths shall be minimum 300mm above finished ground level. Minimum 75mm thick lean concrete (1:4:8) shall be provided below all underground structures, foundations, trenches etc. to provide a base for construction. Concrete made with Portland slag cement shall be carefully cured and special importance shall be given during the placing of concrete and removal of shuttering. The design and detailing of foundations shall be done based on the approved soil data and sub-soil conditions as well as for all possible critical loads and the combinations thereof. The Spread footings foundation or pile foundation as may be required based on soil/sub-soil conditions and superimposed loads shall be provided. If pile foundations are adopted, the same shall be cast-in-situ driven/bored or precast or under reamed type as per relevant. parts of IS Code 2911. Only RCC piles shall be provided. Suitability of the adopted pile foundations shall be justified by way of full design calculations. Detailed design calculations shall be submitted by the bidder showing complete details of piles/pile groups proposed to be used. Necessary initial load test shall also be carried out by the bidder at their cost to establish the piles design capacity. Only after the design capacities of piles have been established, the Contractor shall take up the job of piling. Routine tests for the piles shall also be conducted. All the work (design & testing) shall be planned in such a way that these shall not cause any delay in project completion. The contractor shall go for vertical load testing or lateral load testing. The contractor may choose static or dynamic load testing upon site condition and time constraint.

8.1.5

8.1.6

8.1.7

8.1.8

8.2

Design

8.2.1 All foundation shall be of reinforced cement concrete. The design and construction of RCC structures shall be carried out as per IS :456 and minimum grade of concrete shall be M-25. Limit state method of design shall be adopted unless specified otherwise in the specification. For detailing of reinforcement IS: 2502 and SP: 16 shall be followed. Cold twisted deformed bars conforming to IS: 1786 shall be used as reinforcement. However, in specific areas mild steel (Grade I) conforming to IS:432 can also be used. Two layers of reinforcement (on inner and outer face) shall be provided for wall & slab sections having thickness of 150 mm and above. Clear cover to reinforcement towards the earth face shall be minimum 40 mm. RCC water retaining structures like storage tanks, etc. shall be designed as uncracked section in accordance with IS: 3370 (Part I to IV) by working stress Page 2.10 of 2.26

8.2.2

8.2.3

8.2.4

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

method. However, water channels shall be designed as cracked section with limited steel stresses as per IS: 3370 (Part I to IV) by working stress method. 8.2.5 The procedure used for the design of the foundations shall be the most critical loading combination of the steel structure and or equipment and/or superstructure and other conditions, which produces the maximum stresses in the foundation or the foundation component and as per the relevant IS Codes of foundation design. Detailed design calculations shall be submitted by the bidder showing complete details of piles/pile groups proposed to be used. Design shall consider any sub-soil water pressure that may be encountered following relevant standard strictly. Necessary protection to the foundation work. If required shall be provided to take care of any special requirements for aggressive alkaline soil. Black cotton soil or any other type of soil, which is detrimental / harmful to the concrete foundations. RCC columns shall be provided with rigid connection at the base. All sub-structures shall be checked for sliding and overturning stability during both construction and operating conditions for various combinations of loads. Factors of safety for these cases shall be taken as mentioned in relevant IS Codes as stipulated elsewhere in the Specifications, For checking against overturning. weight of soil vertically above footing shall be taken and inverted frustum of pyramid of earth on the foundation should not be considered.

