Documente Academic

Documente Profesional

Documente Cultură

Compressor Size

Încărcat de

Subhash KumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Compressor Size

Încărcat de

Subhash KumarDrepturi de autor:

Formate disponibile

Sent: Wednesday, June 13, 2007 5:04 PM To: oheikal@eim.

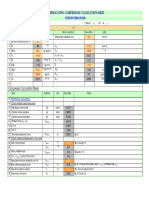

ae Subject: Compressor size

TME Vessel Capacity Vessel Diameter Vessel Bottom Level Space Between Level Sensors Min Air Ratio (HH) Chamber Area Vessel Top Level Upper Water Level Min Air Volume Lower Water Level Max Air Volume Max Air Ratio (LL) % Air/Water Ratio at HWL m3 m3 m3 m3 % m2 m m m3 m m3 % % V D H S LAR A TL UWL LAV LWL MAV MAR 60 2.8 1.5 1.2 20 6.158 11.244 9.295 12 8.095 19.389 32.315 22 TL UWL

LWL

Ramping Time

N Air Volume at HL (22% A/W ratio) Initial Presssure Final Pressure Final air volume Initial air volume (Water at Normal Level) Required air volume m3 bar bar m3 m3 m3 52.8 8.5 15.5 818.40 510.00 308.40 818.40 510.00 308.4 120 2.57 154 Minutes Nm3/min Nm3/hr Ramp up Time Compressor Capacity

High to Normal Level

N Air Volume between HL & NL Required Air Volume Time m3 m3 min 9.85 152.71 59

Sent: Wednesday, June 13, 2007 5:04 PM Compressor Sizing.election based on Compresso calculation document from M/s ILF ref.G5809-00-ME-02-223-DC-0501-00 Ref. ILF Document ref.G5809-00-ME-02-223DC-0501-00-Air Compressor calculation. MZ PS CASE 1 a b c Intial filling of surge vessels NO OF SURGE VESSLES-N PRESURE INSIDE SURGE VESSEL VOLUME OF SURGE VESSEL Air volume operating in steady state one vesel Air density at 0C Air mass in surge vessel when filling from atmosphere to operating pressure = N X (Patm x Vsurge vessel)/(Rair x T air ) mass of air mass in surg vessel at steady state after filling with water , at steady state = N X (PSV x V air IN surge vessel)/(Rairx T air ) The difference is the air to be supplied by the compressor Assuming 24 hours, both compressor running for filling , each compressir capacity is Compressir capacity in air volume , density of air 1.293 kg/NM3. If only duty compressor is allowed to run during operation then compressor capacity shall be Decreasing air mass -air loss units no. bar m3 m3 Kg/Nm3 4 14.5 107.5 22.5 1.293 SCHEME A & B PS 3 14 60 5.67 1.293 Scheme C PS. 3 13.5 60 5 1.293

A1

kg

555.8854873

232.6962505

232.6962505

A2

kg kg

1664.986742 1109.101255

303.8313737 71.13512321

258.3600117 25.66376116

kg/hr Nm3/hr

23.10627614 17.87028317

1.481981734 1.146157567

0.534661691 0.413504788

A3

Nm3/hr

35.74056634

2.292315133

0.827009576

CASE B

A4

Compenasation start at 5 % mass loss, preset Total air mass at steady state -A2 Air mass loss @5 % Time for recharrging as per control philosophy hence mass flow rate required for Duty compressor is acc. Flow rate required for duty compressor is Hence the higher value out A3/A4 is selected as compressor capacity. SAFETY MARGIN 15 % Calculated compressor capacity Final sizing Pressure

1664.986742 83.24933709 4 20.81233427 16.09615953 17.87028317 20.55082564 21 13.5

303.8313737 15.19156869 4 3.797892171 2.937271594 2.937271594 3.377862333 3.5 13

258.3600117 12.91800058 4 3.229500146 2.497679927 2.497679927 2.872331916 3 12.5

Nm3/hr Bar g

S-ar putea să vă placă și

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 paginiCalculation of time needed to mix liquids with pitch blade impellershadiÎncă nu există evaluări

- Norgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)Document5 paginiNorgren Sizing Calculations Cylinder Sizing Calculations Force Pressure X Area of Piston (F PA)navneetÎncă nu există evaluări

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 paginiControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986Încă nu există evaluări