8.2.6

8.2.7

8.2.8 8.2.9

8.2.10 Earth pressure for all underground structures shall be calculated using coefficient of earth pressure at rest. Co-efficient of active or passive earth pressure (whichever is applicable). However, for the design of substructures of any underground enclosures, earth pressure at rest shall be considered. 8.2.11 In addition to earth pressure and ground water pressure etc., a surcharge load of 2T/Sq.m shall also be considered for the design of all underground structures including channels, sumps, tanks, trenches, and substructure of any underground hollow enclosure etc, for the vehicular traffic in the vicinity of the structure. 8.2.12 Following conditions shall be considered for the design of water tank in pumps house, channels, sumps, trenches and other underground structures: 8.2.12.1 Full water pressure from inside and no earth pressure & ground water pressure & surcharge pressure from outside (application only to structures, which are liable to be filled up with water or any other liquid). 8.2.12.2 Full earth pressure, surcharge pressure and ground water pressure from outside and no water pressure from inside. 8.2.12.3 Design shall also be checked against buoyancy due to the ground water during construction and maintenance stages. Minimum factor of safety of Page 2.11 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

1.5 against buoyancy shall be ensured ignoring the superimposed loadings. 8.2.13 Base slab of any underground enclosure shall also be designed for empty condition during construction and maintenance stages with maximum groundwater table (GWT). Minimum factor of safety of 1.5 against buoyancy shall be ensured ignoring the super-imposed loadings. 8.2.14 Base slab of any underground enclosure like water storage tank shall also be designed for the condition of different combination of pump sumps being empty during maintenance stages with maximum GWT. Intermediate dividing piers of such enclosures shall be designed considering water in one pump sump only and the other pumps sump being empty for maintenance. 8.2.15 The foundations shall be proportioned so that the estimated total and differential movements of the foundations are not greater than the movements that the structure or equipment is designed to accommodate. 8.2.16 The foundations of transformer shall be of block type foundation. Minimum reinforcement shall be governed by IS: 2974 and IS: 456. 8.2.17 The equipment foundations shall be checked for a factor of safety of 2.2 for normal condition and 1.65 for short circuit condition against sliding, overturning and pullout. The same factors shall be used as partial safety factor over loads in limit state design also. 8.3 Admixture & Additives 8.3.1 Only approved admixtures shall be used in the concrete for the Works. When more than one admixture is to be used, each admixture shall be batched in its own batch and added to the mixing water separately before discharging into the mixer. Admixtures shall be delivered in suitably labeled containers to enable identification. Admixtures in concrete shall conform to IS: 9103. The waterproofing cement additives shall conform to IS: 2645. Owner shall approve concrete Admixtures/ Additives. The contractor may propose and the Owner may improve the use of a water-reducing set-retarding admixture in some of the concrete. The use of such an admixture will not be approved to overcome problems associated with inadequate concrete plant capacity or improperly planned placing operation sand shall only be approved as an aid to overcoming unusual circumstances and placing conditions. The water-reducing set-retarding admixture shall be an approved brand of Lignosulphonate type admixture. Page 2.12 of 2.26

8.3.2

8.3.3

8.3.4

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

8.3.5 The waterproofing cement additives shall be used as required/advised by the Owner.

9.0

9.1

IRC WELD MESH FENCING, GATE General

Fencing shall be designed for the most critical loading combination taking care of wind force, stability, tension on wires, minimum requirements as per this clause for are materials IS 8910 and fabrication IS 800 as per recommendations

9.2

Areas and Requiring Fencing Fencing shall be providing for the following areas: 9.2.1 Site fencing for the complete Outdoor substation including Power transformer area. Gates shall be provided for men and machine / equipment to be taken out of the substation. Capacitor bank cage, which shall be part of the capacitor bank supply. Wherever necessary anti-reptile fixture/arrangement shall be provided along with fencing. Fencing of Aux. Substation Transformer

9.2.2 9.2.3 9.3

Product Material The minimum requirements are as follows: 9.3.1 IRC Weld Mesh Fencing in accordance to relevant IS Code Size of IRC mesh Nominal wire size Width of fencing pannel Height of fencing Fabrication of panels Paint 25X75mm 6 mm 2400mm 2000mm 40mm Dia M.S. Pipe (medium duty) & 40 x 5 mm Flats Aluminum Paint

9.3.2

Posts Intermediate Straining Post Base Plate : 50mm dia , .M.S. Pipe (medium duty) : 12mm.M.S. Plate with 4 Nos of hole

All structural steel shall confirm to IS: 2062 and shall be painted with a coat of approved steel primer and two coats of Aluminum Paint. The IRC weld mesh Panels shall be fixed to the post at the top and bottom of the 50mm dia, .M.S. Pipe by Nuts and bolts. The Intermediate straining Posts to be Page 2.13 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

erected by using Holding down bolts and nuts grouted in toe wall around the Yard (the height of Yard Toe wall to be atleaset 450 mm above the yard level and 340 mm wide)

All structural steel shall confirm to IS: 8910 and shall be painted with a coat of approved steel primer and two coats of synthetic enamel paint. The Chain Link fabric shall be fixed to the post at the top and bottom of the fence by welding/fixing 50 mm MS flat all through its length. 9.3.3 The Tension wire shall be single strand, three layer and high tensile galvanized steel wire of 4mm diameter.

9.4

Installation

9.4.1 9.4.2 9.4.3 9.4.4 Fence shall be installed along all three transformers periphery. Post holes shall be excavated by approved methods. Intermediate posts shall be spaced 2.5 m apart measured parallel to ground surface. Posts shall be set in 1:2:4 plain cement concrete blocks of minimum dimension (340 mm x 340 mm x750 mm deep) Concrete work shall conform to relevant clause. Post shall be braced and held in plumb position and true alignment and elevation until concrete has set. Fence fabric shall not be installed until concrete has cured a minimum of 7 days. Bottom and top of the fence fabric shall be fixed with MS flats of 50 mm x. 6mm (min). Toe wall of Brick masonry, with notches over 75 mm thick PCC (1:4:8 ) shall be provided below all fencing and shall be minimum 450 mm above and 450 mm below finished ground level. All exposed surfaces of brick toe wall shall be provided with 1:6 cement sand plaster and coated with two coats of Acrylic Smooth exterior paint with a base coat of approved cement primer.

9.4.5 9.4.6

9.4.7

9.5 Gates 9.5.1 The Gate frame shall be made of medium duty MS pipe conforming to relevant IS with welded joints. The gates shall be fabricated with welded joints to achieve rigid connections. The gate frames shall be painted with one coat of approved steel primmer and two coats of synthetic enamel paint. Page 2.14 of 2.26

9.5.2

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

9.5.3

Gates shall be fitted with approved quality iron hinges, latch and latch catch. Latch and latch catch shall be suitable for attachment and operation of pad lock from either side of gates. Hinges shall permit gates to swing through 180 degree back against fence. Gates shall be fitted with galvanized chain hook or gate hold back to hold gates open. Double gates shall be fitted with centre rest and drop bolt to secure gates in closed position. Gates shall be installed in locations shown on drawings. Next to the main gate, a men gate (1.25 m wide, single leaf) shall also be provided. With a wicked gate. Bottom of gates shall be set approximately 40mm above ground surface and necessary guiding mechanism shall be fitted.

9.5.4

9.5.5

9.5.6

10.0 BUILDINGS

10.1 General Requirements The scope include the design, engineering and construction including anti-termite treatment, plinth protection DPC of Building including sanitary, water supply, electrification false ceiling etc. of control room building. The building shall be of RCC framed structure of concrete of M25 grade (Min.) 10.2 Control Room Building Minimum floor area requirements have been given in tender drawings, which may be increased at the time of detailed engineering to suit project requirements. An open space of 1 m minimum shall be provided on the periphery of the rows of panel and equipment generally in order to allow easy operator movement and access as well as maintenance. Future extension of one floor shall be considered at the time of design. Any other possibility of annex building shall be taken care of while finalising the layout of the control room building. 10.2.1 Design a) The Building shall be designed on Green Building Concept. The design of control room building shall be such decided thats minimum one floor can be added in future. To the requirements of the National Building Code of India and the standards quoted therein. The contractor shall also arrange approval of building from any local authorities such as MCD or fire officer if required so. The official fees shall be born by BRPL. Page 2.15 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

The layout shall be such decided thats third transformer bay can be added in future. For the specified climatic & loading conditions.