- John Crane Dash BoardDocument44 paginiJohn Crane Dash BoardYogaditya ModukuriÎncă nu există evaluări

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pagini(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaÎncă nu există evaluări

- C3CYCLVDocument13 paginiC3CYCLVUok RitchieÎncă nu există evaluări

- Properties of liquid hydrocarbons in pumpsDocument1 paginăProperties of liquid hydrocarbons in pumpsmahesh_eilÎncă nu există evaluări

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 paginiGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Pipes. Maxi 1Document1 paginăPipes. Maxi 1Nasrul AdliÎncă nu există evaluări

- Heat Capacity Ratio of Real GasesDocument2 paginiHeat Capacity Ratio of Real GasesilyesinÎncă nu există evaluări

- Blind Flange Minimum Thickness CalculationDocument2 paginiBlind Flange Minimum Thickness CalculationwidhiyogaÎncă nu există evaluări

- Air cooler size estimation parametersDocument1 paginăAir cooler size estimation parametersmacielÎncă nu există evaluări

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 paginiWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Heat Load Calculation-Rect-Tank-2019Document8 paginiHeat Load Calculation-Rect-Tank-2019Hasmukh DaveÎncă nu există evaluări

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 paginiHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraÎncă nu există evaluări

- Gas Conditioning System Specification Sheet: Process InformationDocument3 paginiGas Conditioning System Specification Sheet: Process InformationNITIN P SHAHÎncă nu există evaluări

- ChE450 TBWS15.28Document6 paginiChE450 TBWS15.28HaematomaÎncă nu există evaluări

- Spreadsheet Heat Loss from a PipeDocument1 paginăSpreadsheet Heat Loss from a PipeJogender DhayalÎncă nu există evaluări

- Progress and Development in Hydrogen EnergyDocument81 paginiProgress and Development in Hydrogen EnergyBolWolÎncă nu există evaluări

- Compressor Settleout Pressure Temperature EstimationDocument3 paginiCompressor Settleout Pressure Temperature EstimationMirsoÎncă nu există evaluări

- XSteam Excel v2.6Document3 paginiXSteam Excel v2.6pchanycÎncă nu există evaluări

- Restriction OrificeDocument8 paginiRestriction OrificekarthickÎncă nu există evaluări

- Electrical Generators Rev3.1Document115 paginiElectrical Generators Rev3.1genergiaÎncă nu există evaluări

- GEMI Equations ToolDocument10 paginiGEMI Equations TooljnmanivannanÎncă nu există evaluări

- Air Receiver Sizing CalculationDocument1 paginăAir Receiver Sizing CalculationAziz HaqueÎncă nu există evaluări

- Perancangan Plate Adn Frame HEDocument36 paginiPerancangan Plate Adn Frame HEDavid LambertÎncă nu există evaluări

- LP FlashDocument6 paginiLP FlashMario Avalos Salazar100% (1)

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pagini10.9. Gas Liquid Separators: Chemical EngineeringsterlingÎncă nu există evaluări

- Pressuredrop Calculations by Kern Method SRRDocument18 paginiPressuredrop Calculations by Kern Method SRRrajeev50588Încă nu există evaluări

- Air Ingress CalculationsDocument5 paginiAir Ingress CalculationsMallinatha PNÎncă nu există evaluări

- Double FdexchangerDocument8 paginiDouble FdexchangerBoško IvanovićÎncă nu există evaluări

- Pressor CurvesDocument8 paginiPressor CurvesKeyren JuliantoÎncă nu există evaluări

- Water PropertiesDocument4 paginiWater Propertiesaw_aeÎncă nu există evaluări

- NASA CC3 ImpellerDocument22 paginiNASA CC3 ImpellerPaul BarlowÎncă nu există evaluări

- Dynamic Simulation of Centrifugal Compressor Startup With Inlet Guide VaneDocument8 paginiDynamic Simulation of Centrifugal Compressor Startup With Inlet Guide VaneKong LingweiÎncă nu există evaluări

- Distillation Column: Major Equipment DesignDocument45 paginiDistillation Column: Major Equipment Designrubesh_rajaÎncă nu există evaluări

- EC D-3 Charcoal Tower Sizing Equations BreakdownDocument5 paginiEC D-3 Charcoal Tower Sizing Equations BreakdownPrathmesh GujaratiÎncă nu există evaluări

- Friction Loss in Pipe LineDocument3 paginiFriction Loss in Pipe LineAvinash VasudeoÎncă nu există evaluări