To adequately suit the requirements of the equipment and apparatus contained in the buildings and in all respects to be compatible with the intended use and occupancy. With a functional and economical space arrangement. To be aesthetically pleasing. Different buildings shall show a uniformity and consistency in architectural design. To allow for easy access to equipment and maintenance of the equipment. With, wherever required, fire retarding materials for walls, ceilings and doors, which would prevent supporting or spreading of fire. With materials preventing dust accumulation.

b) Suitable expansion joints shall be provided in the longitudinal direction wherever necessary with provision of twin columns. c) Individual members of the buildings frame shall be designed for the worst combination of forces such as bending moment, axial force, shear force, torsion etc. d) Permissible stresses for different load combinations shall be taken as per relevant IS Codes and American standards. e) The building lighting shall be designed in accordance with the requirements of relevant section. f) The building auxiliary services like exhaust and ventilation systems, fire protection and detection systems and all other miscellaneous services shall be designed in accordance with the requirements specified in relevant section or elsewhere in this Specification.

g) Two nos. of emergency exists shall be provided in the building. 10.2.2 Design Loads Building structures shall be designed for the most critical combinations of dead loads, super- imposed loads, equipment loads, crane load, wind loads, seismic loads, and temperature loads Dead loads shall include the weight of structures complete with Page 2.16 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

finishes, fixtures and partitions and should be taken as per IS:1911. Super-imposed loads in different areas shall include live loads, minor equipment loads, cable trays, small pipe racks & hangers and erection, operation and maintenance loads. Equipment loads shall constitute, if applicable, all load of equipments to be supported on the building frame The wind loads shall be computed as per IS 875, Seismic Coefficient method shall be used for the seismic analysis as per IS 1893 with importance factor 1.5. For temperature loading, the total temperature variation shall be considered as 2/3 of the average maximum annual variation in temperature. The average maximum annual variation in temperature for the purpose shall be taken as the difference between the mean of the daily minimum temperature during the coldest month of the year and mean of daily maximum temperature during the hottest month of the year. The structure shall be designed to withstand stresses due to 50% of the total temperature variation. Wind and Seismic forces shall not be considered to act simultaneously. Floors/slabs shall be designed to carry loads imposed by equipment. Floors shall be designed for live loads as per relevant American standards. Cable and piping loads shall also be considered additionally for floors where these loads are expected. In addition, beams shall be designed for any incidental point loads to be applied at any point along the beams, the floor loads shall be subject to Owners approval. For consideration of loads on structures IS: 875, the following minimum superimposed live loads shall however be considered for the design.

Roof

2.5 KN/M2 0.75 KN/M2 (i) 5 KN/M2 (ii) 15 KN/M2 (min)

for accessible roofs for in-accessible roofs for offices for equipment floors or actual requirement, if higher than 15KN/M2 based on equipment Component weight and Layout plan

RCC-Floor

Stairs & balconies Toilet Rooms Chequered plate floor Walkways

5 KN/M2

2 KN/M2 4 KN/M2 3 KN/M2 Page 2.17 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

Any additional load coming in the structure shall be calculated as per IS: 875.

10.2.3 Submission The following information shall be submitted for review and approval to the owner:

a)

Design criteria shall comprise the codes and standards used. Applicable climatic data including wind loads, earthquake factors maximum and minimum temperatures applicable to the building locations, assumptions of dead and live loads, including equipment loads, impact factors. safety factors and other relevant information. Structural design calculations and drawing (including construction/fabrication) for all reinforced concrete and structural steel structures. Fully, dimensioned concept plan including floor plans, cross sections, longitudinal sections, elevations and perspective view of each building. These drawings shall be drawn at a scale not smaller than I : 50 and shall identify the major building components. Fully dimensioned drawings showing details and sections drawn to scales of sufficient size to clearly show sizes and configuration of the building components and the relationship between them. Product information of building components and materials, including walls partitions flooring ceiling, roofing, door and windows and building finishes. A detailed schedule of building finishes including colour schemes. A door & window schedule showing door types and locations, door lock sets and latch sets and other door hardware.

b)

c)

d)

e)

f) g)

Approval of the above information shall be obtained before ordering materials or starting fabrication or construction as applicable.

10.2.4 Finish Schedule The finishing schedule is given in subsequent clauses. 10.2.5 Flooring Flooring in various rooms of control room building shall be as for detailed schedules given in Table 1.

Page 2.18 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

10.2.6 Walls Control room buildings shall be of framed superstructure. All walls shall be non-load bearing walls. Min. thickness of external walls shall be 230 mm (one brick) with 1:6 cement coarse sand mortars. 10.2.7 Plastering All internal walls shall have minimum 12mm thick 1:4 (1 Cement : 4 fine Sand) cement sand plaster. The ceiling shall have 6mm thick 1:4 cement sand plaster 10.2.8 Finishing All external surfaces shall have Marble / Dholpur Chips with colour pigment (with groves formed) (DSR 13.112) finish over, 12mm thick cement sand plaster 1:4 (1 cement:4 coarse sand) mixed with water proofing compound in the ratio 8S recommended by the manufacturer. Suitable pigment shall be added to render the surface aesthetically pleasing as per directions of Engineer-in-charge. 10.2.9 Under Deck Insulation The method of fixing shall consist of slotted M.S. angles 75 x 50 x 4 mm fixed to soffit of RCC roof slab at 600mm centers in both directions by Rawl plugs of adequate strength. The slots shall have 14 GG.I. tie wire drawn through them. 50mm thick insulation mat Fiberglass Crown - 100 or equivalent shall, be made out of fiber-glass or approved equivalent conforming to IS: 8183, backed with 34G aluminum foil and 22G x 12mm mesh wire netting. The net shall be stretched tightly across the slotted angles or slotted plates holding it in place by means of wires. The joints of the wire netting shall be butted and tightly laced down with 14G G.I. wire. The system shall be got approved 10.2.10 Door & Window The details of doors and windows of the control room building shall be as per finish schedule Table-l and tender drawing with the relevant IS, code. Rolling steel shutters and rolling shutters grills shall be provided as per layout and requirement of buildings. Paints used in the work shall be of best quality specified in CPWD specification. 10.2.11 Partition Partition made of anodised aluminium frame provided with 6.0 mm thick clear glass shall be supplied and installed at locations shown in tender drawings. 10.2.12 Plumbing & Sanitation

Page 2.19 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

a) All plumbing and sanitation shall be executed to comply with the requirements of the appropriate bye-laws, rules and regulations of the Local Authority having jurisdiction over such matters. The Contractor shall arrange for all necessary formalities to be met in regard to inspection, testing, obtaining approval and giving notices etc. b) PVC syntex or equivalent make Roof water tank of adequate capacity depending on the number of users for 24 hours storage shall be provided. Minimum 2 Nos. 1500 litres capacity shall be provided. c) Galvanised MS pipe of medium class conforming to IS:1239 shall be used for internal & external piping work for potable water supply. d) Sand CI pipes with lead joints: confonning to IS: 1729 shall be used for sanitary works above ground level. e) Each toilet shall have minimum fittings i) WC (Western type) 390 mm high with toilet paper roll holder and all fittings or WC (Indian Type) Orissa Pattern (580 x 440 mm) with all fittings. (both types of WCs shall be provided at alternate locations). ii) Half Stall Urinal (430 x 260 x 350 mm size) with all fittings. iii) Wash basin (550 x 400 mm) with all fittings. iv) Bathroom mirror (600 x 450 x 6 mm thick) hard board backing v) CP brass towel rail (600 x 20 mm) with C. P. brass brackets vi) Soap holder and liquid soap dispenser. f) Water cooler for drinking water with adequate water storage facility shall be provided and located near control room instead of near toilet block.