- Stacks: Ammonia Injection: A Route To CleanDocument8 paginiStacks: Ammonia Injection: A Route To CleanZEN MA100% (1)

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocument9 paginiReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 paginiBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingÎncă nu există evaluări

- Nozzle Load - PumpDocument1 paginăNozzle Load - Pumpduf fu0% (1)

- Sizing Duct Work SheetDocument4 paginiSizing Duct Work SheetMaulana MaftuhiÎncă nu există evaluări

- Tank or Silo - Volume and Level Calculations-D1.9SDocument24 paginiTank or Silo - Volume and Level Calculations-D1.9SJacques J PienaarÎncă nu există evaluări

- Volume Calculation For Pressure Vessel TankDocument2 paginiVolume Calculation For Pressure Vessel Tanksai srikarÎncă nu există evaluări

- Heat CalcDocument13 paginiHeat Calciese027Încă nu există evaluări

- Calculating Gas Properties with Mixing Rule SpreadsheetDocument2 paginiCalculating Gas Properties with Mixing Rule Spreadsheetvictor javier nuñezÎncă nu există evaluări

- Tank Vent Calculation SpreadsheetDocument3 paginiTank Vent Calculation SpreadsheetJack SonÎncă nu există evaluări

- Distillation Theoretical Stages CalculatorDocument1.557 paginiDistillation Theoretical Stages Calculatorgautam_96948069Încă nu există evaluări

- Mixer (So3 Jadi H2so4)Document6 paginiMixer (So3 Jadi H2so4)Evi SiswantoÎncă nu există evaluări

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocument1 paginăCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaÎncă nu există evaluări

- Nonboiling Liq Outflow F Vertical Cyl VesselDocument26 paginiNonboiling Liq Outflow F Vertical Cyl VesselSrihari KodimelaÎncă nu există evaluări

- Hydroulics Calculation and Gas PropertiesDocument3 paginiHydroulics Calculation and Gas PropertiesSteve WanÎncă nu există evaluări

- NPSHa Calculation SpreadsheetDocument3 paginiNPSHa Calculation Spreadsheetprasad durgaÎncă nu există evaluări

- API 2000 guidance for inert gas blanketing of tanksDocument2 paginiAPI 2000 guidance for inert gas blanketing of tankssandeshÎncă nu există evaluări

- Pipe Size CalculationDocument5 paginiPipe Size CalculationChristoberÎncă nu există evaluări

- Practical Chemical Thermodynamics for GeoscientistsDe la EverandPractical Chemical Thermodynamics for GeoscientistsÎncă nu există evaluări

- Multiphase Flow 1995De la EverandMultiphase Flow 1995A. SerizawaÎncă nu există evaluări

- PressorsDocument8 paginiPressorsManoj MisraÎncă nu există evaluări

- Calculation and Design of Packed Column For AcidDocument14 paginiCalculation and Design of Packed Column For AcidDavid LambertÎncă nu există evaluări

- Asme B36.10M PDFDocument31 paginiAsme B36.10M PDFSubhash KumarÎncă nu există evaluări

- Hdpe Pipe presentation-PressureTest Procedure PDFDocument18 paginiHdpe Pipe presentation-PressureTest Procedure PDFSubhash KumarÎncă nu există evaluări

- Hdpe Pipe presentation-PressureTest Procedure PDFDocument18 paginiHdpe Pipe presentation-PressureTest Procedure PDFSubhash KumarÎncă nu există evaluări

- Particular Spec-Sewerage PDFDocument1 paginăParticular Spec-Sewerage PDFSubhash KumarÎncă nu există evaluări

- Branch Reinforcement For CS PipeDocument2 paginiBranch Reinforcement For CS PipeSubhash Kumar33% (3)

- European Standards for Valve Sizing CalculationDocument11 paginiEuropean Standards for Valve Sizing CalculationleotvrdeÎncă nu există evaluări

- Power of Compounding - Vaishnavi SomaniDocument2 paginiPower of Compounding - Vaishnavi SomaniVaishnavi SomaniÎncă nu există evaluări

- The Doppler Effect (Or The Doppler Shift) Is The: Page 1 of 27Document27 paginiThe Doppler Effect (Or The Doppler Shift) Is The: Page 1 of 27Mohamed Aswir AswirÎncă nu există evaluări