g) An Eye & face fountain conforming to IS:1052 shall be provided for battery room. h) I no, stainless steel kitchen sink with Drain board (510 x 1040 x 178mm bow I depth) for pantry shall be provided. i) j) All fittings, fastener, grating shall be chromium plated. All sanitary fixtures and fittings shall be of approved quality and type manufactured by well known manufacturers. All items brought to site must bear identification marks of the type of the Manufacturer.

k) Soil, waste and drain pipes, for underground works shall be stoneware for areas not subject to traffic load. Heavy-duty cast iron pipes shall be used otherwise.

Page 2.20 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI 11.0 STORM WATER DRAINAGE FOR CONTROL ROOM BUILDING

The building drain shall be provided for the collection of storm water from the roofs. This water shall be collected in junction boxes and these boxes shall drain to the main drainage system of the station. Cast Iron rain water down comers conforming to IS:1230 with water tight lead joints shall be provided to drain off the rain water from the roof. These shall be suitably concealed with masonry work of cement concrete or cladding material. The number and size of down comers shall be governed by IS:1742 and IS:2527. All drains inside the buildings shall have minimum 40 mm thick grating covers and in areas where heavy equipment loads would be coming, precast RCC covers shall be provided in place of steel grating. For all buildings, suitable arrangement for draining out water collected from equipment blow down, leakages, floor washings fire fighting etc. shall be provided for each floor.

12.0 TESTING

The sampling & testing of the construction materials will be in accordance to CPWD Specifications 2009 Volume I & Volume II as stated in the sub Heads No. 1.0 to 23.0 related to all activities of the building and other civil construction works. .

13.0 MISCELLANEOUS GENERAL REQUIREMENTS

13.1 Dense concrete with controlled water cement ratio as per IS-code shall be used for all underground concrete structures such as pump-house, tanks, water retaining structures, cable and pipe trenches etc. for achieving water tightness. 13.2 All joints including construction and expansion joints for the water retaining structures shall be made water tight by using PVC ribbed water stops with central bulb. However, kicker type (externally placed) PVC water stops shall be used for the base slab and in other areas where it is required to facilitate concreting. The minimum thickness of PVC water stops shall be 5 mm and minimum width shall be 230 mm. 13.3 All mild steel parts used in the water retaining structures shall be hot-double dip galvanised. The minimum coating of the zinc shall be 610 gm/sq. m. for galvanised structures and shall comply with IS:2629 and IS:2633. Galvanizing shall be checked and tested in accordance with IS:2633. The galvanizing shall be followed by the application of an etching primer and dipping in black bitumen in accordance with BS:3416. 13.4 A screed concrete layer not less than 100 mm thick and of grade not weaker than M10 conforming to IS:456-1978 shall be provided below all water retaining structures. A sliding layer of bitumen paper or craft paper shall be provided over the screed layer to destroy the bond between the screed and the base slab concrete of the water retaining structures.

Page 2.21 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI

13.5 Bricks having minimum 75-kglcm2 compressive strength can only be used for masonry work. Contractor shall ascertain himself at site regarding the availability of bricks of minimum 75 i\:g/cm2 compressive strength before submitting his offer. 13.6 Doors and windows on external walls of the buildings (other than areas provided, with insulated metal claddings) shall be provided with RCC sunshade over the openings with 300 mm projection on either side of the openings. Projection of sunshade from the wall shall be minimum 450mm over window openings and 750 mm over door openings. 13.7 All stairs shall have maximum riser height of 150 mm and a minimum tread width of 300 mm Minimum width of stairs shall be 1500 mm. Service ladder shall be provided for access to all roofs. RCC fire escape staircase shall be provided in control buildings. 13.8 Angles 50x50x6 mm (minimum) with lugs shall be provided for edge protection all round cut outs/openings in floor slab, edges of drains supporting grating covers, edges of RCC cable/pipe trenches supporting covers, edges of manholes supporting covers, supporting edges of manhole precast cover and any other place where breakage of comers of concrete is expected. 13.9 Anti termite chemical treatment shall be given to column pits, wall trenches, foundations of buildings, filling below the floors etc. as per IS:6313 and other relevant Indian Standards. 13.10 Hand-railing minimum 900mm high shall be provided around all floor/roof openings, projections/balconies walk ways, platforms, steel stairs etc. All handrails and ladder pipes shall be 32 mm nominal bore MS pipes (medium class) and shall be galvanised (mediumclass as per IS:277). All rungs for ladder shall also be galvanised as per IS: 277 medium class. For RCC stairs, hand railing with 20 mm square MS bars, balustrades with suitable MS flats & aluminum handrails shall be provided. 13.11 The details given in tender drawings shall be considered along with details available in this section of the specification while deciding various components of the building. Items/components of buildings not explicitly covered in the specification but required for completion of the project shall be deemed to be included in the scope

14.0 INTERFACING

The proper coordination & execution of all interfacing civil works activities like fixing of conduits in roofs/walls/floors, fixing of lighting fixtures, fixing of supports/embedments, provision of cutouts etc for indoor illumination, ventilation & Air conditioning shall be the sole responsibility of the Contractor. He shall plan all such activities in advance and execute in such a manner that interfacing activities do not become bottlenecks and dismantling, breakage etc. is reduced to minimum

Page 2.22 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI 15.0 WATER SUPPLY

15.1 Water shall be made available by Owner at any feasible point near scope boundary at single point to the contractor. Contractor shall state the total water requirement both in terms of quantity and head to the Owner. 15.2 The Contractor shall carry out all the plumbing/erection works required for supply of water in control room building beyond the single point as at (i). 15.3 A scheme shall be prepared by the Contractor indicating the layout and details of water supply which shall be got approved by the Owner before actual start of' work including all other incidental items not shown or specified but as may be required for complete performance of the works. 15.4 Bore wells and pumps for water supply is not in the scope of contractor. Although contractor shall provide a underground water reservoir inside a room, near the gate of minimum 50 M3 or sufficient capacity for refill of one fire tender. The water reservoir shall be provided with a high-pressure pump and single point fire hydrant outlet outside the room for refilling the fire tender in case of fire and emergency. Necessary valve shall be provided in the outlet

16.0 SEWERAGE SYSTEM

16.1 Sewerage system shall be provided for control room building. 16.2 The Contractor shall construct septic tank and soak pit suitable for 50 users. 16.3 The system shall be designed as per relevant IS Codes.

17.0 STATUTORY RULES

17.1 Contractor shall comply with all the applicable statutory rules pertaining to factories act (as applicable far the State). Fire Safety Rules of Tariff Advisery Committee. Water Act for pollution control etc. 17.2 Provisions for fire proof doors, no. of staircases, fire separation wall. plastering on structural members (in fire prone areas) etc. shall be made according to the recommendations of Tariff Advisory Committee. 17.3 Statutory clearance and norms of State Pollution Control Board shall be followed as per Water Act for effluent quality from plant. 17.4 Foundation system adopted by Bidder shall ensure that relative settlement and other criteria shall be as per provision in IS: 1904 and other Indian Standards.

Page 2.23 of 2.26

Corporate office: BSES Bhawan, Nehru Place, New Delhi- 19

Volume I Technical Specifications for Civil Works.

TECHNICAL SPECIFICATION FOR TURNKEY EXECUTION OF 33KV SAKET COURT COMPLEX I/D GRID SUBSTATION AT DELHI