- Calculating Measures of Position: Grade 10Document10 paginiCalculating Measures of Position: Grade 10jacqueline deeÎncă nu există evaluări

- Stationary and Non StationaryDocument5 paginiStationary and Non StationaryAkriti SinghÎncă nu există evaluări

- Permutation Vs CombinationDocument26 paginiPermutation Vs CombinationGeraldine Mina100% (1)

- HP Prime Graphing CalculatorDocument761 paginiHP Prime Graphing CalculatorMikhaelA.RodriguezÎncă nu există evaluări

- 1st Quarter Finals g9Document2 pagini1st Quarter Finals g9neil balajadia100% (1)

- Optimization of Single-Stage FFT Architectures Using Multiple Constant MultiplicationDocument8 paginiOptimization of Single-Stage FFT Architectures Using Multiple Constant MultiplicationCanalDTodoUnPoco PCÎncă nu există evaluări

- Éric Alliez - On Deleuze's BergsonismDocument22 paginiÉric Alliez - On Deleuze's BergsonismAni MarkÎncă nu există evaluări

- Final Project Part2Document3 paginiFinal Project Part2api-305255197Încă nu există evaluări

- Projectile Motion Lesson ExplainedDocument5 paginiProjectile Motion Lesson ExplainedShari Mayne SEGOVIAÎncă nu există evaluări

- Distance ProblemDocument17 paginiDistance ProblemAnneÎncă nu există evaluări

- Compaction Tests ExplainedDocument56 paginiCompaction Tests ExplainedPaula SisonÎncă nu există evaluări

- Solved Bridget Has A Limited Income and Consumes Only Wine andDocument1 paginăSolved Bridget Has A Limited Income and Consumes Only Wine andM Bilal SaleemÎncă nu există evaluări

- 72552Document8 pagini72552Andres GuevaraÎncă nu există evaluări

- HEATTRANSFERDocument36 paginiHEATTRANSFERAkhil SriramÎncă nu există evaluări

- Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Document16 paginiStorage Tank Heat Loss Calcs - Rev.1 31.12.2010Jade GeronimoÎncă nu există evaluări

- Research Proposal 1 PDFDocument5 paginiResearch Proposal 1 PDFMunem BushraÎncă nu există evaluări

- Mathematics A: Paper 4H Higher TierDocument24 paginiMathematics A: Paper 4H Higher Tiermanz 123Încă nu există evaluări

- Digital Logic Design - (Eceg-3141) Project: Institute of Technology (Amit) Faculty of Electrical and Computer EngineeringDocument4 paginiDigital Logic Design - (Eceg-3141) Project: Institute of Technology (Amit) Faculty of Electrical and Computer EngineeringYeshiwas KefaleÎncă nu există evaluări

- I. Waiting Lines (Queueing) : - Ii. SimulationDocument55 paginiI. Waiting Lines (Queueing) : - Ii. SimulationAnna Jane CatubagÎncă nu există evaluări

- Unit 6 - Week-05: Assignment-05Document4 paginiUnit 6 - Week-05: Assignment-05FidhaÎncă nu există evaluări

- Intro Abstract AlgebraDocument200 paginiIntro Abstract AlgebraThales mathÎncă nu există evaluări

- Landing Gear Integration in Aircraft Conceptual DesignDocument20 paginiLanding Gear Integration in Aircraft Conceptual DesignJin Hwan ParkÎncă nu există evaluări

- Fourier's Law and The Heat Equation: Chapter TwoDocument18 paginiFourier's Law and The Heat Equation: Chapter TwoAnonymous 3H9KhhDOÎncă nu există evaluări

- Analysis of Functions of BCD To 7 Segment DecoderDocument5 paginiAnalysis of Functions of BCD To 7 Segment Decodercoker yusufÎncă nu există evaluări

- Beams Bending and Boundary Conditions Boundary ConditionsDocument3 paginiBeams Bending and Boundary Conditions Boundary ConditionsAbhay KumarÎncă nu există evaluări

- NCERT Class 10 Mathematics PDFDocument369 paginiNCERT Class 10 Mathematics PDFRB ENGÎncă nu există evaluări

- WITRICITYDocument17 paginiWITRICITYSai VikramÎncă nu există evaluări

- Palindrome: Public Class Private PublicDocument19 paginiPalindrome: Public Class Private Publicarturog_4Încă nu există evaluări